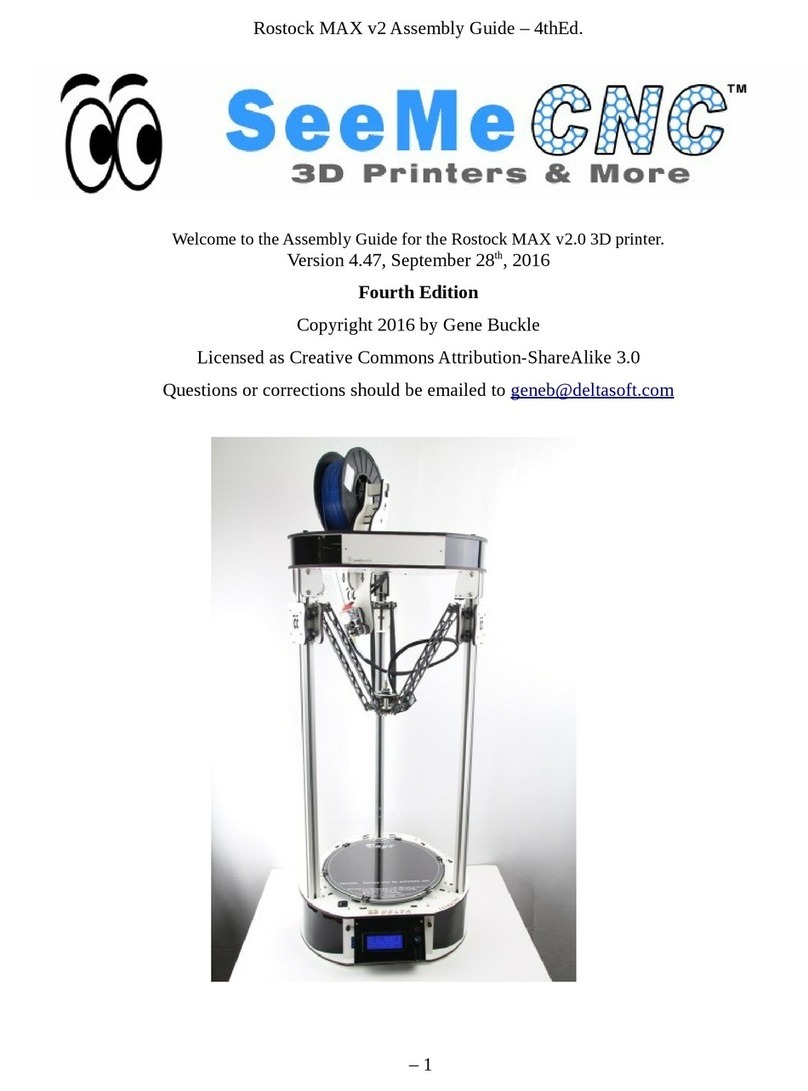

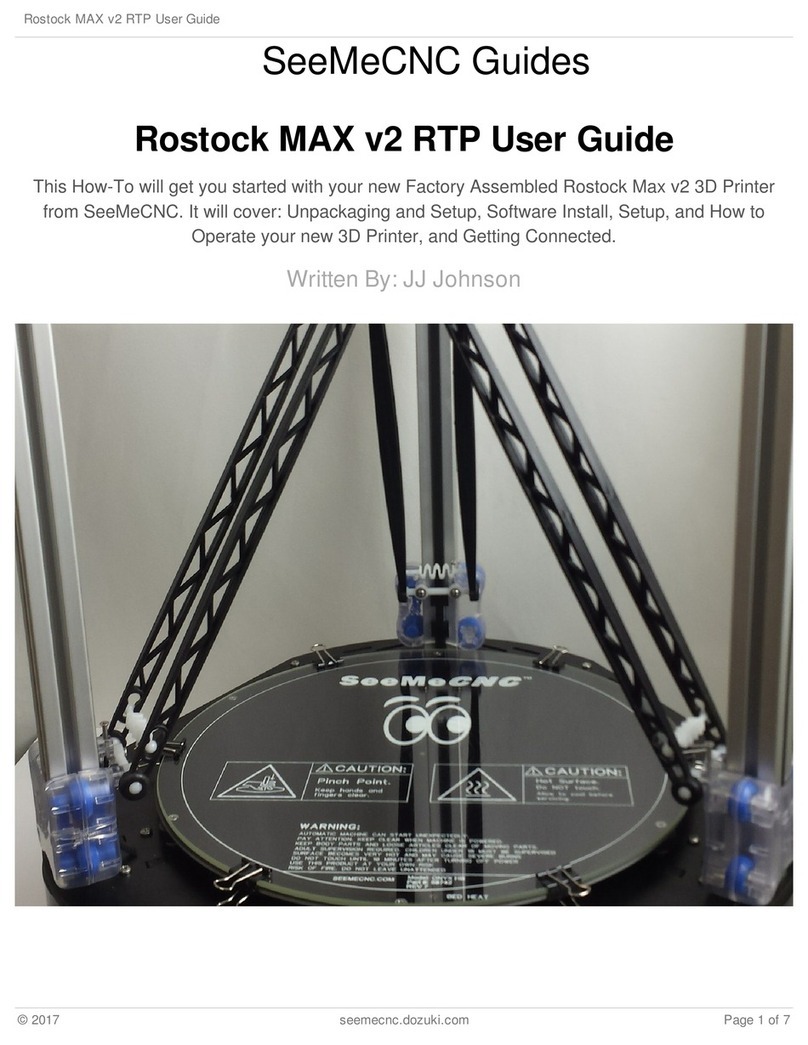

SeeMeCNC Rostock MAX v2 User manual

Rostock MAX v2 Assembly Guide

Read Me First!

This document is your instruction manual for your new SeeMeCNC® 3D printer machine.

Before using your new 3D printer, thoroughly read and understand this manual for safe and effecti e

operation of the machine.

2

Warning

Adult supervision required. Children under 18 years of age require supervision.

Risk of Fire. Do not leave machine unattended.

Use genuine parts manufactured or designated y SeeMeCNC.

Keep a copy of this manual near the machine, easily accessi le to all operators.

Use of this machine is at your own risk.

Personal property damage, serious injury or death can result from not following

instructions or warning in the manual or misuse of the machine.

Automatic machine can start unexpectedly. Pay close attention and keep clear

while power is connected to the machine

The machine power supply is connected to AC voltage

and can e hazardous. Disconnect power efore

servicing this machine.

The hot end of the machine can reach very high

temperatures of 700F and can cause serious urns.

The heated print surfaces (heated ed) can also reach

temperatures high enough to cause severe urns. Allow

oth to cool for 20 minutes after turning off power.

Use caution near moving parts of the machine. Keep

ody and loose articles clear.

Poisonous gas, smoke, or fumes could e emitted y some materials you could

use with the machine. In such case, you should install ventilation.

Choking Hazard. This machine contains small parts and

can produce small parts which can e a choking hazard

to children.

Visit http://www.seemecnc.com to contact us if you have any questions.

Rostock MAX v2 Assembly Guide

Table of Contents

READ ME FIRST!.....................................................................................................................................2

0 – Introduction and Acknowledgments....................................................................................................6

1 – Required Tools And Materials..............................................................................................................8

2 – isual Bill of Materials......................................................................................................................11

3 – Prepping the Hot End and Power Supply...........................................................................................28

Preparing the Hot End...........................................................................................................28

Preparing the Power Supply..................................................................................................33

4 – Building the Base...............................................................................................................................40

Installing The Feet.................................................................................................................41

Preparing the ertical Supports.............................................................................................42

Installing the ertical Supports and Power Supply...............................................................47

Installing the Drive Gears on the Stepper Motors.................................................................51

Assembling the Tower Supports............................................................................................54

Installing the Base Top Plate.................................................................................................62

5 – Installing the Onyx Heated Bed.........................................................................................................66

Installing the Thermistor, Power LED and Power Wires......................................................66

Mounting the Onyx Heated Bed to the Base.........................................................................75

6 – Installing the Towers & Tower Wiring...............................................................................................79

Running Wire in the Towers..................................................................................................79

Setting the Towers.................................................................................................................87

7 – Assembling, Installing, and Wiring the Top Section..........................................................................91

Prepping the Upper Tower Mounts.......................................................................................92

Installing the Upper Tower Mounts.......................................................................................93

Installing the End Stop Switches...........................................................................................96

Installing the Upper Tower Mounting Hardware..................................................................98

Installing the Upper Idler Bearings.......................................................................................99

A little prep work is in order................................................................................................100

Attaching the Top Plate.......................................................................................................101

Connecting the End Stop Switches.....................................................................................105

Routing the wires & binding them......................................................................................107

Tightening the Towers.........................................................................................................113

