SFA Saniflo Sanicubic 2 User manual

Other SFA Plumbing Product manuals

SFA

SFA Sanifloor+ 4 wedi User manual

SFA

SFA SANIPACK User manual

SFA

SFA SANICUBIC 2 GR User manual

SFA

SFA SANIPLUS User manual

SFA

SFA SANISUB Manual

SFA

SFA SANIPACK User manual

SFA

SFA SANIBROYEUR PRO User manual

SFA

SFA SANICUBIC 1 User manual

SFA

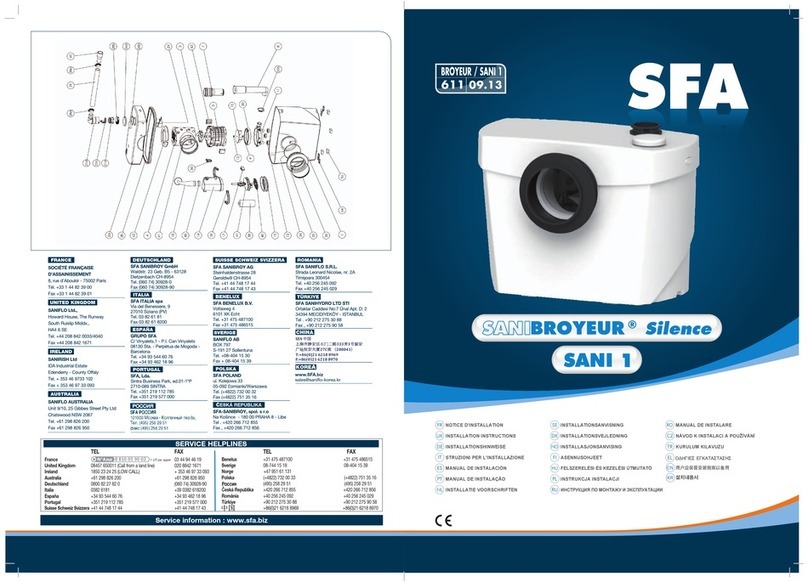

SFA SANIBROYEUR Silence SANI 1 User manual

SFA

SFA Saniflo Sanicom 2 User manual

SFA

SFA Sanisan Series User manual

SFA

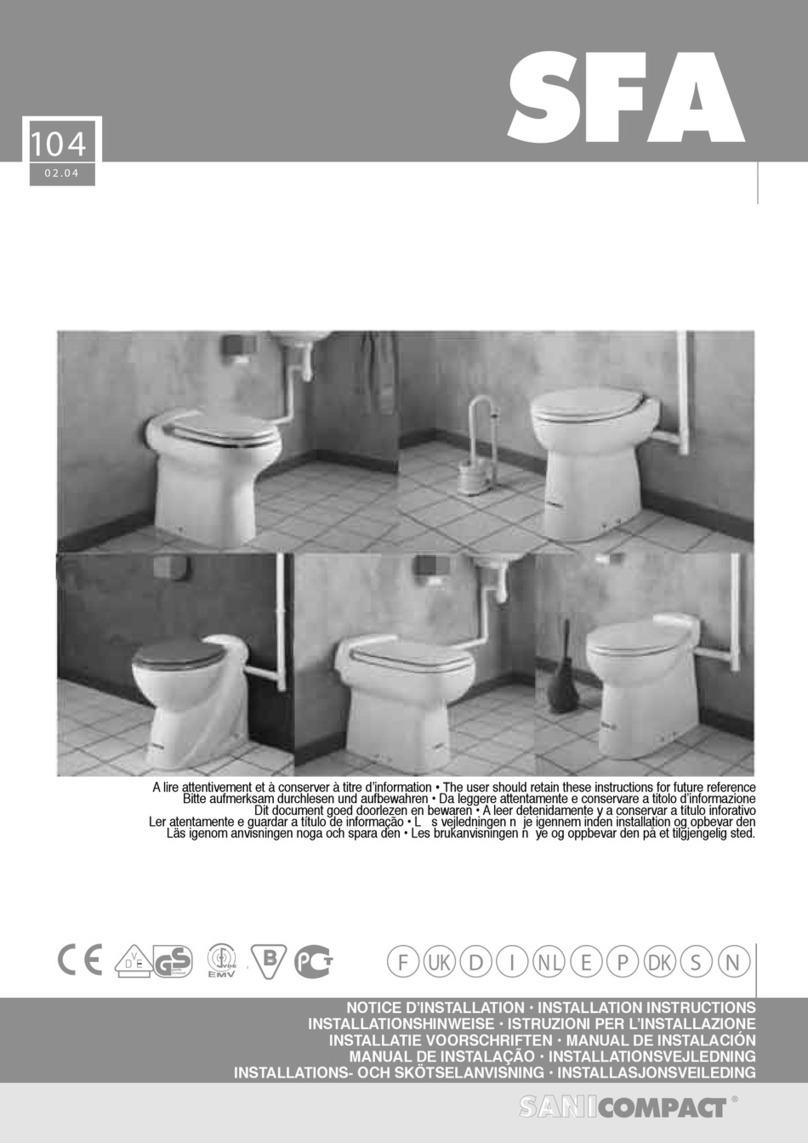

SFA SANICOMPACT LUXE C3 User manual

