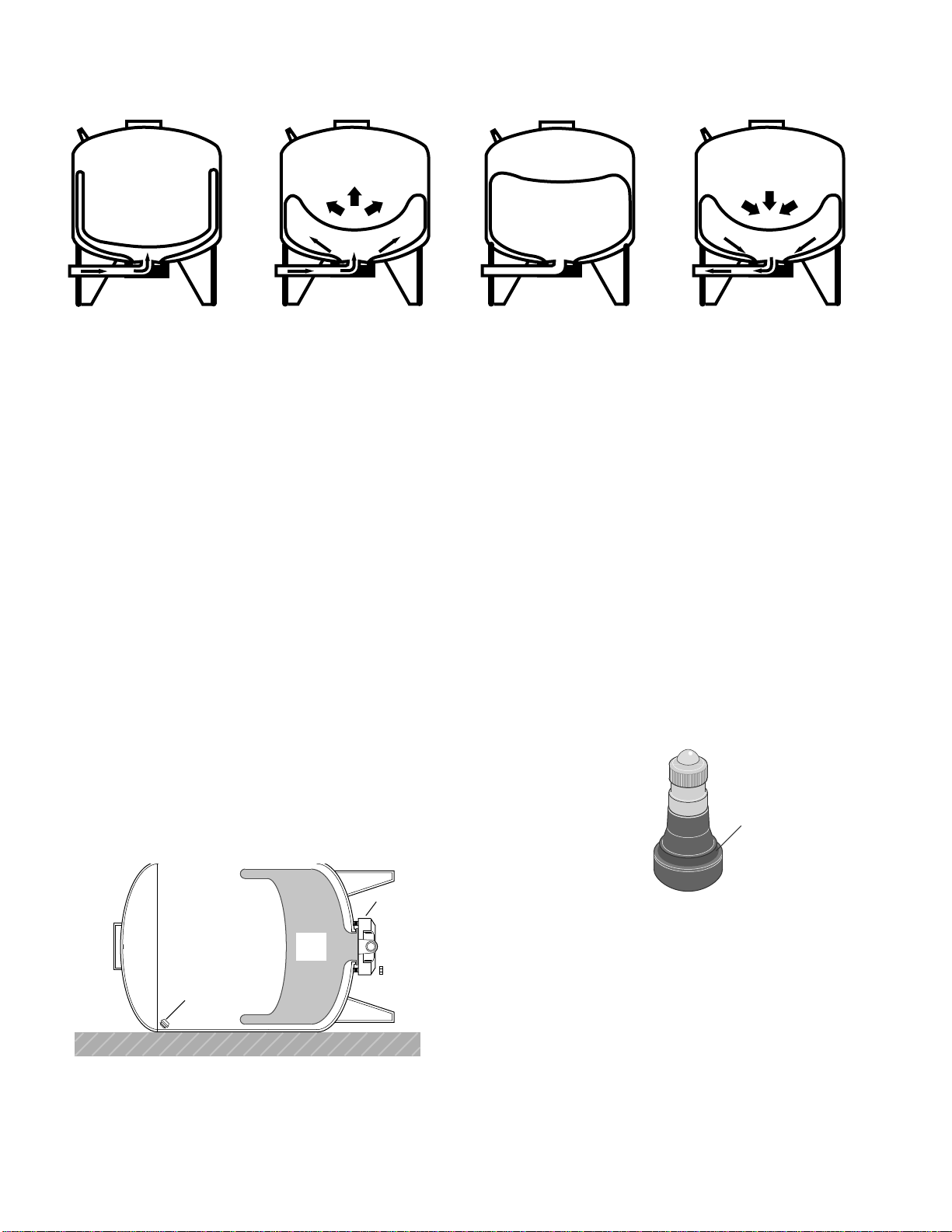

5. With sharp knife, cut off stem as close to tank as pos-

sible. Push remaining portion into tank.

6. Lay tank on side and remove six (6) nuts from studs.

Tap cover to break seal and remove cover assembly

from tank. You can now see the vinyl bag. See Figure

11.

7. Before removing vinyl bag from groove seat in tank, BE

SURE all water is drained from bag. This can be ac-

complished by tipping tank upright and allowing re-

maining water to drain.

8. Carefully remove lip portion of bag from groove seat

and push bag into tank.

