PC200SDAUTO.V3 Issue No.2 19/10/09

Original Language Version

7. WET VACUUM CLEANING

inflow. The leave a gap at the top of the nozzle opening to

allow an air inflow. The machine is fitted with a float valve which

stops the suction action when the tank has reached its

maximum capacity. The user will notice an increase in motor

speed. When this happens, turn off the machine, disconnect

from power supply and empty the container either by removing

the power head and pouring the liquid out or by removing the

drain cap at the base of the container. After wet vacuuming,

turn the machine off and unplug from power supply. Empty the

container and clean and dry the inside and outside before

storage. Remember! After wet vacuuming the foam filter must

be removed and a cartridge filter must be fitted before dry

vacuuming again.

WARNING! Ensure you read, understand and apply

Section 1 ‘Safety Instructions’. Reminder: Remove plug

from power supply before opening unit. DO NOT vacuum

solvents, explosives, inflammable and/or hazardous

liquids such as petrol, oil, spirits, paint, thinners, acids etc.

WARNING! Not designed for liquid storage. Always

empty liquids after use and before storing.

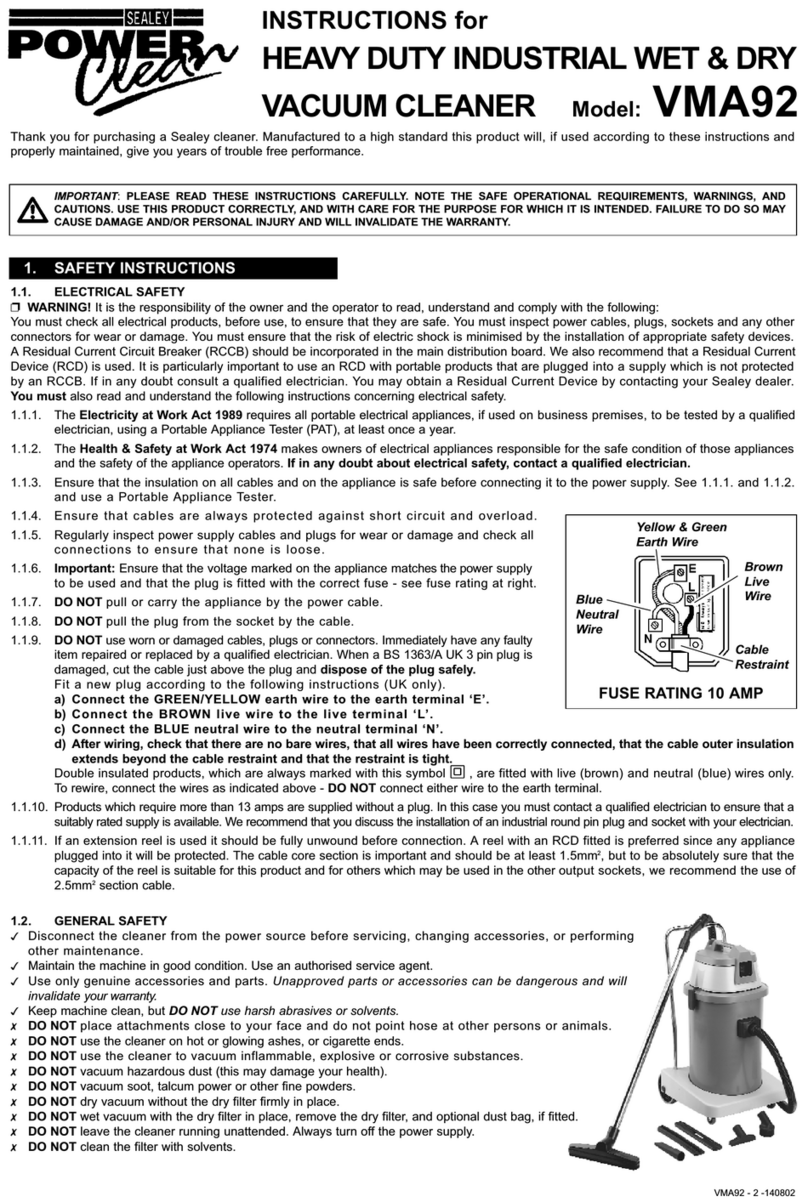

7.1 Ensure the machine is unplugged from the power supply.

Make sure the tank is clean and free from dust and dirt.