8 – Assembling and Installing the Cheapskate Carriages......................................................................116

Assembling the Cheapskate Rollers....................................................................................116

Assembling the U-Joint Carriers.........................................................................................118

Installing the U-Joint Axles.................................................................................................121

Installing the Belt Clip T-Nuts............................................................................................122

Assembling and Installing the Cheapskate Carriages.........................................................123

Adjusting the Cheapskate Carriages...................................................................................126

9 – Installing the Drive Belts.................................................................................................................127

Belt Routing........................................................................................................................127

3

Rostock MAX v2 Assembly Guide

Installing the Belt Clamps...................................................................................................131

Adjusting the Belt Tension..................................................................................................133

10 – Assembling and Installing the EZStruder......................................................................................136

Assembling the EZStruder..................................................................................................136

Installing & Mounting the EZStruder.................................................................................140

Wiring the EZStruder Stepper Motor..................................................................................146

11 – Installing the Hot End and Bowden Tube......................................................................................149

Preparing the Hot End Wiring.............................................................................................149

Wiring the Hot End.............................................................................................................152

Attaching the Hot End to the Hot End Mounting Plate.......................................................155

Installing the Bowden Tube.................................................................................................157

12 – Installing the Effector Platform and Delta Arms............................................................................159

Assembling the Effector Platform.......................................................................................159

Installing the Delta Arms.....................................................................................................161

Attaching the Effector Platform..........................................................................................164

13 – Installing the Hot End....................................................................................................................166

14 – Finishing the Top End....................................................................................................................168

Installing the Spool Holder.................................................................................................168

Installing the Top Plate and Spool Support Arm.................................................................172

15 – Assembling & Installing the LCD Panel Mount............................................................................176

Assembling the Front Panel................................................................................................176

Installing the LCD Trim Panels...........................................................................................179

16 – Installing & Connecting the RAMBo Controller...........................................................................182

Preparing the RAMBo Mounting Plate...............................................................................182

Mounting the RAMBo Controller.......................................................................................184

Wire Prep: End Stops..........................................................................................................186

Wire Prep: The Hot End Thermistor Connector..................................................................188

Wire Prep: The Heated End Thermistor Connector............................................................189

Wire Prep: Extruder Motor Connector................................................................................190

Wiring the RAMBo Controller – Terminal Block...............................................................191

Plugging cabling into the RAMBo......................................................................................193

Installing the RAMBo Into The Machine Base...................................................................196

Installing the Power Switch and LCD Controller Cables...................................................197

17 – Final Assembly Tasks.....................................................................................................................200

Attaching the Base Covers & LCD Panel...........................................................................200

Attaching the Power and USB Cables.................................................................................203

Installing the Acrylic Cover Panels.....................................................................................205

Dem Feet!............................................................................................................................207

Installing the Borosilicate Glass Build Plate.......................................................................208

Smoke Test!.........................................................................................................................210

18 – Driver and Software Installation....................................................................................................211

Installing the RAMBo Driver..............................................................................................211

Installing the Arduino IDE..................................................................................................213

Configuring the Arduino IDE..............................................................................................214

Test Upload.........................................................................................................................215

4

Rostock MAX v2 Assembly Guide

Uploading Repetier-Firmware.............................................................................................217

The LCD and Front Panel Controls.....................................................................................219

19 – Installing MatterControl and Calibrating the Printer.....................................................................222

Downloading, Installing, and Configuring MatterControl..................................................222

Initial Function Tests...........................................................................................................229

Optimizing The Temperature Control Algorithms..............................................................234

Setting the Z Height............................................................................................................238

Adjusting The End-Stops....................................................................................................239

erifying Extruder Stepper Operation.................................................................................244

Extruder Calibration............................................................................................................245

20 – First Print: PEEK Fan Shroud........................................................................................................246

Configuring the Slicer.........................................................................................................246

Printing The PEEK Fan Shroud..........................................................................................250

Loading Filament................................................................................................................251

Preparing the Heated Bed....................................................................................................252

Printing the PEEK Fan Shroud............................................................................................253

Installing the PEEK Fan and Shroud...................................................................................255

21 – Second Print: Layer Fan Shroud....................................................................................................259

Appendix A: Maintenance and Troubleshooting...................................................................................262

Print Layer Issues................................................................................................................263

Machine Won't Move!.........................................................................................................265

Belt Damage or The Delta Arm Blues!...............................................................................265

5

Rostock MAX v2 Assembly Guide

0 – Introduction and Acknowledgments

I’d like to welcome you to the second edition of the Rostock MAX v2 assembly guide!

