CARLO GAVAZZI CD34CNFLF Series User manual

Other CARLO GAVAZZI Accessories manuals

CARLO GAVAZZI

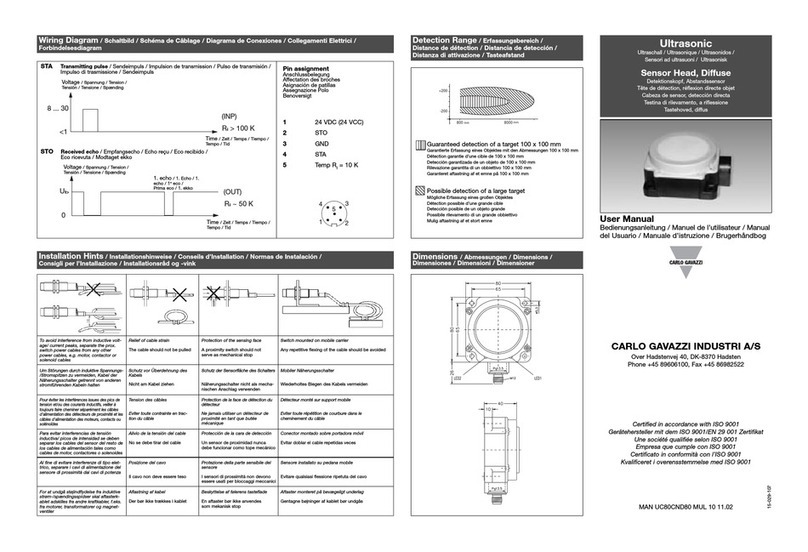

CARLO GAVAZZI UC80CND80 User manual

CARLO GAVAZZI

CARLO GAVAZZI PD30CTP/R BP IO Series User manual

CARLO GAVAZZI

CARLO GAVAZZI SBPSMWBAT User manual

CARLO GAVAZZI

CARLO GAVAZZI PD30CTB BP Series User manual