7.2 Remove the cartridge filter and fit a foam filter over the filter

basket. Replace the top section onto the container.

7.3 To the same flexible hose as used in dry cleaning fit the

desired nozzle.

7.4 Ensure the switch is ‘Off’ (position ‘0’) before plugging into

the power supply.

7.5 Press the switch to ‘On’ (position ‘I’).

Note: To vacuum large quantities of liquid, from a sink or

tank etc, do not immerse the nozzle completely in the liquid,

leave a gap at the top of the nozzle opening to allow an air

WARNING! Ensure you read, understand and apply

Section 1 ‘Safety Instructions’. Reminder: DO NOT

vacuum hazardous substances. Use of an incorrect

cartridge filter will invalidate your warranty.

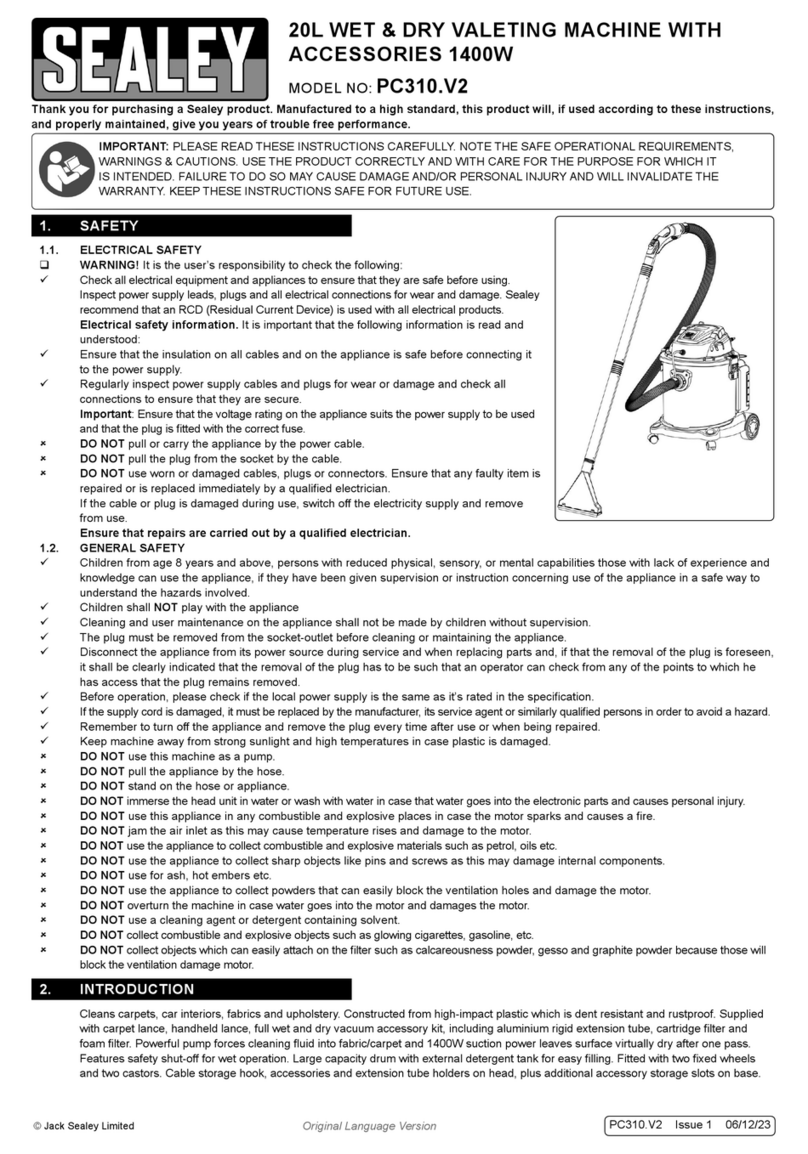

6.1 Ensure the machine is unplugged from the power supply.

6.2 Remove the top section and with the raised rim uppermost fit

the cartridge filter tube down over the filter basket and push

fully home. Place the locking disc onto the top of the filter

and turn the locking bar until the latch drops into the slot in

the top of the filter cage. Continue turning until the filter is

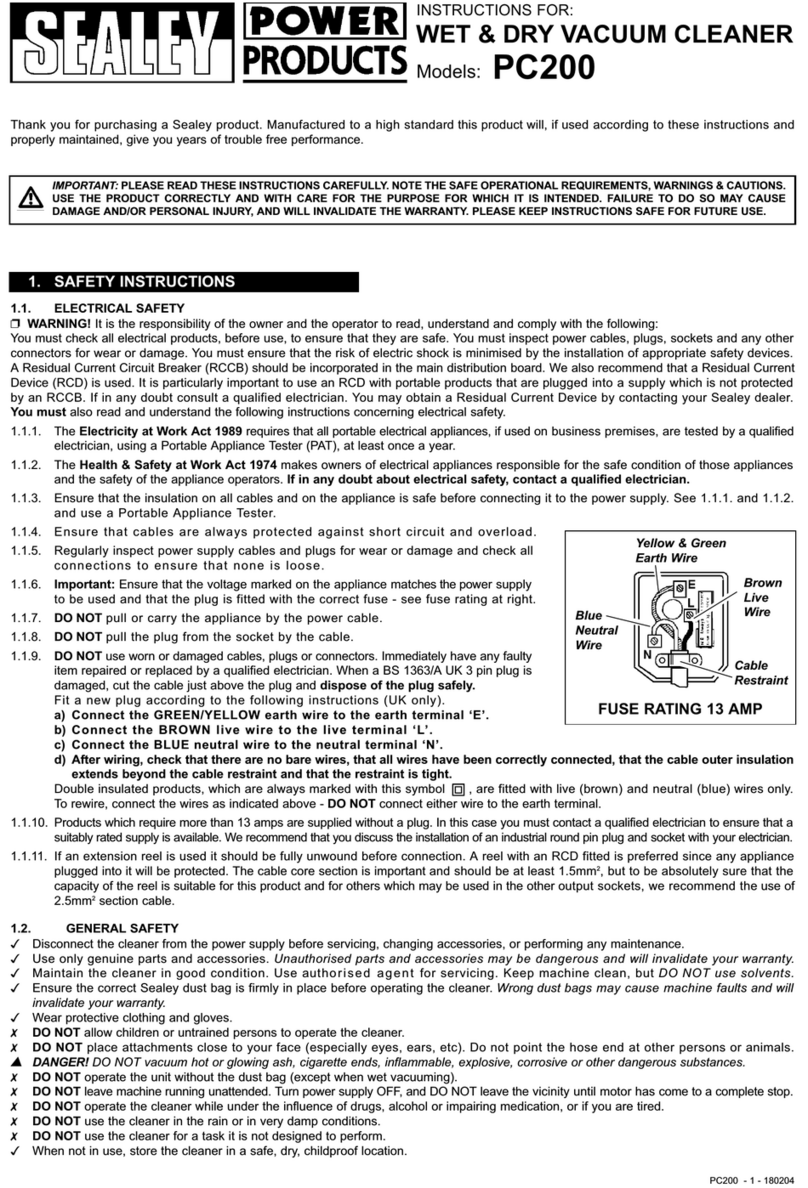

fully locked down. (see 2 below)

6.3 Reposition the head onto the drum body, and clip in place.

6.4 Insert the larger end of the flexible hose into the front inlet on

the container and lock in place. Push the required attachment

onto the free end of the hose.