Even if you've built an original Rostock MAX v1 3D printer, you'll want to read this manual

carefully. There are no common Melamine parts from the v1 design. The construction has been greatly

streamlined and should prove to be a shorter build. The design changes made will ensure that you've

got a long lasting, easy to calibrate, delta configuration 3D printer.

Please read this entire guide before you begin assembly of your new Rostock MAX v2! It will

help you avoid any unpleasant surprises and will ensure that you’ve got everything you need BEFORE

you need it! Understand that the photographs in this assembly guide do NOT tell the whole story of

each step! Make sure you read and understand the accompanying text for each step!

A quick note on the RAMBo, the controller for your Rostock MAX. The RAMBo is static

sensitive, so please don't take it out of the static bag it ships in until you're ready to use it.

The box containing the RAMBo and its wiring should also contain a printed, black & white

sheet that looks like this:

http://www.reprap.org/wiki/File:Rambo-conn-all.jpg

Please refer to this sheet when you reach Chapter 18. This is a valuable guide to wiring the

RAMBo up to your Rostock MAX. Note that the connector polarity is clearly marked on the board for

the “MOSFET Outputs”.

Making Crimped Connections

Towards the end of the build, you'll be required to apply four crimp on sockets to the extruder

wire extension. Teaching you how to properly crimp a connector is beyond the scope of this manual.

However, that being said, I've done a lot of research on this in order to make this task as easy and

accessible as I can. Chris Hansen over at Hansen Hobbies has written the most excellent treatise on the

use of inexpensive crimp tools that I've yet seen. You can download the PDF of the tutorial here:

http://www.hansenhobbies.com/products/connectors/Connectors.pdf

The focus on the tutorial is on connectors commonly found on R/C servos, but the crimp

sockets featured are essentially identical to those that you'll be required to use during your Rostock

MAX v2 Build.

6

Rostock MAX v2 Assembly Guide

Acknowledgments

I'd like to thank the gentleman that runs http://minow.blogspot.com.au/ for his excellent guide

on calibrating delta configuration 3D printers.

I'd also like to thank the whole gang over at the SeeMeCNC forums for providing excellent

feedback. This would be a much lesser creation without their contributions and insights.

7

Rostock MAX v2 Assembly Guide

1 – Required Tools And Materials

Before you begin assembly of your Rostock MAX v2, please make sure you’ve got everything

on the following list of tools and additional materials.

•P1 & P2 sized Phillips screwdrivers

•Standard flat head screwdriver

•A small flat head screwdriver.

•3/32” Allen (hex) wrench. A ball-end, T-handle version is a good choice for this and the other

sizes of Allen wrenches used

•5/32” Allen (hex) wrench.

•7/64” Allen (hex) wrench.

•Needle nose pliers

•Slip joint pliers

•Forceps – these will come in handy when routing the belts and reaching for small, hard to reach

parts. They can be purchased from Amazon for as little as $3.50 for a set of two.

•Wire strippers

•Wire cutters

•5/16” open-ended wrench (Used primarily on the nuts that hold the Cheapskates together)

•2 7/16” open end wrenches. (used to adjust Cheapskate Bearings)

•11/16” open-ended wrench (used for hot-end mount)

8

Rostock MAX v2 Assembly Guide

•PermaTex Ultra Copper High Temp RT

•A small razor knife like an X-Acto knife. This will be handy for cleaning the flashing off the

injection molded parts.

•1/2” wide roll of Kapton tape

•A digital caliper. These can be purchased from Harbor Freight tools for around $10.

•A small squeeze clamp that can open at least 6”

•Battery powered screwdriver. If you ever needed an excuse to buy one of these, THIS IS IT.

•Pencil.

•40W Soldering Iron.

•Blue thread locking compound (Loctite or Permatex Threadlocker Blue)

•A small file.

•Elmer's Glue Stick – must be marked “Disappearing Purple”.

•Toothpicks

•Isopropyl Alcohol

•12” framing square.

•1 Roll of ABS filament. Needed to print the fan shrouds at the end of the build.

9

Rostock MAX v2 Assembly Guide

The following is a list of optional things that can make your life easier in the long run.

•Electrician's tape.

•Standard sized nylon wire ties.

