SeaPerch Remotely Operated Vehicle Instructions for use

Version 2010-04NW

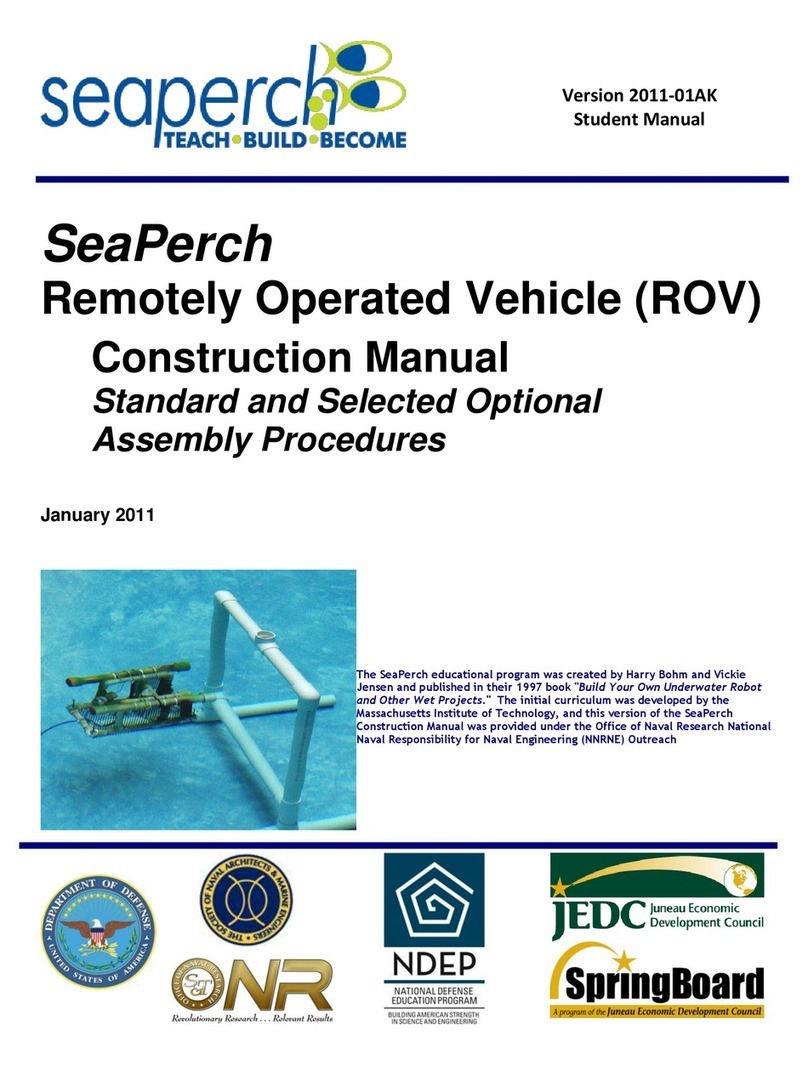

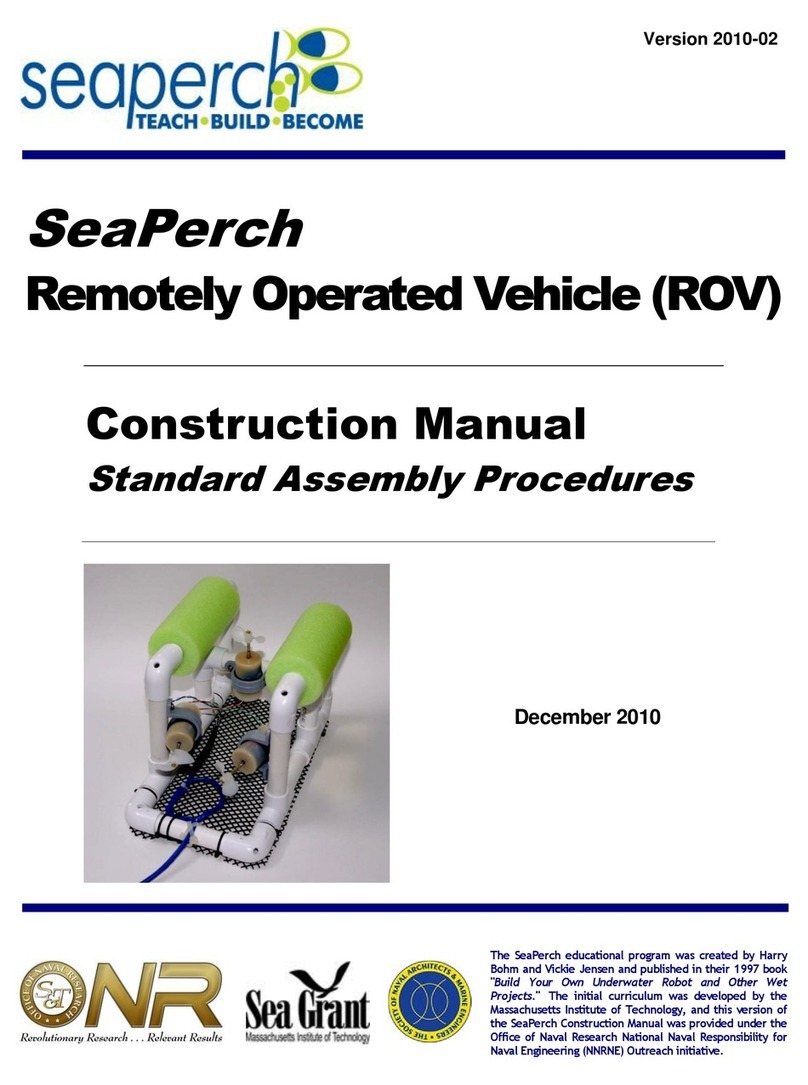

SeaPerch

Remotely Operated Vehicle (ROV)

Construction Manual

Standard and Selected Optional

Assembly Procedures

August 2010

The SeaPerch educational program was created by Harry

Bohm and Vickie Jensen and published in their 1997 book

"Build Your Own Underwater Robot and Other Wet

Projects." The initial curriculum was developed by the

Massachusetts Institute of Technology, and this version of

the SeaPerch Construction Manual was provided under the

Office of Naval Research National Naval Responsibility for

Naval Engineering (NNRNE) Outreach initiative.