6.5 Plug in the power supply.

6.6 Switch to the ‘On’ (position ‘I’).

6.7 When you have completed vacuuming, press the switch to

‘Off’ (position ‘O’) and unplug from power supply. Regularly

check the container and dispose of dust and debris when it

is 1/2 full.

6. DRY VACUUM CLEANING

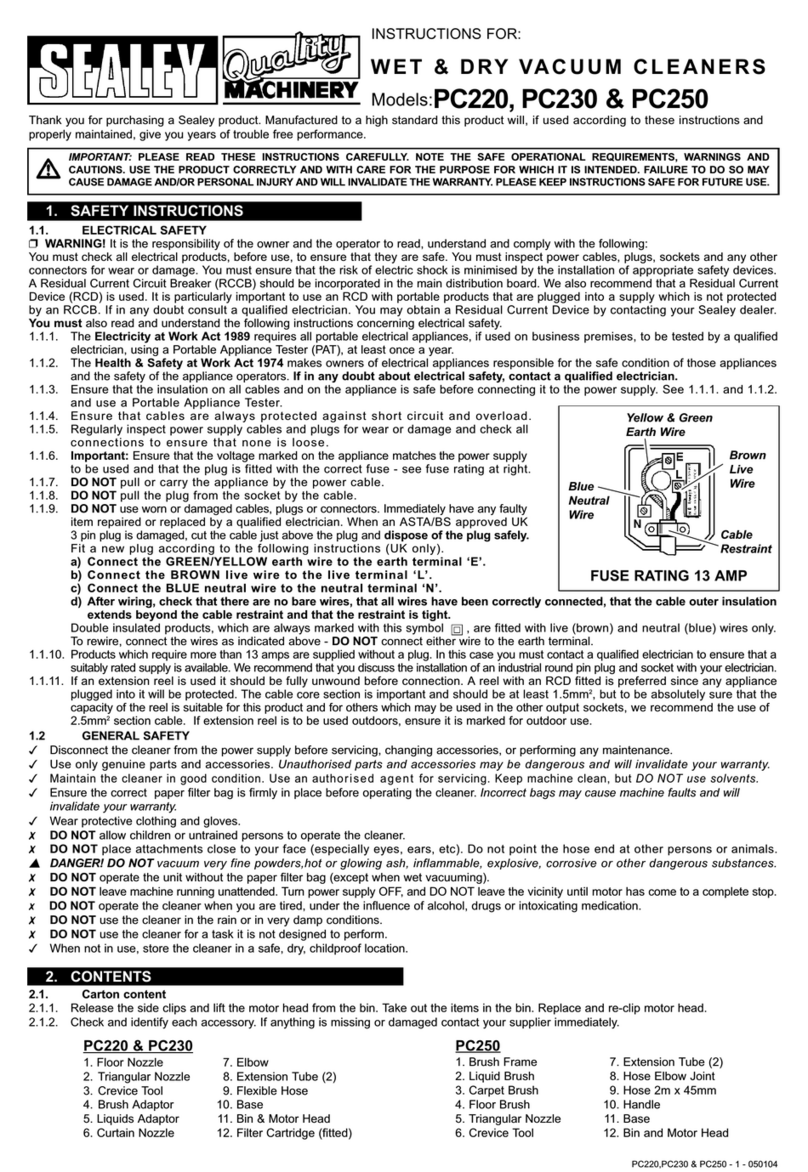

5. SWITCH OPERATION

5.1 USE WITH VACUUM CLEANER ONLY.

The single bar position switches on the vacuum cleaner only.

5.2 USING VACUUM WITH DUST FREE TOOL

The double bar position is for the use of dust free tools. See

section 9.

