the current clamp method.

Method 3 Earth loop impedance measurement

If the earth electrode is used in conjunction with

an RCD the earth electrode resistance can be

tested by using the following method.

i. Switch off the supply and disconnect the earth

electrode from the main earthing terminal.

ii. Connect the loop tester between the line

conductor at the source and the

earth electrode.

iii. Perform an earth loop impedance test. The

measured value is taken as the earth electrode

resistance (RA).

iv. Ensure that the supply is then safely isolated

BEFORE the earthing conductor is

reconnected to the main earthing terminal.

NOTE: The nstallat on s unprotected aga nst

earth faults wh lst the earth electrode s

d sconnected.

Maximum Values of Earth Electrode

Resistance for TT Installations

Assuming: 120 V≤UO≤230 V

*UOis the nominal voltage to earth

In practice values over 200Ωmay not be stable

as soil conditions change as soil dries or freezes.

Thus 200Ωmay be taken as a maximum ‘rule of

thumb’ value.

The tests indicated in this text are the basic

safety requirements for an electrical installation

(i.e. they must be found to be satisfactory before

the supply can be switched on). More

comprehensive guidance can be found in

BS7671 Requirements for Electrical Installations

IEE Wiring Regulations Seventeenth Edition or

the IEE On-Site Guide.

HEALTH & SAFETY

REMOVE ALL LINKS WHEN THE TEST

SEQUENCE IS COMPLETE AND BEFORE

CONNECTING THE INSTALLATION TO THE

SUPPLY.

11

Tri ed. Tested. Trusted.

electrode e.g. 20m for a 2m long electrode.

i. A measurement is made with the potential

spike P2 initially positioned midway between

the earth electrode and the current spike C2.

ii. The measurement is repeated with the

potential spike P2 moved to a position 10% of

the earth electrode to current spike C2

distance towards the earth electrode.

iii. The measurement is repeated with the

potential spike P2 moved to a position 10% of

the earth electrode to current spike C2

distance towards the current spike C2.

iv. The average of the 3 measurements is

calculated and the percentage deviation

calculated by finding the maximum deviation

from the average and expressing this as a

percentage of the average.

v. If the percentage deviation is greater than 5%

the measurements should be repeated with a

larger separation between the current spike

C2 and the earth electrode.

Note: The earth electrode must be d sconnected

from the nstallat on to avo d measurement errors

due to parallel earth paths through bonded parts,

for example, water or gas serv ce p pes. Tak ng

the example of an earth electrode w th a relat vely

h gh res stance to earth, say 1000Ω, and the

electrode s connected to a water serv ce p pe

w th a res stance to earth of say 10Ω. If the earth

electrode s not d sconnected before attempt ng

to make a measurement, the effect of the parallel

path v a the water serv ce p pe w ll be to g ve an

apparent earth electrode res stance of 1000Ωn

parallel w th 10Ω.e. 9.9Ω.e. the h gh earth

electrode res stance s masked by the presence

of the parallel path v a the water serv ce p pe.

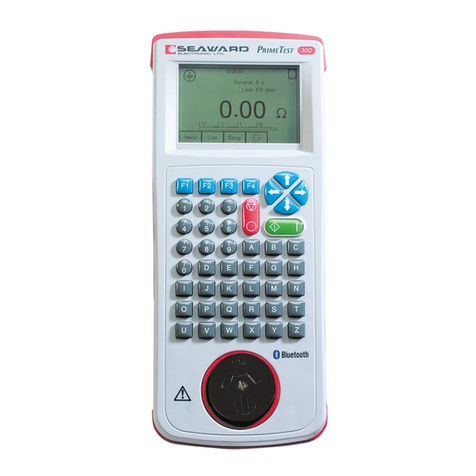

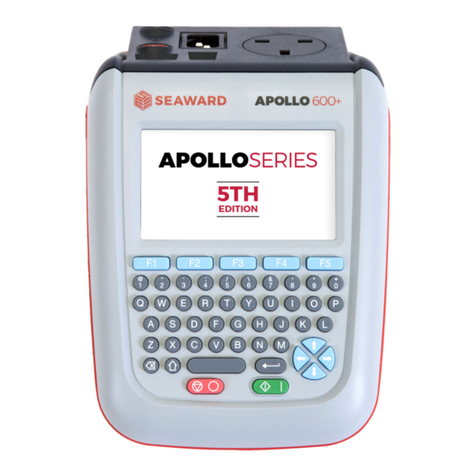

Method 2 Current clamp measurement

Some earth resistance test instruments such as

the Seaward ERT 1557 have a measurement

mode which uses an external current clamp to

measure the current through the earth electrode.

This eliminates the effects of parallel paths and

allows measurement of the earth electrode

resistance without disconnecting the electrode

from the installation. The benefit is that the

installation does not need to be shut down in

order to measure the earth electrode resistance.

D agram 10: Earth electrode res stance measurement w th

current clamp

The measurement technique is as per the three

pole method but with the external current clamp

placed around the earth electrode. The

measured value is the earth electrode resistance.

Note: The earth electrode does not have to be

d sconnected from the nstallat on when us ng

10

www.seaward.co.uk