4. OPERATING THE TRUCK

5. ADJUSTMENTS

6. MAINTENANCE

7. TROUBLE SHOOTING

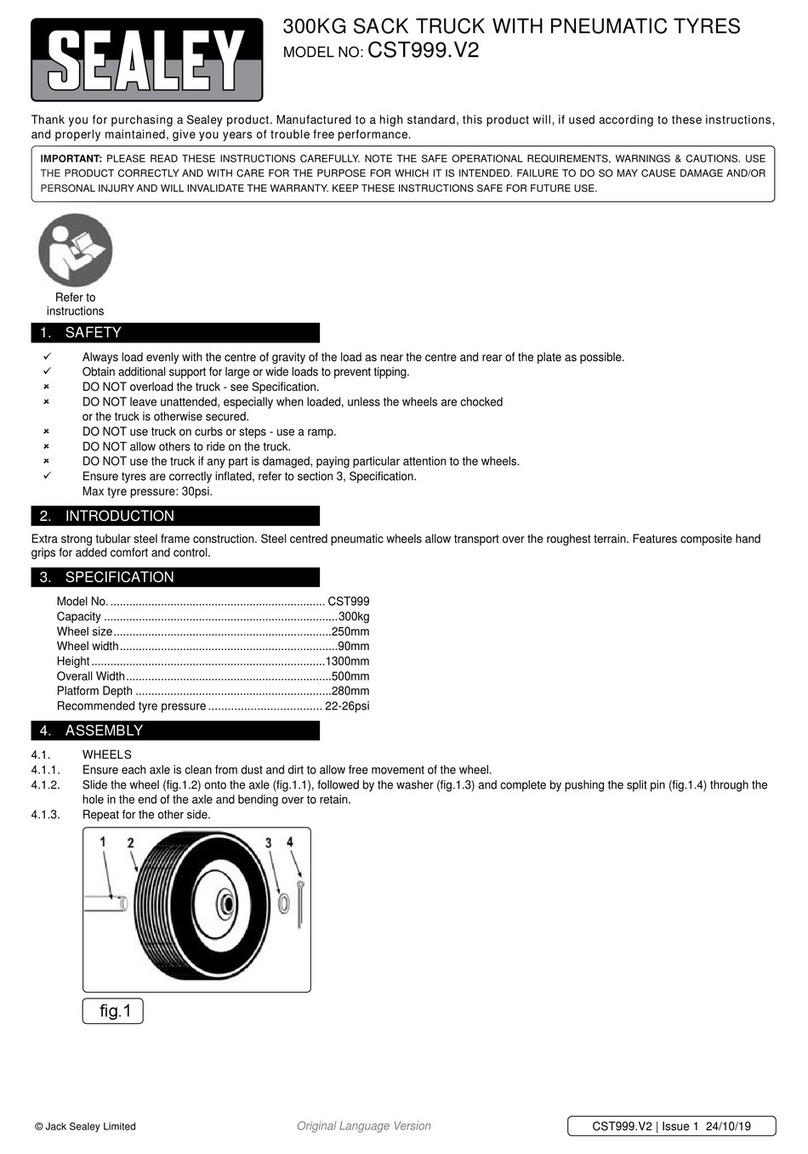

fig 2

4.1 Before using the truck you must read and understand the safety instructions in Section 1.

The truck should only be operated by those persons who have been trained in its use.

4.2 The operator must be physically capable of pushing or pulling the load and must also be

capable of stopping a rolling load.

4.3 Before lifting any load the operator should check that the pallet is the correct width and length

for the truck and that the pallet itself is not damaged.

