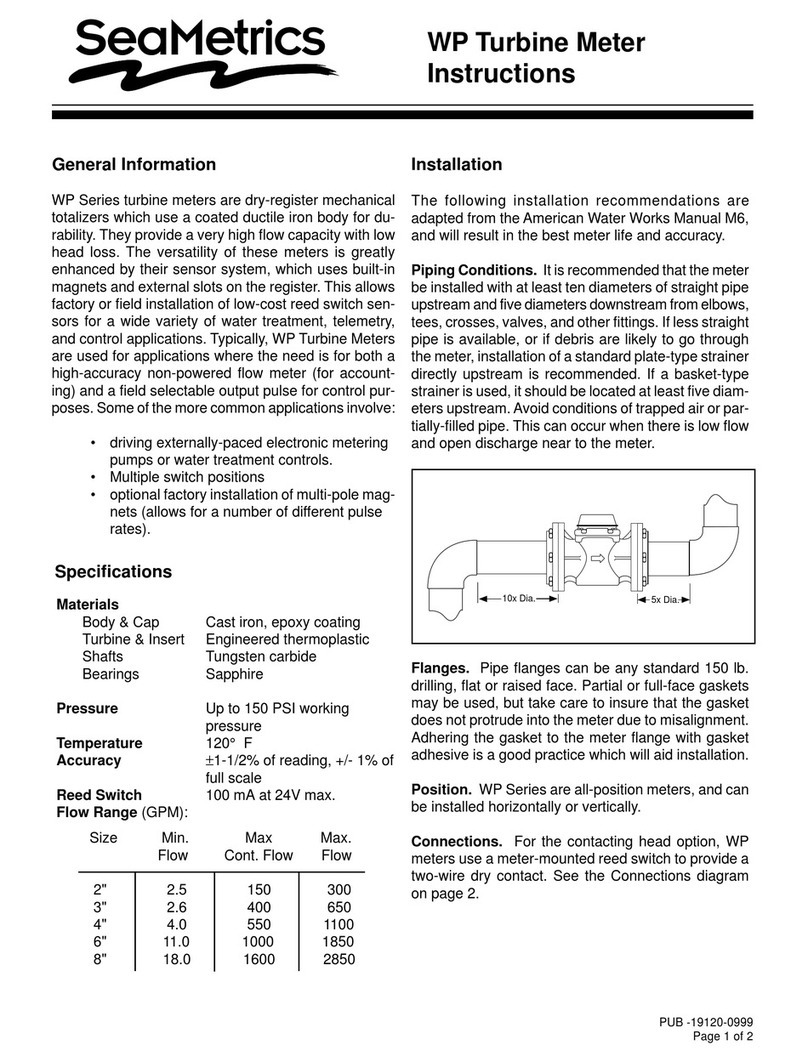

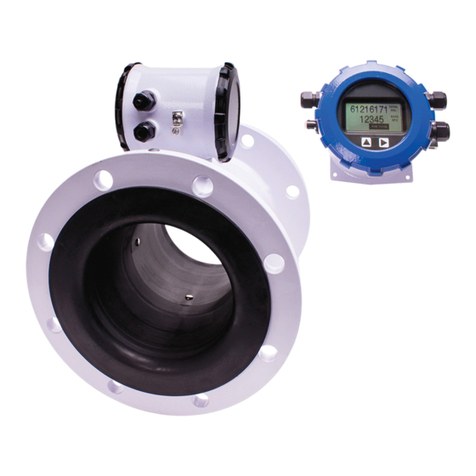

Position. MD-Series meters should be installed hori-

zontally with the register up. Vertical mounting will result

in some degree of under-measurement and shortened

life of the bearings.

Couplings. Couplings are included with each meter.

Theseprovidemale NPT threads the same nominal size

as the meter. The threads on the end of the meter are

IPSstraight threads one size bigger thanthe meter size.

It is possible to thread a standard pipe coupling directly

onto the meter for close coupling, but the meter cou-

plingsaremuch preferable because they provide a union

connectionformeterservice. Be sure to use the included

gasket between the end of the meter and the coupling.

Inlet Conditions. Noupstreamstraightpipeisrequired.

A strainer is built in to protect from solids, and should be

periodically cleaned.

Air Bleed. When the meter is first installed, trapped air

should be removed. To do this, loosen the meter cou-

plings slightly and rotate the meter to an inverted

position. Allow water to flow, then rotate the meter

back to an upright position and tighten.

