PT1150SC.V3 Issue 1 30/01/2020

Original Language Version

© Jack Sealey Limited

4.3. MEASURING GROSS WEIGHT

NOTE: To switch measurement between kilograms and pounds, depress the “MODE” key (fig.2.3).

4.3.1. Set the operating handle control lever to the LOWER position and lower the pallet truck.

4.3.2. Place the pallet forks under the load to be weighed. Ensure that the load is correctly balanced. Refer to fig.3 and 4.2.4.

4.3.3. Set the operating handle control lever to the RAISE position and pump the operating handle. Ensure that the pallet is clear of the floor.

NOTE: The reading indicated on the console is the gross weight, i.e. the weight of the goods and the pallet.

4.4. MEASURING NET WEIGHT (Automatic mode)

NOTE: This method is used for goods packed on a standard pallet.

4.4.1. “ZERO” the scale readout.

4.4.2. With an empty pallet on the forks, pump the operating handle with the control lever in the RAISE position until the pallet is clear of the

ground,quickly press the “TARE” key (refer to fig.2.2). The console will then display 0kg.

4.4.3. If you were to remove the pallet from the pallet truck forks. The console will then display minus the weight of the pallet, (e.g. -20kg)

4.4.4. Add items to the pallet to see the weight then depress the “TARE” key (fig.2.2).

4.5. MEASURING NET WEIGHT (Programmed mode)

4.5.1. “ZERO” the scale readout.

4.5.2. Press and hold the “TARE” button to enter program mode.

4.5.3. Use “ZERO” and “TARE” buttons to change values. Step through the digits display using the “MODE” button.

4.5.4. When the required value has been input press the “PRINT” button to confirm.

4.5.5. To switch measurement between kilograms and pounds, depress the “MODE” key (fig.2.3).

5. MAINTENANCE

5.1. DAILY MAINTENANCE CHECK

5.1.1. Check the state of the wheels and the axles since thread, rags and other foreign objects can jam the wheels making safe, effective

operation difficult.

5.1.2. On completion of each task, unload the forks and return them to the lowest position.

5.2. OIL CHECK

5.2.1. Check the oil level at six monthly intervals. Sealey hydraulic jack oil is used with the pallet truck. The viscosity of the oil should be

30cSt at 40°C. The amount used in the pallet truck is approximately 0.4 litres.

5.3. LUBRICATION

5.3.1. The bearings and shafts of the pallet truck have long-life grease applied to them during manufacture. The bearings will only require

greasing at monthly intervals or after the pallet truck had been serviced down to the lubrication points.

5.4. PURGING AIR FROM THE HYDRAULICS

5.4.1. Air can get into the hydraulic oil through transportation, or the pump becoming misaligned. As a result, the forks will not elevate.

5.4.2. The air can be purged by setting the control level to the LOWER position and pumping the operating handle up and down for 30 - 40

seconds.

5.4.3. When the pallet truck is not in use, lower the forks and park the truck where it will not be a hazard.

5.5. BATTERY REPLACEMENT

5.5.1. To insert batteries, first remove the back cover at the rear of the console display unit.

5.5.2. Insert 4XAA cells making sure that they are correctly placed in the display unit.

5.5.3. Replace the cover on the display unit.

6. TROUBLESHOOTING

Problem (pallet truck) Cause Solution

The forks cannot be raised to their maximum

height.

There is insufcient oil in the reservoir. Replenish the oil to the correct level.

See 6.1 and g.4

The forks cannot be raised. No hydraulic oil or impurities or air in the oil.

The adjusting nut is too high keeping the

pumping valve open.

Air has entered the hydraulic system.

Replenish or change the oil.

Reset the adjusting nut or bolt.

Purge air from the hydraulic system.

The forks cannot be lowered. The piston rod or the pump is deformed.

Forks have been kept in the raised position

resulting in the rod jamming.

The adjusting nut or bolt is incorrectly

positioned.

Replace the piston rod or pump.

Keep the forks in the lowest position when

not in use.

Adjust the nut or bolt.

The forks lower without the release valve

operating.

Impurities, or air, has got into the release

valve oil.

Parts of the hydraulic system have been

damaged.

Adjusting nut or bolt incorrectly positioned.

Replace the oil/or purge the air from valve.

Inspect and replace the damaged parts.

Adjust the nut or screw.

