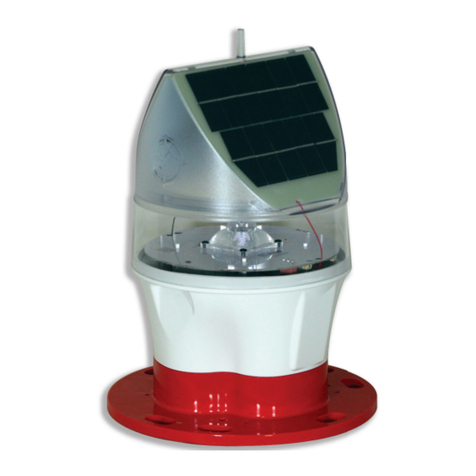

Sealite TRIDENT-2600Q Supplement

Other Sealite Marine Lighting manuals

Sealite

Sealite SL60 Supplement

Sealite

Sealite SL-155 Series Supplement

Sealite

Sealite SL-75 User manual

Sealite

Sealite SL-15 Supplement

Sealite

Sealite SLC600 Supplement

Sealite

Sealite SL-300-1D5 Series Supplement

Sealite

Sealite SL-BR Supplement

Sealite

Sealite SL-75 Supplement

Sealite

Sealite SL-300-2D5 Series Supplement

