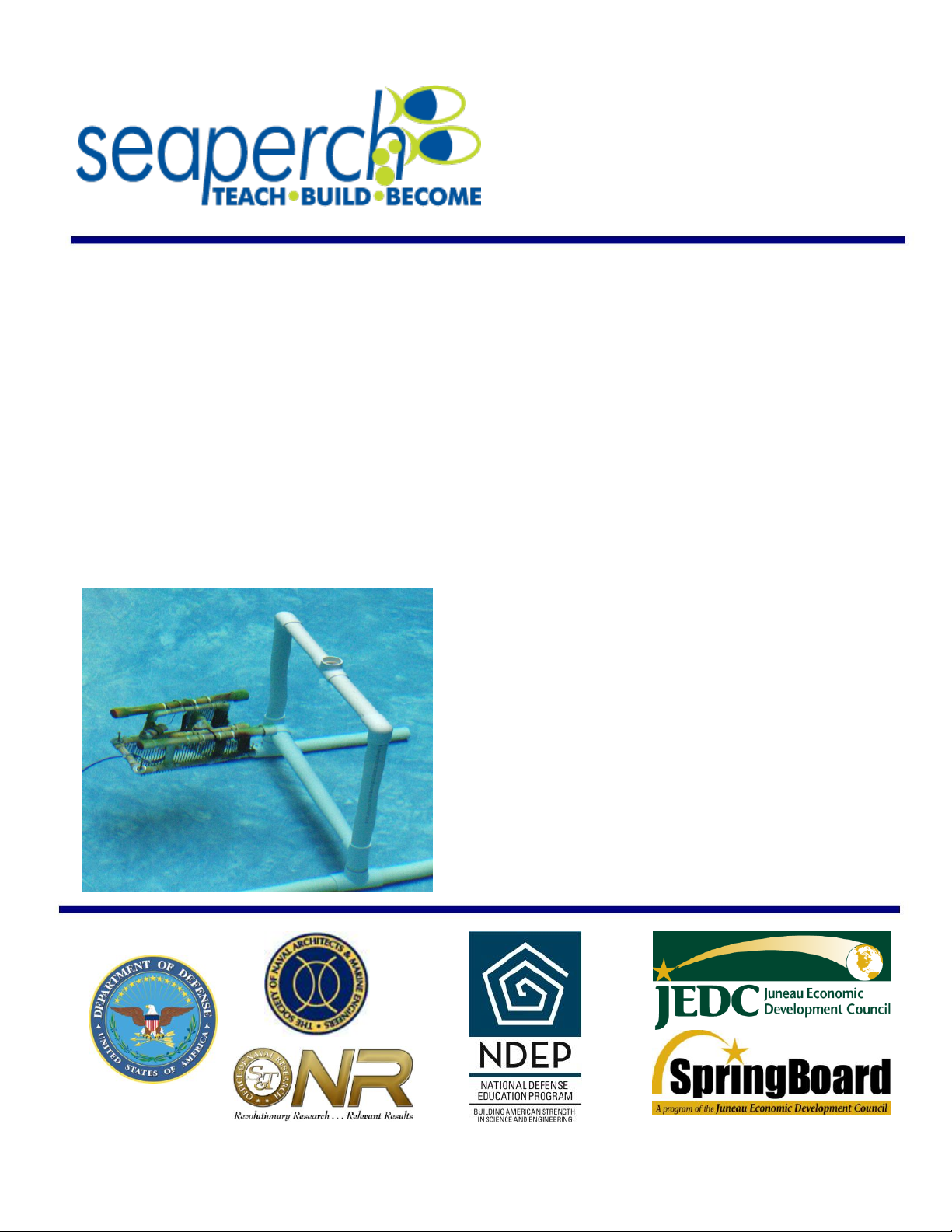

SeaPerch ROV Instructions for use

SeaPerch ROV Build v.2011-01AK Student Manual

i

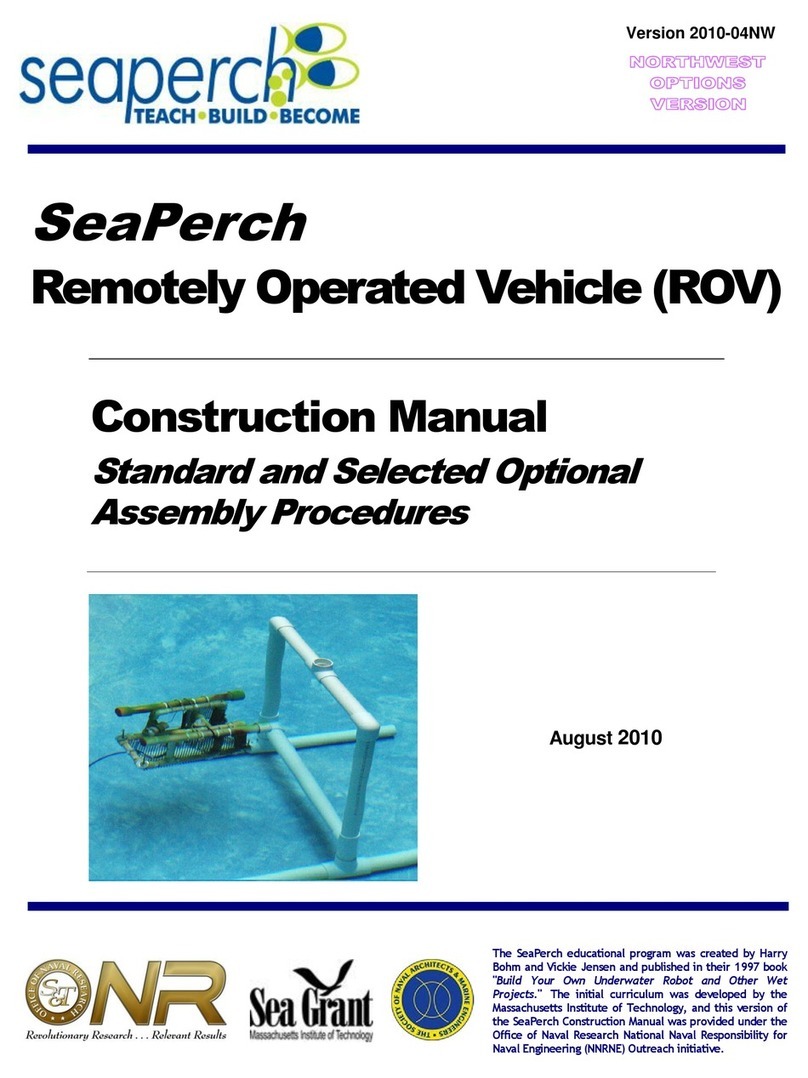

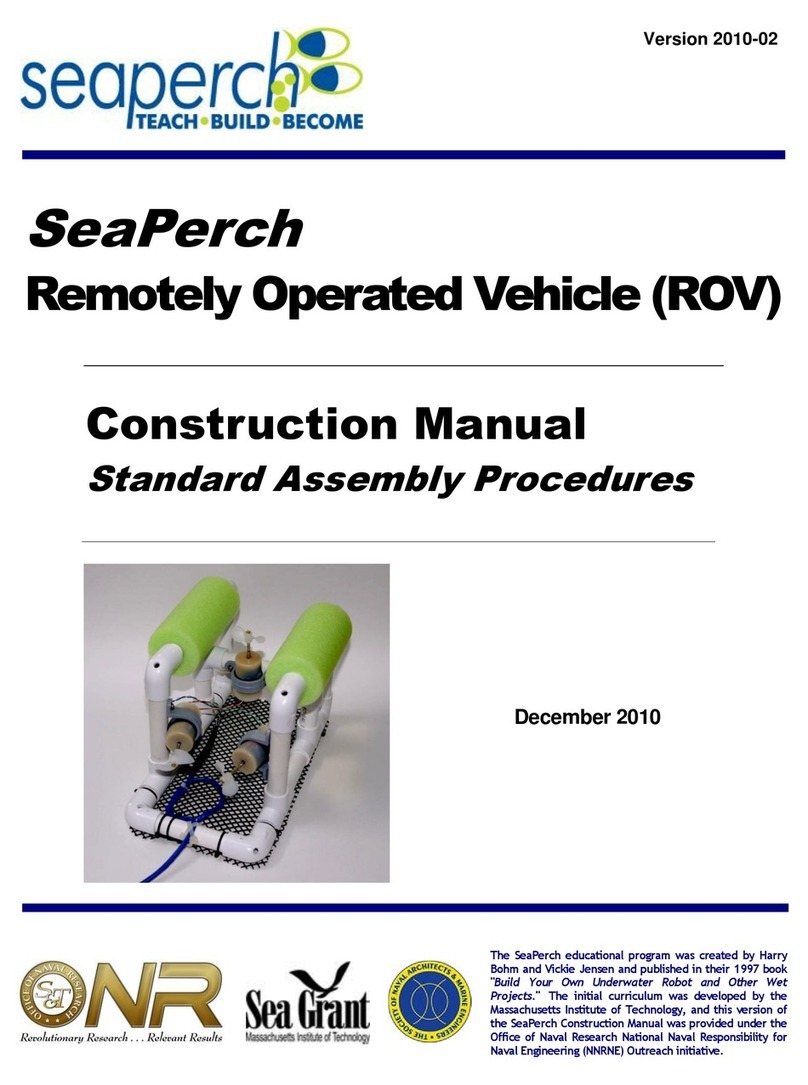

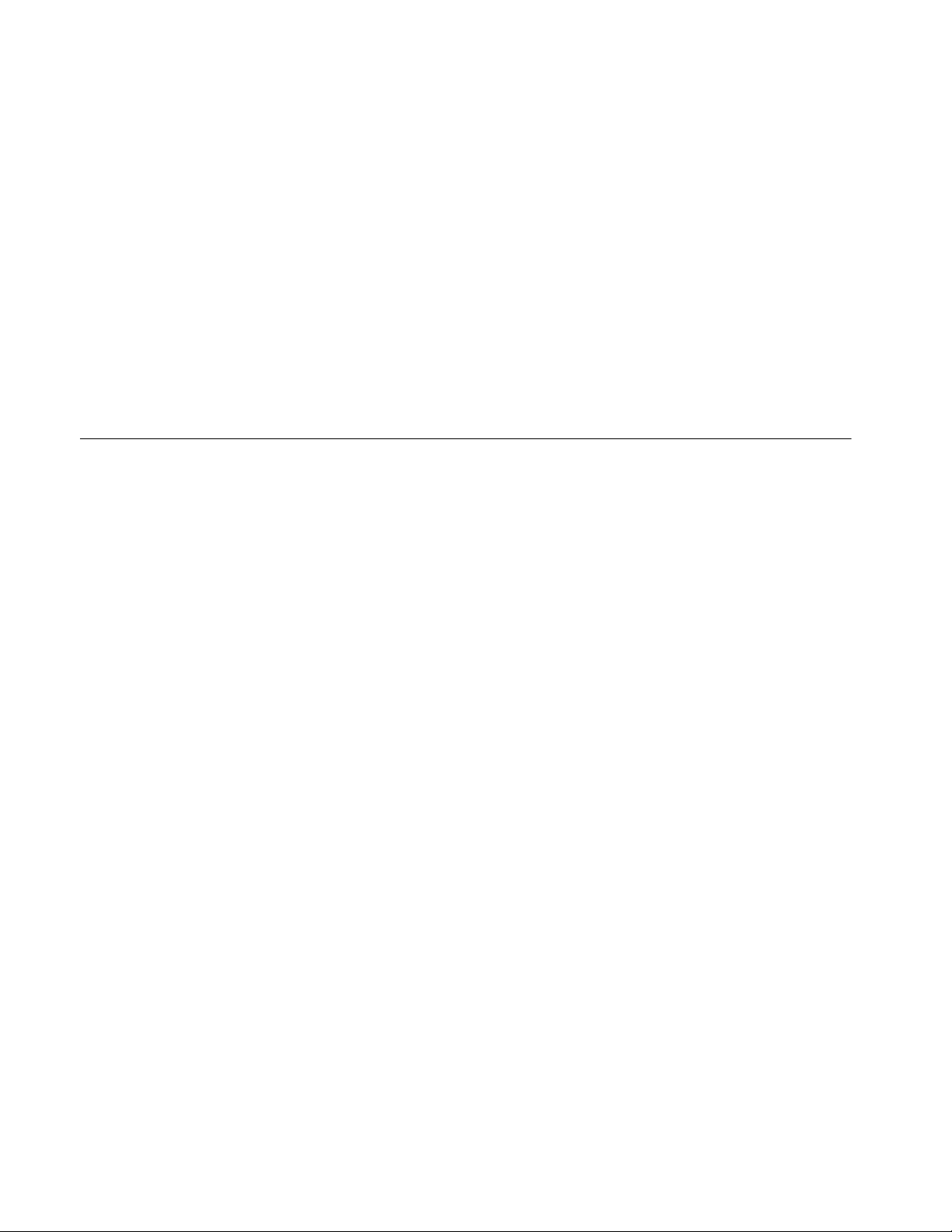

SeaPerch

Remotely Operated Vehicle (ROV)

Construction Manual

Standard and Selected Optional

Assembly Procedures

January 2011

The SeaPerch educational program was created by Harry Bohm and Vickie

Jensen and published in their 1997 book "Build Your Own Underwater Robot

and Other Wet Projects." The initial curriculum was developed by the

Massachusetts Institute of Technology, and this version of the SeaPerch

Construction Manual was provided under the Office of Naval Research National

Naval Responsibility for Naval Engineering (NNRNE) Outreach

Version 2011-01AK

Student Manual

SeaPerch ROV Build v.2011-01AK Student Manual

i

SeaPerch ROV Build v.2011-01AK Student Manual

i

Table of Contents

Safety Overview…………………………………………………………………………….…i

Protective Eyewear

Materials Handling Safety

Safety While Using Hand Tools

Safety While Drilling

Safety While Soldering

Safety While Potting Motors for Thrusters

Safety with Electricity and Batteries

Unit 1 –Assembly of Subsystem One –The Vehicle Frame……………………1

Tools and Materials Needed

Time Needed to Complete Unit 1

Procedure 1.1 –Cut the Frame Parts

Procedure 1.2 –Drill the Drain Holes

Procedure 1.3 –Assemble the Vehicle Frame

Procedure1.4 –Assembly and Installation of the PVC Tube Floats

Procedure 1.5 –Attach the Thruster Mounts

Procedure 1.6 –Attach the Payload Net

Unit 2 –Assembly of Subsystem Two –The Thrusters…………………………11

Tools and Materials Needed

Time Needed to Complete Unit 2

Procedure 2.1 –Test the Motors and Mark their Terminals' Polarity

Procedure 2.2 –Seal the Motors So That Wax Cannot Get Inside

Procedure 2.3 –Drill Holes in the Thruster Housings

Procedure 2.4 –Connect the Tether Cable Wires to the Motors

Procedure 2.5 –Pot (Waterproof) the Motors with Wax

Procedure 2.5a –An Alternative to Potting Motors with Wax

Procedure 2.6 –Mount the Propellers on the Thruster Motors