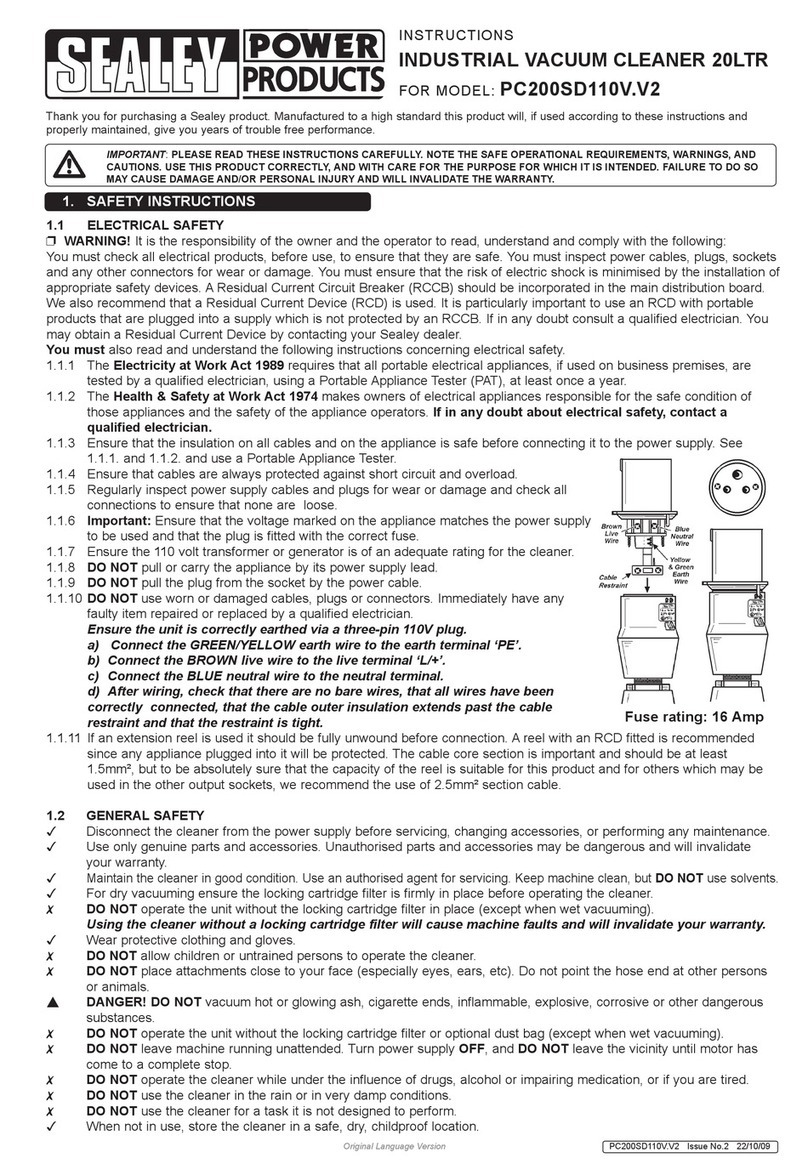

9.1 Connect the tool to the hose using the rubber adaptor supplied.

Ensure that the ON/OFF switch is in the OFF position then

plug the dust free tool into the covered socket provided on

the front of the power head (see fig.1-16). Move the switch to

the double bar position. The vacuum cleaner will start

automatically when the tool is switched on. When the tool is

switched off the vacuum will continue to run for 10 seconds to

ensure that the tool and hose are left free of dust.