Popular Marine Lighting manuals by other brands

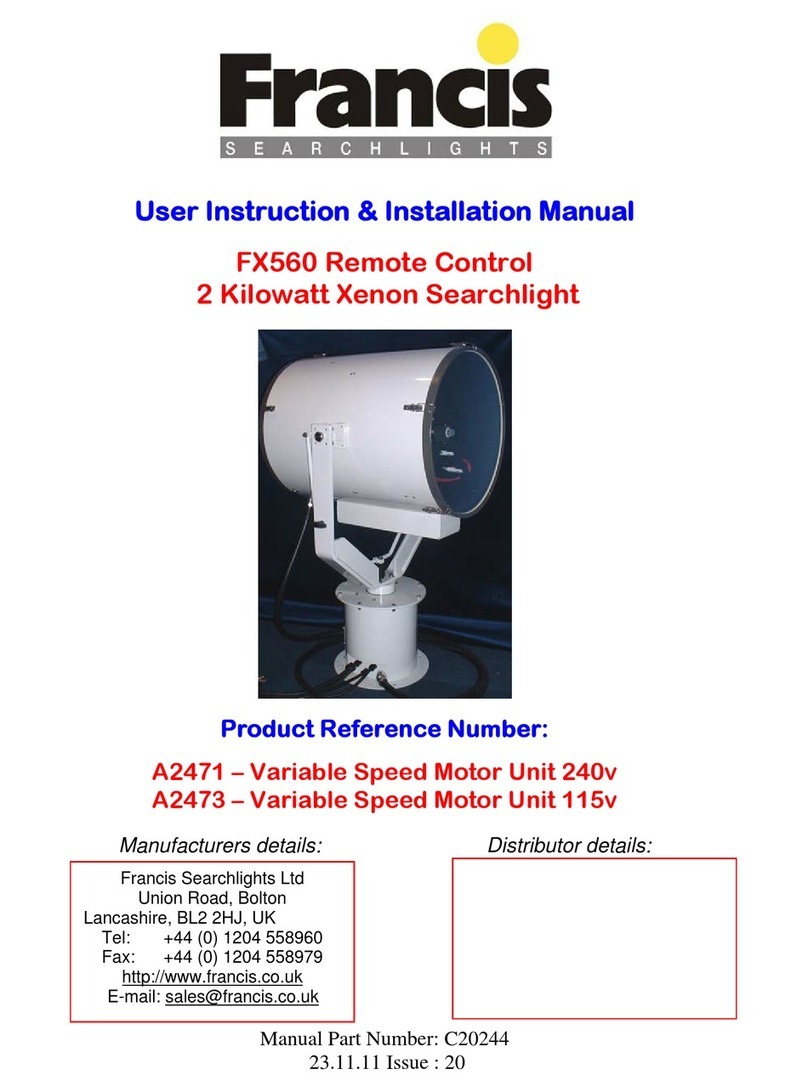

Francis Searchlights

Francis Searchlights FX560 User instruction & installation manual

Attwood

Attwood 5095 installation instructions

Glamox

Glamox aqua signal TX20 Series Service manual

Attwood

Attwood 3100 installation instructions

Imtra

Imtra BCM California 60 Installation and operation manual

Hella marine

Hella marine NAVILED PRO 2NM manual