Procedure 2.7 –Mount the Thrusters onto the Vehicle Frame

Procedure 2.8 –Waterproof and Secure the Tether Cable

Unit 3 –Assembly of Subsystem Three –The Control Box……………………25

Tools and Materials Needed

Time Needed to Complete Unit 3

SeaPerch ROV Electrical Circuit Diagram

Procedure 3.1 –Locate the Parts for the Control Box

Procedure 3.2 –Prepare the Control Box

Procedure 3.3 –Assemble the Power Cord

Procedure 3.4 –Wire the Vertical Thruster Control Switch

Procedure 3.5 –Wire the Horizontal Thruster Control Switches

Procedure 3.6 –Finish the Control Box

Table of Contents

SeaPerch ROV Build v.2011-01AK Student Manual

ii

Testing and Ballasting the ROV…………………………………………………..38

Initial Electrical Testing

Ballasting and Trimming the ROV

Using the SeaPerch ROV…………………………………………………………..41

Safety Precautions

Environments Suitable for Using a SeaPerch ROV

Driving the SeaPerch ROV

Post-Run Cleaning and Maintenance of the ROV System

Appendix I –Troubleshooting Your SeaPerch ROV…………………………..43

Appendix II –How to Solder Like a Pro………………………………………….45

Appendix III –Installing a DB-9 Connector on the Tether Cable……………51

Appendix IV –Installation of an Underwater Video Camera………………....55

SeaPerch ROV Build v.2011-01AK Student Manual

i

Safety During the Build

Protective Eyewear

Students, teachers, and classroom helpers should wear protective eyewear at all times when building

SeaPerch ROVs. Although some procedures do not usually involve significant eye hazards, the

students often work close to others, who at any time may be performing more potentially hazardous

steps. Activities such as soldering, cutting, drilling, applying adhesives, and potting thrusters can easily

cause materials or parts of broken tools to fly significant distances. Below are some examples:

Soldering: Solder contains rosin flux in its core to help clean the electrical connections, which

helps the solder to adhere to the metal properly. Small amounts of flux can occasionally pop

out of the melting solder and sometimes travel far enough to reach the eye of the person

soldering, or even someone nearby. Protective eyewear is essential for everyone in the area.