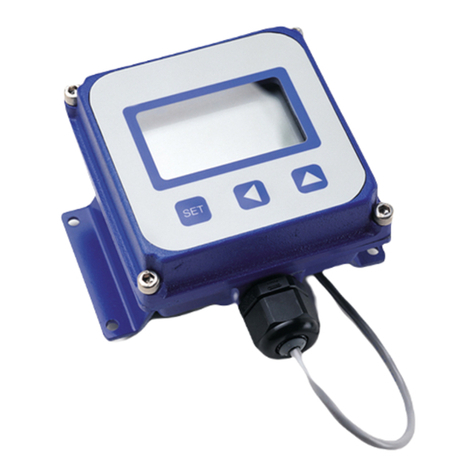

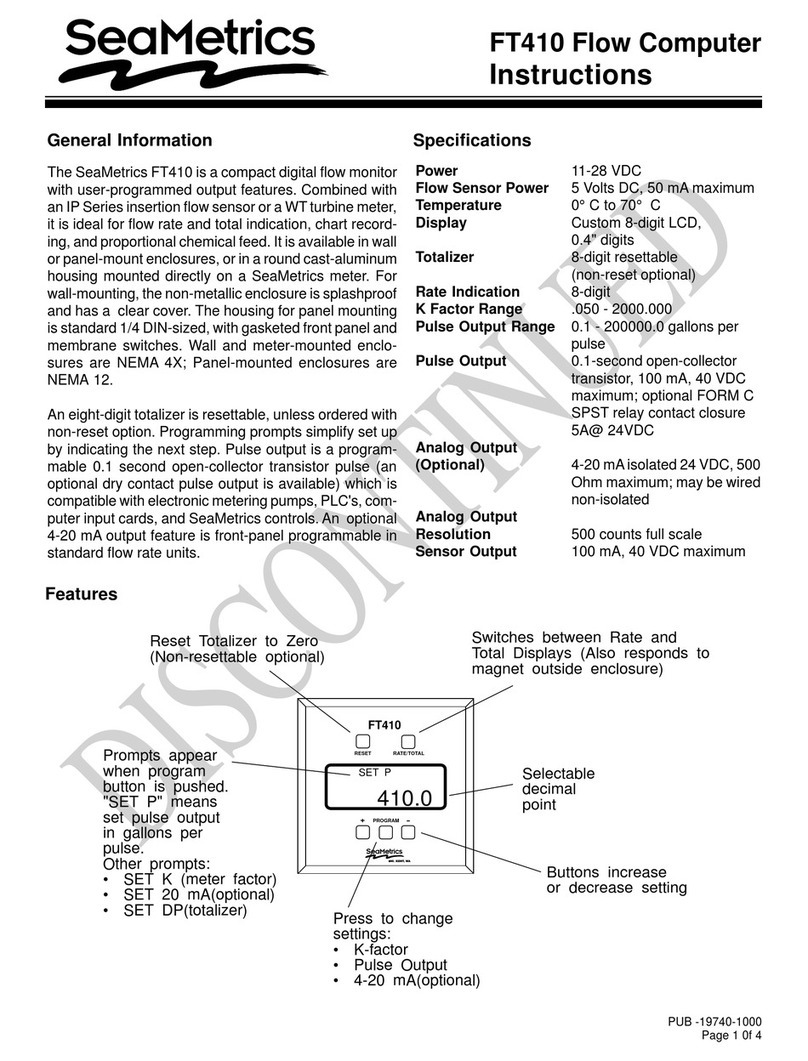

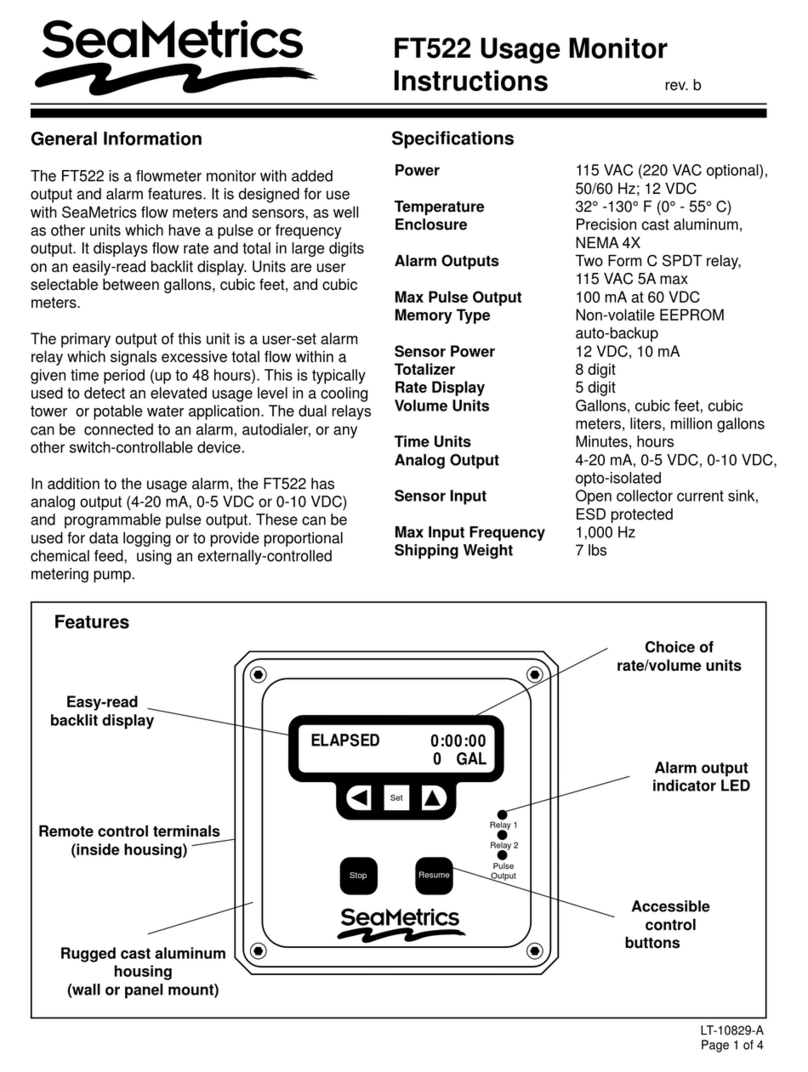

Connections. MDEandMDR sensors are supplied with

a color coded output cable. See the diagram for color

codes and polarity. Optional connectors can be ordered

to plug directly into a SeaMetrics control or a specific

brand of metering pump.

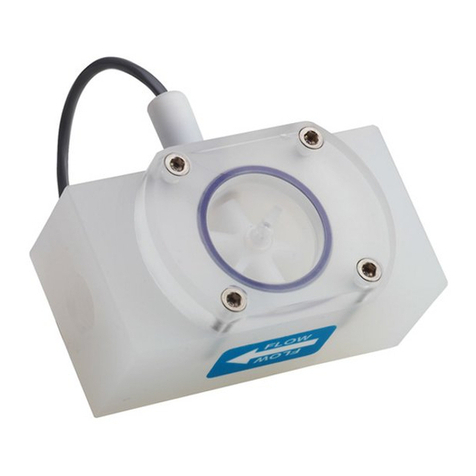

Pulse Output. Both MDE and MDR sensors respond to

a magnet which rotates on the face of the meter under

the lens. The sensor turns on and off once each time

the magnet passes under it. Sensors are designed for

electroniccontrolloads,andshouldnotbeusedto switch

power loads or line voltages. See maximum current and

voltage ratings, under Specifications.

Maintenance

SeaMetrics recommends all service to be performed by

authorized distributor or factory to maintain the integrity

of the protective tamper-proof wire-and-seal.

Inlet Strainer. Clean the strainer yearly, or as required,

depending on water condition. Pull out the strainer or

backflush the meter to loosen trapped particulates.

Calibration. Meters used for billing or billing exemption

may be regulated by state or local authorities. New

metersare factory-tested to meet theAWWAC-708Multi-

Jet Meter accuracy specification. Some states

requireretestingatvariousintervals,typicallyeightyears

for 3/4" meters, six for 1", and four for 1-1/2" and 2".

Meters used for control should be tested every 5-10

years. Testing can be done by local meter shops autho-