4.4 The operator should ensure that the load on the pallet is safe to move. If the load appears to

be loosely stacked, unevenly distributed, too high or too wide it should be repacked safely

before moving. Also check that the weight of the load is within the capacity of the truck

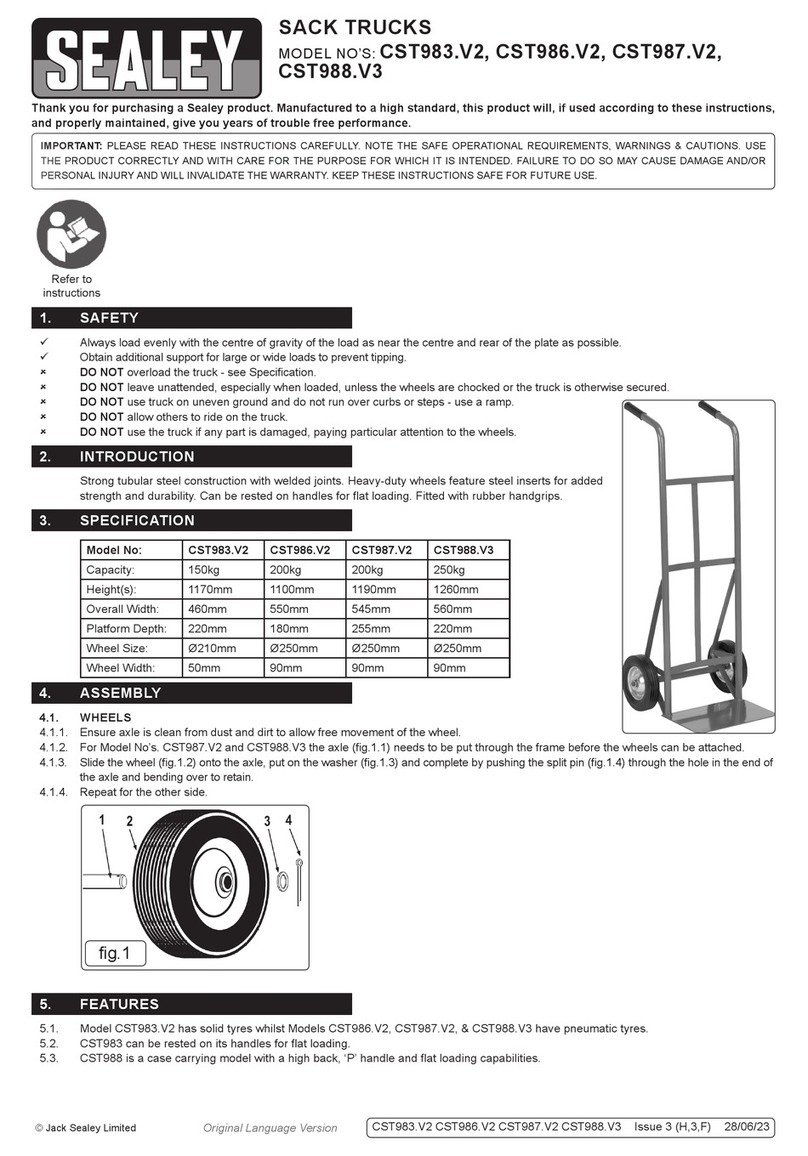

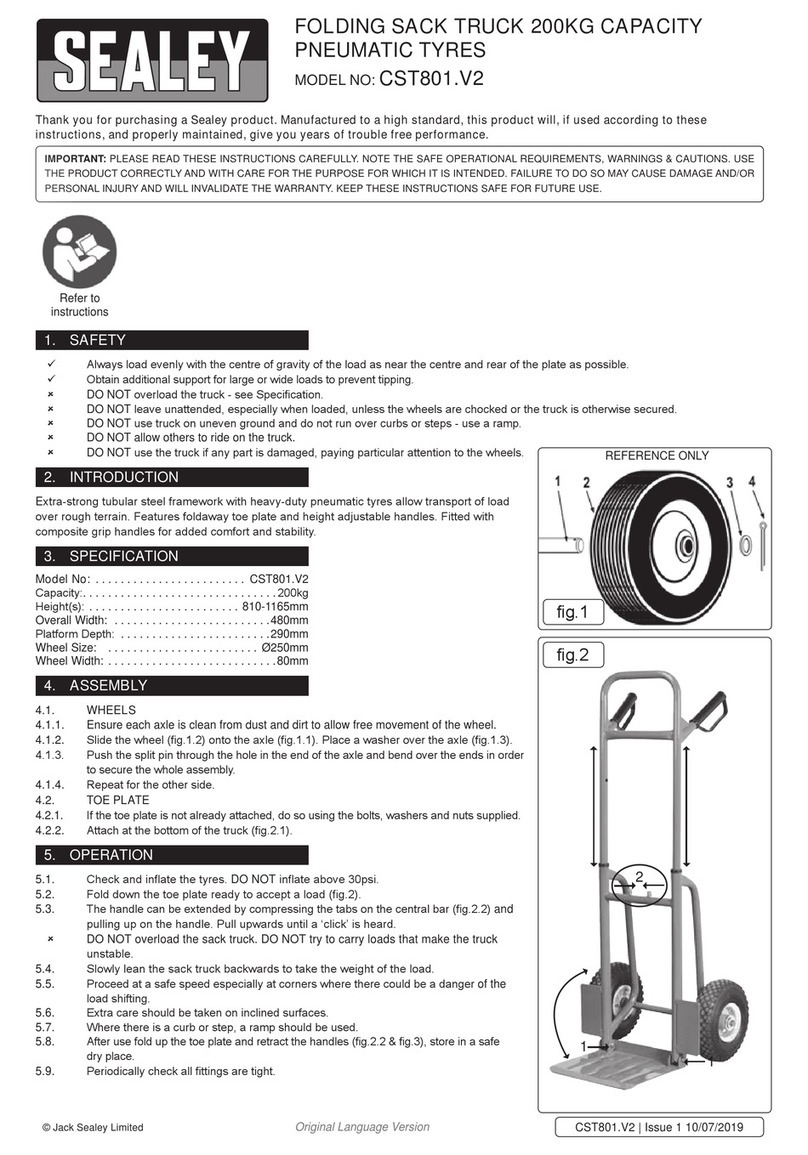

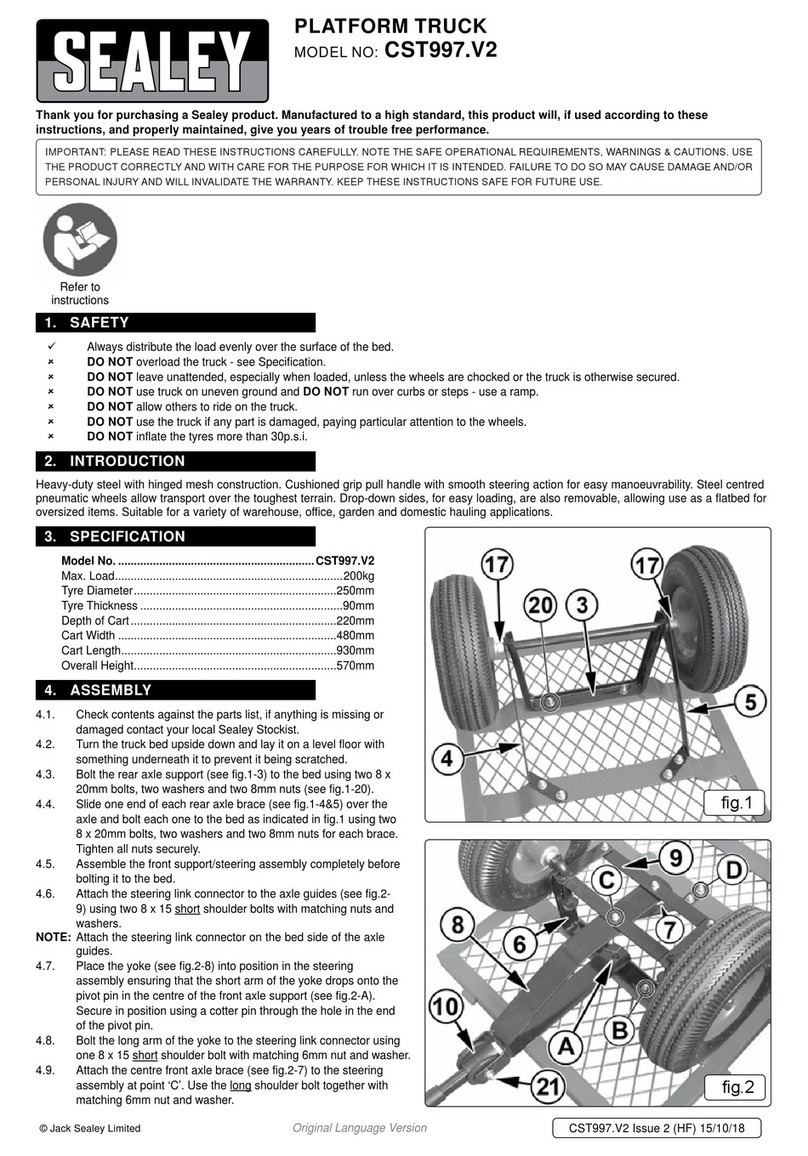

4.5 Lowering the truck. ( See fig.3 - L) Before inserting the truck into the pallet ensure that the truck

forks are in their lowest position by pulling the operating lever into the upper position and holding it

there until the truck has settled down to the lowest level.

4.6 Neutral position. ( See fig.3 - N ) The lever can now be released and will return to its neutral, middle position.

4.7 Push the truck into the pallet ensuring that it is fully inserted. If the pallet is shorter than the forks the load should be placed at the

centre point of the length of the forks.

4.8 Lifting a load. ( See fig.3 -R) To lift the load push the operating lever to its lowest position where it will latch. Pump the handle up

and down to lift the load from the floor. When the forks reach their maximum height the lifting action will stop even if you continue to

pump the handle.

4.9 Before you move off return the operating lever to its neutral position.

4.10 Due care should be taken when manouvering a load to ensure that no collision takes place with any objects or people.

4.11 The faster the truck is moved the more difficult it will be to stop it. Therefore proceed at a slow and even pace.

4.12 Bring the truck to a stop where required and lower the load to the floor by pulling the operating lever to its highest position and holding