CARLO GAVAZZI

CARLO GAVAZZI SBPSUSL45 User manual

CARLO GAVAZZI

CARLO GAVAZZI SBPBASEA User manual

CARLO GAVAZZI

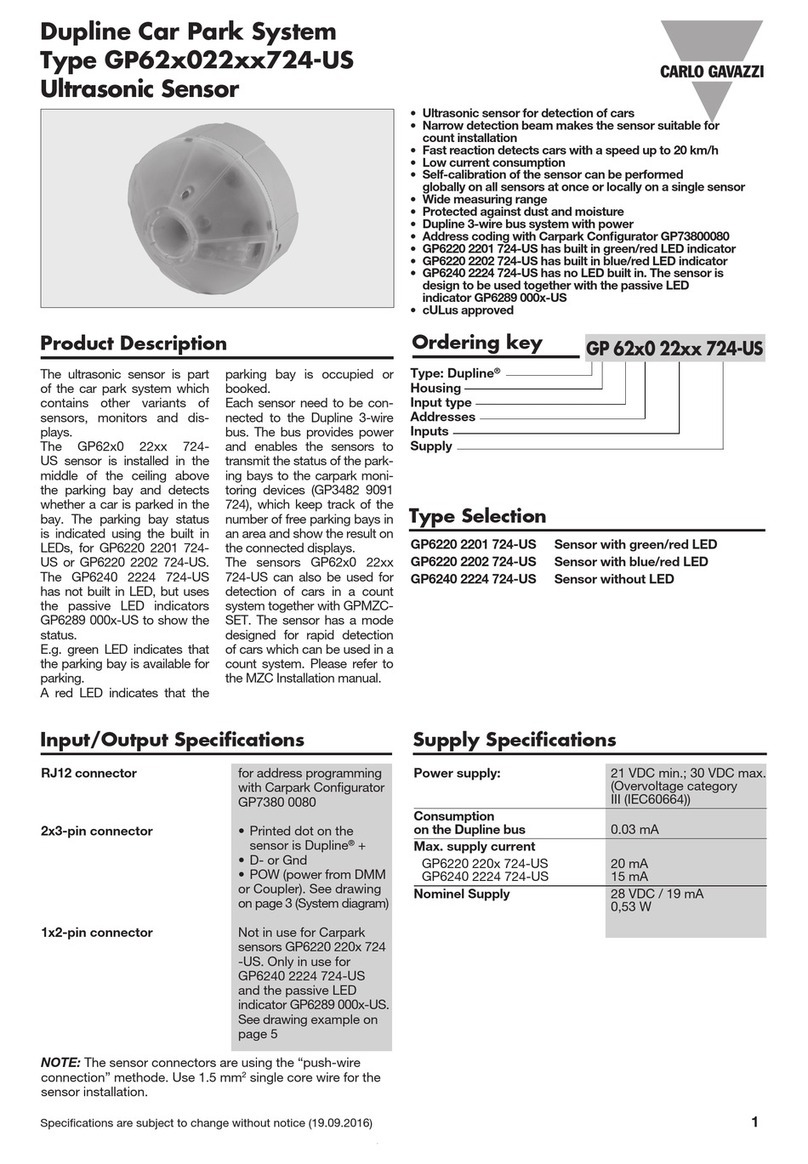

CARLO GAVAZZI GP62x022xx724-US Series User manual

CARLO GAVAZZI

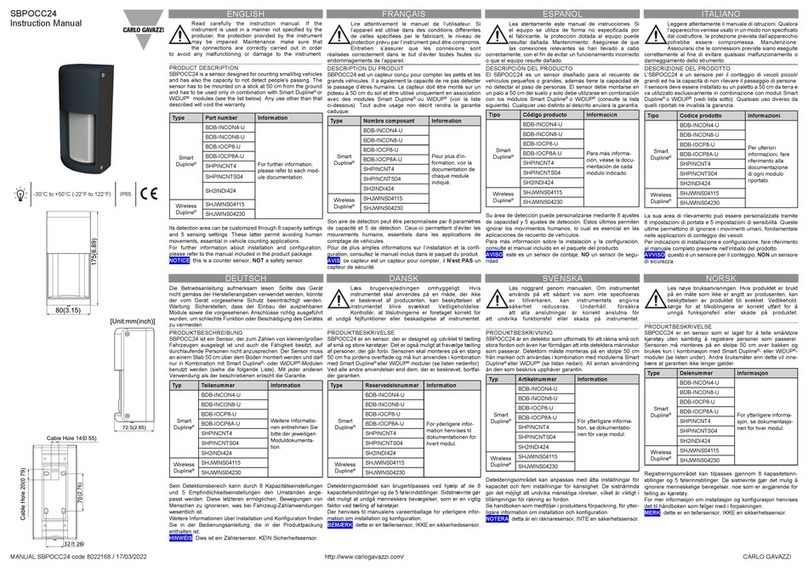

CARLO GAVAZZI SBPOCC24 User manual

CARLO GAVAZZI

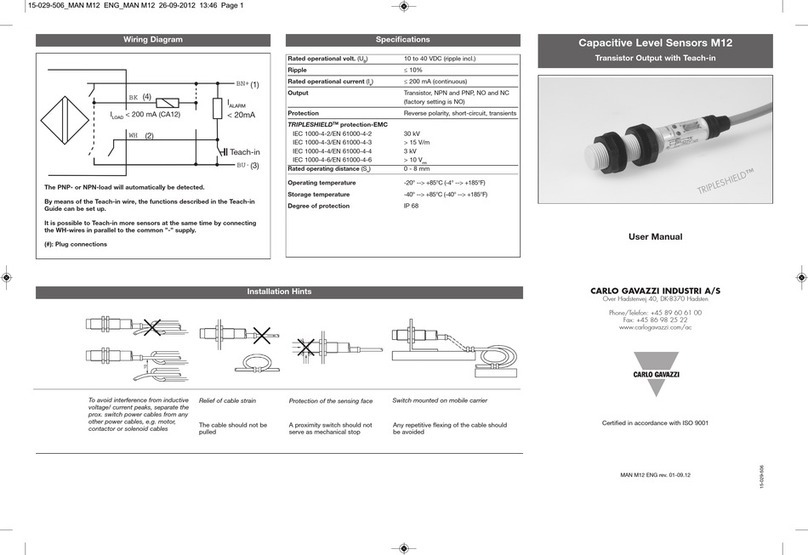