Potting Thrusters with Wax (if this method is used): Melting wax tends to stay in the

melting container or where it is poured. However, there is one step in the potting process that

can occasionally cause wax to fly a significant distance, often reaching a ceiling, wall, or floor,

and it therefore presents a risk for nearby eyes (as well as skin and clothing). This step is the

one in which the lid is pushed onto the thruster housing. If performed too quickly, it can result in

wax squirting out of the hole in the lid (where the wires pass through). Quick, hard pressing of

the lid is common, as students excitedly put the lid in place before the wax hardens or spills.

The picture above is an actual result of such an accident (held by a forever-committed safety-

glasses wearer).

Materials Handling Safety

Builders of SeaPerch ROVs should be made aware

of a few potential hazards related to some of the

materials used. The following activities require

careful handling of materials.

Soldering: Many common types of solder

contain lead, tin and sometimes other metals.

Solder should never be placed in one’s

mouth, and hands should always be washed

after working with solder. Breathing the

smoke from the melting flux (from inside the

solder) should be avoided.

Potting Wax (if used): Bowl ring wax is

made from “petrolatum” – basically the same type of material that, when more refined,

becomes common petroleum jelly. It is safe to handle when cooled, but quite sticky, and difficult

to remove if it solidifies on clothing. Hands should be washed with warm water and soap after

handling the wax. Obviously, it must not be ingested. Wearing eye protection, as noted earlier,

is essential.

Adhesives (if used): Adhesives, particularly two-part epoxy, “super glue” type adhesives, and

PVC primer and cement (some versions of SeaPerch ROVs don't use all of these types) can

present hazards to skin as well as eyes. Wearing eye protection and gloves is recommended

when working with any adhesives, and hands should always be washed after working with such

materials.

SeaPerch ROV Build v.2011-01AK Student Manual

ii

Protection of Our Environment: All waste or scrap materials from the SeaPerch ROV

construction process should be disposed of properly, in accordance with manufacturers’

recommendations and school policies. Recycling of usable excess materials and disassembled

vehicles is encouraged for environmental protection and cost avoidance considerations. Most

of the ROV components can be re-used in building future vehicles or as spare parts.

Safety While Using Hand Tools Using Hand Tools

Hand tools such as screwdrivers, pliers, and wire cutters can be used safely when operated as

intended. Examples of activities to avoid are below:

Screwdrivers: Screwdrivers should not be used to pry or make holes. Care should be

exercised while inserting or removing screws to avoid having the screwdriver tip slip off of the

screw head and poke into a body part or damage a table top. The size of the screwdriver tip

should be appropriate for the size of the screw.

Wire Cutters: Nothing should be cut with small wire cutters other than copper wire or plastic

tie wraps. Never cut pipe or metal fasteners, which could ruin the cutting edges. Be careful

when handling wire cutters to avoid being cut or poked by their sharp cutting edges or tips.

Needle-Nose Pliers: Small, thin, needle-nose pliers should be used only to help place wires

onto switch or motor terminals, as their jaws can bend or break if used for tightening tie wraps

or any prying activity. Large needle-nose pliers or standard club-nose pliers are better for

tightening tie wraps. Needle-nose pliers should also not be used for tightening the retaining

nuts on control box switches, as the jaws are not parallel like the edges of a nut, so they can

easily slip off. Use club-nose pliers or a small wrench instead to tighten the nuts on switches.

PVC Pipe Cutters: The blades on typical PVC pipe cutters can be damaged easily if used to

cut anything except PVC pipe, or if used incorrectly. When squeezing the tool to cut pipe, work

slowly so that the blade has time to move through the material. Do not twist the tool, and

always keep fingers away from the sharp blade. Store the tool in its closed position.

Safety While Drilling

Drilling is perhaps the most potentially hazardous activity involved in the SeaPerch project. Some

important safety considerations are as follows:

Get Permission to Use Power Tools: Always get the teacher’s permission and adult

supervision before using a drill or other power tool.

Installing and Removing Drill Bits: Install and remove drill bits from the chuck of a drill motor

or drill press manually, not by energizing the drill motor to spin the chuck closed. Make sure

that the bit is inserted straight into the chuck and that it is tight in the chuck before use; spin it

briefly to check before drilling.

Holding Objects Being Drilled: Never try to hold an object being drilled in your hand alone.

Instead, it should be always be either held in a vise (or clamp), firmly held down by hand onto a

solid surface (if that surface will not be subjected to possible damage during the drilling

process), or attached firmly to an object that can be safely held by hand. This keeps the

objectsteady, prevents it from spinning and hurting your hand if the drill bit should bind, and

keeps your fingers away from the bit while drilling. Never place a body part in the path of a drill

bit. Always think about what is behind the object being drilled (particularly body parts and

SeaPerch ROV Build v.2011-01AK Student Manual

iii

tabletops!). If using a drill press, make sure that the object is held firmly and fingers are not

near the drill bit.

Safety While Soldering (refer to Appendix II –How to Solder Like a Pro for tips)

Soldering Uses High Heat: All soldering involves a very hot soldering iron as well as

temporarily-hot electrical connections which take a few moments to cool after soldering. Do not

touch the tip area of a soldering iron, even when it appears to be off or unplugged, as it does

not look different when it is hot compared to when it is cold and it can remain hot for 10 minutes

or more after use. Connections should be allowed to cool after soldering before they are moved

or touched. As noted earlier, always wear eye protection, even when just in the same area as

someone who is soldering.

Keep the Soldering Iron in Its Holder When Not in Use: Great care should be taken to

place the soldering iron back into its holder whenever it is not in use for soldering. Never just

set it down on a tabletop, where it could burn anything it touches.

Safety While Potting Motors for Thrusters

SeaPerch ROV thrusters are assembled by potting small electric motors in wax. The following safety

issues should be reviewed with everyone involved in the potting process:

Melting Wax: The standard SeaPerch wax-melting approach is to warm “toilet bowl ring” wax

in a heated pot or a metal container placed in a hot water bath, usually employing an electric

hotplate to heat the water (and wax). It is important to always monitor the temperature of the

wax or use a water bath (and NOT let all of the water evaporate - keep adding water to

maintain it at about ½” to 1” deep). Otherwise, the wax can get EXTREMELY hot, even hot

enough to melt the plastic thruster housings. Fortunately, bowl ring wax has a relatively low

melting temperature, but it must still be heated to about 150 degrees Fahrenheit (F) for proper

pouring. Although its flash point is over 500 degrees F, manufacturers usually recommend not

exceeding 200 degrees F, so you should try to keep the wax at about 180 degrees F or below

(using a thermometer is best, as temperature control knob markings may be inaccurate). If the

wax is allowed to get too hot, skin burns are possible. In case of a burn, quickly rinse the area

with plenty of cold water and seek medical attention. Care should be taken to prevent getting

the hot wax onto skin or clothing. Wearing a protective smock or apron and gloves is

recommended. Pour the wax slowly and carefully to prevent spills and potential burns.

During the final step of thruster potting when the lid is placed onto the thruster housing, melted

wax can squirt out of the small hole in the lid where the wires pass through. If the lid is pressed

quickly into place, wax can even squirt as high as the ceiling or onto nearby walls and people.

Placing a paper towel over the lid and pressing slowly is recommended to avoid the wax-

squirting problem. Protect nearby walls and floor areas with paper or tarps. Obviously,

everyone in the area should be wearing eye protection.

Safety with Electricity and Batteries

The low-voltage (12 volts, direct current (DC)) battery power source used with SeaPerch ROVs is

relatively safe and well-proven in students’ hands. However, they should be cautioned about potential

problems from short-circuits as well as electrical safety issues in general.

