3. SPECIFICATION

Model ...................... HPT1000

Capacity (kg) ...................1000kg

Min platform height (mm) .........430mm

Max platform height (mm) ........1020mm

Platform length ...............1015mm

Wheel diameter ................150mm

4. ASSEMBLY

fig.2

4.1 A minimum of two people will be required to lift the truck

out of its packaging. Alternatively, cut and fold down flat

one end of the box and wheel the truck out.

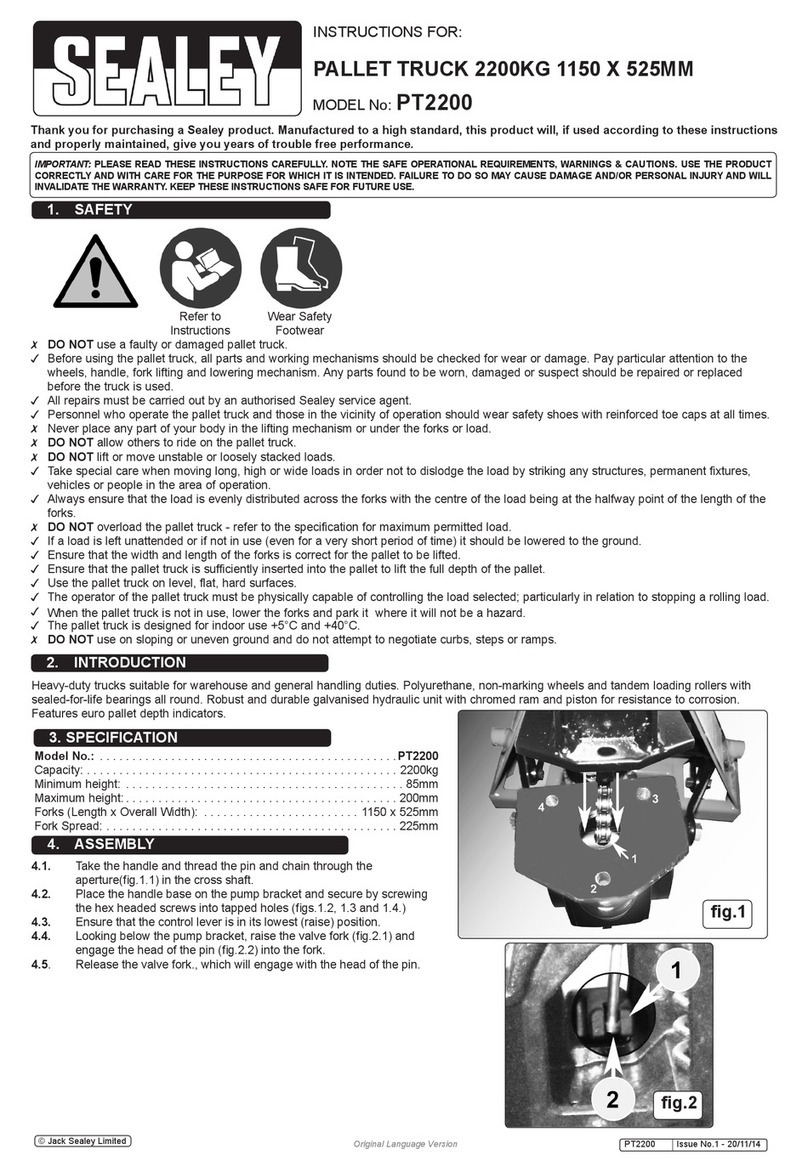

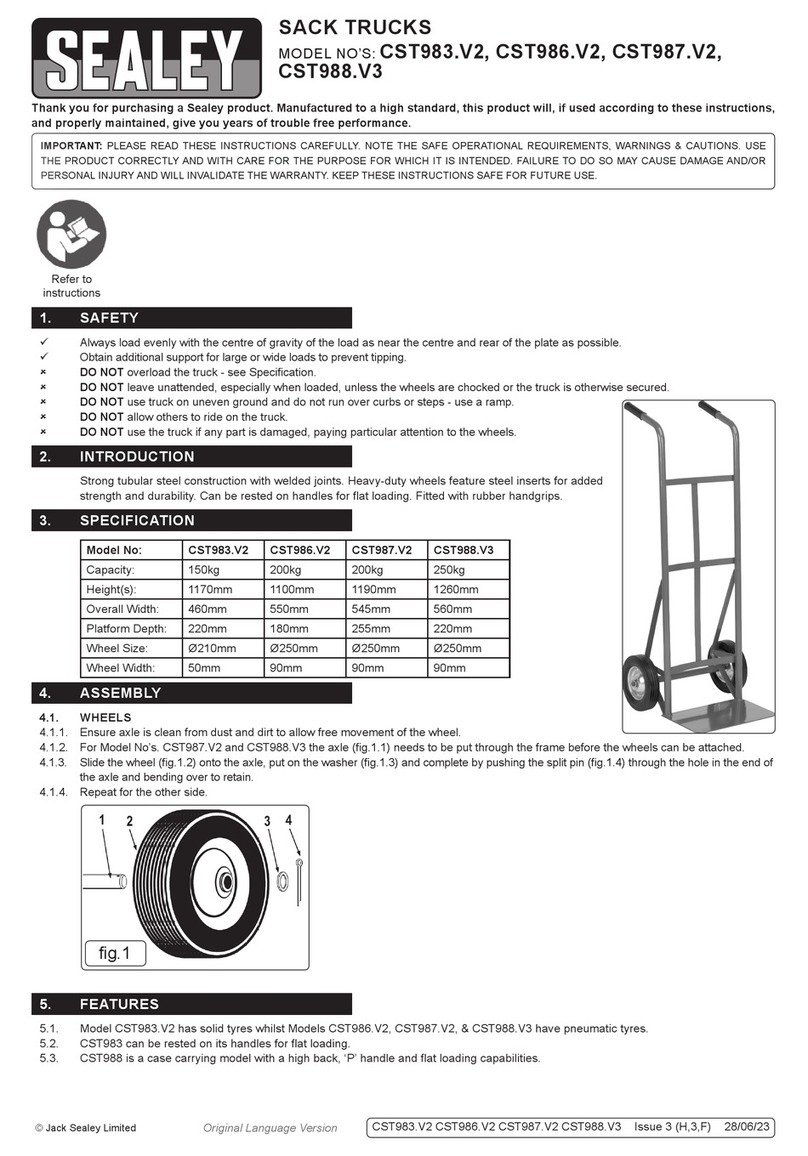

4.2 Fitting the handle.

The ends of the chrome handle have flanges which sit

down onto flat platforms at either side of the truck. The

handle is retained by two large socket cap bolts inserted

from underneath. See fig.1A & B. You will require a 10mm

Allen Key to tighten the bolts. Place a split washer followed

by a plain washer over each bolt before inserting and

tightening.

4.3 Fitting the foot pedal. Slide the end of the foot pedal into

the socket situated centrally between the two handle

uprights. (See fig.1C). The footpedal retaining bolt (See

fig.1D) screws directly into the material of the foot pedal

stem. Place a split washer over the pedal retaining bolt

followed by a plain washer, before inserting the bolt.

Ensure the fixing is tight enough to hold the pedal firmly in

place but do not over tighten.