ACR Electronics

ACR Electronics 3940 Product support manual

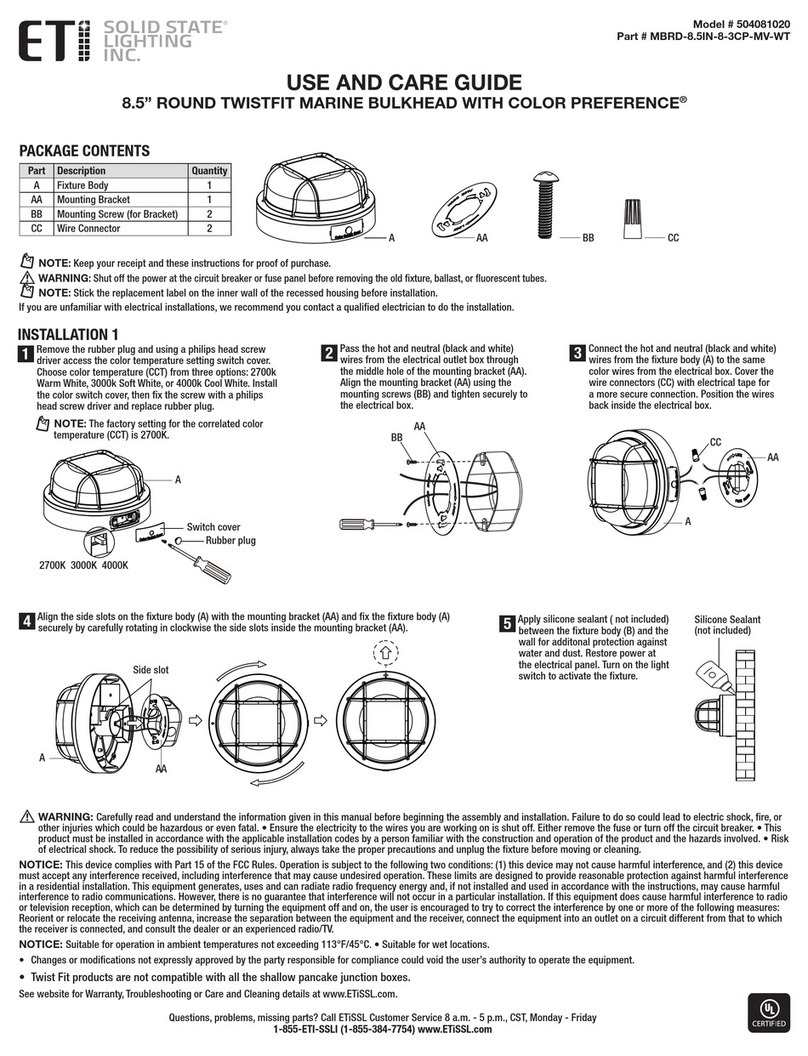

ETI Solid State Lighting

ETI Solid State Lighting 504081020 Use and care guide

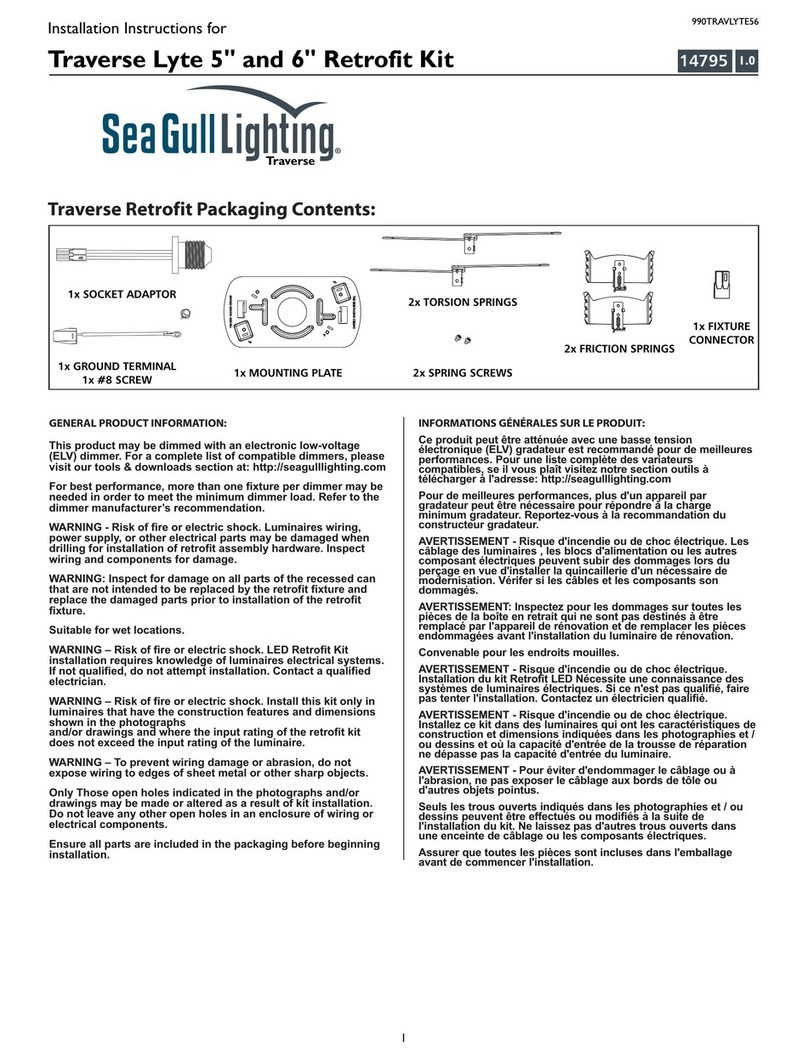

Sea gull lighting

Sea gull lighting Traverse Lyte Retrofit Kit installation instructions

Attwood

Attwood 3830 instructions

Attwood

Attwood 911339 installation instructions

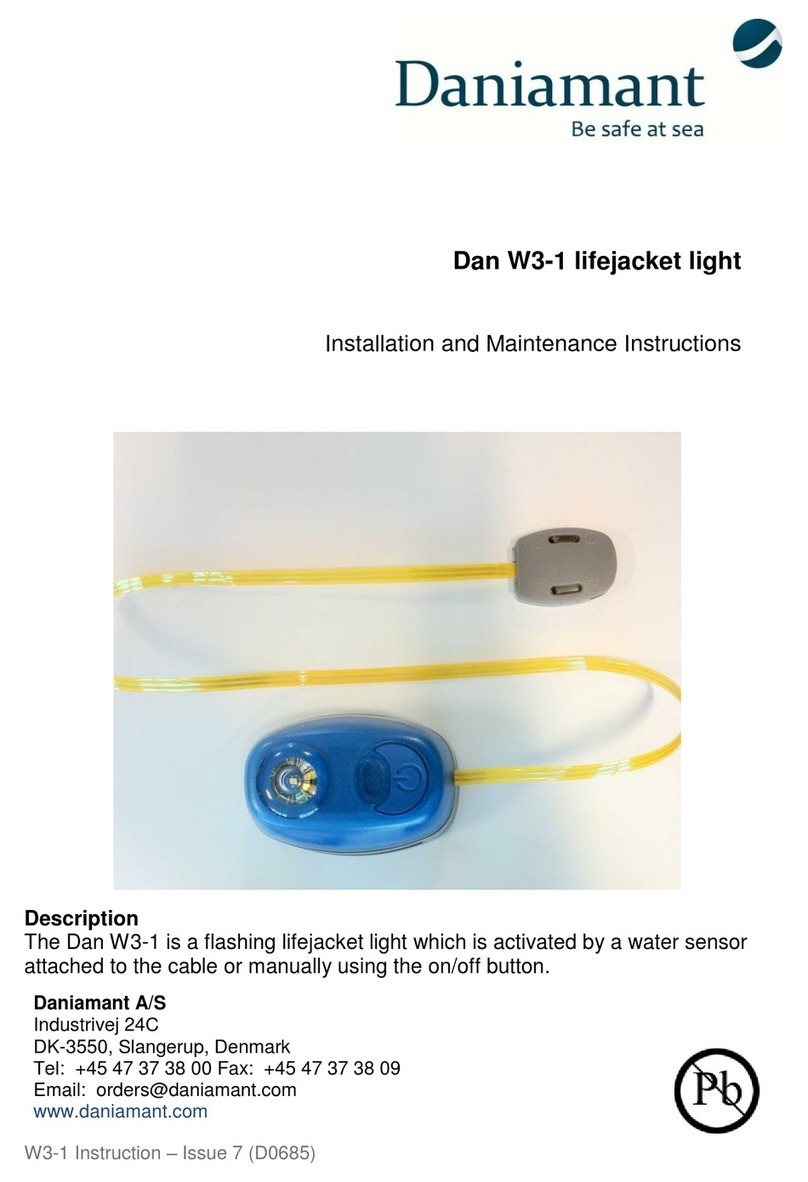