Battery Short-Circuit Hazard: Although the battery can be used quite safely when it is

connected properly to the ROV, it can be damaged, cause wires to melt, or even start a fire if

its positive and negative terminals are connected directly together. That is called a “short

SeaPerch ROV Build v.2011-01AK Student Manual

iv

circuit,” and it will allow the battery to essentially discharge all of its stored energy at once.

Besides resulting in sparks when such an improper connection is made, the wire or metal

object shorting across the terminal will immediately become extremely hot and may even melt.

That could obviously cause burns or ignite an object in contact with the shorting material. Never

connect anything between the battery terminals except an appropriate electrical “load” such as

the ROV circuitry, through its fused power cord. Be careful to keep the battery terminals

covered or away from all wires and metal objects when not in use. Do not connect the ROV

circuitry or components to the battery until instructed to do so.

Avoid Creating Other Short Circuits During ROV Construction: When wiring circuits or

conducting tests, take care to avoid unintended connections or accidental short circuits. While

handling partially or fully completed circuits, ensure that wires do not move and touch together

where they should not. Always check the circuitry carefully and conduct the recommended tests

before connecting the battery.

General Electrical Safety: When working with electrical circuits with power applied, do not

allow any body parts to “become part of the circuit.” In other words, do not touch both the

positive and negative terminals of a battery with your hands or touch a battery terminal with one

hand and part of the circuitry with the other. Make sure that all switches are in their off positions

while connecting or disconnecting the battery, and connect just one power wire at a time.

SeaPerch

Remotely Operated Vehicle

Assembly of Subsystem One

The Vehicle Frame

January 2011

Version 2011-01AK

SeaPerch ROV Build v.2011-01AK Student Manual

2

Assembly of Subsystem One

The Vehicle Frame

Tools and Materials Needed

Procedure 1.1 - Cut the Frame Parts

Tools: Materials:

Ruler 5’ ½” Schedule 40 PVC pipe

Marker

PVC Pipe Cutter or Hacksaw

Construction Steps:

1. From a cleanly-cut end of a length of ½” pipe, measure and cut the pieces listed below. Cut the

longest pieces first, in case a mistake is made (smaller pieces may be cut from a longer piece

that is accidentally cut too short). You will find the old adage, “measure twice; cut once,” to be

the best advice here. Try to cut straight, so that the ends of each piece are square with the

sides, but don’t worry if they are not perfect.

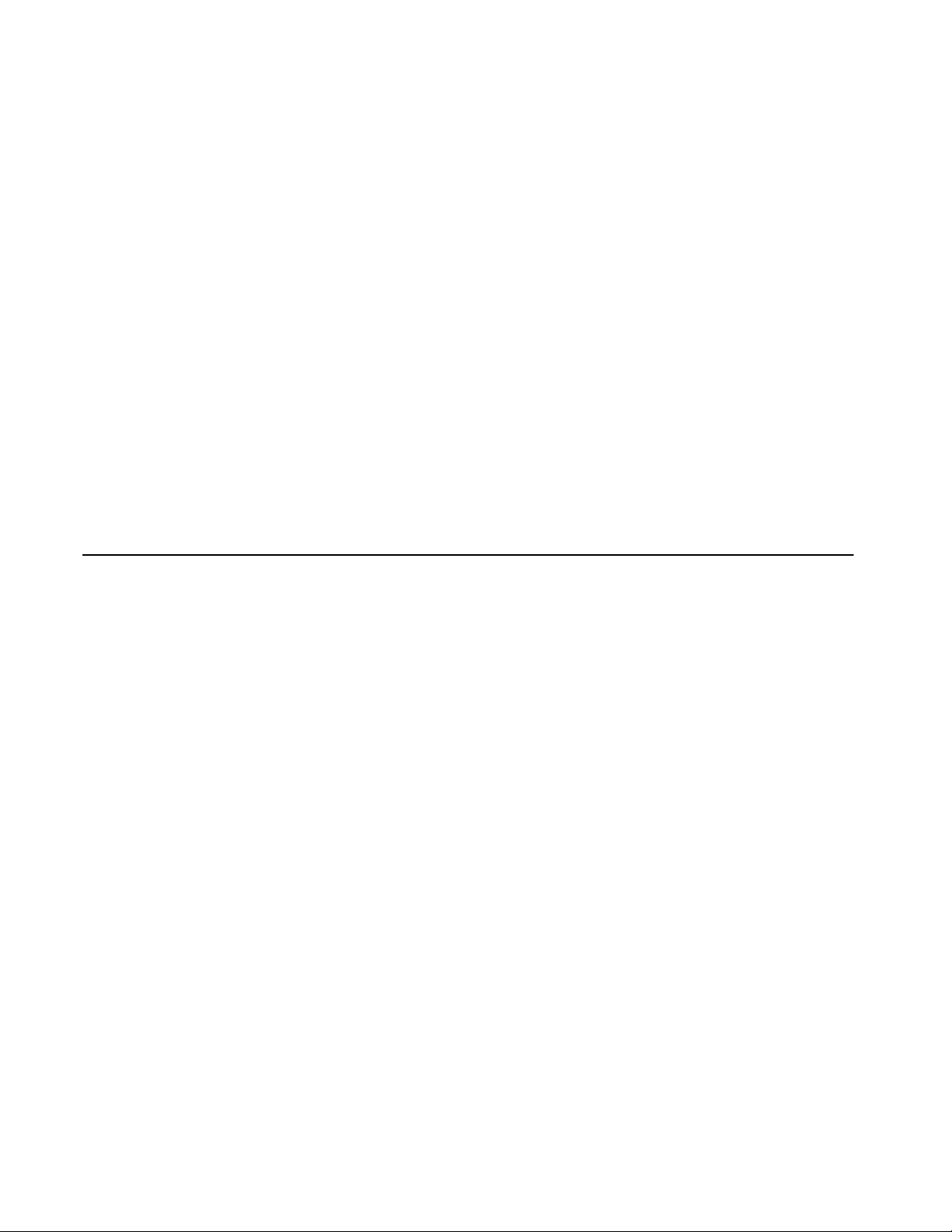

Two pieces –5½” long Two pieces - 3” long

Two pieces –4½” long Two pieces –2¼” long

Two pieces –4” long Four pieces –1¾” long

One piece –3½” long Six pieces –1½” long

Write the length on each piece to keep track of cuts and to identify them later.

Tools

Materials

Eye Protection (Always Worn)

Ruler

Marker or Pencil

PVC Pipe Cutter (or Saw)

#2 Phillips Screwdriver

Flush Wire-Cutting Pliers

Drill (or Drill Press)

¼” Drill Bit

5/64” Drill Bit

Vise or Clamp

Pliers

Hack Saw

5’ (1.5 m) ½” PVC Pipe (Schedule 40 )

9½” PVC Elbows

9 ½” PVC Tees

28” (71 cm) 1” PVC Pipe (200 PSI Type)

4 1” PVC Pipe Caps

3 Thruster Mounts (1” Conduit Clamps)

6 #8 x ½” Phillips Sheet Metal Screws

6 #8 Washers (Optional)

1 12” x 6.5” (31 x 17 cm) Payload Net

1 Wire Coat Hanger

20 6” Tie Wraps (Zip Ties)

8 8” Tie Wraps (Zip Ties)