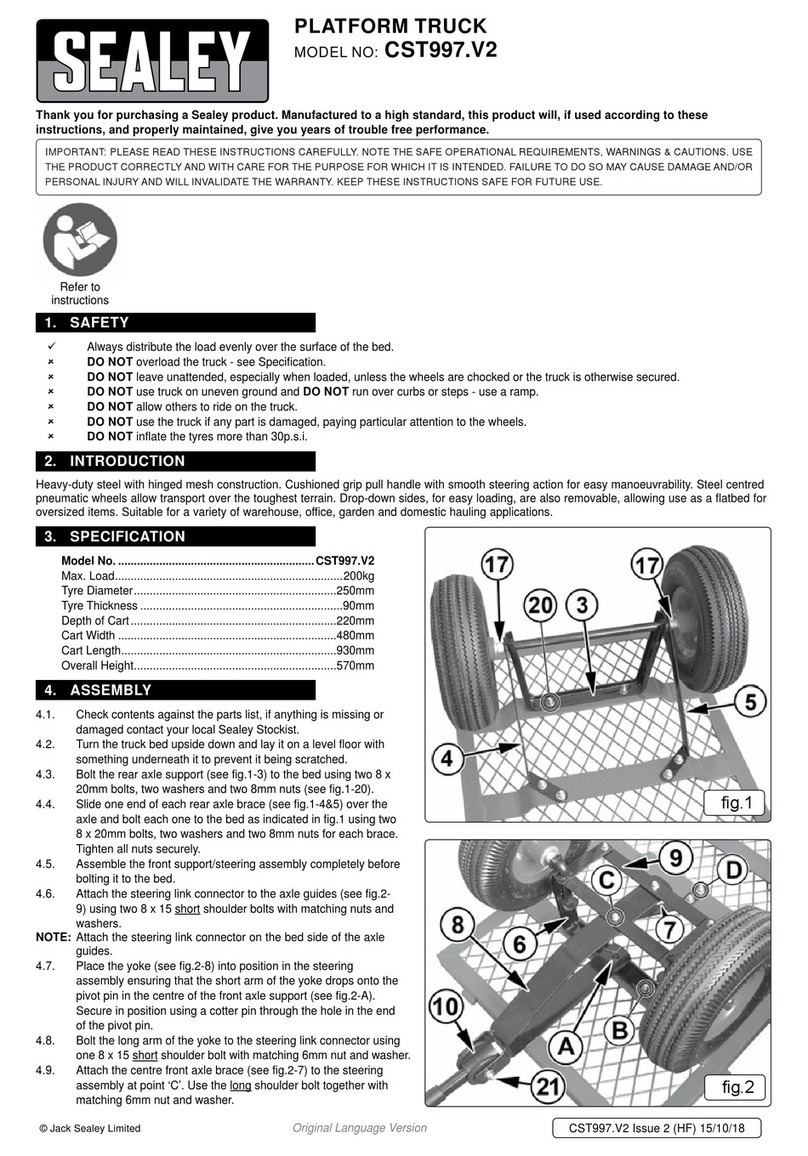

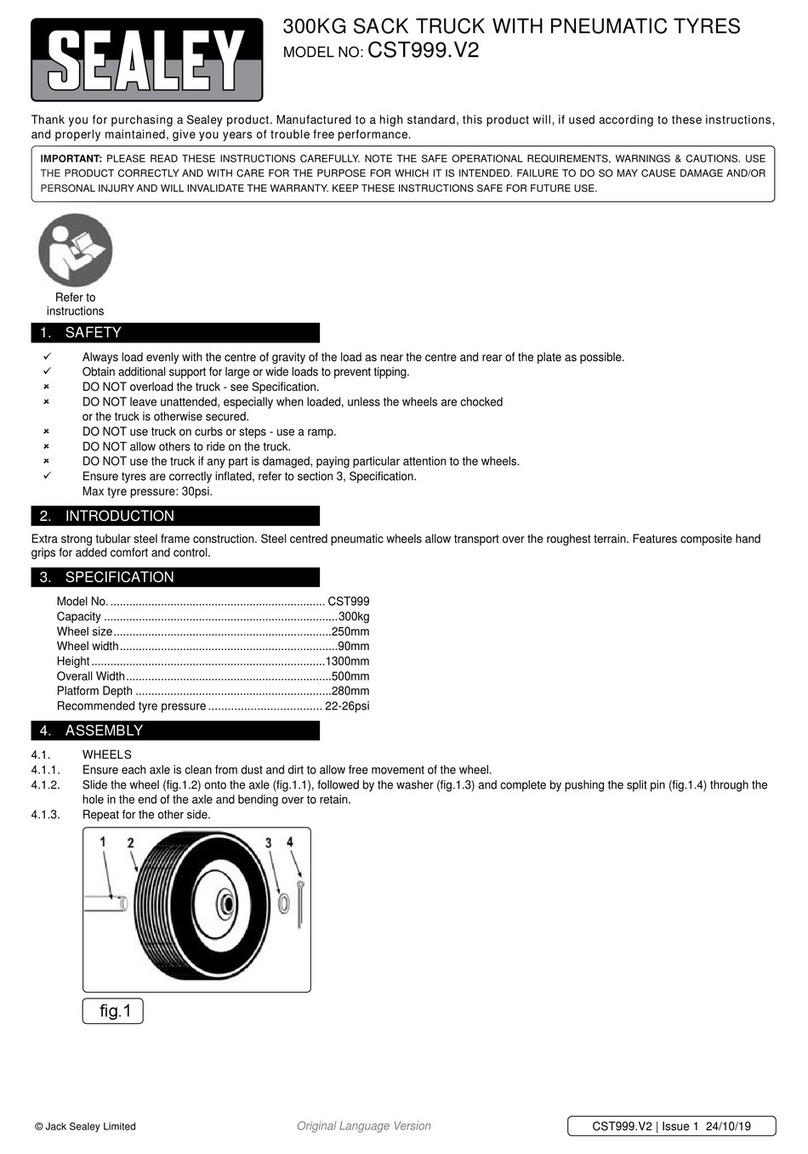

4.4 Connecting the control cable. Remove the cable guide

bush (fig.2X) from the free end of the cable and feed the

end of the cable and cable sheath through the cable guide

tubes welded to the handle and the underside of the frame.

