8

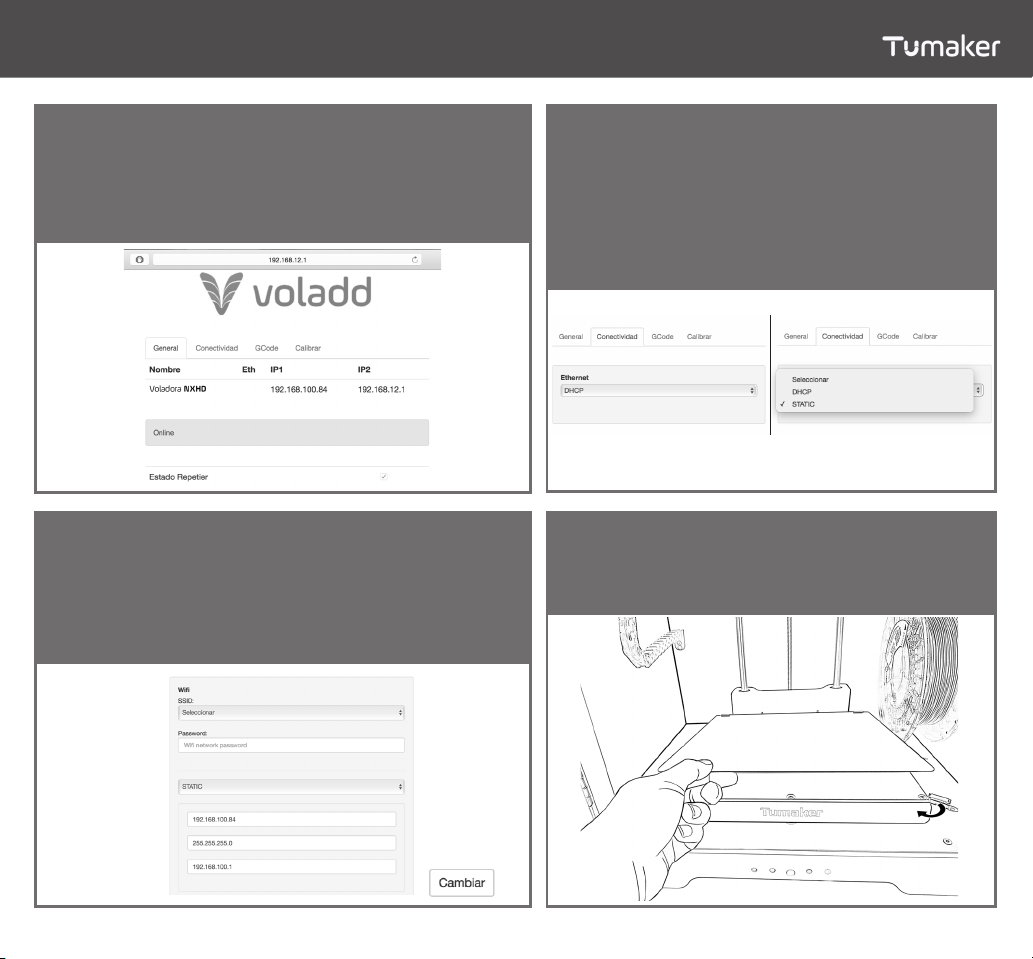

The calibration of the Pellet 3D printer is essential to achieve quality prints and to ensure optimum performance. The

distance between the head nozzle and the bed has to be perfect.

1. Head Heating:

Heat up the head to the recommended fusion

temperature. If the melting temperature exceeds 260°,

keep the head warm for 5 minutes before starting.

Adhesion temperatures:

- PLA & similars: 45º

- ABS & similars: 80º

- Polycarbonate & similars: 120º

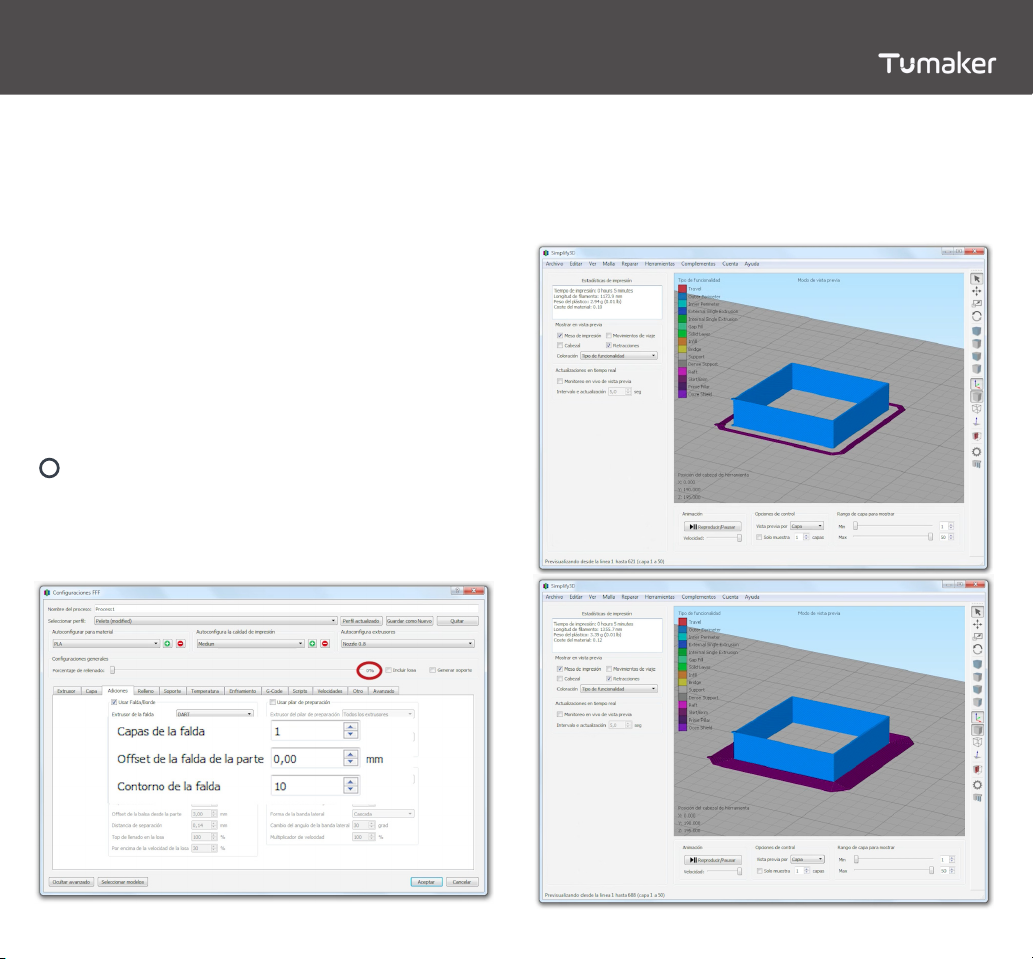

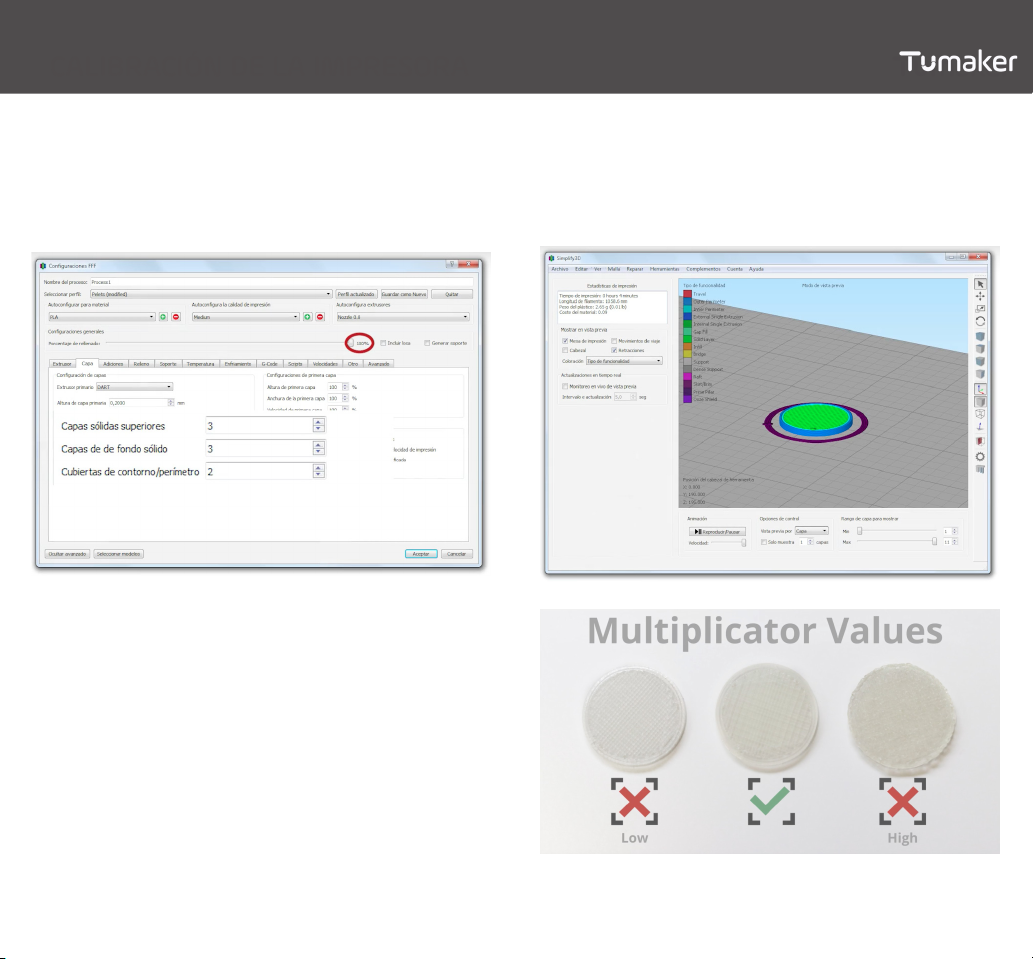

2. Extrusion multiplicator:

We will use this parameter to regulate the ow of the

head. For common materials, the possible values from

2 to 3.

Pellets with irregular shape and size will be more

dicult to calibrate. Besides, ow irregularities may

happen, and, in consequence, part’s appearance can

be negatively aected.

The fusion temperature may aect to a greater or

lesser extent on the material ow.

CALIBRACIÓN DE LA IMPRESORA

Use lacquer or other adherent system to get a better

adherence to the printing base

IMPORTANT NOTE

PRINTER CALIBRATION