rized for this purpose, or can be done by the factory.

Please contact SeaMetrics before sending meter in for

calibration or servicing.

Internal Parts Replacement. All of the internal parts of

an MD-Series meter lift out as a unit, after the top has

beenunscrewed.Thelens can then beremoved and the

internal assembly lifted out. The three pieces of the

assembly can be separated by hand.

Excessiveflowcancausebreakage. Compare maximum

flow with the flow rating table.

Changing Pulse Rates. After removing the meter top,

lift off the center magnet to expose the gears. If the only

change required is moving the drive gear (for example

from one gallon/pulse to ten gallons/pulse), gently pull

the drive gear off its shaft. Remove the pointer on the

target shaft and push the drive gear onto the target shaft

as far as it will go. Put the pointer on the vacant shaft

and push on.

If a different gear set is required, follow the same proce-

dure, replacing rather than moving the drive gear. To

install a drive gear on another shaft, remove the pointer

and then press the gear down until it bottoms. Use the

pulse rate chart to determine the position.

2 of 4

(BLACK) Power (-)

(BROWN) Common

(WHITE) Signal

(WHITE) N.O.

(RED) Power (+) 6-24 VDC

sensor connection

MDRsensor connection

MDE

Installation

These water meters are not

recommended for installation

indoors or anywhere leakage

may cause damage.

WARNING

DO NOT INSTA

meter in overhead

Indoor piping or where

leakage

may cause damage