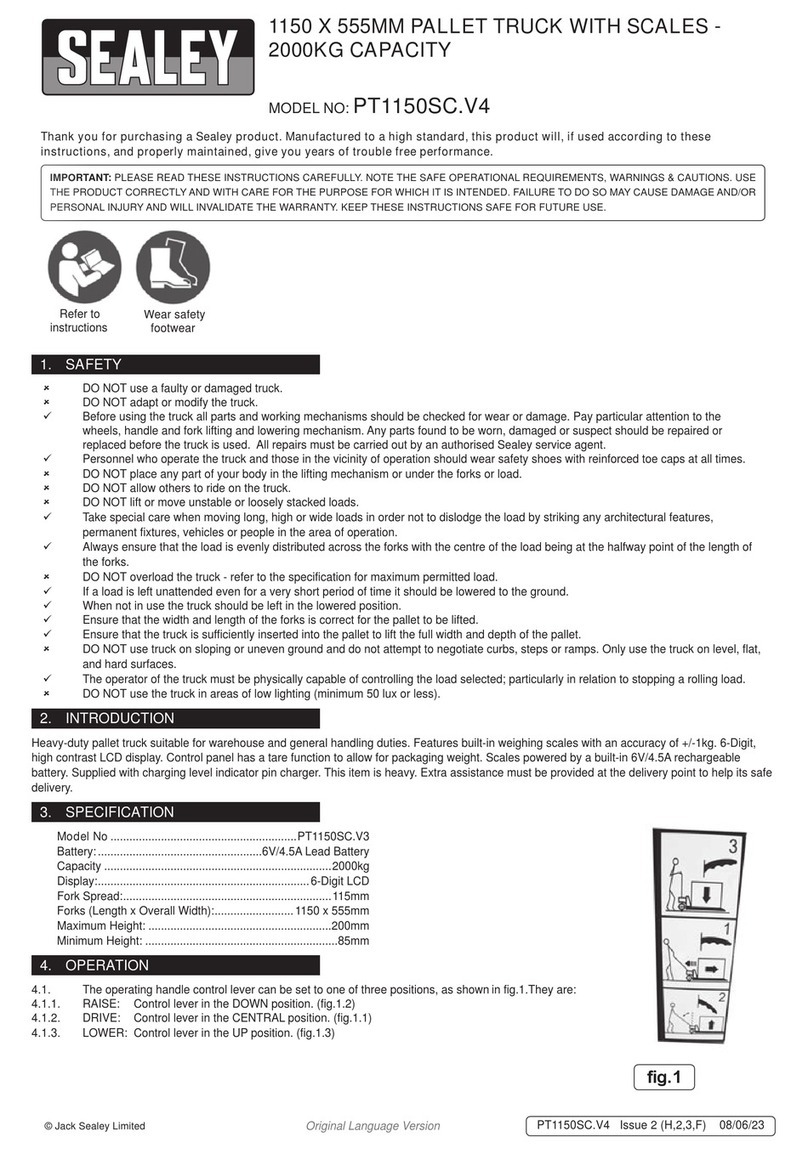

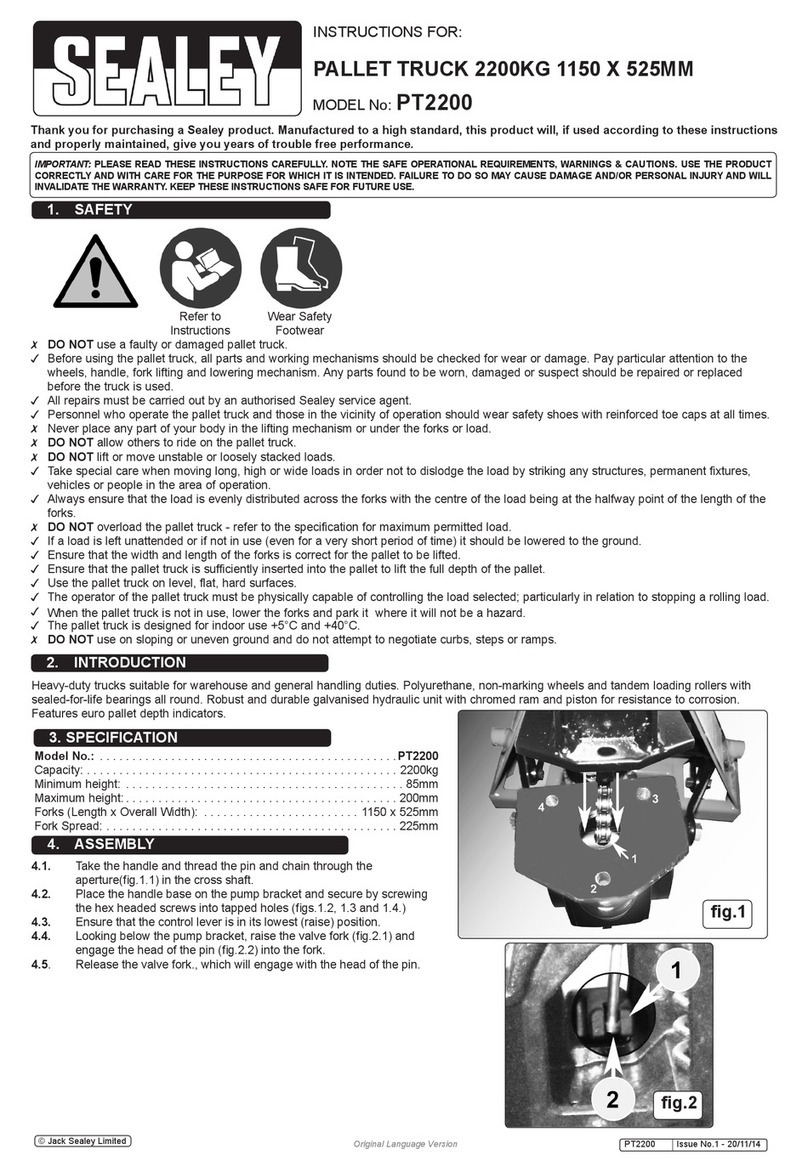

6.1. OIL TOP UP (fig.4)

6.1.1. Remove plastic cover to reveal rubber container.

6.1.2. Remove container lid and top up oil to within 20mm of lip.

6.1.3. Work the pump several times to let air out of the hydraulic circuit.

6.1.4. Replace lid and plastic cover.

g.4