WHY USE ULTRASONICS?

It is commonly known that faults, malfunctions, and/or flaws in mechanical, electrical, and pneumatic devices, as well as manufactured

container type objects, start as small defects or leaks. These defects are of such relatively small size that the sounds they produce are above

the range of human hearing and are not detectable aurally. Most commonly, these faults manifest themselves in the

38 kHz to 43 kHz range. These frequencies fall within the spectrum of frequencies generally referred to as being in the ultrasonic range. It is

of great use to be able to hear these ultrasonic emissions from these faults in order to be aware of imminent problems. Since these sounds

are above the normal level of hearing, a device that can transform or convert the ultrasound to an audible level has been produced to answer

this need in a cost justifiable manner with high quality results. To employ the ultrasound methodology in a usable manner, it is imperative the

listener be able to have access to an audible sound that bears a resemblance to the natural sound of the defect. That is to say, a mechanical

bearing with a defective ball should sound like such. Likewise, a microscopic leak in a compressed air system should sound like a gas leak.

Simply converting the ultrasound frequencies to audible frequencies is not sufficient with regard to rendering a usable signal.

It is for this reason that the VS919 Ultrasonic Detection Kit incorporates a process whereby the audible signal bears a close likeness to the

natural incoming sample. This range of sounds is at twice the upper frequency of normal human hearing, 20 kHz. The VS919 uses a

technology called heterodyning to convert the ultrasonic range into the audible range. Since this unit is tuned to listen to the ultrasonic range,

it is unaffected by everyday sounds such as wind, voices, and traffic which can further hinder the technician’s ability to listen for a potential

problem. The VS919 also incorporates AGC (automatic gain control), which allows one to study ultrasonic sounds associated with the roar of

a valve leak or literally the blink of an eye. AGC stops the need for high/low sensitivity switches by allowing the internal circuitry to seek the

optimum level of gain for the given situation. This ultimately allows the VS919 to be picked up and learned immediately without having to

concentrate on obtaining the correct settings.

The ultrasound detection kit is extremely effective yet easy to use, allowing the technician to concentrate on analysing the problem and not on

the operation of the instrument. Using the mechanical bearing example, should a ball within the bearing develop a small pit, this small defect

will emit ultrasonic evidence of its existence. This ultrasonically emitted indicator goes undetected by the human ear. The defective equipment

remains in service and the fault worsens over time. Eventually, the fault will increase to such a size that its resonant frequency descends into

the audible range. At this point, prudent maintenance personnel will repair the fault hopefully before it has caused damage to related

equipment and/or systems. The utility of the ultrasound detection products is that had one listened to the initial small fault, it would have

sounded like the consequent sound that was emitted by the fully defective device or object - It is this ability of this instrument that sets it apart

from those that lack the ability to convert ultrasonic frequencies into audible frequencies while retaining the same timbre and/or nature of the

sound.

The directional aspect of ultrasonic waves allows one to isolate a suspect signature sound from other background noises and detect its exact

location. This sound analysis can be used for efficiently investigating five major areas of repair and preventive maintenance in the automotive,

industrial, and trade businesses:-

1) Air leaks - Both vacuum and compressed air leaks create an energy packet or wave front which can result in an ultrasonic

emission with a differential of 1 lb/sq.in. and/or a hole down to 1/200th inch.

2) Gas and liquid turbulence - Turbulence associated with steam trap and internal valve leaks, cavitation, and blockages in liquid and

air/gas lines.

3) Electrical discharge - Electrical discharge associated with insulation breakdown, tracking, corona, and arcing.

4) Mechanical wear - State of mechanical wear in bearing and race assemblies, shafts, and gears (indicating the state of lubrication).

5) Sound generation - Can be used in conjunction with sound generators to detect container cracks and seals, door seals and

compartments. (The transmitter is matched to the receiver’s peak response.)