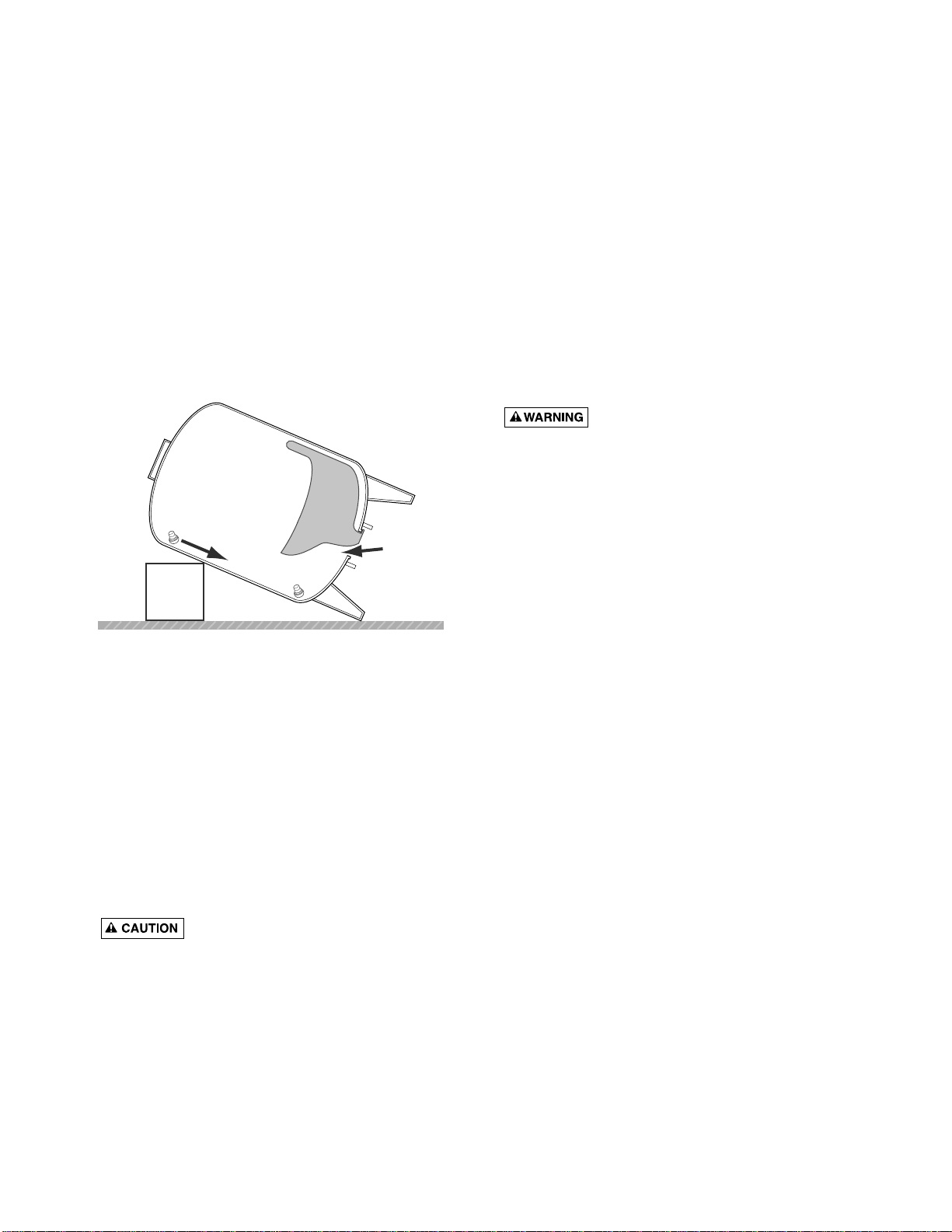

9. Block up tank as shown in Figure 13. This will allow

cutoffportionofstem toslidedowntobottomoftank.

Reach in around bag until you find it and remove it.

10. Wipe a thin film of soapy solution on top half of re-

placement stem and insert in stem hole in top of tank.

It is necessary to use a valve stem pulling tool to pull

stemthruopening.Thistollisthesame asusedbyyour

local filling station and Sears Automotive Center when

servicing tubeless tires.

11. Pullneckofbagoutoftankopeningandseatin groove.

BE SURE ring groove is clean.

12. Clean sealing surface of cover assembly and place on

studs.

13. Hand tighten all nuts on studs.

It is important that nuts be tightened as

follows: First, hand tighten all nuts. Then tighten one

nut to a snug fit. Next, tighten the one opposite to a

snug fit. Proceed, tightening the others in opposite

pairs to a snug fit. Recheck all nuts in same opposite

patterns to be sure they are evenly tightened and you

have a good seal. DO NOT overtighten, as you may

twist the studs off the tank. With a torque wrench,

tighten to 85 inch pounds.

14. Tip tank upright and assemble for operation.

15. Recharge tank with proper amount of air.

TESTING FOR LEAKAGE OF VINYL BAG

1. Disconnect power to pump.

2. Relieve (drain) ALL water in system by opening faucet

closest to tank.

3. Relieve (expel) ALL air pressure in tank by removing

core from inside of air valve.

4. Disconnect outside piping only to tank.

5. Turn tank upside down.

NOTICE: BE CAREFUL not to damage air valve when

tipping tank. Removal of air valve is not required. If

waterleaks out ofthevalvecore opening,thevinylbag

has a hole in it and must be replaced.

PROCEDURE FOR REPLACING VINYL

BAG

Be sure all air has been expelled from tank

before removing nuts.

