SFA Sanifast ZH190 Manual

Other SFA Water Pump manuals

SFA

SFA SANISUB 400 Manual

SFA

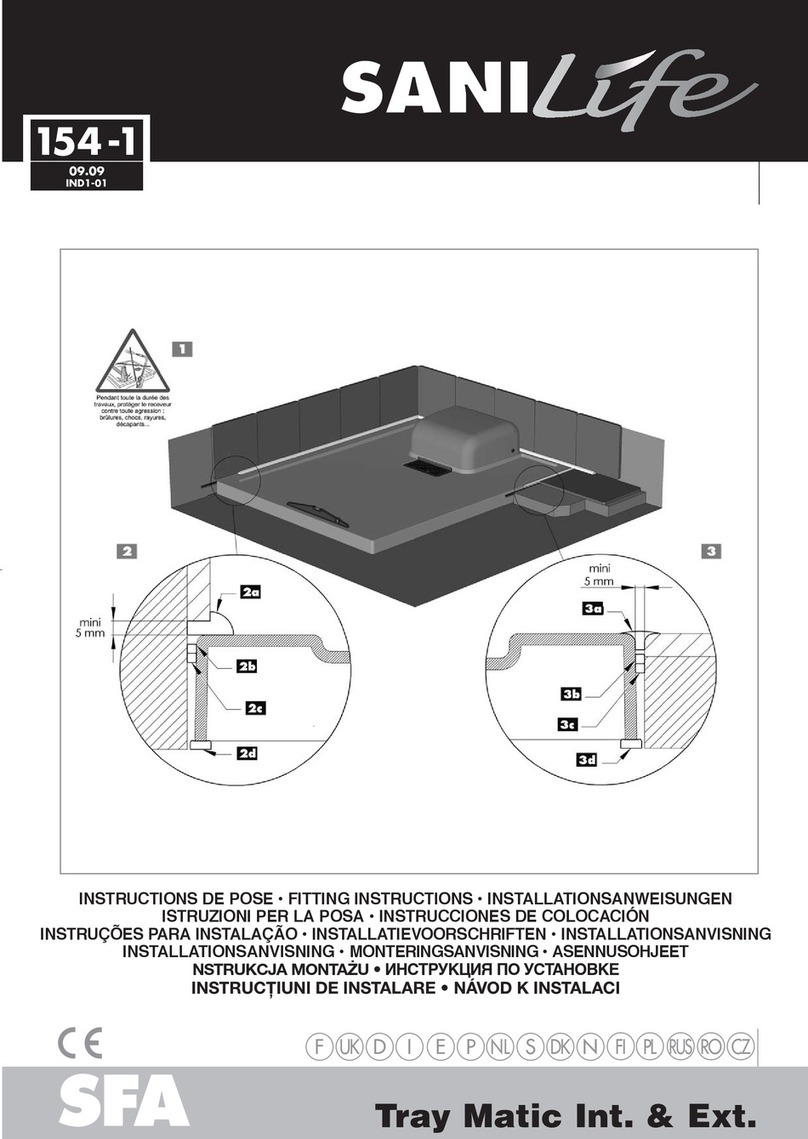

SFA SANILife Tray Matic User manual

SFA

SFA Sanipro XR User manual

SFA

SFA SANICOM 1 Manual

SFA

SFA SANICONDENS CLIM MINI User manual

SFA

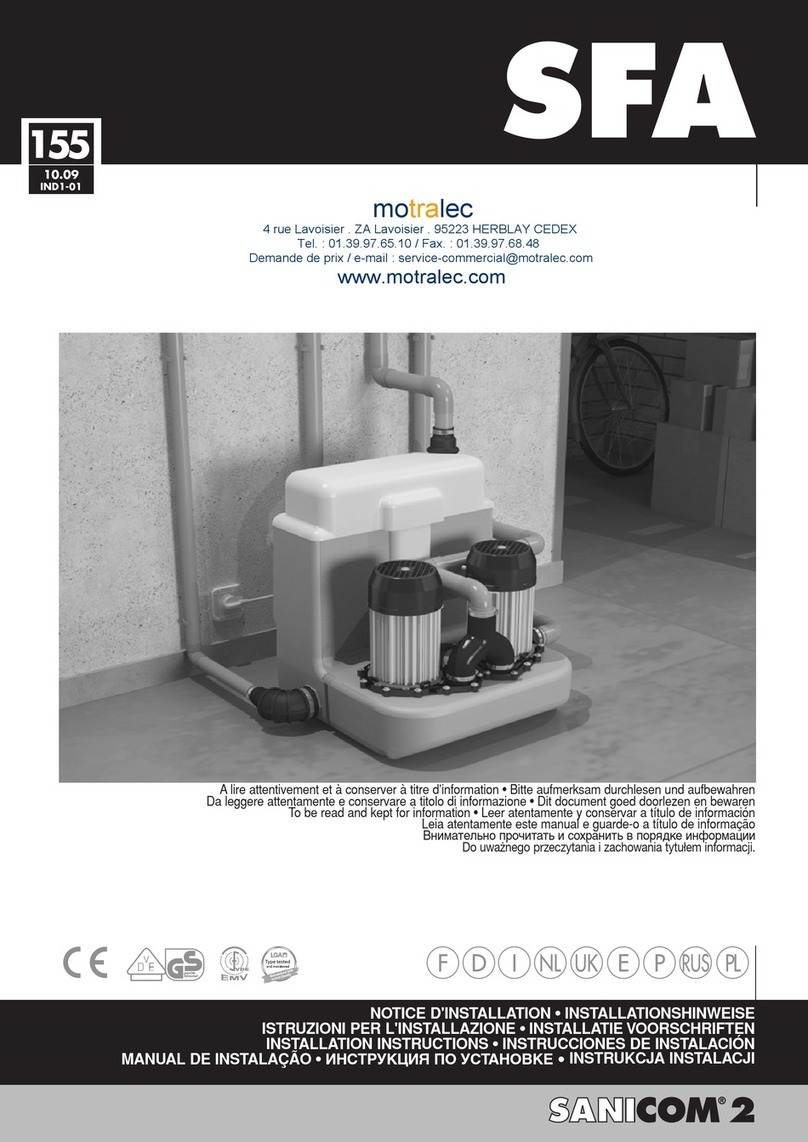

SFA SANICOM 2 User manual

SFA

SFA SANITOP Operation manual

SFA

SFA SANICUBIC SC Series User manual

SFA

SFA SANICUBIC AL02-R90 User manual

SFA

SFA SANICOM 1 Manual

SFA

SFA SANICONDENS Best Manual

SFA

SFA Sanipump SLD 700 S Manual

SFA

SFA Sanicondens Clim Deco User manual

SFA

SFA SANIBROYEUR PRO User manual

SFA

SFA SANIACCESS User manual

SFA

SFA SANIACCESS3 User manual

SFA

SFA SANIMARIN User manual

SFA

SFA SANIACCESS 1 User manual

SFA

SFA SaniPump Manual

SFA