•Waxed lacing cord. You can use this in place of wire ties in pretty much any application. You

can find it here: http://www.skygeek.com/wht-string.html. While expensive, you'll never really

need to buy a wire tie again and it'll likely last you the rest of your life. :)

I'd also recommend a little plastic box with part compartments in it. They're really cheap at

craft stores and are perfect for building a kit like this – you can store all the various fasteners and have

them ready to go as you need them. Here's the one I use for my various projects:

10

Rostock MAX v2 Assembly Guide

2 – isual Bill of Materials

The Rostock MAX v2 kit shipping box should contain the following items:

•Four Melamine laser cut part sheets

•1 Acrylic Parts Package

•1 Power Supply

•1 Hardware Box

If you're planning on painting your Rostock MAX v2, especially the part edges, you would be

well served to carefully trace the outline of each part with a razor knife in order to cut the supporting

masking tape. This way you can retain the protective mask on the parts in order to make painting the

edges easier. Otherwise you'll have to re-apply a mask to avoid getting paint on the Melamine surfaces

of the parts.

11

Fig. 1-1: Shipping box contents.

Rostock MAX v2 Assembly Guide

The Melamine parts are covered with a special cutting mask that prevents the laser cutting

operation from depositing cutting byproducts on the Melamine surface. You'll need to remove all of

this material before beginning construction.

This process is called the Five Stages of Masking Tape.

1. Denial - Oh there's no way I need to scrape all this tape off those parts? Do I?

2. Anger - @#$%@#! This sucks! I've NE ER SEEN SO MUCH TAPE IN

ONE PLACE IN MY LIFE!

3. Bargaining - “Well hi there, Significant Other! Would you PLEASE remove

all this tape for me? PLEASE?”

4. Depression - This tape hates me. *sobs quietly*

5. Acceptance - Well I suppose if I'm ever going to get this thing built, I'd better

get on with it and get all this tape removed...*sigh*

Ok, it's not THAT bad, it just seems like it. It beats having sticky residue all over your nice and

clean Melamine parts. :)

You'll notice that there's a few strips of 2” wide masking to remove as well. This tape holds the

parts in the sheets so they're not damaged during shipping. I recommend removing this tape FIRST.

Take special care when removing the laser cut parts from the sheets. Sometimes the laser

doesn't quite cut all the way through. If you find a part like this, you'll want to gently score the back

side of the sheet along the faint cut line and then press the part out from the front of the sheet. The

front and back of the sheet is easily identifiable – the front of the sheet will have very dark laser cut

lines with “flash” deposits to either side of the laser cut line. The back of the sheet will have much

fainter marks.

12

Rostock MAX v2 Assembly Guide

The white cardboard box will contain the laser cut Acrylic parts that are used in the build.

The Acrylic parts have a paper protective covering on them. Please leave that in place until

you're ready to install them.

The large cardboard box contains the hardware & electronic components required to build the

Rostock MAX v2. Many are in individual baggies, some are in heat-sealed bag “packs”. As you go

through the following Bill of Materials, please count and check off each item. This is important as you

don't want to be short a vital part during the build. It's better to find out before hand than being forced

to stop the assembly process due to a missing part. If you are missing any parts, please contact

[email protected] with the subject line of “Missing Parts!”.

13

Fig. 1-2: Acrylic parts.

Fig 1-3: Hardware & Electronic

co ponents.

Rostock MAX v2 Assembly Guide

For those that aren't sure how to identify the various screw types, Bolt Depot has made available

some excellent references. I would recommend Fastener Basics (http://www.boltdepot.com/fastener-

information/Printable-Tools/Fastener-Basics.pdf) and their Fastener Type Chart

(http://www.boltdepot.com/fastener-information/Type-Chart.aspx).

Let's go ahead and do an inventory of the parts to ensure that you're not missing anything!

Please check off each item as you locate it. Where possible, I'll include the SeeMeCNC part number

enclosed in square brackets. Quantities are surrounded by parentheses.

Hardware Package 1

Rubber foot pack. Contains the following components:

(___) (6) #10-32, 5/8” Nylon Pan Head Screws [29998]

(___) (6) #10-32 Nylon Finish Nuts [30170]

(___) (6) Injection molded feet (black) [17505]

(___) (6) Soft rubber “shoes” [44010]

(___) (9) #10-32, 3/4” Knurled Nylon Thumb Screws. [30172]

These are for the right & left base covers as well as the LCD panel.