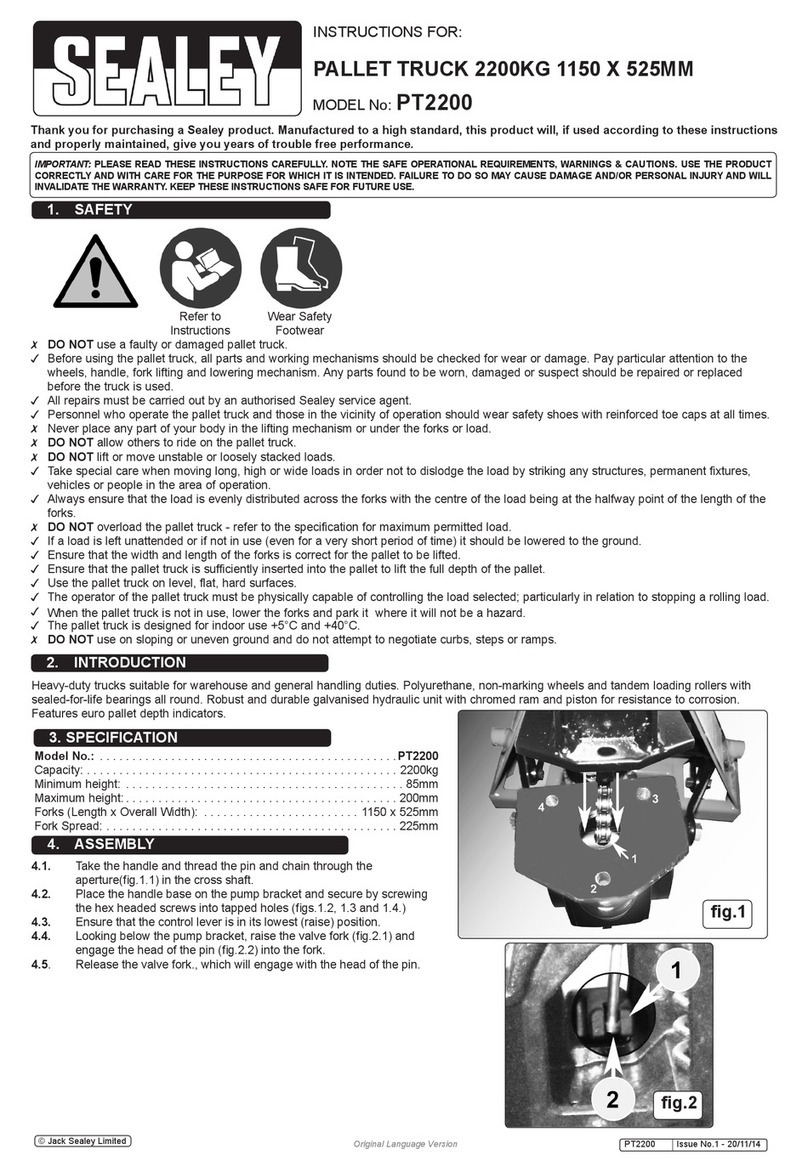

it there until the load has settled to the floor. Alternatively the load can be lowered by pressing the foot pedal. ( See fig.2 - F)

4.13 It is not recommended that the load is lowered whilst the truck is still moving as a sudden stop may dislodge the load causing damage

to property and/or people.

4.13 When the truck is not in use, lower the forks and park the truck where it will not be a hazard.

fig 3

5.1 The operating lever mechanism is adjusted in the factory but should the adjustment be lost or the

mechanism not perform as it should it may be necessary to re-adjust to restore correct operation.

5.2 The primary adjustment should be made with the lever in the neutral position.( See fig.3 - N) Once

adjustment has been carried out and there is no movement it will be necessary to test the

performance of the truck with the lever in the other two positions.

5.3 Fine adjustment is done using the nut on the threaded rod at the end of the operating chain.

( See fig.2 - E ). To access this nut hold down the foot pedal and slide the rod out of the slot in the

end of the pedal. Rotate the nut in the desired direction and re-insert the rod into the slot. If this

adjustment is too fine use the main adjusting screw and locknut below the foot pedal. ( see G in

fig.2. )

5.3 Testing NEUTRAL.If moving the handle up and down in the neutral position causes the forks to rise

turn the adjuster clockwise until the pumping action produces no movement of the forks.

5.4 If moving the handle up and down in the neutral position causes the forks to descend turn the

adjuster anticlockwise until the pumping action has no effect on the raised forks.

5.5 Testing RAISE. Now put the lever into the lower position ( See fig.3 - R) to test the raising action. If the

forks do not elevate when pumping turn the adjuster anticlockwise until a raising action is achieved.

