6

OPERATION

3.1 SPECIFIC SAFETY INSTRUCTIONS

●Before starting work, make sure that the safety and trig-

ger devices are working perfectly and that all screws and

nutsarermlytightened.

●Do not manipulate the stapler in any way.

●Do not dismantle or block any part of the stapler. This ap-

plies in particular to the trigger safety mechanism!

●Do not perform any „emergency repairs“ using inappropri-

ate methods.

●Ensure that the stapler undergoes regular and proper

maintenance.

●Avoid any weakening or damage to the stapler, e.g. from

- knocking or engraving

-modicationworknotauthorisedbythemanufacturer

- working on templates made of hard material (e.g. steel)

-droppingorpushingovertheoor

- using it as a hammer

- any type of violent force.

3.2 CONNECTION TO THE COMPRESSED AIR SUPPLY

3.2.1 Requirements for the compressed air supply

Toensurethatthestapleroperates,perfectlyltered,dry,

oiledcompressedpressureisrequiredinsufcientquan-

tities (see chap. 1.2, „Technical data“). Observe the fol-

lowing points when selecting the compressed air supply:

●If the pressure in the supply network is higher than the

permissible operational pressure of the stapler (8.3

bar), an additional pressure control valve (pressure

regulator) with a downstream pressure control valve

must be installed in the supply line.

●When compressed air is generated by a compres-

sor the natural atmospheric humidity condenses. This

condensation must be removed by a moisture trap.

Otherwise corrosion can begin in the compressed air

system and in the stapler and cause wear and tear.

●Permanently installed lines for the compressed air

system should have an internal diameter of at least 19

mm. The hose connection to the stapler should have an

internal diameter of at least 8 mm.

●Compressed air lines should be laid with a downward

slope from the compressor to the consumer.

●Terminals for consumers should be connected to the

upper side of permanently installed compressed air

lines.

3.2.2 Lubrication

If there is no maintenance unit, oil the air inlet on the

stapler with SENCO pneumatic oil; under normal op-

erational conditions 5-10 drops twice daily is enough.

3.2.3 Connection

To connect the stapler to the compressed air supply

carry out the following steps:

1. Ensure that the pressure in the compressed air system

does not exceed the permissible operational pressure

of the stapler (8.3 bar).

2. Set the air pressure at the lowest level of the recom-

mendedoperationalpressure(6bar).

3. Empty the magazine to avoid a staple from being eject-

ed in the following steps. This could happen if parts of

the stapler are not in the starting position due to previ-

ous maintenance or repair work or due to transport.