CARLO GAVAZZI M12 User manual

CARLO GAVAZZI

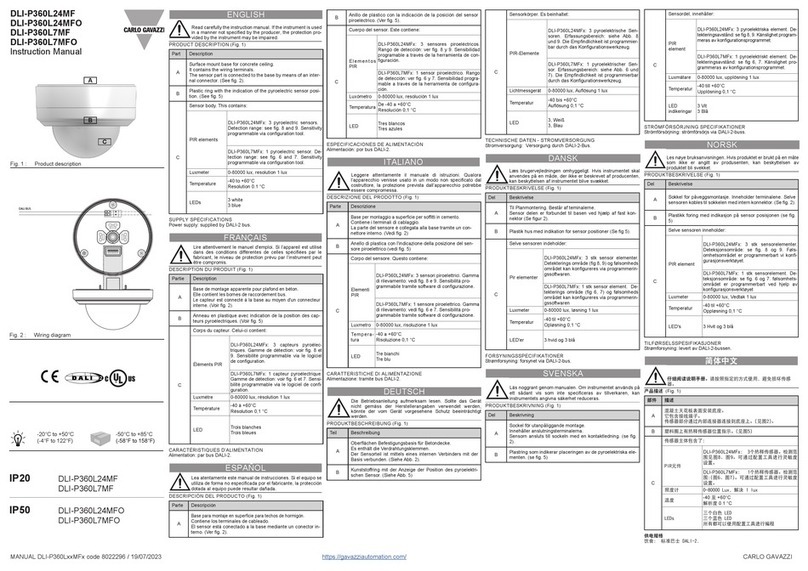

CARLO GAVAZZI DLI-P360L M Series User manual

CARLO GAVAZZI

CARLO GAVAZZI ROG400 User manual

CARLO GAVAZZI

CARLO GAVAZZI MC36C User manual

CARLO GAVAZZI

CARLO GAVAZZI PD140 User manual

CARLO GAVAZZI

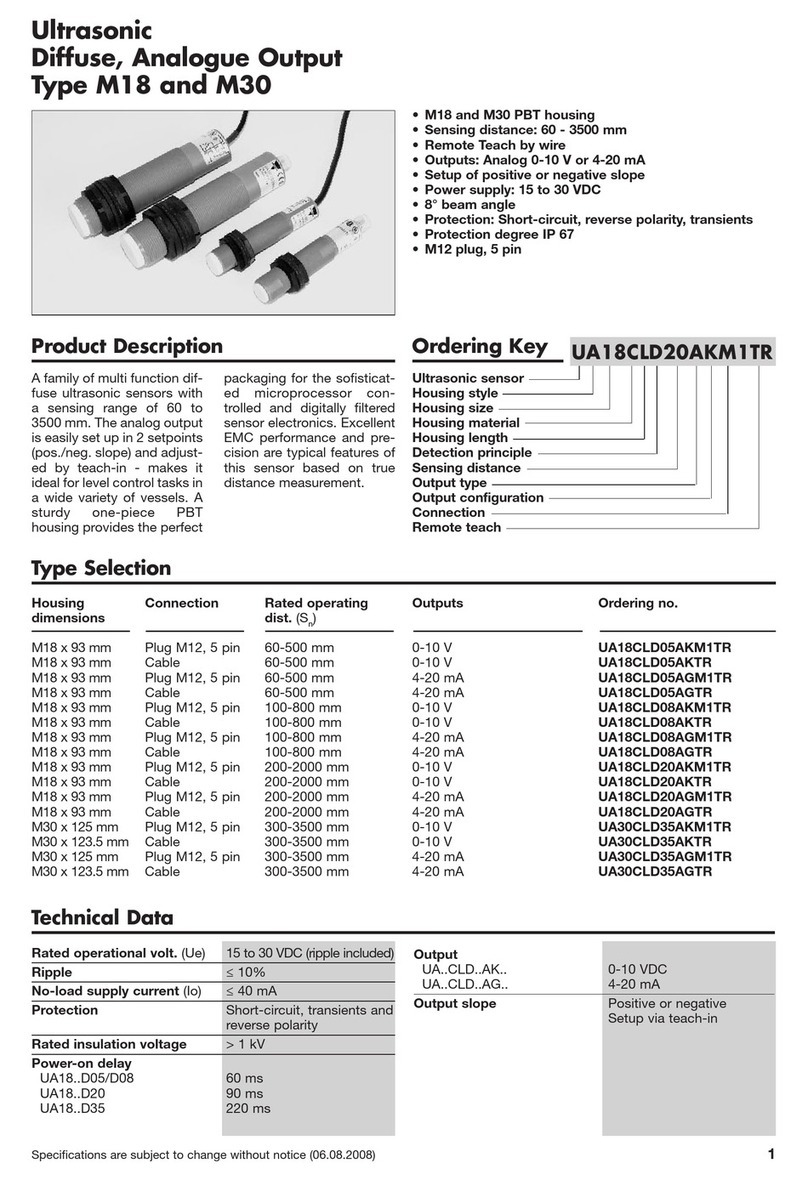

CARLO GAVAZZI UA 30 CLD User manual