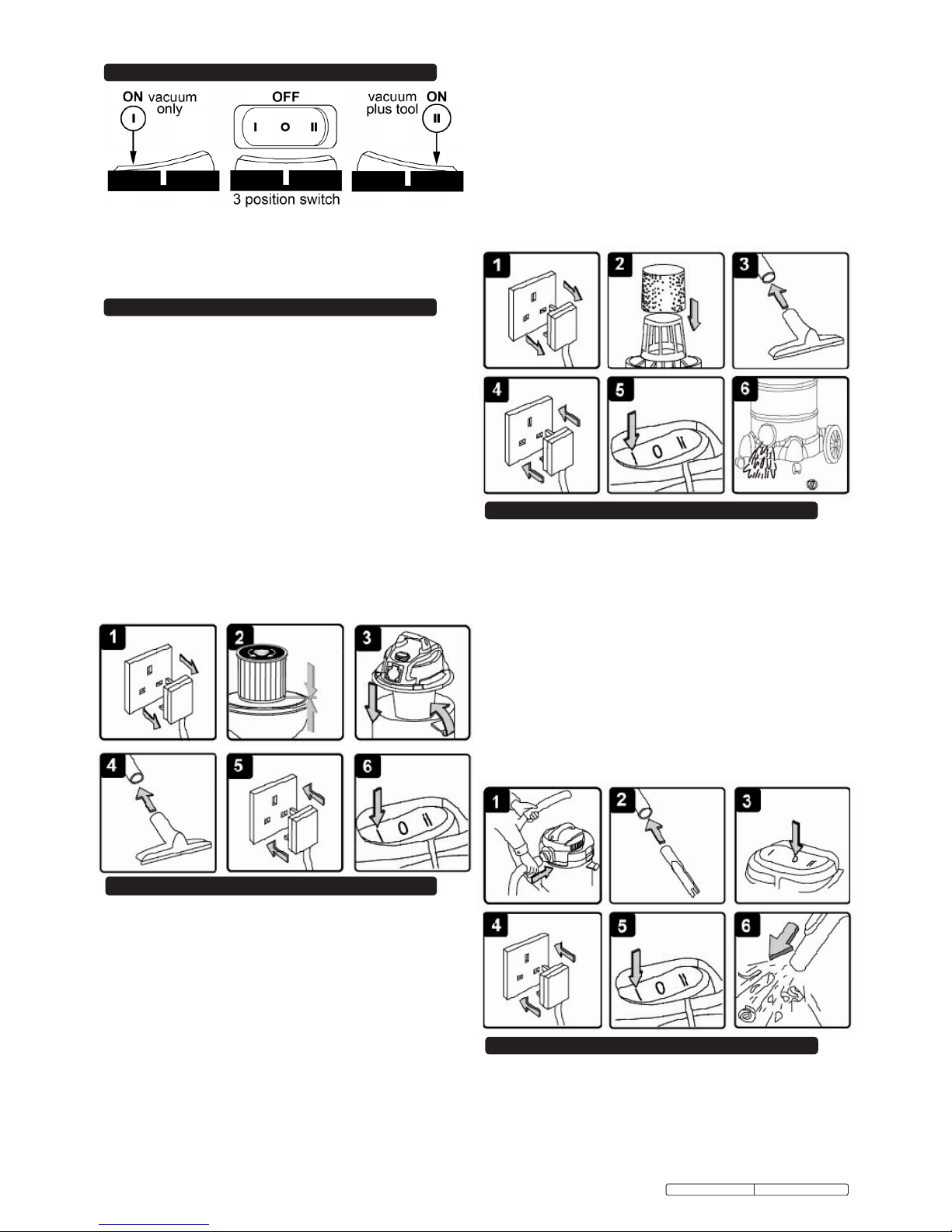

8. BLOWING

WARNING! Wear a dust mask if blowing creates dust

that might be inhaled.

WARNING! Always wear safety goggles when using the

unit for blowing.

WARNING! Keep bystanders clear from blowing debris.

WARNING! Make sure the container is empty before

using the unit as a blower.

8.1 Remove the hose from the vacuum port and insert the large

end of the hose into the blowing port on the other side of the

power head and twist to the right to lock it in place.

8.2 Fit the desired extension tube/nozzle to the free end of the

vacuum hose.

8.3 Ensure the ON/OFF switch is in the central OFF position.

8.4 Plug the unit into the mains power supply.

8.5 Take firm hold of the loose end of the hose and select the

single bar position 'I' on the ON/OFF switch to start the motor.

8.6 If the unit does not appear to be blowing, switch OFF and

check for blockages in the hosepipe.

9. USING DUST FREE TOOLS