PVC Primer & Cement

Paper Towels & Rubbing Alcohol

SeaPerch ROV Build v.2011-01AK Student Manual

3

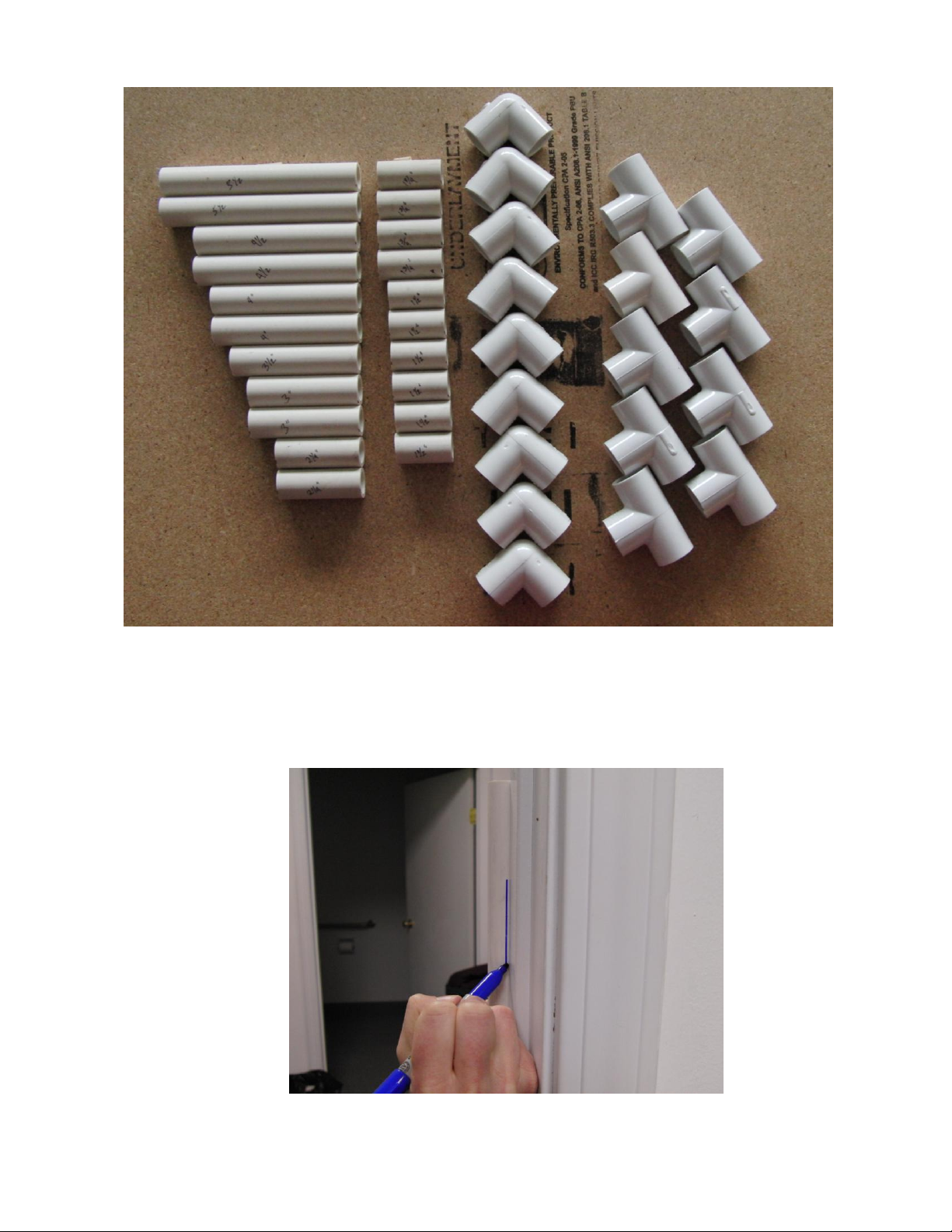

Take a piece of the 4½” pipe and place it in a piece of door frame molding. Draw a straight line on the

pipe parallel to its axis using the door frame as the straightedge. This line will be used when mounting

thruster brackets in Procedure 1.5. Repeat for the other 41/2” piece, and for the two 4” pieces of pipe.

SeaPerch ROV Build v.2011-01AK Student Manual

4

Procedure 1.2 - Drill the Drain Holes

Tools: Materials:

Hand drill or drill press 9 ½” PVC elbows

¼” drill bit

Vise or clamp

NOTE: Why are drain holes needed?

Drill Safety Reminders:

Drills can be dangerous pieces of equipment, but they are not difficult to operate properly. Always get your teacher’s

permission and supervision before using a drill or other power tool. Always wear safety glasses when building

your SeaPerch ROV (and when using any hand or power tool).

It is good practice to secure the object you are drilling in a vise or clamp before drilling. This keeps it steady, prevents

it from spinning and hurting your hand if the drill should bind, and keeps your fingers away from the sharp drill bit while

drilling. Be aware of what is behind the object you are drilling, to avoid extra holes in table tops or in other undesired

places!

If you do not have a vise or clamp available, push the elbow onto one end of a long (5” or more) piece of PVC pipe,

and hold the pipe while drilling the hole. DO NOT drill the elbow while holding it in your hand!

Construction Steps:

1. Inspect the PVC elbows to see if they have ¼” holes drilled in them (such as from a previous

use). If they all have ¼” holes, skip to Procedure 1.3.

2. Secure a PVC elbow in a vise or clamp.

3. Place the ¼" drill bit in the drill (or drill press), and drill a hole in the corner of the elbow. Drilling

from the interior of the elbow outward works best, as the bit can easily slip off of the rounded

exterior of the elbow.

4. Repeat Steps 2 and 3 for other PVC elbows that don’t have the ¼” holes.

Procedure 1.3 –Assemble the Vehicle Frame

Tools: Materials:

Rubber-faced hammer 23 Cut Pieces of pipe from Procedure 1.1

9 ½” PVC elbows from Procedure 1.2

9 ½” PVC Tees

Construction Steps

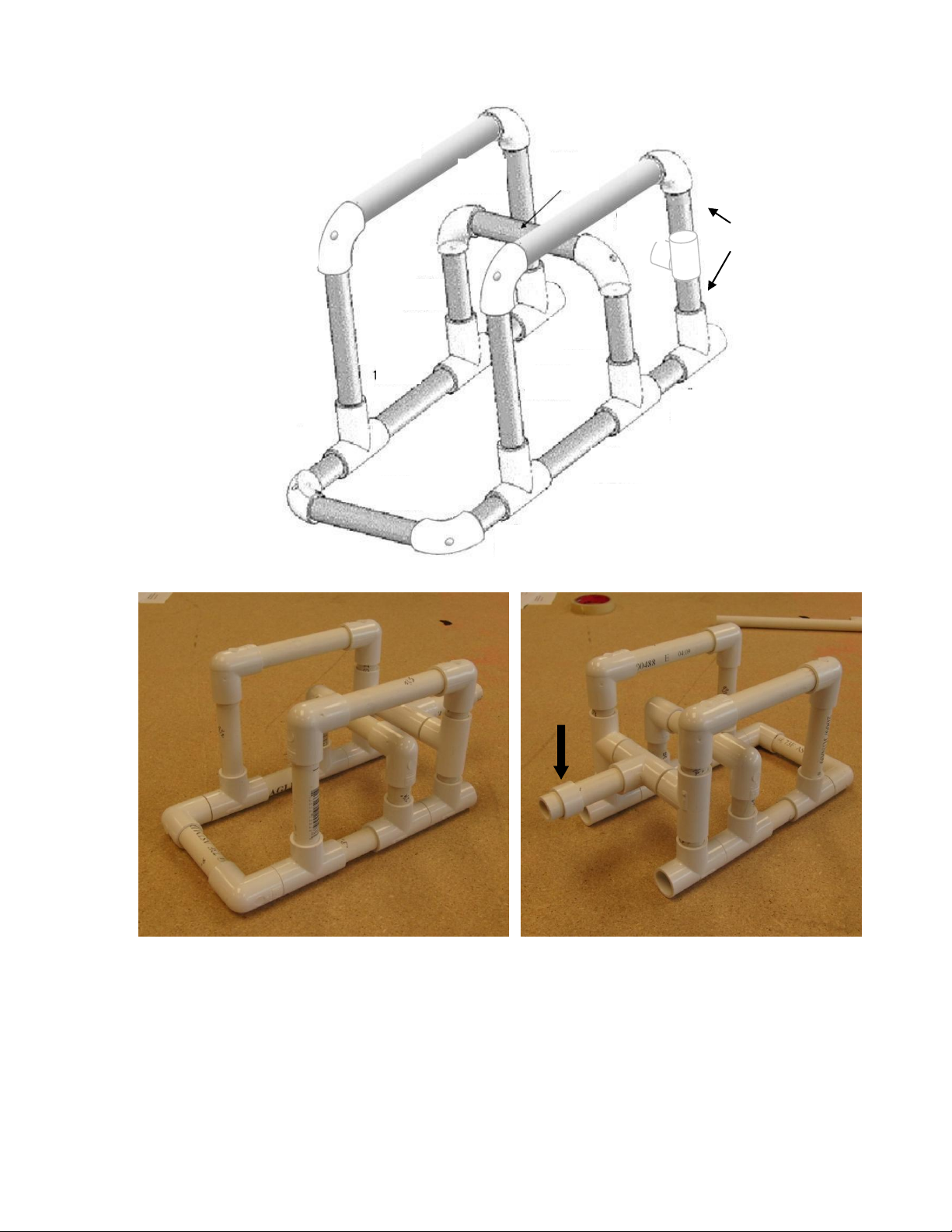

1. Assemble the frame using the PVC parts as shown below. Do not glue any of the connections.

Note that the two pieces of 1 ¾” pipe connected by a tee is shown only for the starboard

upright –an identical assembly would make up the port upright (not shown). The two tee’s, left

and right, will be connected by 2 pieces of 1 ½” PVC pipe with a tee in between them. Finally,

insert the 3 ½” piece of pipe into the tee and point it forward to act as a “nose”, able to pick up

objects. Refer to the two pictures to clarify what the final assembly should look like.

