7. DRY VACUUM CLEANING

WARNING! Ensure you read, understand and apply Section 1

'Safety Instructions'.

Reminder: DO NOT vacuum hazardous substances. Use of an

incorrect cartridge filter will invalidate your warranty.

7.1 Ensure the machine is unplugged from the power supply.

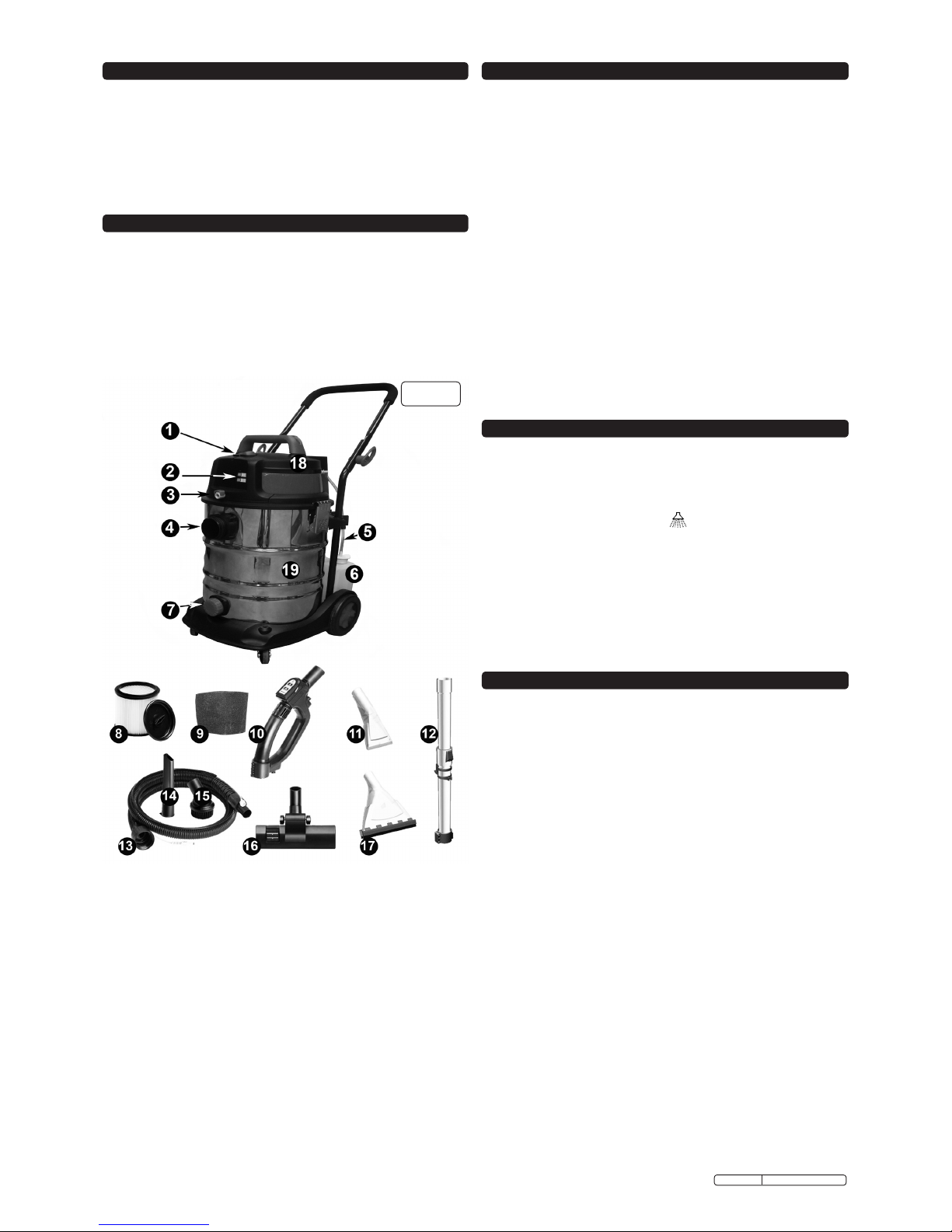

7.2 Fit the cartridge filter and lid (8) over the basket and lock in

place. Attach a dust collection bag over the hose attachment

on the inside of the main drum (19) if desired.

7.3 Re-position the top section (18) onto the main drum (19), and

clip in place.

7.4 Insert the larger end of the suction hose (13) into the suction

hose inlet (4) on the main drum (19) and screw in place.

7.5 Twist and lock the nozzle (10) onto the free end of the flexible

hose (13).

7.6 Push the required attachment onto the free end of the nozzle

(10).

7.7 Plug into the power supply and set the main switch (1) to the 'I'

position.

7.8 Switch the motor to vacuum only mode, indicated by the

symbol, using either the button (2) on the top section of the

cleaner or the button on the nozzle (10).

7.9 When you have completed vacuuming, switch off the cleaner

by pressing either the vacuum button on the nozzle (10) or the

button on the top section of the cleaner (2).

7.10 Set the main switch (1) to the 'O' position and unplug machine

from the power supply.

WARNING! Ensure you read, understand and apply

Section 1 ‘Safety Instructions’. Reminder: Remove plug

from power supply before opening unit. DO NOT vacuum

solvents, explosives, inflammable and/or hazardous

liquids such as petrol, oil, spirits, paint, thinners, acids

etc. Use of an incorrect filter will invalidate your warranty.

