5. OPERATION

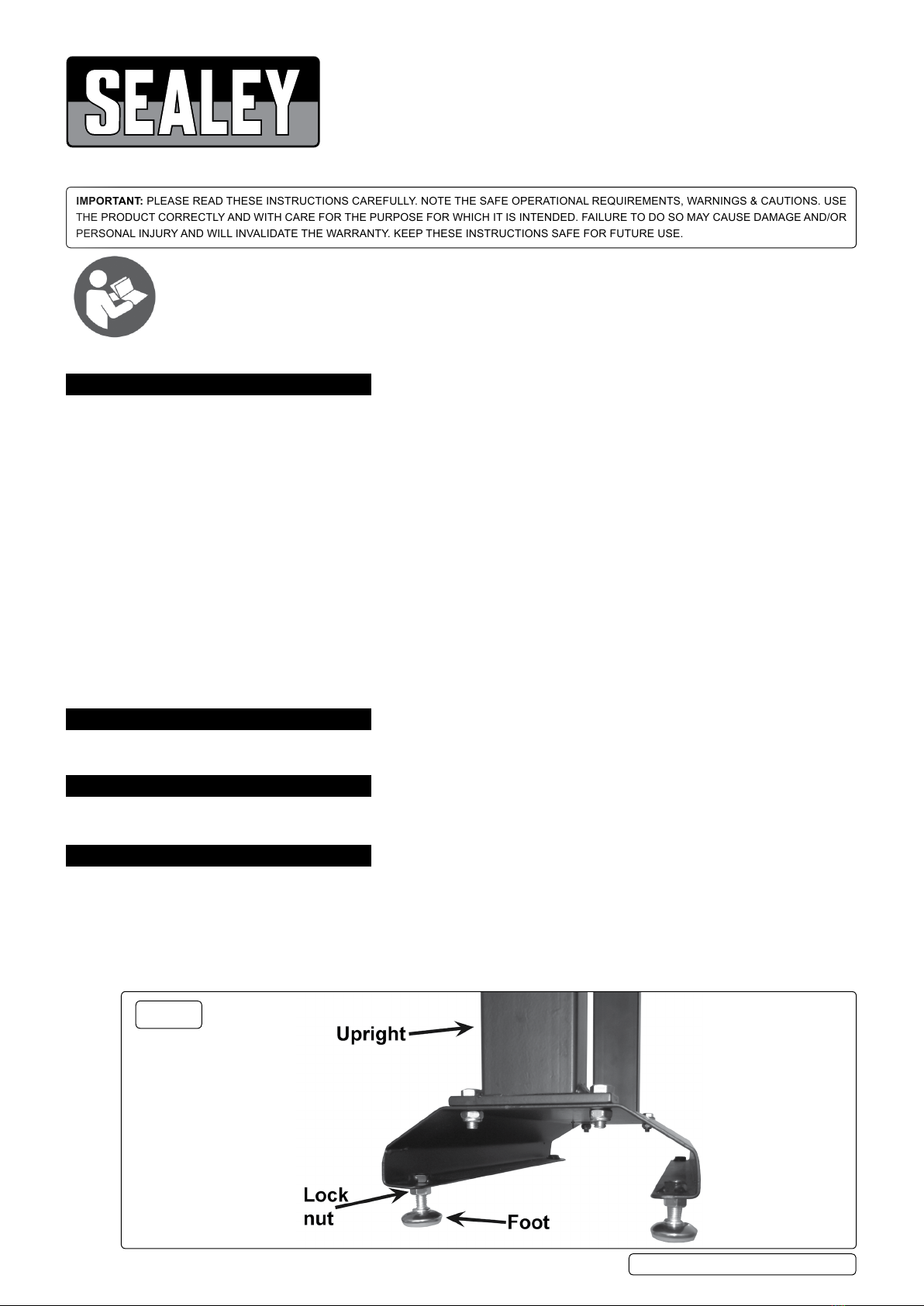

5.1. Use the balancer on a stable, level surface. If necessary

adjust the feet until the bubble level is central. Screw the leg

nuts tight to the base to secure the legs.

5.2. Slide the balancer spindle through the motorcycle wheel hollow

axle and slide a cone onto either end of the spindle so that the

tapered ends enter the wheel bearings. When the wheel is

central on the spindle, secure the cones by tightening the grub

screw in each using a 3mm hex key. Check that the wheel is

central on the spindle and firmly secured by the cones for best

results. See fig.3

5.3. With the wheel securely on the wheel balancer, gently rotate the

wheel. When the wheel settles, the spot at the bottom of the

wheel is the heavy spot.

5.4. Now with the heavy spot at the bottom mark the top of the wheel

directly opposite the heavy spot using chalk or adhesive tape.

This is the light spot see fig.4A.

5.5. Gently spin the wheel again to ensure that the heavy spot will

again settle at the bottom. (fig.4)

5.6. Attach some wheel weights to the rim of the wheel at the light

spot (fig.4A) and spin the wheel gently.

5.7. If the light spot falls to the bottom, too much weight has been

added to the wheel. If the heavy spot falls to the bottom, not

enough weight has been added to the wheel. Add / Remove

weight as required (fig.5)

5.8. Turn the light spot 90 degrees so it sits horizontally with the

heavy spot and observe its movements, if again it falls to the

bottom, too much weight has been added, if the heavy spot falls,

too little weight has been added. (fig.5)

5.9. Repeat until the light spot and heavy spot are on a horizontal line through the centre of the wheel. Once this has been achieved the

wheel should rest still at any position through the wheels circumference.

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

g.2

g.3 g.4 g.5

VS1819.V3 Issue 2 14/05/18

Original Language Version

© Jack Sealey Limited