SeaPerch ROV Build v.2011-01AK Student Manual

5

5.5”

5.5

”

4.5”

4.5”

3”

3”

4”

4”

1.5”

1.5”

1.5”

2.25”

2.25

”

1.75”

Front

Note the PVC “collar” on the front nosepiece. This is added to help in firmly mounting the

camera on its shoe during camera installation, if used. It is made by snipping one leg off an

elbow as shown, carefully using the PVC pipe cutter.

Collar

SeaPerch ROV Build v.2011-01AK Student Manual

6

Slide the collar onto the nose. You will make final positioning adjustments when the camera is

installed (Appendix IV –Installation of an Underwater Video Monitor). Finally, firmly tap all of

the pieces of the frame together using a rubber-faced hammer, making sure that the frame is

squared up and parallel.

Procedure 1.4 –Assembly and Installation of the PVC Tube Floats

Tools: Materials:

PVC Pipe Cutter or Hacksaw 28” 1” PVC Pipe

Flush-Cut Wire Cutters 4 1” PVC End Caps

PVC Primer/Cement

8 8” Zip Ties

Paper Towels

Construction Steps:

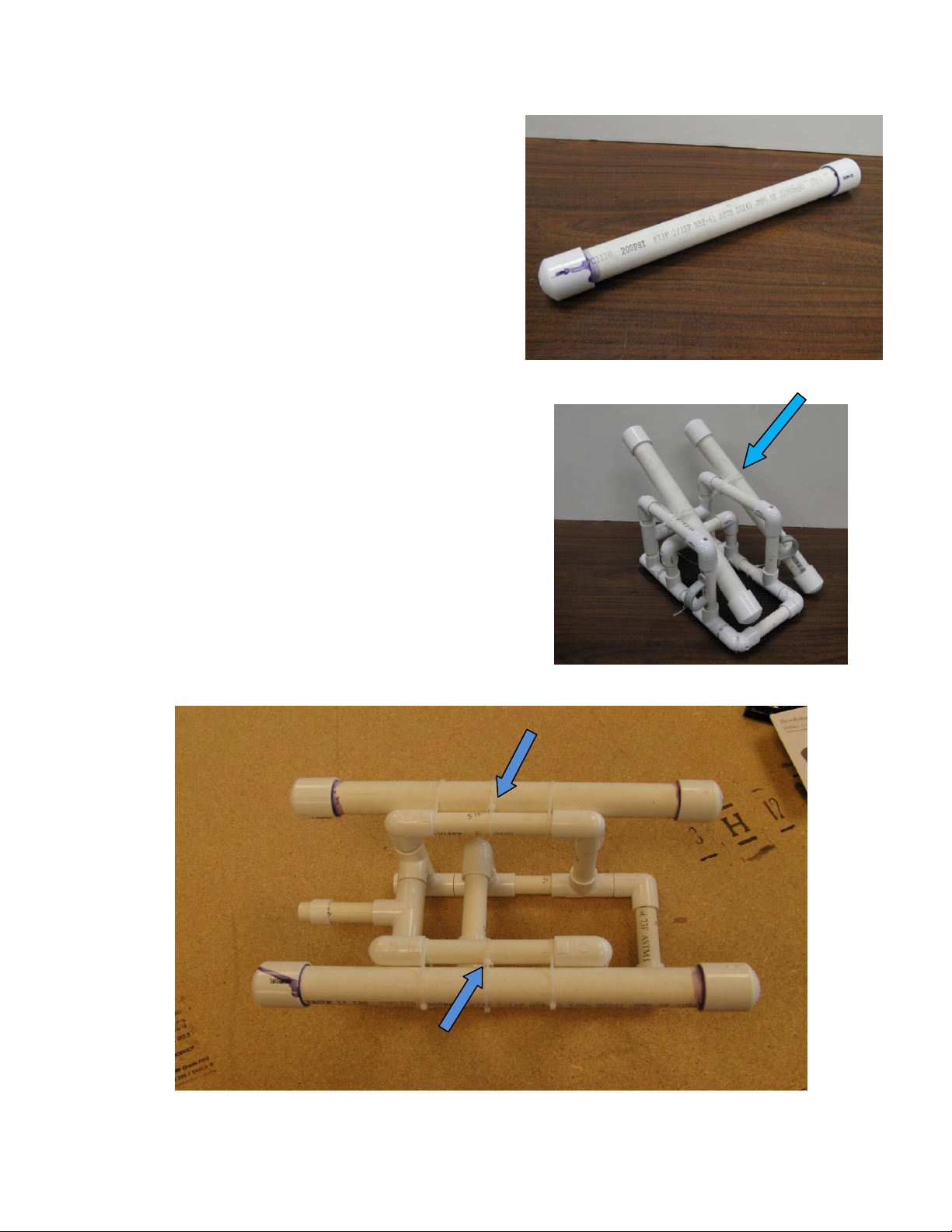

1. Cut two pieces of 1” PVC Pipe, exactly 14” (35.5 cm) each. Measure and cut carefully so that

the completed flotation tubes will have the correct buoyancy.

2. Work in a WELL-VENTILATED area (outdoors or under a vent hood), with several layers of

paper towel or newspaper to protect the work surface and floor area from stains. Apply a VERY

SMALL amount of the purple PVC primer to each end of the two pipes, to about 1 inch from

each end, as indicated in the picture, being very careful not to drip the primer onto your clothes

or other objects that could get stained. Similarly, apply the primer around the inside surface of

each of the four end caps. The primer cleans the PVC and softens it in preparation for

cementing the pieces together. Immediately

close the primer container.

3. Again, in a well-ventilated area and over the

protected floor or table top, quickly apply a thin

layer of PVC cement all of the way around one

end of one of the 1” PVC pipes and inside one

of the end caps. Glue just one end cap at a

time. Immediately after applying the adhesive,

push the end cap onto the pipe, twist it about a

quarter turn, and hold it firmly in place for a few

seconds. Put the cap back on the adhesive

container as soon as possible, to minimize the

SeaPerch ROV Build v.2011-01AK Student Manual

7

escape of vapors and to prevent the contents from drying out. Remove any excess glue from

the outside of the pipe using a paper towel;

discard the towel.

4. Repeat step 3 for the other end of the pipe, and

then for each end of the other pipe, one end at a

time. After all four end caps have been glued

onto the pipes, discard the paper that was used

to protect the table top and floor.

5. Position the float tubes so that they are parallel

to the top frame members. Attach the floats by

using three 8” zip ties on both port and

starboard sides and wrap them around the float

and the frame piece. Leave the ties a little loose for now.

6. Move the float so that it is at an angle to the frame

pipe as shown. Slide all of the zip ties towards the

cross angle between the two pipes, as shown.

Tighten the ties using a pair of blunt-nose pliers.

7. Move the float so that it is parallel to the frame pipe

and move the ties back along the length of the float.

Then frap the zip ties by wrapping an 8” tie around

each existing tie between the float and the frame

pipe. Tighten as much as possible using pliers, and

trim all of the tails using the flush-cut cutters.

SeaPerch ROV Build v.2011-01AK Student Manual

8

Procedure 1.5 –Attach the Thruster Mounts

Tools: Materials:

Drill Vehicle Frame

5/64” Drill Bit 3 1” Plastic Pipe Strap

#2 Phillips Screwdriver 6 #8 x ½” Phillips Head Sheet Metal Screws

Thruster Mounting Tips:

For now, don’t worry about the direction in which the three thruster mounts are positioned. Since you do not glue the

joints in the PVC frame, you can change the angles of the mounts later by simply turning the pipe in its joints using a

pair of pliers. It is easier to drill and attach the thruster mounts on the back (outside) of the frame… we’ll adjust them

later.