CARLO GAVAZZI

CARLO GAVAZZI DLI-P360L24MF User manual

CARLO GAVAZZI

CARLO GAVAZZI SMS Series User manual

CARLO GAVAZZI

CARLO GAVAZZI LD30 BI10BP IO Series User manual

CARLO GAVAZZI

CARLO GAVAZZI SBPSUSL45 User manual

CARLO GAVAZZI

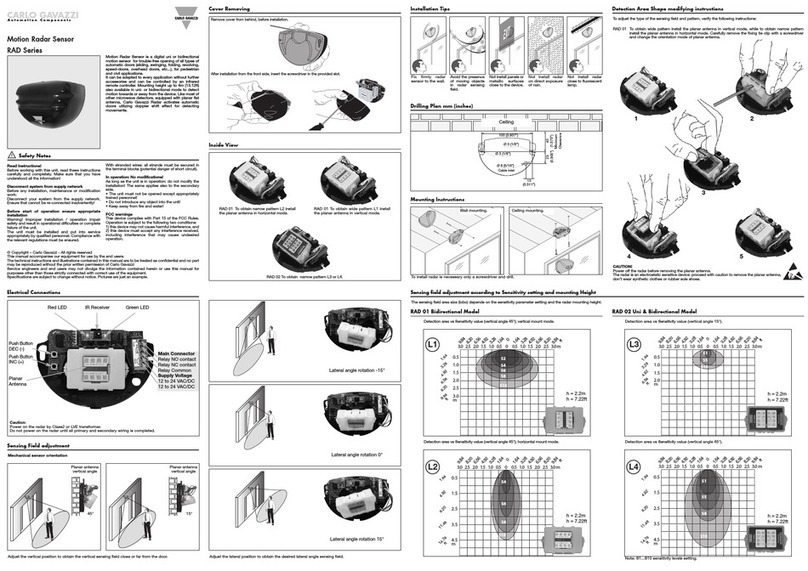

CARLO GAVAZZI RAD User manual

CARLO GAVAZZI

CARLO GAVAZZI CD34 User manual