(___) (4) #6-32, 1/2” Slotted Pan Head Screws (Nylon). [30121]

These are used to mount the ATX power supply

(___) (31) #6-32, 1” Phillips Pan Head Screws. Used for general

assembly. [30033]

14

Rostock MAX v2 Assembly Guide

(___) (6) #6-32, 5/8” Socket Head Cap Screws. Used for mounting

the U-Joint carrier to the Cheapskate plates. [30006]

(___) (12) #6-32, 1-3/4” Phillips Pan Head Stainless Steel screws.

Used for 608 idlers in the motor mounts as well as the hot end standoffs.

[30034]

(___) (63) #6-32 Stainless Steel Nylon Lock Nut – covers all #6-32

screws. [30164]

(___) (14) #6-32, 2” Phillips Pan Head Stainless Steel screws. Used

for Cheapskate plates and EZStruder mount. [30037]

(___) (15) #6-32, 1/2” 18-8 Stainless Steel Flathead screw. Used inside

of base and top side plates, to retain acrylic panels and the three end-stop

triggering screws installed in the Cheapskate U-Joint mounts. [30135]

(___) (25) #¼-20, 1/2” Stainless Steel Button Head Cap Screws. Used for

tower mounting. [30149]

(___) (25) #¼-20 nut plates. Used for T-Slot mounting. [32005]

15

Rostock MAX v2 Assembly Guide

(___) (10) #4-40 T-Nuts. Used for belt clamps and RAMBo

mounting. [30222]

(___) (4) #4-40, 3/4” Phillips Flat Head Machine screws. Used for

mounting the RAMBo Controller. [30236]

(___) (6) #4-40, 1/2” Stainless Steel Socket Head Cap screws. Used

for the belt clamps. [30232]

(___) (14) #2-56, 5/8” Pan Head Phillips Machine screws. Used for

LCD mounting and end-stop switch mounting. [30650] (Combined

Package)

(___) (14) 2-56 Finish Nuts. Used for LCD mounting and end-stop

switch mounting. [30642] (Combined Package)

(___) 14 each, #4, 3/8” Phillips Pan Head Sheet Metal screws. Used for

LCD sides and tower alignment stops. [30250]

(___) (12) M3x.5, 10mm Pan Head Machine screws. Used for

mounting the stepper motors. [30318]

16

Rostock MAX v2 Assembly Guide

(___) (18) #6 Stainless Steel Flat washers. Used on the 608 bearings

that go in the top & bottom T-Slot rails. [30450]

(___) (6) #4 Stainless Steel Flat washers. Used with the belt clamp

screws. [30449]

(___) (21) 608ZZ Ball Bearings. Used in the Cheapskates and belt

idlers. [35065]

(___) (1) #10-32, 5/8” Socket Head Cap Screw. Used as a tap for the

#10-32 Nylon thumb screws. [29999]

17

Rostock MAX v2 Assembly Guide

Hardware Pack 2

(___) (18) 608 Cheapskate Idler Bearing Spacer. Used for belt idlers.

[68340]

(___) (12) 608 Cheapskate Carriage Bearing Spacers (black). [68326]

(___) (12) 608 Cheapskate Eccentric Bearing Spacers (gray). [68340]

(___) (12) Universal Joints (Injection molded Acetal). [68309]

(___) (6) 3-1/8” Steel Universal Joint axle shafts. [68325]

(___) (3) 1” long machined aluminum hot end platform spacers. [68334]

18

Rostock MAX v2 Assembly Guide

Hardware Pack 3

(___) (20) Plastic Bearing Rollers. 4 are used for mounting the

RAMBo and six are used for the belt clamps. [71505]

(___) (12) Small Wire Ties. Used for wire management or Barbie

Handcuffs. Your call.

(___) (1) GT2 2mm pitch belt pulley pack. Includes six grub screws

and hex wrench. [39835]

(___) (3) Carriage base for U-Joints. [68332]

(___) (1) Effector Platform. [70832]

(___) (6) U-Joint Spring Clips. [87940]

19

Rostock MAX v2 Assembly Guide

(___) (1) 15 Tooth Gear. Used for manually operating extruder motor.