SFA

SFA NOT500 User manual

SFA

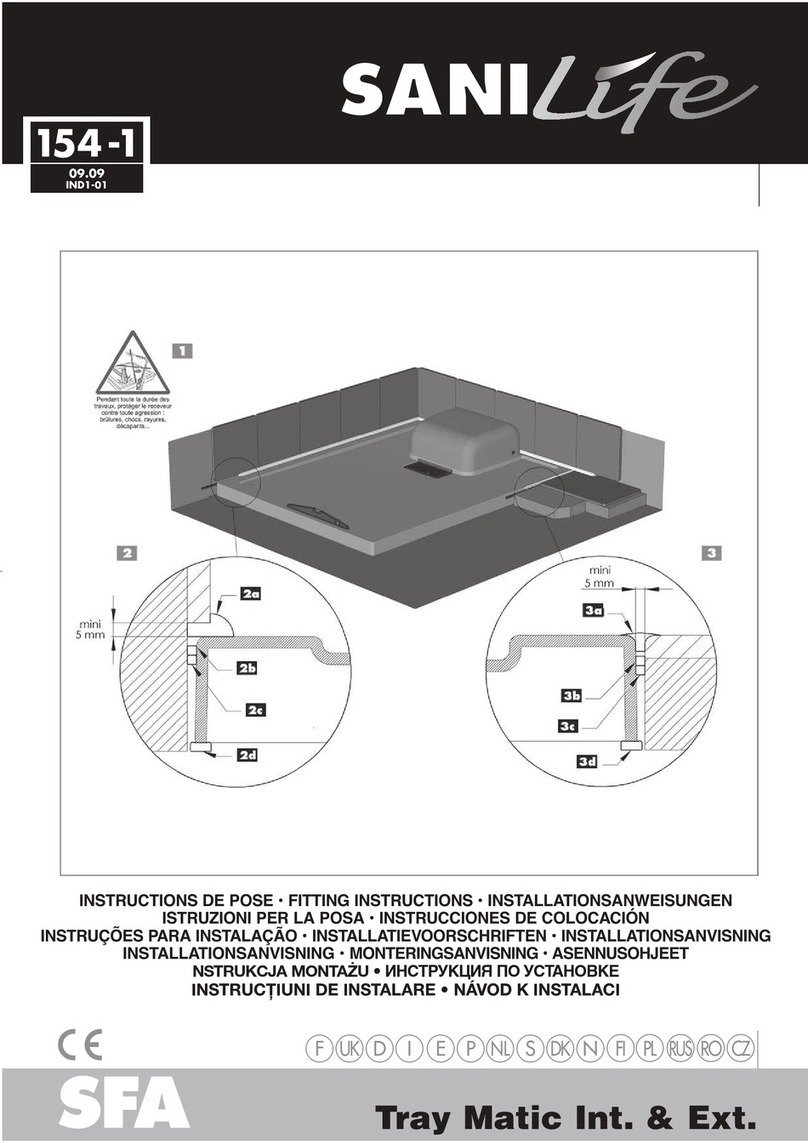

SFA SaniLife 154-1 User manual

SFA

SFA SANI 2 User manual

SFA

SFA SANICUBIC 1 User manual

SFA

SFA SANIPACK P30 User manual

SFA

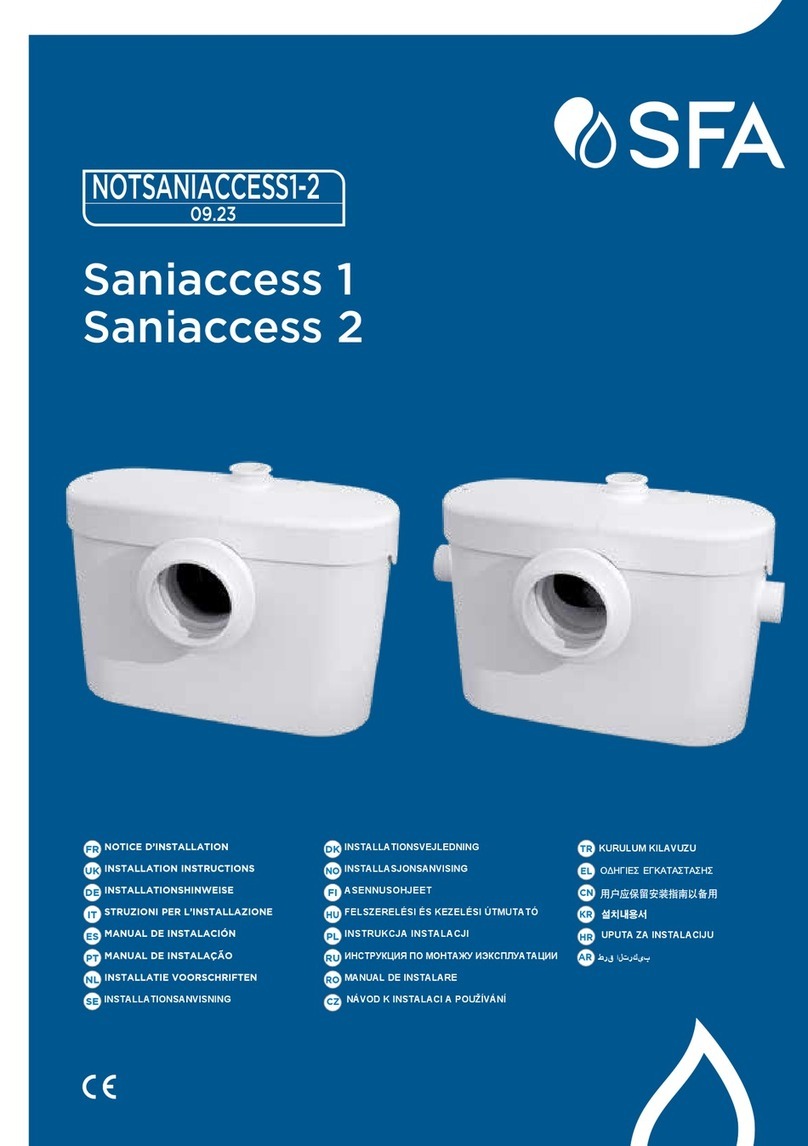

SFA SANIACCESS 1 User manual

SFA

SFA SANI 3 User manual

SFA

SFA Kinedo Smart Design C90 User manual

Popular Plumbing Product manuals by other brands

Franke

Franke SIRIUS ZSIRX0040 Installation and operating instructions

Hans Grohe

Hans Grohe Talis N 220 U-Style 1Jet 72806 1 Series Installation/User Instructions/Warranty

