English Espanol Francais

Safety Warnings Avisos de Seguridad Consignes de Sécurité

General Safety Rules

Read and understand all

instructions. Failure to follow

all instructions listed below,

may result in electric shock, fire

and/or serious personal injury.

SAVE THESE

INSTRUCTIONS

Warning!

Keep bystanders, minors, and

visitors away while operating a

power tool. Distractions can

cause you to lose control.

3

DS200-D2

DS200-D4

Warningsfor the safe use of this tool are included in this manual.

Losavisos para el uso seguro de esta herramienta están incluidos

eneste manual.

Lesconsignes pour l’utilisationen toute sécurité de cet outil se

trouventdans ce manuel.

OperatingInstructions

Instruccionesde Operacion

Moded’Emploi

?????

D600-2 D600-4

D600ATT

*SchematicDrawings Inside

©2007byRex Commercial Toolsand Fasteners, LLC

Questions?Comments?Contact: 1.800.396.3318

orvisitour website: www.tyrextools.com

Lea y comprenda todas las

instrucciones. La falta de ob-

servación de todas las instruc-

ciones listadas a continuación

puede causar choque eléctrico,

incendios o lesiones graves.

GUARDE ESTAS

INSTRUCCIONES

Advertencia! Avertissement !

Maintenez votre zone de

travail propre et bien éclai-

rée. Des établis en désordre

et des zones mal éclairées

augmentent les risques

d’accident.

CONSERVEZ CES

INSTRUCTIONS

Mantenga s los acompañantes,

menores y visitas alsjados mien-

tras usted utiliza la herramienta

de motor. Las distracciones

pueden hacer que usted

pierda el control.

Maintenez les spectateurs,

enfants et visiteurs à l’écart

lorsque vous utilisez de

l’outillage électrique. Toute

distraction risque de vous

faire perdre le contrôle de

votre outil.

Stay alert, watch what you are do-

ing, and use common sense when

operating a power tool. Do not

use tool while tired or under the

influence of drugs, alcohol, or med-

ication. A moment of inattention

while operating power tools

may result in serious personal

injury.

Personal Safety

Cuando utilice una herramienta de

motor, manténgase a;erta, preste

atención a lo que está haciendo y

aplique el sentido común. No use

la herramienta cuando se sienta

cansado o se encuentre bajo los

efectos de drogas, alchol o medi-

camentos. Un momento de falta

de atención mientras utiliza una

herramienta de motor puede

ocasionar lesiones graves.

Seguridad personal

Soyez en bonne condition phy-

sique, soyez attentif à ce que vous

faites et faites preuve de bon sens

lorsque vous utilisez un outillage

électrique. N’utilisez pas votre

outil si vous êtes fatigué ou sous

l’influence de drogues, alcool

ou médicaments. Un moment

d’inattention lors de l’utilisation

d’un outillage électrique peut

être la cause de graves bles-

sures corporelles.

Sécurité corporelle

Do not overreach. Keep

proper footing and balance

at all times. Proper footing

and balance enable better

control of the tool in unex-

pected situations.

No se estire para trabajar.

Mantenga en todo momento

una posición adecuada y

el equilibrio. La posición y

el equilibrio adecuados le

permiten contrilar mejor la

herramienta ante situaciones

inesperadas.

Ne présumez pas de vos

forces. Restez bien stable et

en équilibre à tout moment.

Une position stable et bien

équilibrée vous permettra de

mieux réagir à une situation

inattendue.

Use safety equipment.

Always wear eye protec-

tion. Dust mask, non-skid safety

shoes, hard hat, or hearing protec-

tion must be used for appropriate

conditions. Failure to do so could

result in personal injury.

Use equip de seguridad.

Use siempre protección

para los ojos. A fin de trabajar

en las condiviones apropiadas,

debe usar máscara para polvo,

calzado de seguridad antidesli-

zante, casco duro o protección

para los oídos. El no utilizar

estos elementos puede ocasionar

lesiones.

Utilisez des équipements de

sécurité. Portez toujours des

lunettes de protection. Utilisez

un masque de protection contre la

poussière, des chaussures antidéra-

pantes, un casque et des protections

auditives pour travailler dans les meil-

leures conditions. Un manquement à

ces règles de sécurité peut provoquer

des accidents corporels.

Tool service must be

performed only by

Authorized Senco repair

personnel. Service or

maintenance performed by

unqualified personnel may

result in a risk of injury.

Service Servicio técnico

L’entretien de l’outil ne

doit être assuré que par du

personnel autorisé et qualifié

de Senco . De l’entretien assuré

ou des réparations effectuées

par du personnel non qualifié

peuvent occasionner des

risques d’accident.