5.6 Testing LOWER. If the forks do not descend when the lever is held in the upper position turn the adjuster

clockwise until the forks descend.

6.1 The oil level should be checked every six months. The system contains 0.4lt of hydraulic oil which should conform to ISO VG32. The

viscosity should be 32cSt at 40°C. (See oil level / filler screw ‘D’ in fig.2)

6.2 To purge air from the system hold the operating lever in the lowering position until the truck has descended to its lowest level then

pump the handle up and down 8 to 10 times.

6.3 Apply a long life grease to all bearings and shafts once a month.

The Problem The Cause The Solution

The forks do not reach maximum height. Hydraulic oil level too low. Top up the oil.

The forks do not raise. No hydraulic oil.

The oil is contaminated.

The lifting/lowering mechanism needs adjustment.

Air in the hydraulic system.

Fill with hydraulic oil.

Change the oil.

Follow procedure in Section 5.

Purge the air as described in Section 6.

The forks will not descend. The lifting/lowering mechanism needs adjustment.

Truck stored in raised position allowing exposed piston rod to corrode and jam.

Piston rod or pump body deformed as a result of overloading or unbalanced load.

Adjust as described in Section 5.

Lubricate rod regularly and store truck in lowered position.

Replace piston rod or pump body.

Leaks Seals worn, damaged or cracked Replace seals.

The forks descend and cannot be

maintained in the raised position. The lifting/lowering mechanism needs adjustment.

Release valve not fully closed due to impurities in oil.

Air in the hydraulic system.

Seals worn,damaged or cracked.

Parts of hydraulic system cracked or worn.

Adjust as described in Section 5.

Change the oil.

Purge the air as described in Section 6.

Replace seals.

Inspect and replace.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

Original Language Version PT1150, PT1220 Issue: 2 - 03/11/09