SeaPerch ROV Construction Manual –Version 2010-04NW

I

Table of Contents

Introduction ------------------------------------------------------------------------------------------ I-1

SeaPerch ROV Program Overview ------------------------------------------------------------ I-1

What is SeaPerch? ---------------------------------------------------------------------------- I-1

Program History --------------------------------------------------------------------------------- I-2

Original SeaPerch ROV Manual Development ----------------------------------------- I-2

Updated Information in this Manual ------------------------------------------------------------ I-2

Revised Standard SeaPerch Assembly Instructions ---------------------------------- I-2

Expanded Testing and Operating Information ------------------------------------------ I-3

Added Appendix Containing Troubleshooting Hints ----------------------------------- I-3

Added Supplement for Construction Options and Enhancements ---------------- 1-3

The SeaPerch Assembly Process -------------------------------------------------------------- I-5

Three Individual Building Units ------------------------------------------------------------- I-5

Recording Progress ---------------------------------------------------------------------------- I-5

Testing and Adjustments --------------------------------------------------------------------- I-5

Tools and Materials ---------------------------------------------------------------------------- 1-6

Manual Printing Considerations -------------------------------------------------------------1.6

Safety Overview -------------------------------------------------------------------------------- S-1

Protective Eyewear ------------------------------------------------------------------------------- S-1

Materials Handling Safety ---------------------------------------------------------------------- S-2

Safety While Using Hand Tools --------------------------------------------------------------- S-2

Safety While Drilling ------------------------------------------------------------------------------ S-3

Safety While Soldering -------------------------------------------------------------------------- S-4

Safety While Potting Motors for Thrusters -------------------------------------------------- S-4

Safety With Electricity and Batteries --------------------------------------------------------- S-5

OPTIONAL TABLE OFCONTENTS II –PVC TUBE FLOAT OPTION SeaPerch ROV Construction Manual –Version 2010-04NW

II

Unit 1 –Assembly of Subsystem One –The Vehicle Frame ----- 1.0-1

Tools and Materials Needed ------------------------------------------------------------------ 1.0-2

Time Needed to Complete Unit 1 ------------------------------------------------------------ 1.0-2

Procedure 1.1 –Cut the Frame Parts ------------------------------------------------------1.1-1

Procedure 1.2 –Drill the Drain Holes ------------------------------------------------------- 1.2-1

Procedure 1.3 –Assemble the Vehicle Frame ------------------------------------------- 1.3-1

Procedure1.4A –Assemble the PVC Tube Floats -------------------------------------1.4A-1

Procedure1.4B –Install the Floats and Tighten the Frame --------------------------1.4B-1

Procedure 1.5 –Attach the Thruster Mounts --------------------------------------------- 1.5-1

Procedure 1.6 –Attach the Payload Net --------------------------------------------------- 1.6-1

Unit 2 –Assembly of Subsystem Two –The Thrusters ------------- 2.0-1

Tools and Materials Needed ------------------------------------------------------------------ 2.0-2

Time Needed to Complete Unit 2 -------------------------------------------------------------2.0-2

Procedure 2.1 –Build a Motor Potting Holder (If Not Provided) ----------------------2.1-1

Procedure 2.2 –Test the Motors and Mark their Terminals' Polarity --------------- 2.2-1

Procedure 2.3 –Seal the Motors So That Wax Cannot Get Inside ----------------- 2.3-1

Procedure 2.4 –Drill Holes in the Thruster Housings --------------------------------- 2.4-1

Tips on Soldering –Safety and Techniques ---------------------------------------------- 2.5-1

Procedure 2.5 –Connect the Tether Cable Wires to the Motors -------------------- 2.5-2

Tips on Wax Melting –Safety and Techniques ------------------------------------------ 2.6-1

Procedure 2.6 –Pot (Waterproof) the Motors with Wax ------------------------------- 2.6-2

Procedure 2.7 –Mount the Propellers onto the Motors’ Shafts ---------------------- 2.7-1

Procedure 2.8 –Mount the Thrusters onto the Vehicle Frame --------------------- 2.8-1

Procedure 2.9 –Waterproof and Mount the Tether Cable ---------------------------- 2.9-1

SeaPerch ROV Construction Manual –Version 2010-04NW

III

Unit 3 –Assembly of Subsystem Three –The Control Box ------- 3.0-1

Tools and Materials Needed ------------------------------------------------------------------ 3.0-2

Time Needed to Complete Unit 3 ------------------------------------------------------------ 3.0-2

SeaPerch ROV Electrical Circuit Diagram ------------------------------------------------ 3.0-3

Procedure 3.1 –Gather the Parts for the Control Box Assembly ------------------- 3.1-1

Procedure 3.2 –Prepare the Control Box ------------------------------------------------- 3.2-1

Procedure 3.3 –Assemble the Power Cord ---------------------------------------------- 3.3-1

Procedure 3.4 –Wire the Vertical Thruster Control Switch --------------------------- 3.4-1