FOR 6, 19 AND 36 GALLON TANKS

1. Carefully lay tank on its side.

2. Remove nuts around cover plate.

3. Tap covertobreakthe seal and removecoverassembly

from tank. You can now see the vinyl bag.

4. Bag cannot be removed in one piece. Wherever con-

venient, grip bag with pliers and pull outward. At the

same time cut bag with sharp knife or single-edged

razor blade. Continue pulling and cutting until bag is

completely removed.

5. Clean and dry inside of tank.

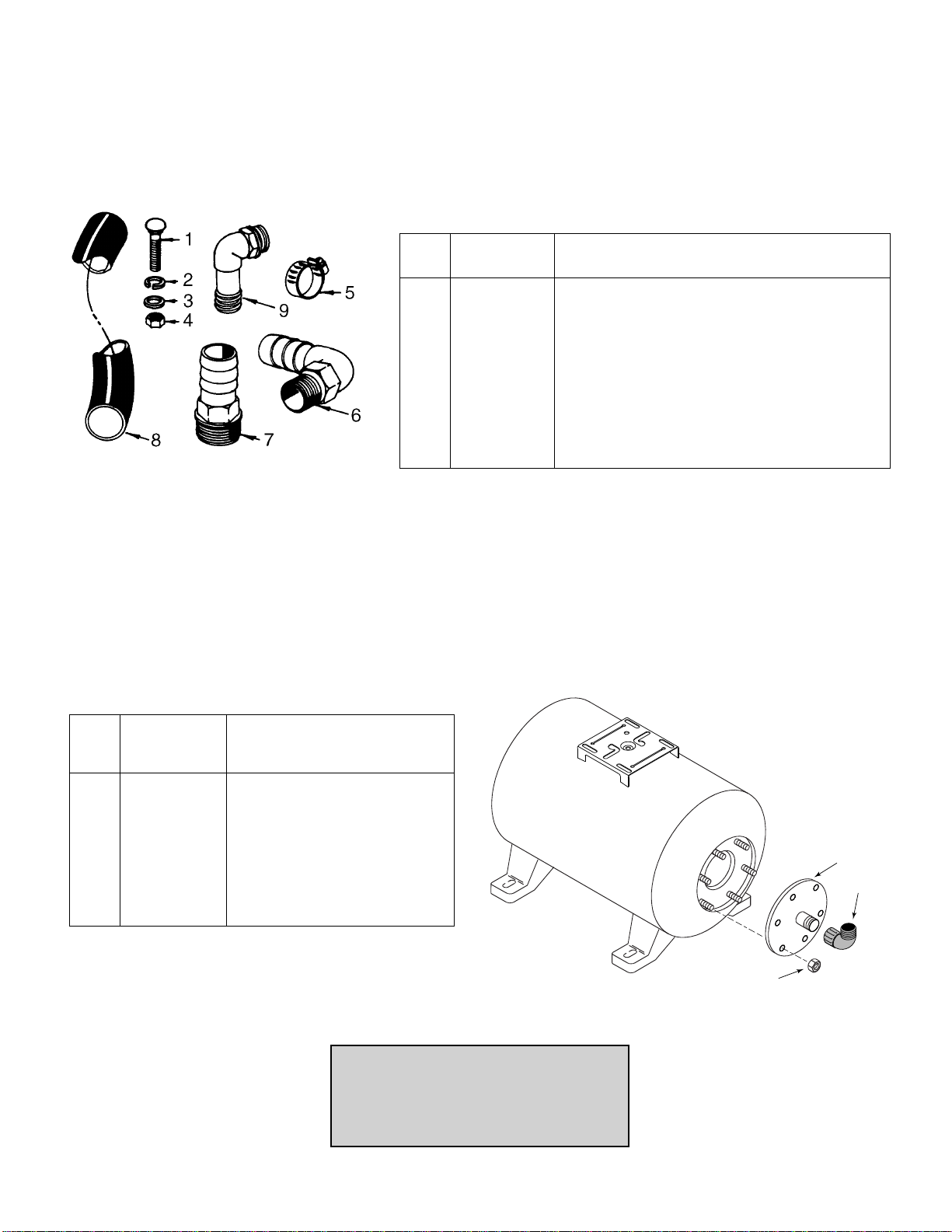

NOTICE: Before replacement bag can be inserted in tank,

it must be tightly rolled up as follows:

1. Place bag on clean surface with opening up.

2. Flatten bag and force air out.

3. Tightly roll bag towards center opening.

4. Beforecenteropening iscoveredup,forceair outofre-

maining portion of bag.

5. Finish rolling bag.

6. Asan aidforinsertingbagintank,sprinkleoutsidewith

talcum powder.

7. With tank upside down, push tightly rolled bag into

tank.

8. Put your arm in bag and push sidewalls outward. It is

NOT important that all wrinkles be removed.

9. Clean flange ring and groove of tank.

10. Pull lip of bag through tank opening and place in ring

groove.

11. MAKE SURE it seals properly in groove.

12. Clean sealing surface of cover assembly and place on

studs.

8

SERVICE HINTS

FIGURE 13