8.1 Ensure the machine is unplugged from the power supply. Make

sure the main drum (19) is clean and free from dust and dirt.

8.2a For wet vacuum cleaning the foam filter (9) must be used.

8.2b When using the foam filter (9) first remove any cartridge filter (8)

fitted. Ensure the foam filter (9) is clean and dry. Place the foam

filter (9) over the filter cage and adjust carefully.

8.3 Fit the required accessories or tubes to the suction hose (13).

8.4 Ensure the main switch (1) is 'Off' (position 'O') before plugging

into the power supply.

8.5 Set the main switch (1) to the 'I'. Press the vacuum selection

mode button on either the nozzle (10) or the top section

(2) and operate the machine.

8.6 When you have completed vacuuming, switch off the machine

using either of the vacuum mode buttons. Set the main switch (1)

to 'O', and unplug from power supply.

8.7 After use, empty the main drum (19) and dry.

WARNING! The main drum (19) is not designed for liquid

storage. Always empty liquids after use. Never store the

cleaner with liquid in the main drum (19).

8.8 To vacuum large quantities of liquid, from a sink or tank etc.,

do not immerse the nozzle completely in the liquid; leave a gap

at the top of the nozzle opening to allow an air inflow. The

machine is fitted with a float valve which blocks the suction

action when the tank has reached its maximum capacity. The

user will notice an increase in motor noise. When this happens,

turn off the machine, disconnect from power supply, remove

cap from the drainage outlet (7) on the main drum and empty the

liquid into a suitable receptacle or drain. To continue vacuuming,

refit the drainage outlet cap (7) and proceed. After wet

vacuuming, turn the machine off and remove plug from power

supply. Empty the main drum (19) from the drainage outlet (7)

and clean/dry the inside and outside before storage.

8. WET VACUUM CLEANING

Original Language Version VMA915 Issue:1 - 21/07/11

9. CARPET/UPHOLSTERY CLEANING

9.1 SET-UP

Water, mixed with a suitable carpet detergent solution, is

pumped deep into the fibres of the carpet via the detergent

application nozzle. The dirty liquid is then sucked back into

the main drum (19) along with the dirt and grime dislodged

by the cleaning solution. Water can be pumped up to 2

metres above the machine so that stairs may also be

cleaned.

WARNING! Ensure you read, understand and apply Section

1 'Safety Instructions'.

Reminder: DO NOT vacuum hazardous substances.

9.1.1 Ensure the machine is unplugged from the power supply.

9.1.2 Fit the foam filter (9).

9.1.3 Reposition the top section (18) onto the main drum (19) and

clip in place.

9.1.4 Ensure that the detergent solution has been mixed with the

recommended proportion of water and pour it into the

detergent tank (6).

9.1.5 Plug the connector on the end of the detergent tank

connecting hose (5) into the detergent inlet coupling on the

rear of the top section (18).

9.1.6 Ensure that the transparent detergent delivery tube is fitted

around the suction hose (13).

9.1.7 Screw the large threaded connector on the end of the suction

hose (13) to the suction hose inlet (4).

9.1.8 Push the connector on the end of the detergent delivery tube

into the detergent pipe coupling (3) on the front of the top

section (18).

9.1.9 Twist and lock the nozzle (10) onto the free end of the suction

hose (13). Twist and lock the detergent delivery tube to the

nozzle (10). Fit the carpet lance (17) to the stainless steel

extension tube (12) and attach the stainless steel extension

tube (12) to the nozzle (10). Connect the detergent delivery

tube from the carpet lance (17) to the nozzle (10). The grey

fitting is a push and twist fit.

9.1.10 The spraying nozzle at the other end of the delivery tube is a

push fit into the mounting on the underside of the carpet

lance. There is a notch in the nozzle which must fit onto a

spigot in the lance mounting to ensure that the nozzle outlet is

the right way round. To clean fabrics and upholstery clip the

spray nozzle with the short tube into the underside of the

hand held lance (11). Push the assembled hand held lance

(11) onto the nozzle (10). Note: The stainless steel extension

tube (12) is not used.

9.1.11 Select the detergent mode , to operate the machine for

detergent application only.

Select both the detergent mode and vacuum mode for

simultaneous detergent application and dirty liquid suction.

9.2 CARPET/UPHOLSTERY CLEANING

Vacuum the carpet/upholstery thoroughly before washing it.

For carpet cleaning we recommend you first remove all

furniture from the room to be cleaned, or move it away from

the cleaning area. Clean the whole carpet systematically in

squares of approximately 1.5m each. This avoids walking over

the cleaned carpet until it is completely dry.

9.2.1 Start furthest away from the doorway to the room, extend the

hose and work backwards.

9.2.2 Select detergent mode to spray detergent into the

area to be cleaned.

9.2.3 Pull the carpet lance (17) back towards you, in lengths of

approx 1.5m. Refill the detergent tank (6) if the fluid spray

stops.

9.2.4 Switch off and return to where you started.

9.2.5 Select the vacuum mode to suck up the dirty solution

and repeat the previous pattern of strokes. Apply more

detergent in any particularly dirty area. The dirty solution

is visible as it is sucked up through the carpet lance (17). Stop

vacuuming when there is no more dirty fluid visible.

9.2.6 Do not walk over any newly cleaned area until it is completely

dry.

9.2.7 The hand held lance (11) is ideal for cleaning sofas, chairs,

stairs and car interiors.