Procedure 3.5 –Wire the Horizontal Thruster Control Switches -------------------- 3.5-1

Procedure 3.6 –Finish the Control Box ---------------------------------------------------- 3.6-1

Testing and Ballasting the ROV

Time Needed to Complete Testing and Ballasting of the ROV ------------------------ T-1

Initial Electrical Testing --------------------------------------------------------------------------- T-1

Ballasting and Trimming the ROV -------------------------------------------------------------- T-2

Initial In-Water Testing in the Classroom, Lab, or Pool ----------------------------------- T-4

Using the SeaPerch ROV

Safety Precautions --------------------------------------------------------------------------------- U-1

Environments Suitable for Using a SeaPerch ROV --------------------------------------- U-1

Driving the SeaPerch ROV -----------------------------------------------------------------------U-2

Post-Run Cleaning and Maintenance of the ROV System ------------------------------ U-3

Appendix A –Troubleshooting Your SeaPerch ROV

Things to Try Before Re-Wiring the ROV or Changing ROV Parts ------------------- A-1

Solving Directional Control Problems ---------------------------------------------------- A-1

Solving Thruster Operational Problems ------------------------------------------------- A-2

SeaPerch ROV Construction Manual –Version 2010-04NW

I-1

Introduction

SeaPerch ROV Program Overview

What is SeaPerch?

SeaPerch is an educational tool –a fun, hands-on learning activity and a

curriculum that can be enjoyed by a wide range of students, rangingfrom late

elementary school through high school and even introductory college programs.

The curriculum is designed to meet many of the national learning standards

identified by the United States Government. Often applied at the middle school

(or junior high school) level, SeaPerch is challenging, creative, and gets kids

excited about science and technology. The SeaPerch program is sponsored

through the National Naval Responsibility for Naval Engineering (NNRNE)

Outreach effort, with the goal of helping to inspire the next generation of naval

architects and marine, ocean, and naval engineers.

A SeaPerch is an underwater robot known as a “remotely operated vehicle,” or

“ROV.”Students learn best by doing, and during the SeaPerch project, they will

completely assemble an inexpensive, yet functional ROV, test it, and then

operate it underwater. The experience will enable them to explore science and

technology both in the classroom and in a pool, or, for some, in natural marine

environments.

The ROVs are built from kits comprised of low-cost, easily-obtained components.

Students often work in small teams to assemble their vehicles, usually over a

period of several weeks. From the classroom activities during SeaPerch

construction through in-water application of the ROV, they will have

opportunities to learn about various subjects including mathematics, robotics,

biology, oceanography, physics, and history, as well as valuable problem

solving and teamwork skills.

The SeaPerch program is structured to provide free training to help teachers

more effectively lead students through the variety of interdisciplinary activities

involved. Within one project,a number of concepts requiredfortheir grade level

can be efficiently addressed, with the further benefit of exposing the students to

additional concepts that may not otherwise be easily covered with their standard

curriculum. Mentors from government and industry are often available to support

and reinforce the lessons as well as to assist with the SeaPerch construction and

application activities in the classroom.

SeaPerchROV Construction Manual –Version 2010-04NW

I-2

Program History

The SeaPerch Remotely Operated Vehicle (ROV) educational program was

inspired by the 1997 book, Build Your Own Underwater Robot and Other Wet

Projects (ISBN 0-9681610-6), by Harry Bohm and Vickie Jensen. In 1997, Dr.

Tom Consi introduced SeaPerch to the Ocean Engineering program at the

Massachusetts Institute of Technology (MIT), in order to interest more students

in majoring in Ocean Engineering. Realizing the potential of SeaPerch to reach

younger students, the MIT Sea Grant (MITSG) College Program created the

SeaPerch initiative in 2003, sponsored by the Office of Naval Research. Dr.

Chryssostomos Chryssostomidis, MITSG Director, and Brandy Wilbur,

Educational Coordinator, were responsible for the effort at MIT Sea Grant.

In late 2007, the Office of Naval Research (ONR) tasked the Society of Naval

Architects and Marine Engineers (SNAME) to research ways to expand and

enhance the SeaPerch initiative as part of the ONR National Naval

Responsibility for Naval Engineering Outreach effort.

Original SeaPerch ROV Manual Development

The SeaPerch Construction Manual was originally developed by MITSG, which

modified the instructions for building a SeaPerch from those found in Build

Your Own Underwater Robot and Other Wet Projects so that the ROV would

be simpler and cheaper to build in the classroom. MITSG created a three-unit

manual with detailed, step-by-step instructions and a complete list of needed

components and tools. The MITSG SeaPerch manual has been revised

several times in recent years as new vehicle components or updated assembly

methods were implemented for the program.

Updated Information in This Version of the SeaPerch Manual

Revised Standard SeaPerch Assembly Instructions

This 2010 manual revision builds upon the extensive work of the MITSG

developers by utilizing the experience gained through years of SeaPerch

program use by educators around the country, incorporating the latest

recommended construction techniques, and providing additional information to

help teachers and students build and use SeaPerch ROVs. While much of this

revision’s technical content is aligned with the instructions found in previous

versions, its revised graphics and content adjustments are designed to provide

additional detail for the more complex construction techniques and to facilitate

high-quality reproduction in either monochrome or color. The addition of sign-

off boxes for the construction steps will better enable students, teachers, and

classroom volunteers to monitor completion progress.

SeaPerchROV Construction Manual –Version 2010-04NW

I-3

The following summarizes the significant changes from previous manuals.

Consolidation of safety information and added program background

information at the front of the manual, to better enable a discussion of all

safety aspects of the project during a class session early in the project.