Entretien

Las tareas de servicio técnico

de la herramienta deben ser

realizadas sólo por personal

de reparaciones de Senco

autorizado. Las tareas de

servicio o mantenimiento

realizadas por personal no

clificado purden ocasionar

riesgos de lesiones.

Authorized

Service Center

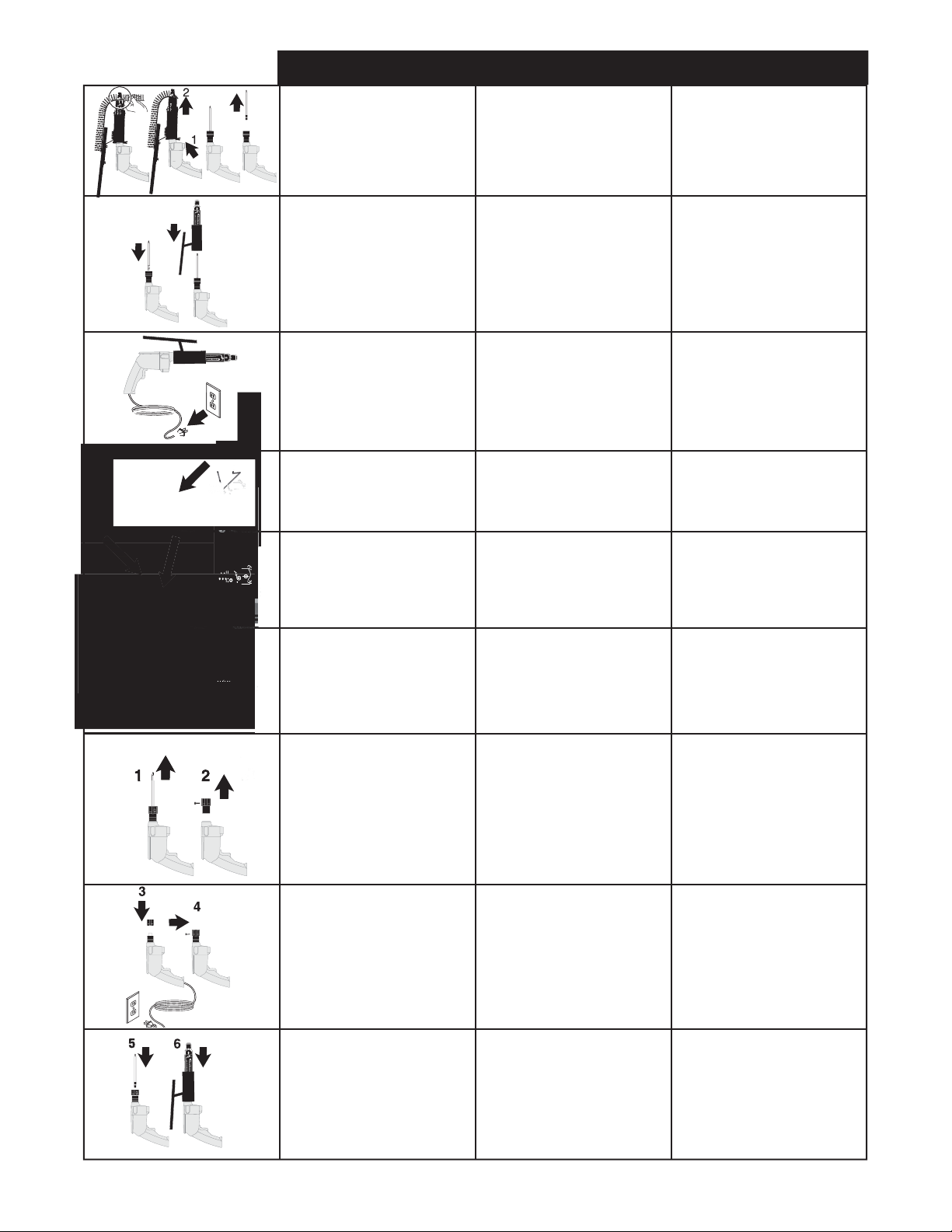

Loading the Tool:

Check to be sure the heads

of the screws are resting on

top of the plastic collation

material. This will prevent

damage to the strip guide.

Carga de la herramienta:

Asegúrese de que las cabezas

de los tornillos descansen

contra el material plástico de

intercalación. De este modo,

se evitarán daños a la guía de

la faja.

Chargement de l’outil :

Vérifiez que les têtes des vis

reposent bien sur le sommet de

la bande collectrice en plastique

pour éviter d’endommager le

guide.