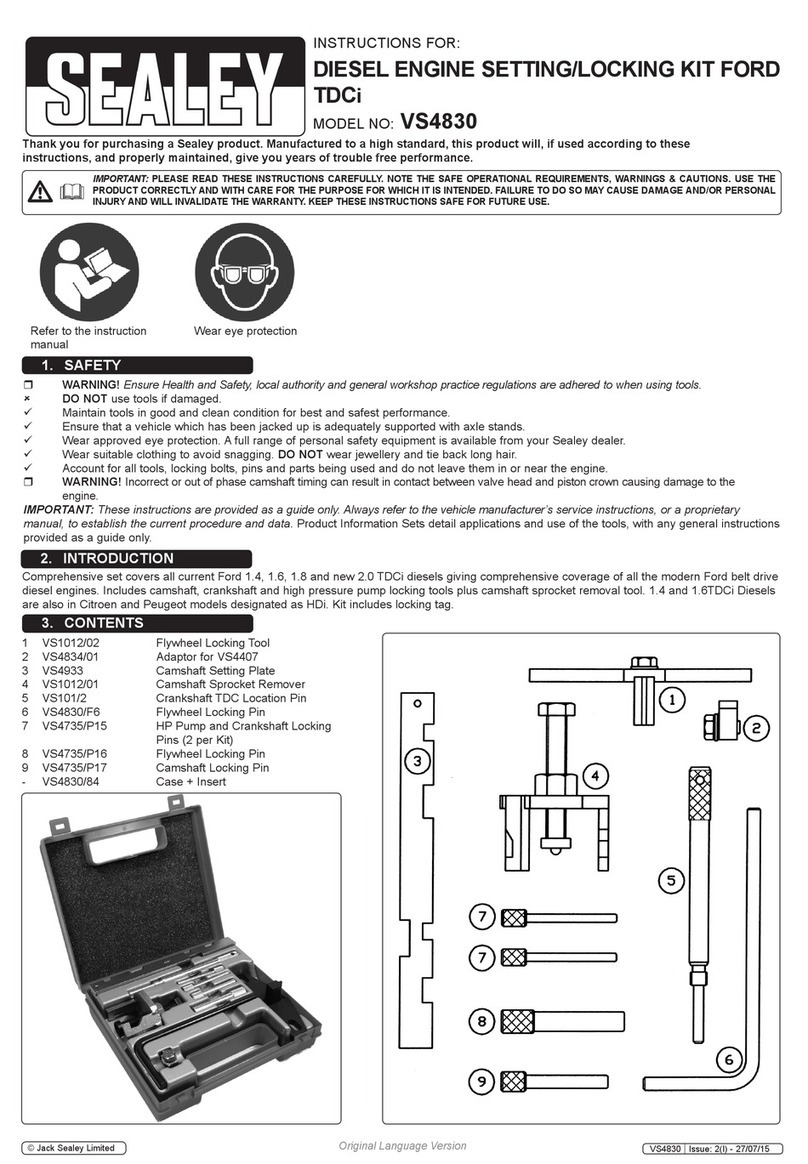

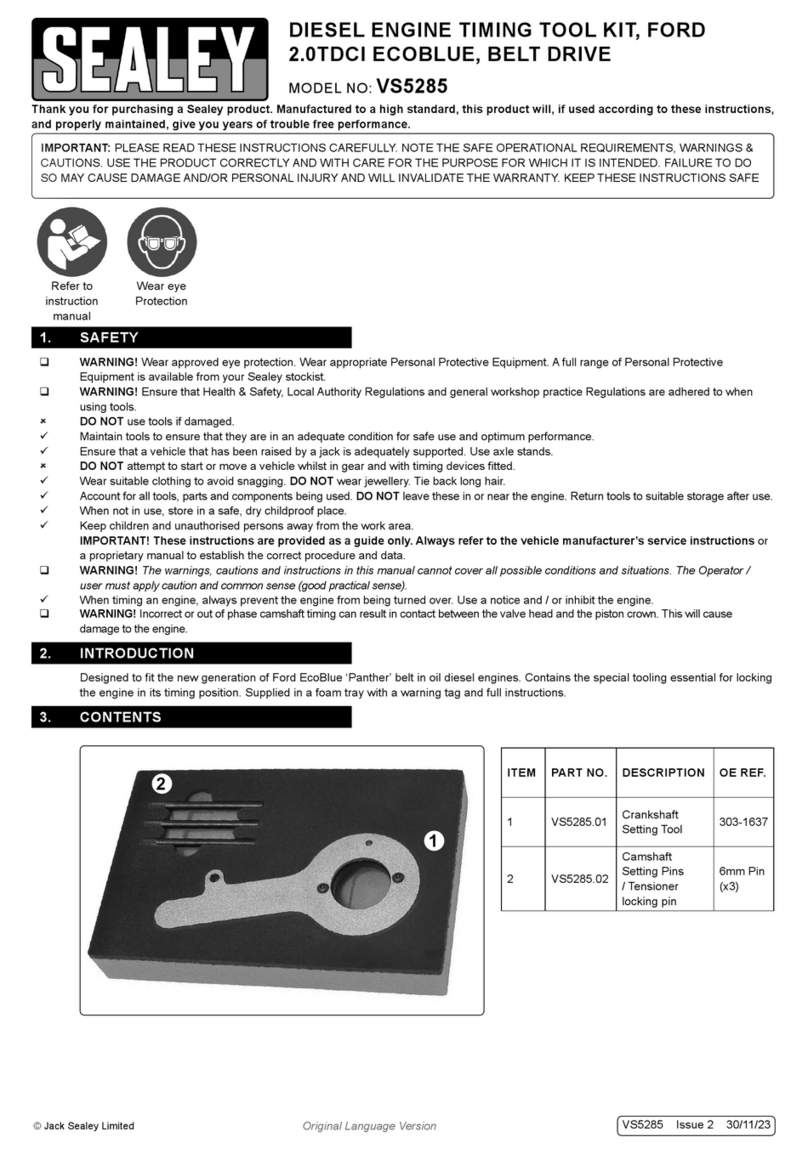

VS919 ULTRASONIC DETECTION KIT OVERVIEW

The VS919 is a unique item of diagnostic test equipment that has achieved outstanding results in reducing downtime and maintenance related

costs. Through the detection of ultrasonic sound, the VS919 is used to inspect and check such items as ignition systems, vacuum problems,

air brake systems, bearings, gear trains, cam and tappet assemblies, internal combustion engine valve gear and piston blow-by, gaseous

piping and ducting seals in refrigerated van bodies, air ducts, hydraulic systems, A/C system Freon leaks, and many other components.

Except for their frequencies, ultrasonic waves are exactly the same as their audible counterparts. Audible sound will propagate and compound

itself through equipment making it difficult to locate the source even with a stethoscope. Because ultrasonic waves are not as penetrating as

those of lower audible frequencies, it is much easier to pinpoint the source of the sound and there is usually less noise interference.

Conversation and most background noises are normally absent. Extremely minute sounds can therefore be detected, analysed, and exactly

located. The energy is amplified by the self-contained circuitry and converted either to sounds, which can be heard through headphones, or

intensity reading on an LED indicator. The ultrasonic transmitter is used with the receiver to check for faulty seals in cabs or trailers, or other

non-pressured enclosures.