Revised graphics to clarify electrical wiring and show recommended

soldering techniques.

Minor changes to some recommended construction methods to avoid

occasional assembly difficulties that have been identified through

experience in a variety of classroom programs.

Revised numbering for major assembly procedures and for the document’s

pages to enable easy substitution of optional or enhancement procedures

for standard SeaPerch procedures.

Addition of separate manual sections for initial testing and ballasting the

ROV as well as for use and cleaning of the vehicle.

Addition of an appendix with troubleshooting hints.

Addition of a separate construction manual supplement document offering a

variety of proven construction options and enhancements.

Expanded Testing and Operating Information

Because properballasting and pre-deployment testing are essential for successful

in-water operation of SeaPerch ROVs, the instructions and supplemental

information forthese activities are now in a separate, expanded section of this

manual entitled “Testing and Ballasting the ROV.”

In addition, operational recommendations, some helpful hints, application ideas,

and post-run vehicle cleaning instructions have been placed in a new, final,

manual section entitled “Using the SeaPerch ROV.”

Added Appendix Containing Troubleshooting Hints

When the initial ROV testing process identifies a problem, it is best for students to

be allowed to try to solve it. However, when help is needed, and before taking

drastic steps to change ROV parts or re-wire a circuit, ROV builders should refer

to Appendix A, “Troubleshooting Your SeaPerch ROV,” which suggests options

for solutions to common problems. This appendix is not necessarily intended to

be included in the student copies of the construction manual; rather, it is provided

for the teacher’s reference and for classroom use at the teacher’s option.

Added Supplement for Construction Options and Enhancements

Occasional challenges in obtaining recommended components, special technical

requirements, and local budget constraints have inspired creativityand

resourcefulness among SeaPerch program implementers, many of whom have

found it useful or necessary to identify alternatives for various aspects of their

ROVs’ construction. In order to provide such needed flexibility while still

SeaPerchROV Construction Manual –Version 2010-04NW

I-4

maintaininga standardized set of assembly instructions that can be fielded

nationwide, the manual’s format has been updated to enable easy substitution of

proven and approved procedures to implement construction "options," in place of

corresponding standard procedures, and addition of newprocedures for

construction “enhancements”to add capabilities to the ROV. These optional and

enhancement proceduresare contained in a separate document, “SeaPerch ROV

Construction Manual Supplement –Options and Enhancements –Version

2010-01,”which may be downloaded from the SeaPerch website.It contains a

number of alternate and added procedures that have been found to be useful to

improve ROV performance, simplifythe build process, and/or lower costs.

This "Northwest Program Options" version of the standard Version 2010-01

manual has been customized to meet the needs of Pacific Northwest and Alaska

schools. It has been assembled with alternate procedures fromthe supplement

for the following SeaPerch construction options and enhancements already

substituted forthe corresponding standard SeaPerch procedures.

Fabrication and Use of Low-Cost PVC Tube Floatsas Alternate Floatation

oInstead of Foam Floats and the H-Columns on which they are Mounted

oImproves ROV Operation in Deep Water & Enables Easy Front-to-Back Trim Adjustment

Use of Front PVC Tees as Attachment Points and for Fast Draining

oInstead of PVC Elbows

Use of a Toggle Switch for the Vertical Thruster

oInstead of Two, More-Expensive, Pushbutton Switches

Use of Alternate Motor 1 with Film Canisters for Thruster Housings

oSmaller, Less-Expensive Motors –Instead of Standard SeaPerch Motors

oUse of Film Canisters for theThruster Housings –Instead of Larger, Costly, Plastic Vials

oSimplified Motor Insertion for the Wax-Potting Procedure –Faster, Easier, & Less Rework

Use of a No-Adhesive Mounting Method for Reusable, Standard Propellers

oInstead of Costly Shaft Couplers with Nuts and Two-Part Adhesive

oPropellers Can Be Reused ManyTimes (Avoided Future Cost)

Use of Quick-Disconnect Battery-Terminal Connectors and an Alternate Motor Test

oInstead of More-Expensive Alligator Clips

Addition of a Payload Capture Net and a Front Payload Net Stiffener

oTo Improve the ROV’s Ability to Pick Up Bottom Objects

More options and enhancements will likely be developed from time to time as

cleverstudents and their teachers continue to invent and demonstrate newways

to build SeaPerch ROVs. Byusing the supplementapproach and the new page

numbering scheme, future new procedures can easily be added to the supplement

document and then to individual classroom manuals when needed, without

impacting the content of the standard build manual.

Future new procedures willneed to go through a short demonstration and

approvalprocessbefore being added to the mastermanual supplement document

that is maintained at the SeaPerch website for downloading as needed.

SeaPerchROV Construction Manual –Version 2010-04NW

I-5

The SeaPerch Assembly Process

Three Individual Building Units

The manual contains three building units, for the frame, the thrusters, and the

control box. They may be used as a single manual, as assembled here, or

they can be removed from this manual and placed into the SeaPerch

classroom integration manual at the separate locations indicated therein. In

either case, the three unit manuals should always be used in order.

Unit 1 is a good confidence-builder for the students who have had little

experience working with tools, and it gets the project going quickly. They will

measure, cut, and drill pipe and fittings and then assemble the parts with quick

results, as the work in Unit 1 provides a recognizable ROV after just a fewclass

periods.

Unit 2 then introduces basic wiring and soldering skills through the work with the

motors for the thrusters. These skills are important for them to have when

building the control box in Unit 3.

Finally, Unit 3 involves the students in more advanced wiring and soldering

activities and provides an opportunity for them to work with a variety of tools and

components used in electrical technologies.