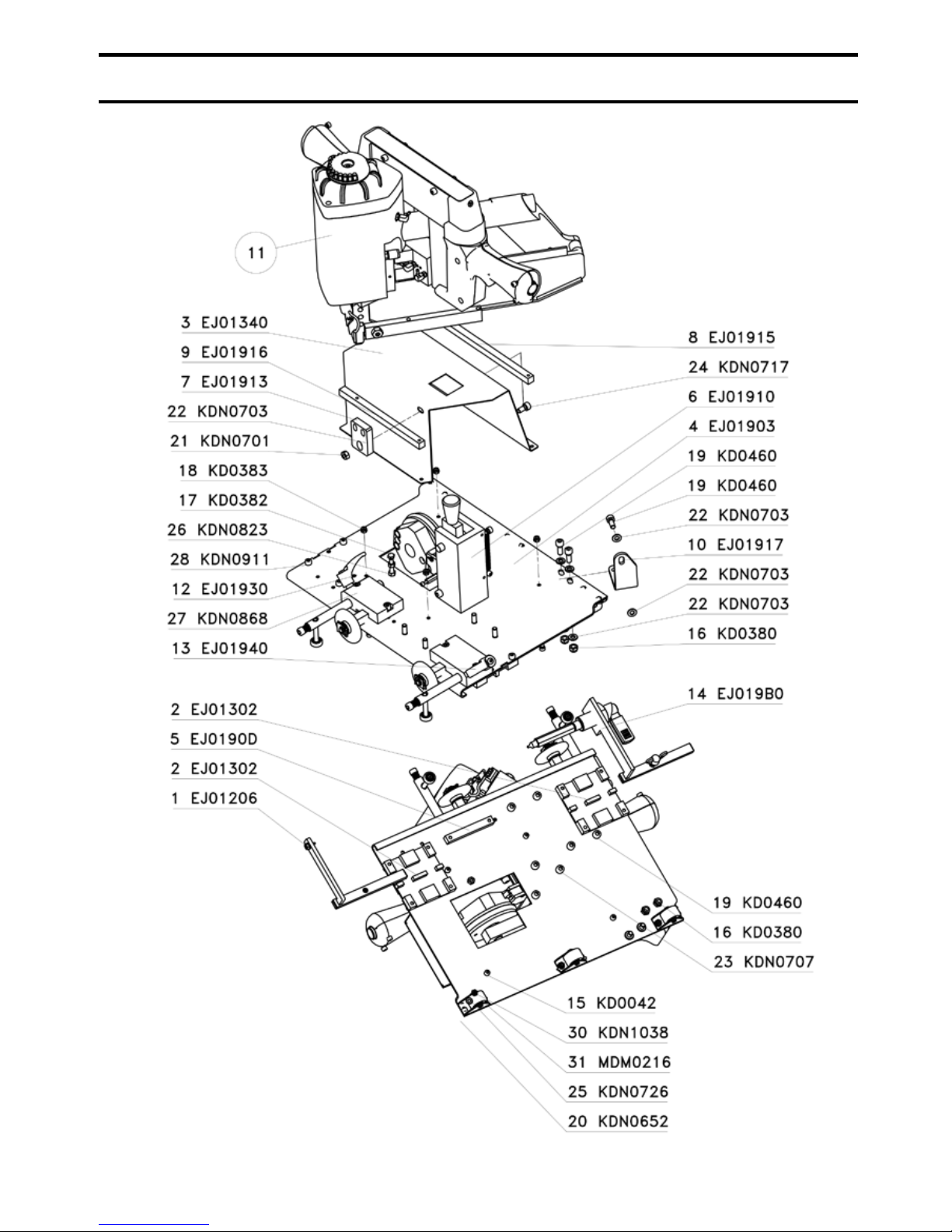

4. Connect the connecting nipple (11) on the stapler to

the compressed air supply using a hose connection

equipped with quick connectors.

5. Make sure the stapler is working perfectly.

To do this, place the outlet on a piece of wood or wood-

work.

- Now pull the stapler towards you without activating the

trigger. The system should not be set off.

- Repeat the process with an activated trigger. The sys-

tem should now be set off at regular intervals.

3.3 FILLING THE MAGAZINE

DANGER

IF INCORRECT STAPLES ARE USED, SAFE OPERA-

TION CANNOT BE GUARANTEED. FOR THIS REASON

YOU SHOULD ONLY USE STAPLES APPROVED BY

THE MANUFACTURER (SEE CHAP. 1.2, „TECHNICAL

DATA“).

Tollthemagazinecarryoutthefollowingsteps:

1. Disconnect the system from the compressed air supply.

2. Pull the staple slide so far back that the rest snaps into

place.

3. Place the staple block with the tips facing down into the

magazine.

4. Unlock the staple slide by pressing on the rest. Let the

staple slide glide forward.

5. Reconnect the compressed air supply.

To empty the magazine, repeat the procedure in reverse.