This is a good time to think about how the angle of the thrusters affects the performance of the ROV. What angles will

get you the best forward and backward thrust? What angles will get you the best turning ability? What is the best

compromise for your mission needs?

Construction Steps:

1. Hold a thruster mount against the frame, positioning the holes on the lines you drew in

Procedure 1.1 in the three locations shown in the picture, and using a marker or pencil, mark

the vehicle frame through the holes in the thruster mounts. Centering the mounts between the

joints on the pipe is more important than placing them at a specific angle around the pipe (they

can easily be turned later).

2. Using the 5/64” drill bit, drill holes through the six marks on the frame.

3. Using #8 screws and washers (washers are optional if the heads on your screws are large

enough that they will not pass through the holes in the thruster mounts, and if the thruster

mounts are metal or hard plastic). LOOSELY attach the thruster mounts to the frame. DO NOT

over-tighten the screws and strip the holes in the PVC!! You will be removing the mounts

later anyway to install the thrusters in them.

SeaPerch ROV Build v.2011-01AK Student Manual

9

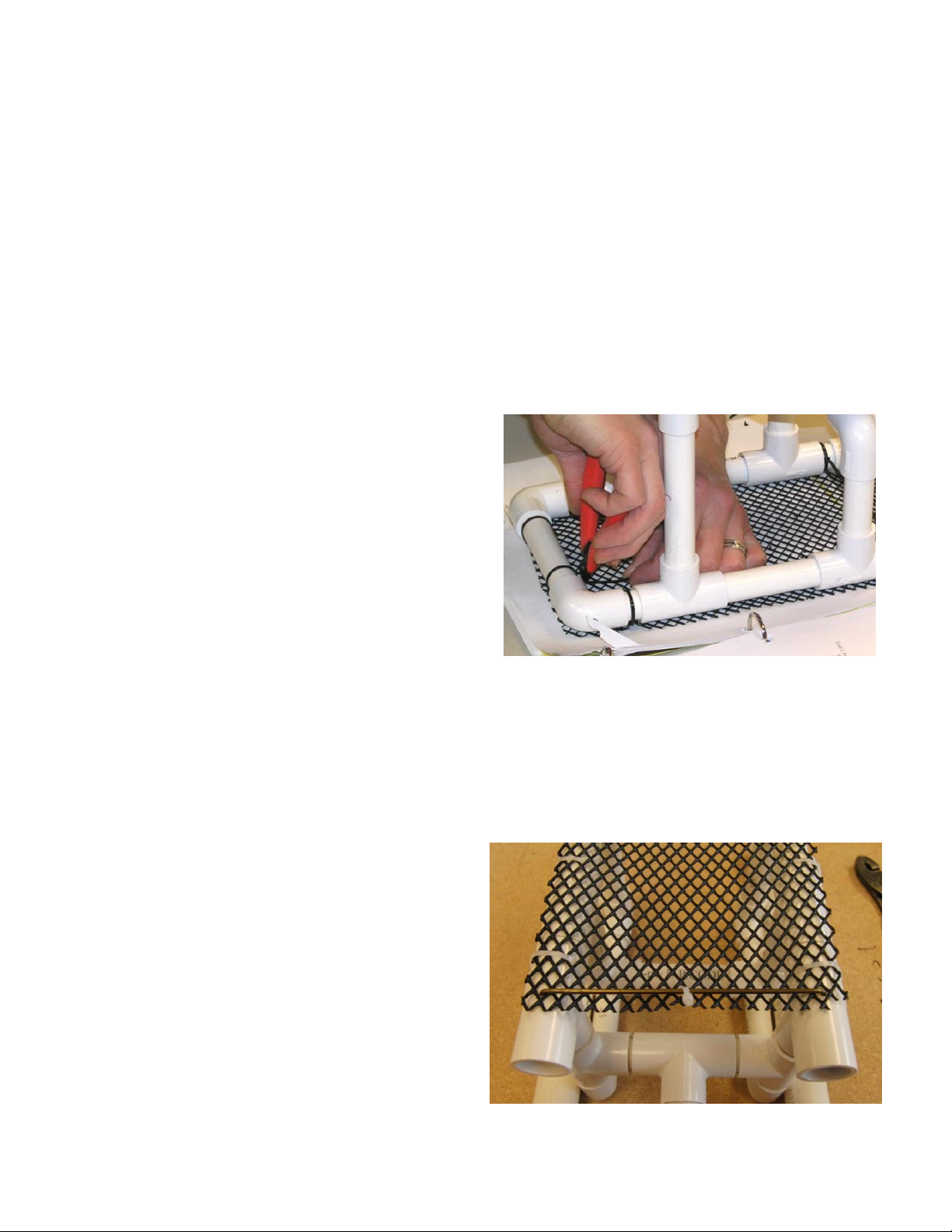

Procedure 1.6 –Attach the Payload Net to the Frame

Tools: Materials:

Scissors Assembled Vehicle Frame

Pliers 12” x 7” Polypropylene Netting

Flush-cut Wire Cutters Wire Coat Hanger

Hack Saw or Tin Snips 12 6” Zip Ties

Drill

3/32” Drill Bit

ROV Painting Tip:

If you wish to paint your vehicle’s frame, do so before attaching the nets, and be sure to use waterproof paint. Also

confirm that all vehicle pipe sections and fittings are as tight as possible and that the frame is squared-up before

painting, as the parts may be difficult to move after the paint has dried.

Construction Steps:

1. Check the frame to ensure that all pipe sections and fittings are pressed tightly together.

2. Place the payload net underneath the vehicle

frame and trim it to size with scissors if

necessary. Leave as little net as possible

extending beyond the edges of the frame.

The net is often a bit curved from being

stored on a roll; make sure that it is placed

under the frame with the concave side facing

toward the frame.

3. Attach the payload net to the frame using

about eight 6” tie wraps (also known as

“cable ties” or “zip ties”). Pull them tight using pliers (NOT thin needle-nose pliers, as their tips

may bend or even break when twisted!). Make sure the net is tight and flat on the bottom of the

ROV, and that the front edge of the net is even with the front vertical pipes, NOT with the

front of the PVC Tees.

4. Trim off the ends of the tie wraps using flush wire-cutting pliers (not scissors, which can leave

very sharp ends that can easily scratch skin) as shown.

5. Using the Flush-cut nippers, trim the ends of the payload net so that it is square with the bottom

footprint of the frame, as shown.