Recording Progress

The checklist-style boxes next to each numbered step in the manual are

intended for the students to write their initials confirming proper completion of

each step as they progress through the project. Multiple sign-off boxes are

provided whenever a step needs to be repeated, such as during assembly of the

three thrusters. Keeping track in this way is important to avoid accidentally

skipping steps, but it also greatly helps the teacher and classroom volunteers (as

well as other team members, if working in teams), to know how far the student or

team has progressed in the building process.

Testing and Adjustments

The last steps in the SeaPerch ROV construction process are to conduct

some basic electrical tests, prior to connecting the battery, and performing

some simple vehicle checks and adjustments prior to its first operational use.

The initial testing in the classroom or lab should help in finding any lingering

wiring or thruster-related issues, and the checks recommended before

operational use should help to ensure a successful operational experience for

all students.

SeaPerchROV Construction Manual –Version 2010-04NW

I-6

Tools and Materials

Each procedure in this manual identifies the needed components and tools

only generically, rather than giving specific descriptions or specifications for

each item. Detailed parts, tools, and materials lists are maintained as

separate documents for use in procuring the items needed to build the ROVs.

This approach allows these assembly instructions to remain applicable even

when the specifics of individual components change, such as when a slightly

different “12 Volt DC Motor” is used or when a similar component must be

substituted due to availability or cost issues.

SeaPerch ROVs are often built by a team of two or three students. For

efficiency during the build process, each team should have its own set of

basic tools, including a screwdriver, flush-type wire cutter, needle-nose pliers,

wire stripper, and soldering iron. Tools such as standard pliers, cable jacket

strippers, pipe cutters, drills, and others that are not used on a daily basis can

be easily shared among a number of teams. A key aspect of planning for

classroom tools is to arrange to obtain enough to ensure that students do not

need to stop long during the build process to wait for availability of needed

tools.

Manual Printing Considerations

Please note that this manual is set up for double-sided (duplex) printing, with a

number ofextra blank pages inserted to force all procedures to start on the front

side of a sheet. Besides some savings in paper, this approach allows any

individual procedure from the supplement (ora future updated version of a

standard procedure) to be swapped into the manual as needed without affecting

an adjacent procedure or the overall page numbering.

The intent, in providingthe manual in double-sided format, isto enable easy

creation of double-sided student manuals, either by directly printing them on a

duplex printer or byprinting a single-sided or double-sided master document to

use to reproduce the student manuals witha two-sided photocopier.

If single-sided reproduction is desired, simplyprint a copy of the manual on a

single-sided printer, pull out the blank sheets, and then reproduce the single-sided

student manuals using a photocopier.

To further conserve paper, the Introduction section of the manual may be left out

of the student copies; however, the Safety Overview should always be included.

SeaPerchROV Construction Manual –Version 2010-04NW

S-1

Figure S-1. Wax Squirted on Student’s Safety

Glasses

Safety Overview

Protective Eyewear

Students, teachers, and classroom helpers should wear protective

eyewear at all times when building SeaPerch ROVs. Although some

procedures do not usually involve significant eye hazards, the students

often work close to others, who at any time may be performing more

potentially hazardous steps. Activities such as soldering, cutting, drilling,

applying adhesives, and potting thrusters can easily cause materials or

parts of broken tools to fly significant distances. Below are some

examples.

Soldering: Solder contains rosin flux in its core to help clean the

electrical connections and help the solder to adhere to the metal

properly. Small amounts of flux can occasionally pop out of the

melting solder and sometimes travel far enough to reach the eye of the

person soldering, or even someone nearby. Protective eyewear is

essential for everyone in the area.

Potting Thrusters with Wax: Melting wax tends to stay in the melting

container or where it is poured. However, there is one step in the

potting process that can occasionally cause wax to fly a significant

distance, often reaching a ceiling, wall, or floor, and it therefore

presents a risk for nearby eyes (as well as skin and clothing). This

step is the one in which the lid is pushed onto the thruster housing. If

performed too quickly, it can result in wax squirting out of the hole in

the lid (where the

wires pass through).

Quick, hard pressing

of the lid is common,

as students excitedly

put the lid in place

before the wax

hardens or spills.

Figure S-1 shows an

actual result (held by a

forever-committed

safety-glasses wearer).

SeaPerch ROV Construction Manual –Version 2010-04NW

S-2

Materials Handing Safety

Builders of SeaPerch ROVs should be made aware of a few potential

hazards related to some of the materials used. The following activities

require careful handling of materials.

Soldering: Many common types of solder contain lead along with tin

and sometimes other metals. Solder should never be placed in one’s

mouth, and hands should always be washed after working with solder.

Breathing the smoke from the melting flux (from inside the solder)

should be avoided.

Potting Wax: Bowl ring wax is made from “petrolatum”–basically the

same type of material that, when more refined, becomes common

petroleum jelly. It is safe to handle when cooled, but quite sticky, and

difficult to remove if it solidifies on clothing. Hands should be washed with

warm water and soap after handling the wax. Obviously, it must not be

ingested. Wearing eye protection, as noted earlier, is essential.

Adhesives: Adhesives, particularly two-part epoxy, “super glue” type

adhesives, and PVC primer and cement (some versions of SeaPerch

ROVs don't use all of these types) can present hazards to skin as well

as eyes. Wearing eye protection and gloves is recommended when

working with any adhesives, and hands should always be washed after

working with such materials.

Protection of Our Environment: All waste or scrap materials from the

SeaPerch ROV construction process should be disposed of properly, in

accordance with manufacturers’ recommendations and school policies.