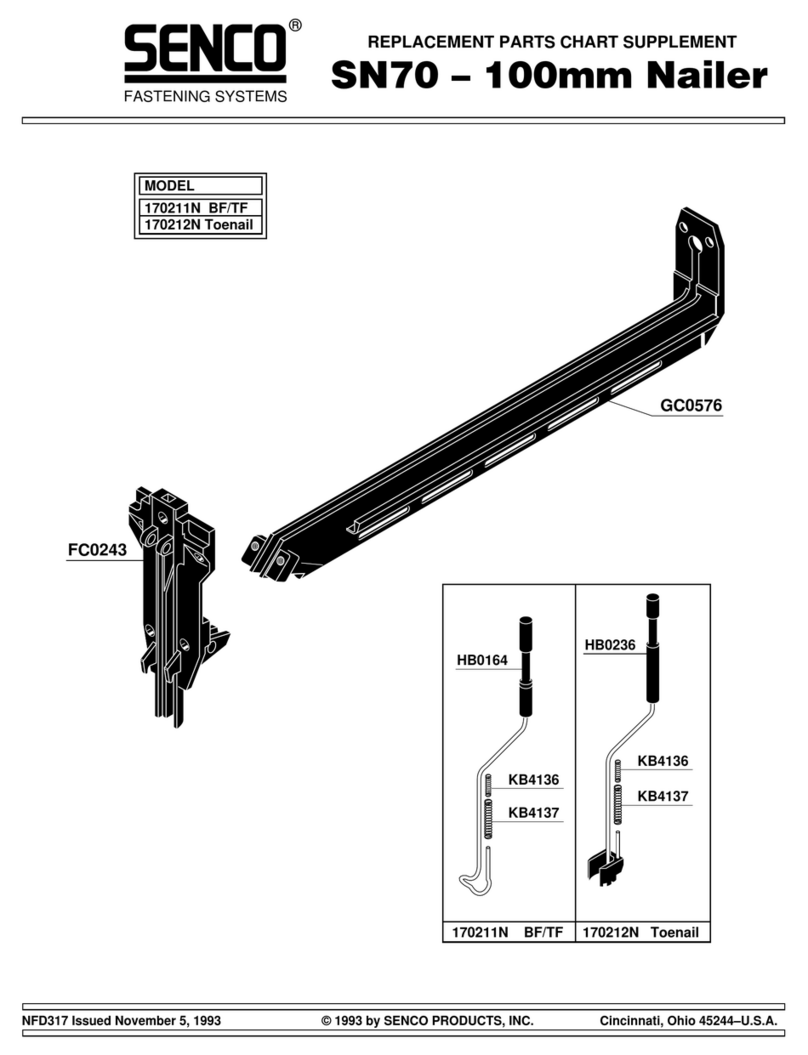

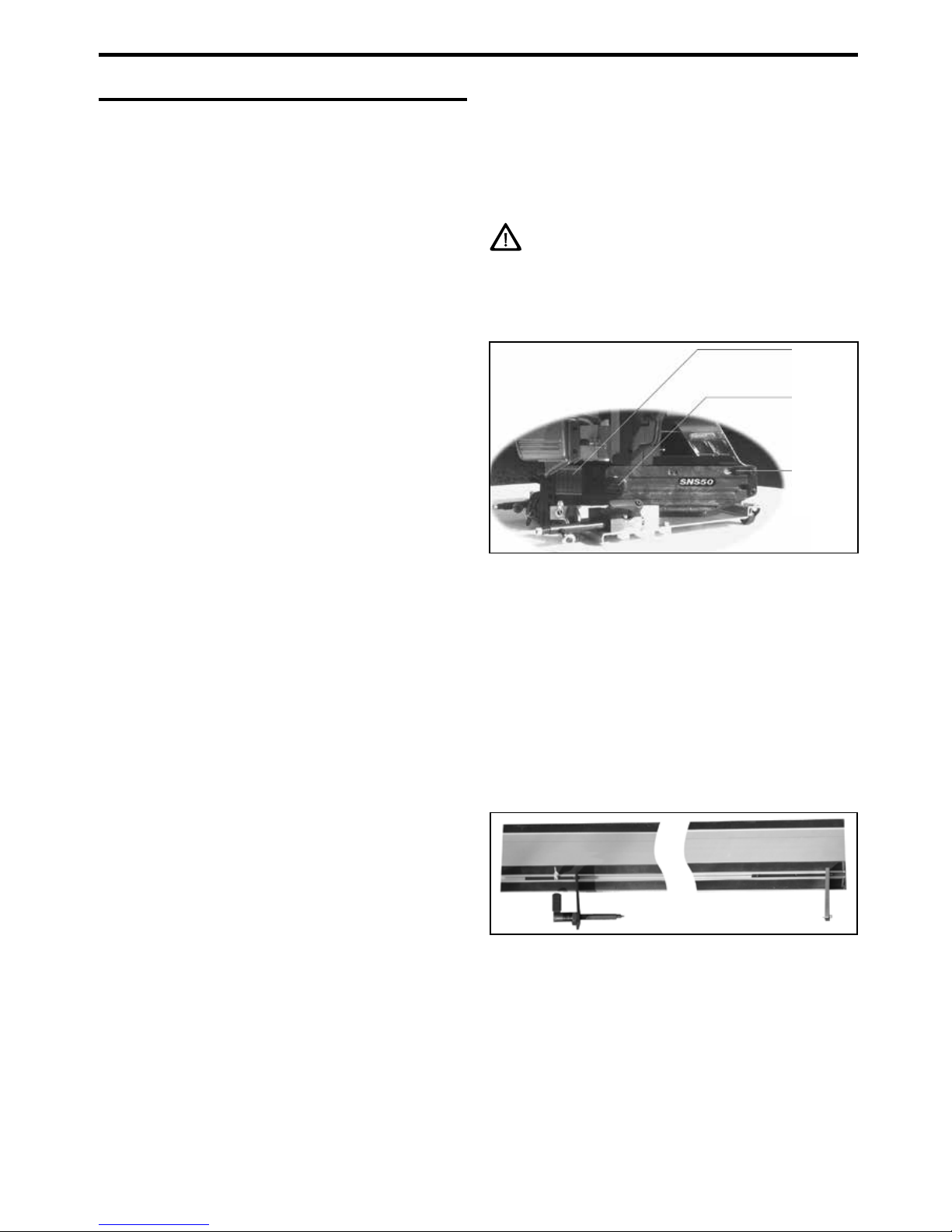

Staple

supply

Staple

slide

(closed)