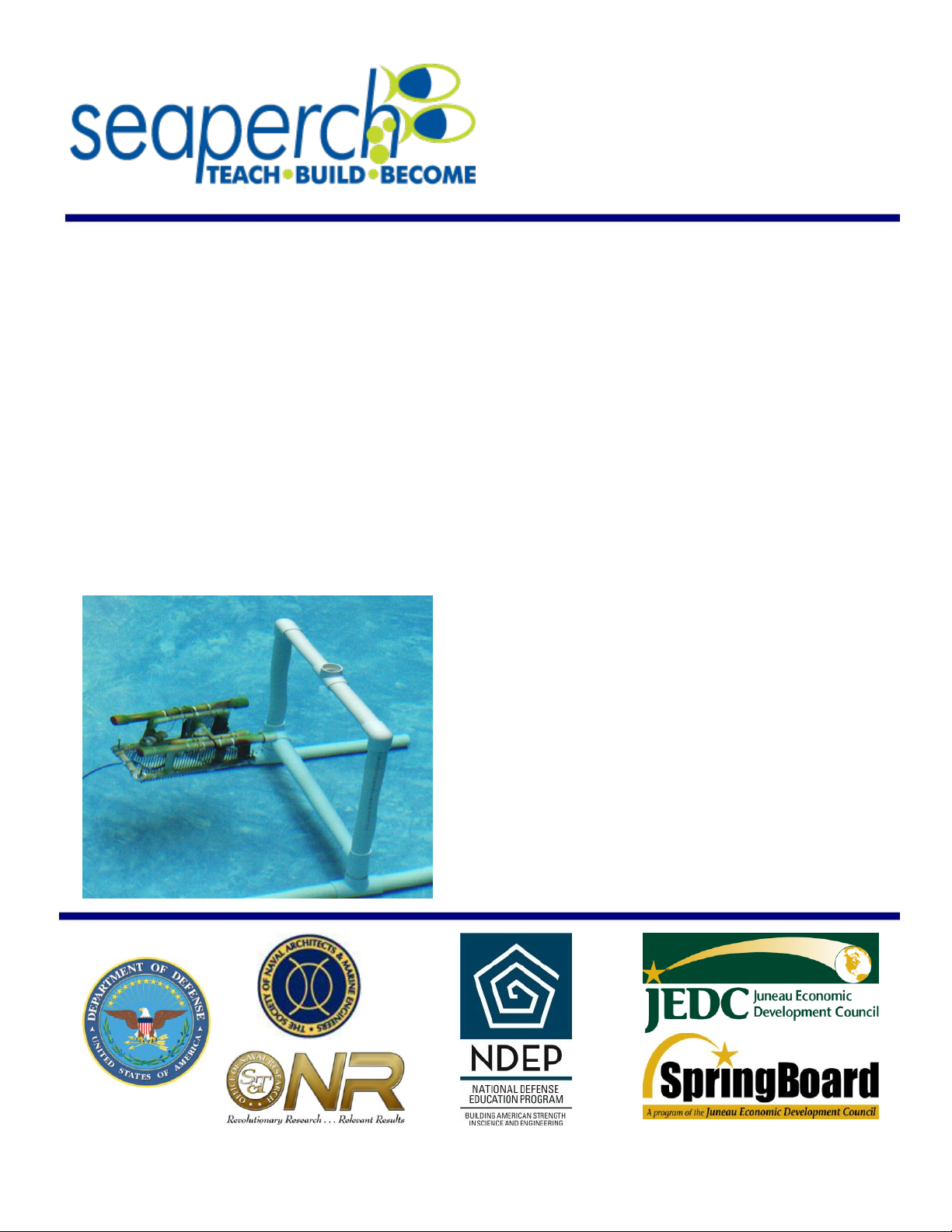

6. Coat hangers usually come in two versions:

a “heavy” one (0.105” dia) and a “light” one

(0.075” dia). You want to use the heavy one

for your stiffener. Turn your ROV upside

down and, using a 3/32” drill bit, drill a hole

through the center of each front frame tee.

7. Cut your wire coat hanger to 9” long and

bend up ~1¾” of wire at each end to 90º.

SeaPerch ROV Build v.2011-01AK Student Manual

10

8. With a little wiggling and maybe the light tap of a hammer, the upturned ends of the wire

stiffener can be inserted and set into the holes, as shown. Turn your ROV back over and attach

the payload net to the stiffener with one or two tie wraps. Trim the tails from the ends of the tie

wraps.

Congratulations! You have completed the frame for your SeaPerch ROV!

SeaPerch ROV Build v.2011-01AK Student Manual

11

SeaPerch

Remotely Operated Vehicle

Assembly of Subsystem Two

The Thrusters

January 2011

Version 2011-01AK

SeaPerch ROV Build v.2011-01AK Student Manual

12

Tools and Materials Needed

Tools: Materials:

Eye Protection 40’ Tether Cable (CAT 5 or 5e)

Drill 3 Plastic Vials

5/64” Drill Bit 3 12VDC Motors

Small Electric Hotplate 3 Propellers

Metal Cup for Wax 3 1/8” x ½” Roll Pins

Pliers 3/4 Wax Bowl Ring

Wire Stripper 16-24 ga. 1” Butyl Rubber Tape

Flush-cut Wire Cutters 24” #22 Stranded Red Hook-up Wire

Locking Long-Nose Pliers 24” #22 Stranded Black Hook-up Wire

Soldering Iron and Rosin Core Solder 1 12VDC Battery

#2 Phillips Screwdriver 12 Zip Ties

3/32” Drill Bit

Alternative Potting Procedure

Wooden Stirrer Marine Potting Epoxy

Procedure 2.1 - Test the Motors and Mark the Terminal Polarity

Tools: Materials:

Marker 3 12VDC Motors

Wire Stripper 2 24” #22 Hook-up Wire, One Red & One Black

12 VDC Battery

Electrical Tape

WARNING - TO AVOID ELECTRIC SHOCK AND POTENTIAL BURNS:

- DO NOT touch exposed wires when making connections to battery terminals.

- DO NOT touch the battery terminals with ANY metal object, especially tools!

- DO NOT CONNECT WIRE OR METAL FROM ONE BATTERY TERMINAL TO THE OTHER!

Construction Steps:

1. Gather the red and black 24” hook-up wires to use as a pair of test wires (these are temporary;

they will be used later to make the power cord and your control box in Unit 3) and some

electrical tape.

2. Strip about 3/8” (1 cm) of insulation from both ends of the black hook-up wire, without cutting

the copper strands inside. Use the 22 ga. notch on the wire stripper.

3. Repeat Step 2 with the red hook-up wire.

4. If the motors have any wire leads soldered to their terminals, clip the wires off and use a de-

soldering tool (such as a vacuum solder remover or a solder-wicking braid) to remove the wires

and any excess solder from the terminals.

5. Cut about 1” (2.5 cm) of electrical tape, and place it temporarily onto the shaft of each motor,

wrapping it around the shaft with the end extending out like a flag, to help you see the motor’s

spin direction when it is energized.

6. Connect the red and black wires to the two terminals on one of the motors (twist them through

or around the terminals) and hold them temporarily in place with small pieces of electrical tape.

Other manuals for ROV

1

Table of contents

Other SeaPerch Educational Equipment manuals

Popular Educational Equipment manuals by other brands

Quanser

Quanser 6 DOF Hexapod Laboratory guide

Surefire

Surefire Flying Model Rocket Kit How to use

ACROME

ACROME myCONTROL STEWART PRO user manual

SmartMan

SmartMan Baby Manikin manual

Nasco

Nasco Life/form LF03840U instruction manual

Pitsco Education

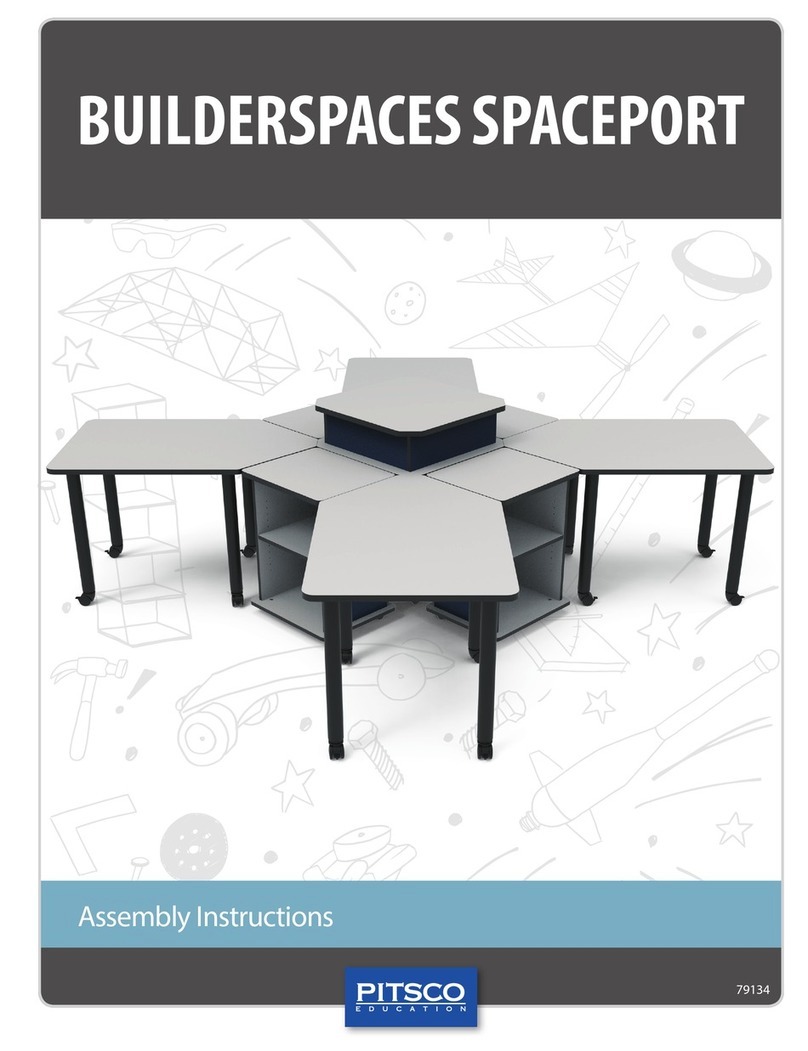

Pitsco Education BUILDERSPACES SPACEPORT Assembly instructions