[71566]

(___) (6) Binder Clips. Used to hold the Borosilicate glass build plate to

the Onyx heated bed. [58761]

20

Other manuals for Rostock MAX v2

3

Table of contents

Other SeeMeCNC 3D Printer manuals

SeeMeCNC

SeeMeCNC Rostock Max v3 User manual

SeeMeCNC

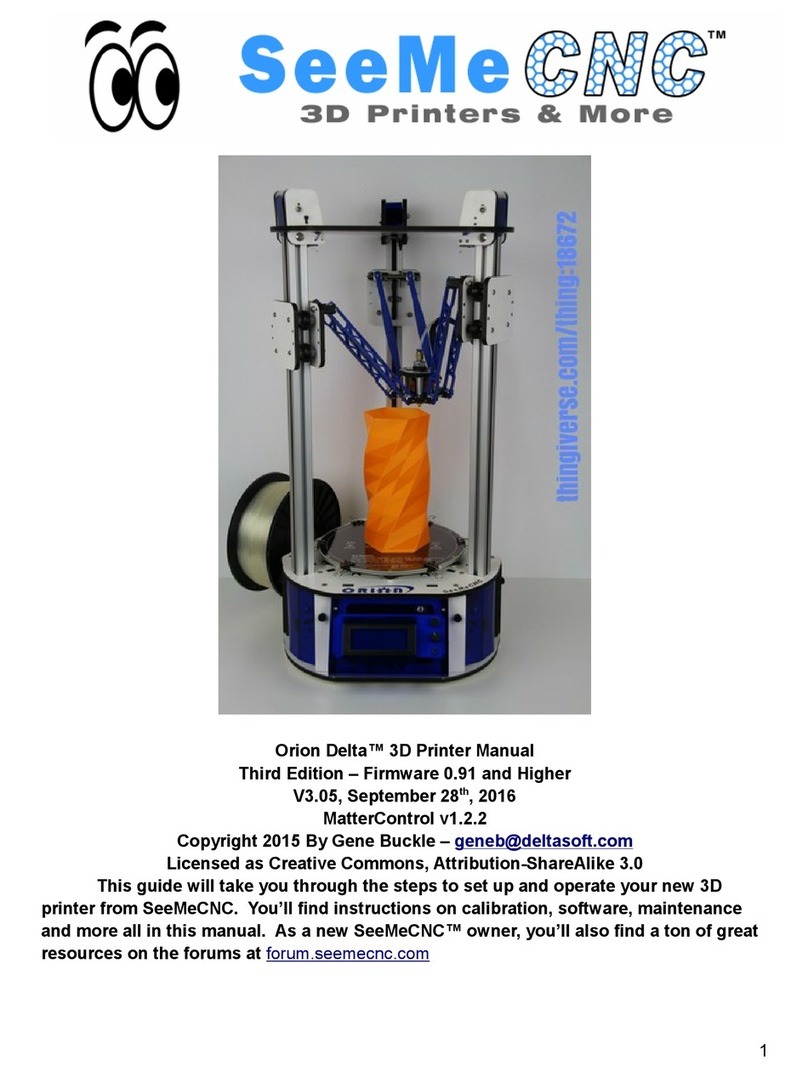

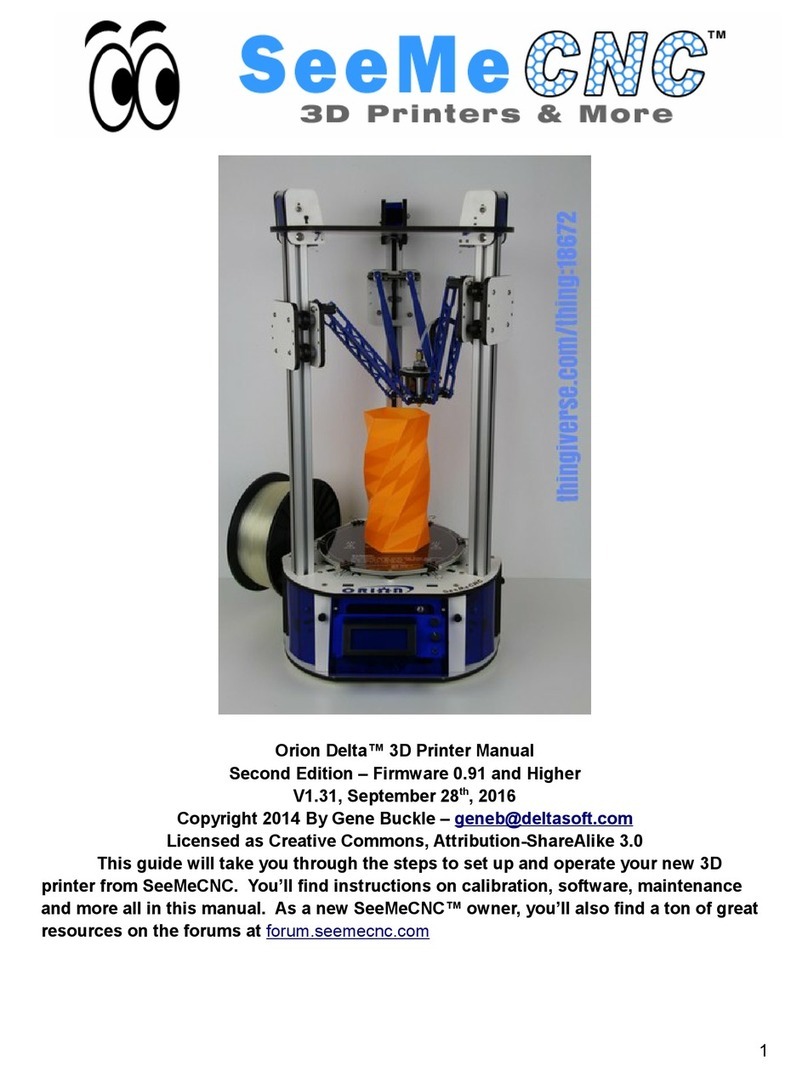