Daniamant

Daniamant W3-1 Installation and maintenance instructions

Attwood

Attwood 91041 instructions

Tranberg

Tranberg TEF 2438N user manual

Weems & Plath

Weems & Plath 700 instructions

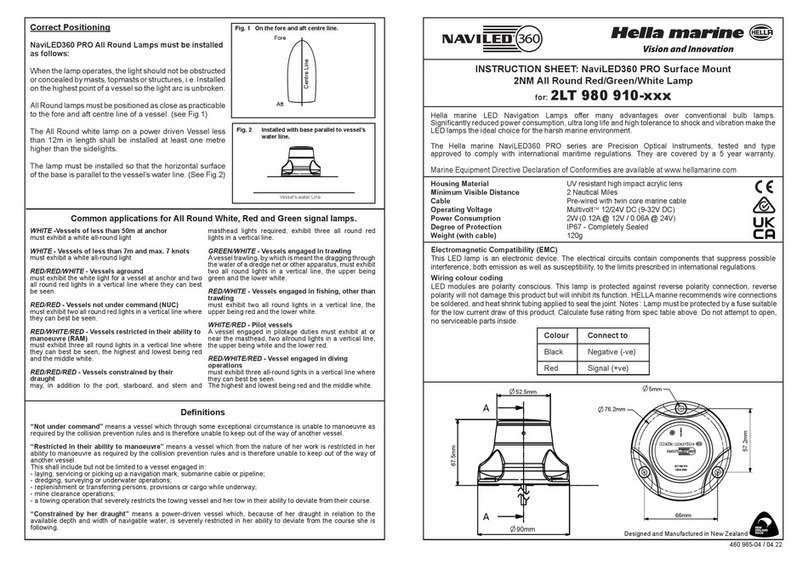

Hella marine

Hella marine NaviLED 360 2LT 980 960-0 Series manual

Hella marine

Hella marine NaviLED 360 PRO 2LT 980 910 Series instruction sheet

Hurley Marine

Hurley Marine LED Sea-Vue instructions