Mustee

Mustee 3739 installation instructions

T&S

T&S B-0291 Series Installation and maintenance instructions

Blanco

Blanco drink.filter EVOL-S Pro user manual

baliv

baliv WT-300 manual

Clou

Clou Freddo 10 CL/06.03014 installation instructions

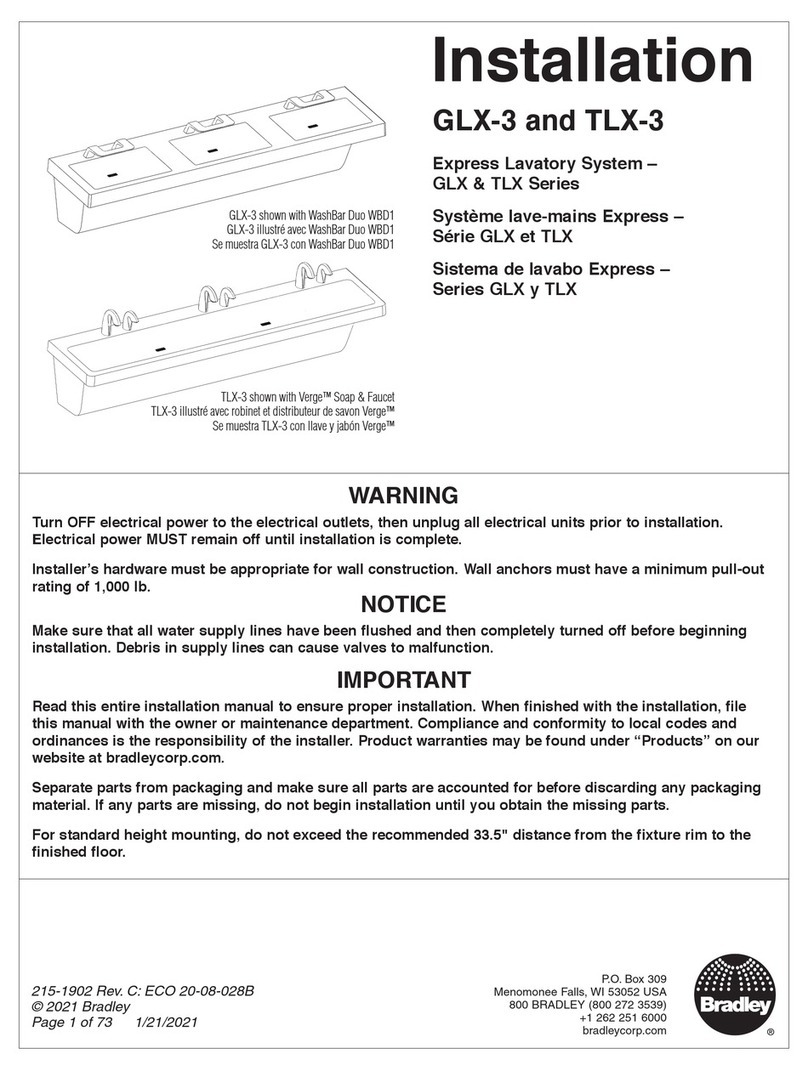

Bradley

Bradley S53-325 Installation

Moen

Moen 82912 Series Specifications

Sanela

Sanela SLU 60B Instructions for use

Bossini

Bossini Mixer Set E37 Instructions for installation, operation and maintenance

Helvex

Helvex Europeo EP-2001 installation guide