Once the cable has been fed through the guides slide the

bush back over the cable and onto the sheath. Feed the

cable through the hole in the bush retaining bracket and

then through the hole in the clamping bolt on the actuating

lever (fig.2Z). Now screw the guide bush into the bracket

with a 12mm spanner (See Fig.2X). Retain the bush by

tightening the locking nut. See fig.2Y. Pull the end of the

cable so that there is no play in the movement of the lever

mounted on the handle. Hold the clamping bolt (fig.2Z)

steady with a ring spanner and tighten the nut on the other

side of the lever with an open spanner.

fig.1

fig.2

5. OPERATION

5.1. Before first use.

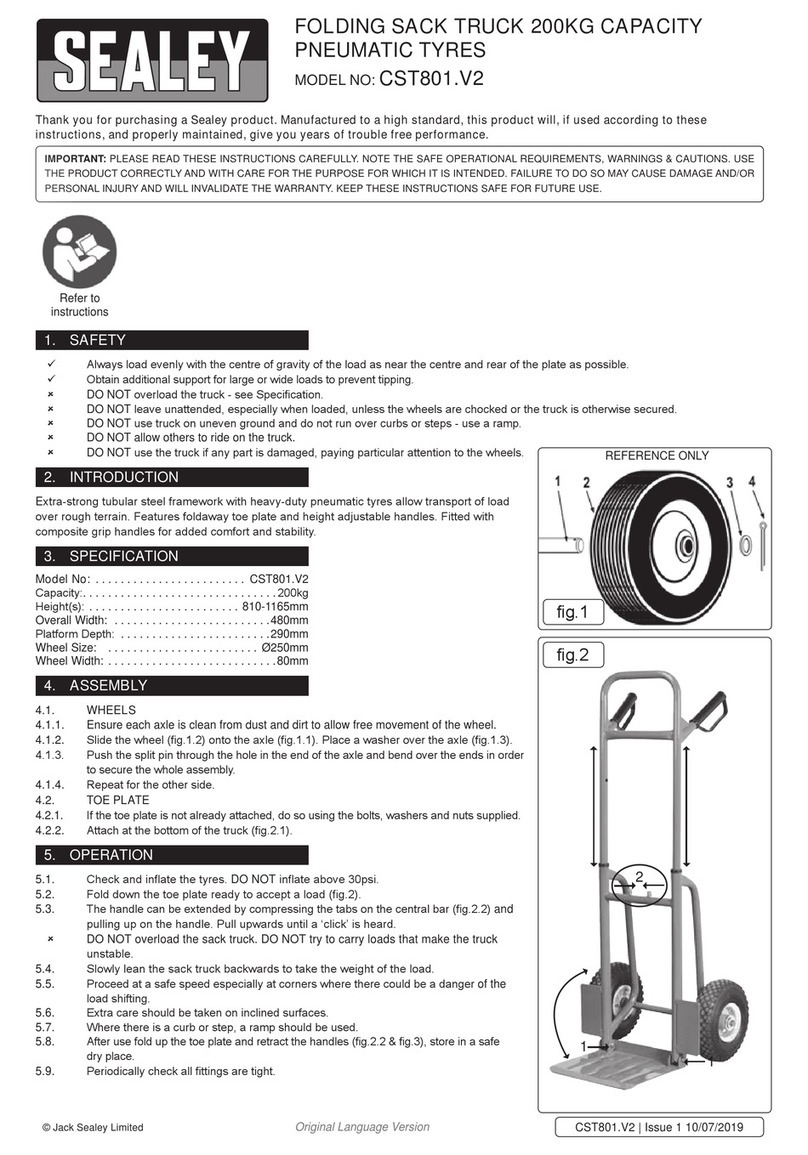

5.1.1. Before using the truck for the first time purge any air from

the hydraulic circuit by pumping the foot pedal 20-30 times

times whilst holding the release lever (fig.3A) in.

5.1.2. To test the truck, release the lever which will close the

hydraulic valve. Pump the foot pedal and raise the truck

platform to its highest position and then pull the valve

lever (fig.3A) to lower the platform, (the platform may be

slow to descend immediately from its highest point). If the

platform fails to descend adjust the cable length to remove

excess play in the release lever movement.

5.2. Using the truck

WARNING! Ensure you read, understand and follow the

safety instructions. Ensure all Health and Safety, local

fig.3

fig.4

authority, and general workshop practice regulations and recommendations are strictly

adhered to when lifting or moving heavy loads. The lifting or movement of heavy

loads may be dangerous if not undertaken correctly.

5.2.1. Move the truck to the required loading area and raise the platform to loading height

and engage safety bars (fig.5A)

5.2.2. Lock the truck wheels by operating the foot pedal as indicated in fig.1E.

5.2.3. Load the truck ensuring that the load is evenly distributed on the platform.

5.2.4. Remove safety bars (fig.5A) and Lower the truck platform to the lowest position before

unlocking the wheels.

WARNING! Ensure the load will not foul on anything, and is clear of your hands and

the handle when lowering (fig.4).

5.2.5. Unlock the wheels and transport the load to the required destination.

5.2.6. To unload, lock the wheels and if required raise platform and engage the safety bars,

then unload the truck.

Note: With or without a load, always transport the truck with platform in its lowest position.

When not in use, store the truck with the platform in the lowest position.

HPT1000 Issue: 4 (I) - 07/04/17

Original Language Version

© Jack Sealey Limited