SeeMeCNC orion delta User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC Artemis 300 User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC orion delta User manual

SeeMeCNC

SeeMeCNC Artemis User manual

SeeMeCNC

SeeMeCNC Rostock Max User manual

SeeMeCNC

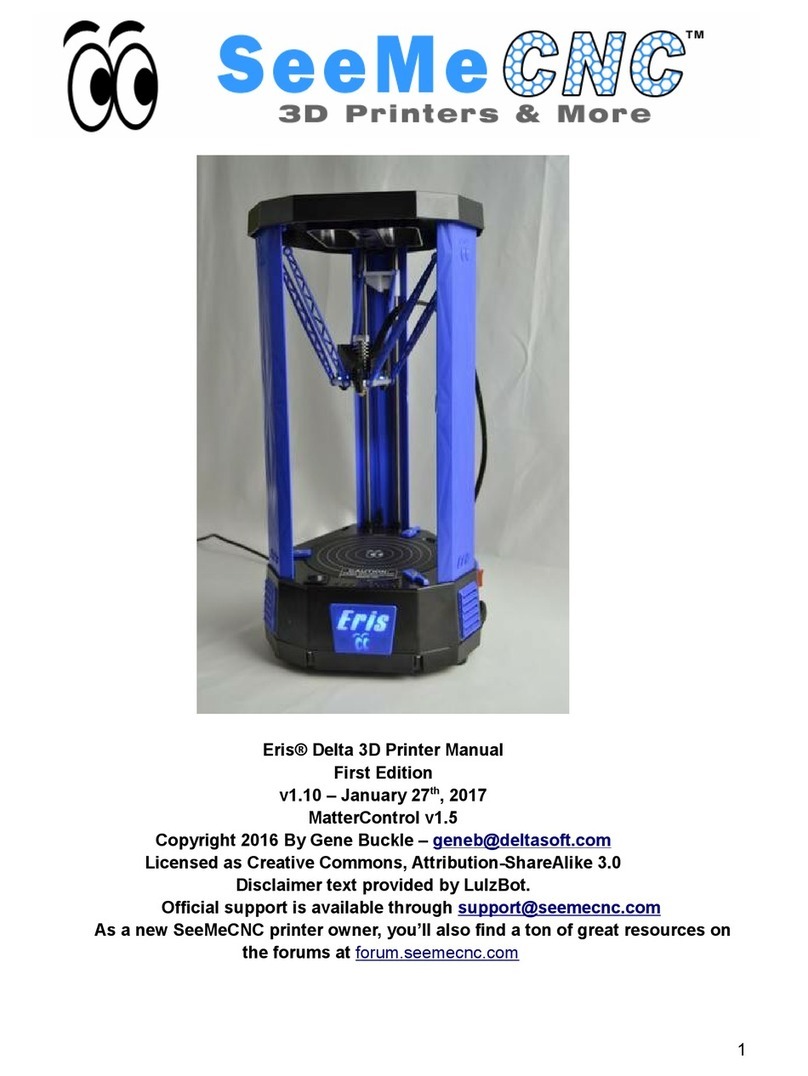

SeeMeCNC ERIS DELTA User manual

SeeMeCNC

SeeMeCNC DropLit User manual