Both the air and contact probe are precision parts and have been designed to optimise the response of the VS919 receiver when needed. The

12" air probe serves to extend reach or to facilitate in isolating a leak among multiple suspect areas. Do not modify the probes in any way and

never use the probes for other than described in this manual. The port openings of the receiver and transmitter contain a precision transducer.

During use, guard against any foreign matter from entering these areas

Batteries and replacement - Both the receiver and transmitter use one PP9 battery each. Zinc or Alkaline are preferred. To replace the battery

in the receiver, the protective rubber boot has to be removed first. The rubber boot is easier to remove when warm because it is more flexible.

To remove, push the bottom edge of the boot off of the inner enclosure and pull enclosure out. Please observe polarity. Replace boot in

reverse manner. When replacing the transmitter battery, be careful not to strain or pinch wires. Always remove battery during a period of long

storage.

The transmitter and receiver have been tuned at our factory and should require no re-calibration under normal conditions during their life.

The LED indicator allows you to home in on a steady source of ultrasonic sound, as in locating an air or vacuum leak or using the transmitter.

Simply watch for a rise or drop in the bar levels on the LED indicator to locate the source of the problem.

The transmitter emits a warble output centred at 40kHz, this output cannot be heard by the human ear. If the red indicator is on,

the unit is transmitting.

4. OVERVIEW

VS919 - 2 - 160306