Rest for

staple

slide

llustration 3.3/1: Filling the magazine

3.4 HANDLING DURING OPERATION

3.4.1 Operation with guide rails

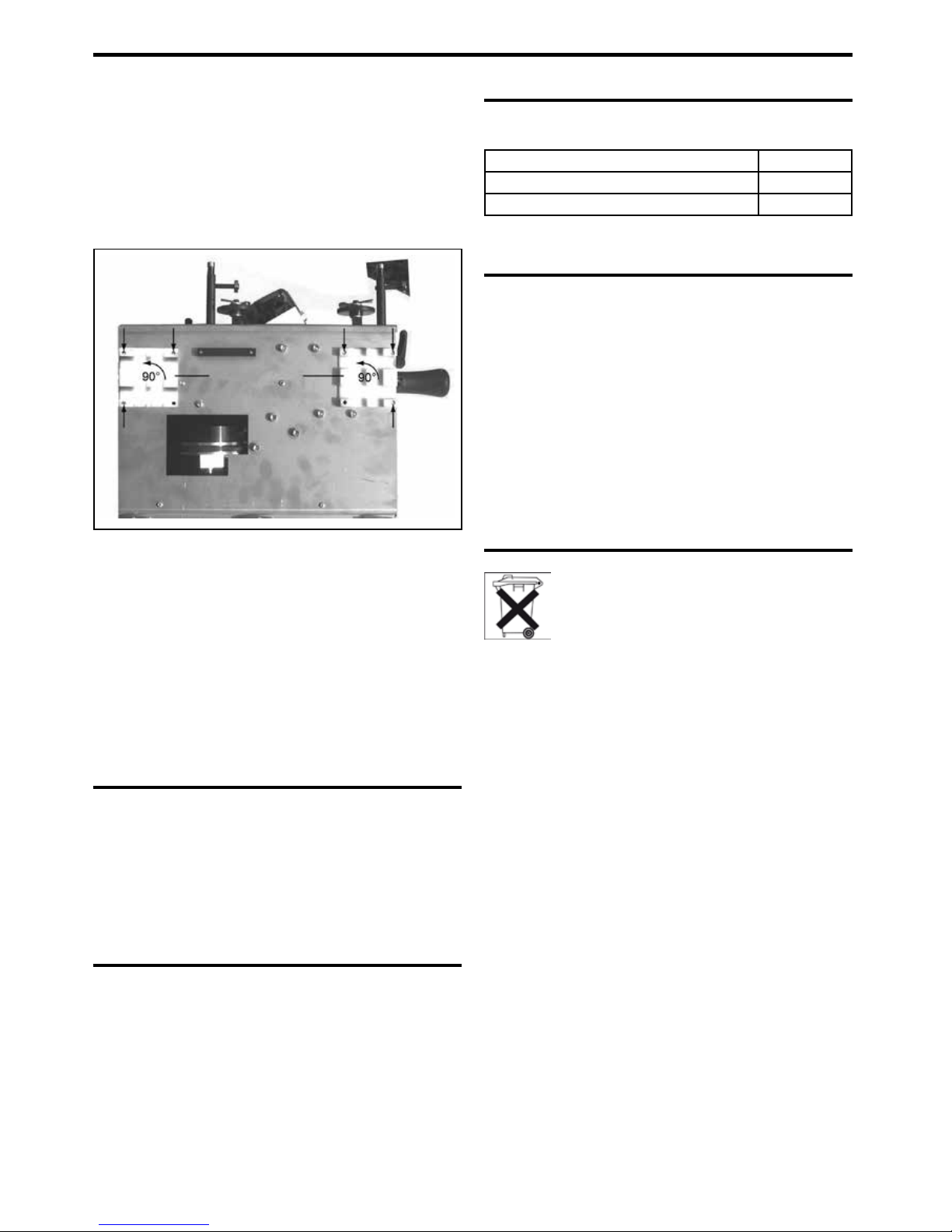

Illustration 3.4.1/1: Guide rails with mounted clamping

arms (view from below)

To use the stapler with guide rails, carry out the following

steps:

1. First, mount the supplied limit stops on the guide rails.

Thexedlimitstop(ontherightinillustration3.4.1/1)

isxedusingelasticity.Pushthetensilelimitstopinto

the guide rails in such a way that it lies in the joint of the

panel to be processed.