Recycling of usable excess materials and disassembled vehicles is

encouraged for environmental protection and cost avoidance

considerations. Most of the ROV components can be re-used in

building future vehicles or as spare parts.

Safety While Using Hand Tools

Hand tools such as screwdrivers, pliers, and wire cutters can be used safely

when operated as intended. Examples of activities to avoid are below.

Screwdrivers: Screwdrivers should not be used to pry or make holes.

Care should be exercised while inserting or removing screws to avoid

having the screwdriver tip slip off of the screw head and poke into a

body part or damage a table top. The size of the screwdriver tip should

be appropriate for the size of the screw.

SeaPerch ROV Construction Manual –Version 2010-04NW

S-3

Wire Cutters: Nothing should be cut with small wire cutters other than

copper wire or plastic tie wraps. Never cut pipe or metal fasteners,

which could ruin the cutting edges. Be careful when handling wire

cutters to avoid being cut or poked by their sharp cutting edges or tips.

Needle-Nose Pliers: Small, thin, needle-nose pliers should be used

only to help place wires onto switch or motor terminals, as their jaws can

bend or break if used for tightening tie wraps or any prying activity.

Large needle-nose pliers or standard club-nose pliers are better for

tightening tie wraps. Needle-nose pliers should also not be used for

tightening the retaining nuts on control box switches, as the jaws are not

parallel like the edges of a nut, so they can easily slip off. Use club-

nose pliers or a small wrench instead to tighten the nuts on switches.

PVC Pipe Cutters: The blades on typical PVC pipe cutters can be

damaged easily if used to cut anything except PVC pipe, or if used

incorrectly. When squeezing the tool to cut pipe, work slowly so that the

blade has time to move through the material. Do not twist the tool, and

always keep fingers away from the sharp blade. Store the tool in its

closed position.

Safety While Drilling

Drilling is perhaps the most potentially hazardous activity involved in the

SeaPerch project. Some important safety considerations are as follows.

Get Permission to Use Power Tools: Always get the teacher’s

permission and adult supervision before using a drill or other power tool.

Installing and Removing Drill Bits: Install and remove drill bits from

the chuck of a drill motor or drill press manually, not by energizing the

drill motor to spin the chuck closed. Make sure that the bit is inserted

straight into the chuck and that it is tight in the chuck before use; spin it

briefly to check before drilling.

Holding Objects Being Drilled: Never try to hold an object being

drilled in your hand alone. Instead, it should be always be either held in

a vise (or clamp), firmly held down by hand onto a solid surface (if that

surface will not be subjected to possible damage during the drilling

process), or attached firmly to an object that can be safely held by hand.

This keeps the object steady, prevents it from spinning and hurting your

hand if the drill bit should bind, and keeps your fingers away from the bit

while drilling. Never place a body part in the path of a drill bit. Always

think about what is behind the object being drilled (particularly body

parts and tabletops!). If using a drill press, make sure that the object is

held firmly and fingers are not near the drill bit.

SeaPerch ROV Construction Manual –Version 2010-04NW

S-4

Safety While Soldering

Soldering Uses High Heat: All soldering involves a very hot soldering

iron as well as temporarily-hot electrical connections, which take a few

moments to cool after soldering. Do not touch the tip area of a soldering

iron, even when it appears to be off or unplugged, as it does not look

different when it is hot compared to when it is cold, and it can remain hot

for 10 minutes or more after use. Connections should be allowed to cool

after soldering before they are moved or touched. As noted earlier,

always wear eye protection, even when just in the same area as

someone who is soldering.

Keep the Soldering Iron in Its Holder When Not in Use: Great care

should be taken to place the soldering iron back into its holder whenever

it is not in use for soldering. Never just set it down on a tabletop, where it

could burn anything it touches.

Safety While Potting Motors for Thrusters

SeaPerch ROV thrusters are assembled by potting small electric motors in

wax. The following safety issues should be reviewed with everyone involved

in the potting process.

Melting Wax: The standard SeaPerch wax-melting approach is to warm

“toilet bowl ring” wax in a heated pot or a metal container placed in a hot

water bath, usually employing an electric skillet to heat the water (and

wax). It is important to always monitor the temperature of the wax or use

a water bath (and NOT let all of the water evaporate - keep adding water

to maintain it at about ½” to 1” deep). Otherwise, the wax can get

EXTREMELY hot, even hot enough to melt the plastic thruster housings.

Fortunately, bowl ring wax has a relatively low melting temperature, but it

must still be heated to about 150 degrees Fahrenheit (F) for proper

pouring. Although its flash point is over 500 degrees F, the

manufacturers usually recommend not exceeding 200 degrees F, so you

should try to keep the wax at about 180 degrees F or below (using a

thermometer is best, as temperature control knob markings may be

inaccurate). Obviously, if the wax is allowed to get too hot, skin burns are

possible; more sensitive skin or large quantities of hot wax may cause

minor burns. In case of a burn, quickly rinse the area with plenty of cold

water and seek medical attention. Care should be taken to prevent

getting the hot wax onto skin or clothing. Wearing a protective smock or

apron and gloves is recommended. Pour the wax slowly and carefully to

avoid spills and potential burns.

SeaPerch ROV Construction Manual –Version 2010-04NW

S-5

Watch Out for Squirting Wax: During the final step of thruster potting,

when the lid is placed onto the thruster housing, melted wax can squirt

out of the small hole in the lid where the wires pass through. If the lid is

pressed quickly into place, wax can even squirt as high as the ceiling or

onto nearby walls and people. Placing a paper towel over the lid and

pressing slowly is recommended to avoid the wax-squirting problem.

Protect nearby walls and floor areas with paper or tarps. Obviously,

everyone in the area should be wearing eye protection.

Safety With Electricity and Batteries

The low-voltage (12 volts, direct current (DC)) battery power source used

with SeaPerch ROVs is relatively safe and well-proven in students’ hands.

However, they should be cautioned about potential problems from short-

circuits as well as electrical safety issues in general.

Battery Short-Circuit Hazard: Although the battery can be used quite

safely when it is connected properly to the ROV, it can be damaged,

cause wires to melt, or even start a fire if its positive and negative

terminals are connected directly together. That is called a “short circuit,”

and it will allow the battery to essentially discharge all of its stored

energy at once.Besides resulting in sparks when such an improper

connection is made, the wire or metal object shorting across the terminal

will immediately become extremely hot and may even melt. That could

obviously cause burns or ignite an object in contact with the shorting

material. Never connect anything between the battery terminals except

an appropriate electrical “load” such as the ROV circuitry, through its

fused power cord. Be careful to keep the battery terminals covered or

away from all wires and metal objects when not in use. Do not connect

the ROV circuitry or components to the battery until instructed to do so.

Avoid Creating Other Short Circuits During ROV Construction:

When wiring circuits or conducting tests, take care to avoid unintended

connections or accidental short circuits. While handling partially or fully

completed circuits, ensure that wires do not move and touch together

where they should not. Always check the circuitry carefully and conduct

the recommended tests before connecting the battery.

General Electrical Safety: When working with electrical circuits with

power applied, do not allow any body parts to “become part of the

circuit.”In other words, do not touch both the positive and negative

terminals of a battery with your hands or touch a battery terminal with

one hand and part of the circuitry with the other. Make sure that all

switches are in their off positions while connecting or disconnecting the

battery, and connect just one power wire at a time.

1.0-1

SeaPerch Program Office

TheSociety ofNavalArchitectsandMarineEngineers

601PavoniaAvenue

JerseyCity,NewJersey07306

Version 2010-04NW

Unit 1

SeaPerch

Remotely Operated Vehicle (ROV)

Assembly of Subsystem One

The Vehicle Frame

August 2010

The SeaPerch educational program was created by Harry

Bohm and Vickie Jensen and published in their 1997 book

"Build Your Own Underwater Robot and Other Wet

Projects." The initial curriculum was developed by the

Massachusetts Institute of Technology, and this version of

the SeaPerch Construction Manual was provided under the

Office of Naval Research National Naval Responsibility for

Naval Engineering (NNRNE) Outreach initiative.

This manual suits for next models

1

Table of contents

Other SeaPerch Educational Equipment manuals

Popular Educational Equipment manuals by other brands

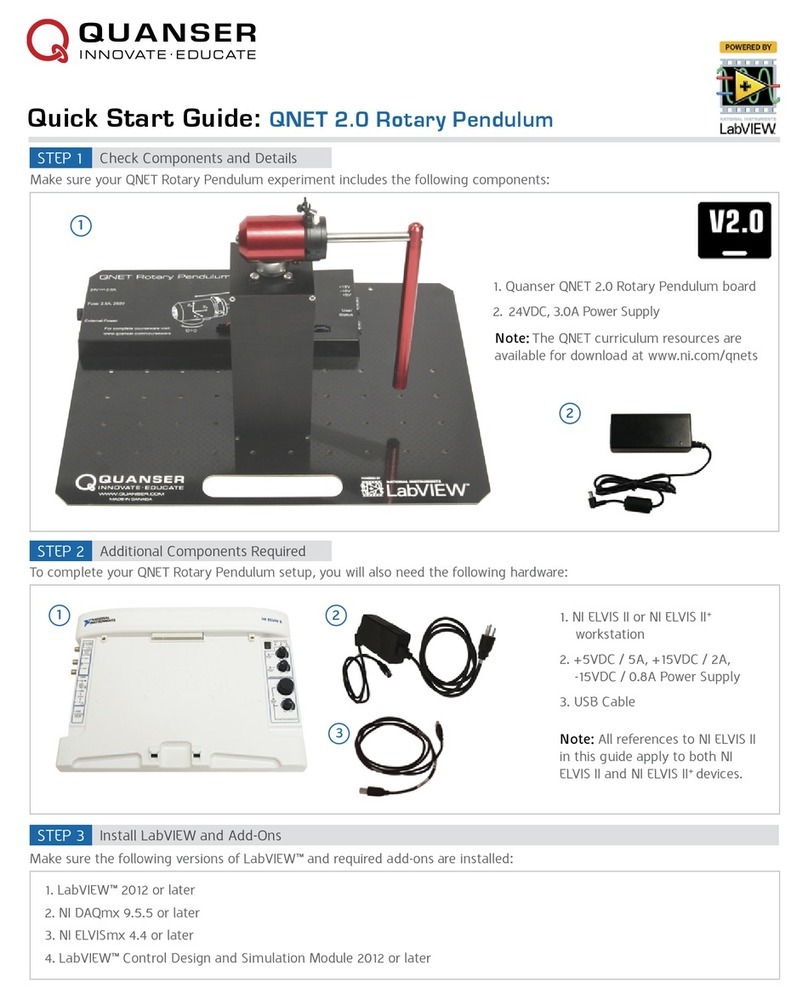

Quanser

Quanser 6 DOF Hexapod Laboratory guide

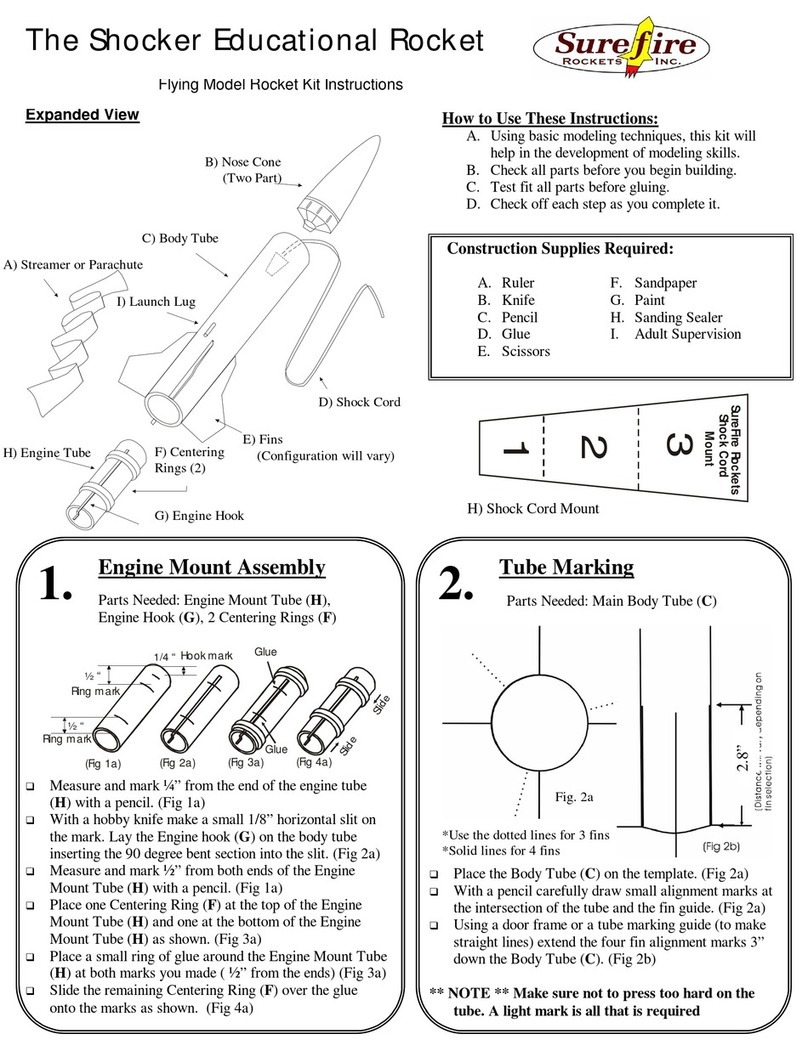

Surefire

Surefire Flying Model Rocket Kit How to use

ACROME

ACROME myCONTROL STEWART PRO user manual

SmartMan

SmartMan Baby Manikin manual

Nasco

Nasco Life/form LF03840U instruction manual

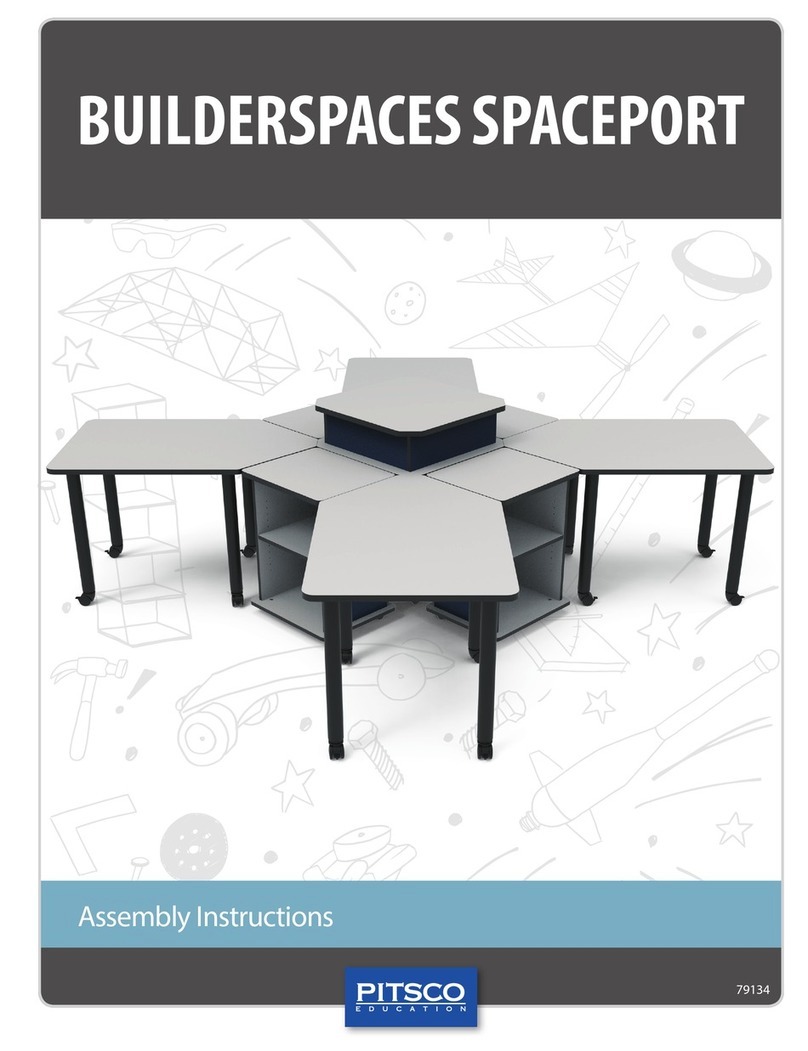

Pitsco Education

Pitsco Education BUILDERSPACES SPACEPORT Assembly instructions