SFA SANISUB 400 Manual

Popular Water Pump manuals by other brands

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS T4A61S-B Installation, operation, and maintenance manual with parts list

Wilden

Wilden Turbo-Flo T8 Engineering, operation & maintenance

Allfett

Allfett ALL-600 Product Introduction and user manual

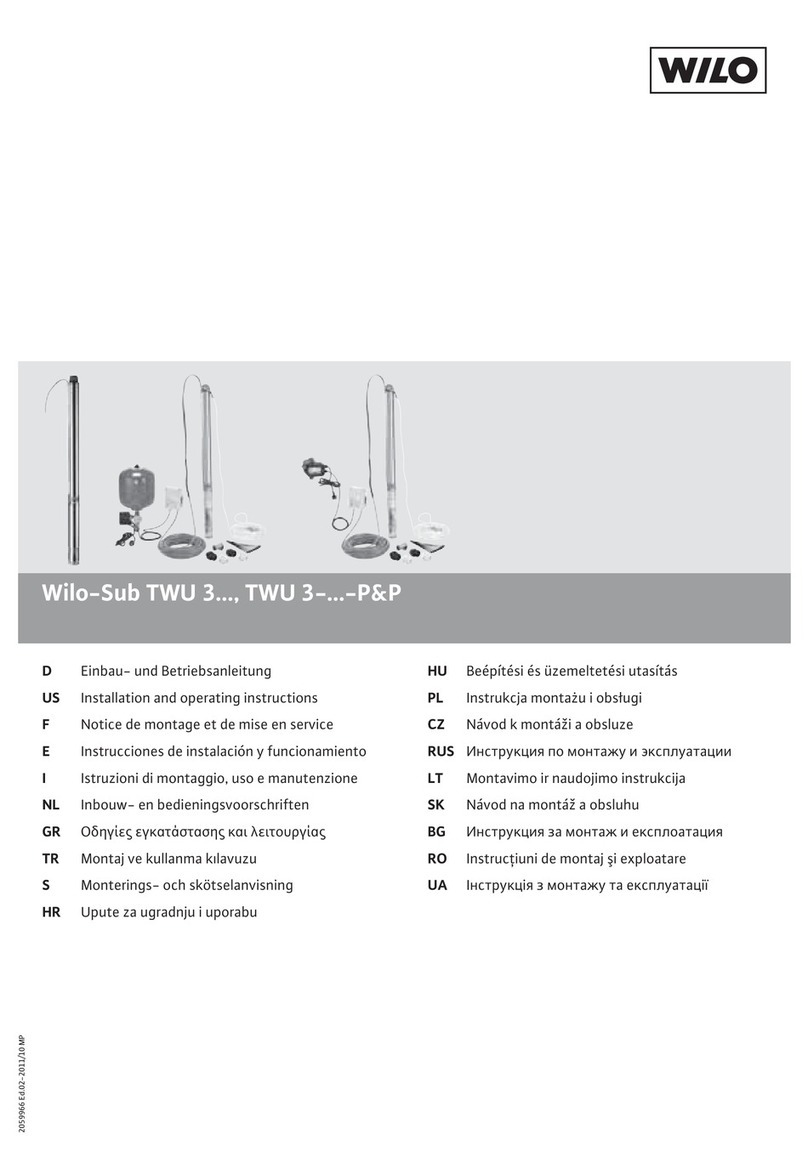

Wilo

Wilo TWU 3 Series Installation and operating instructions

Becker

Becker U 4.100 operating instructions

Cosmo

Cosmo Cosmo CPZ Installation and operating instructions

Wilo

Wilo RP Series Installation and maintenance instructions

Samoa

Samoa LARIUS MINIPEGASO Operating and maintenance manual

Sicce

Sicce Syncra HF instructions

Cole Parmer

Cole Parmer MasterFlex I/P 77420-00 operating manual

TOHATSU

TOHATSU VC52AS owner's manual

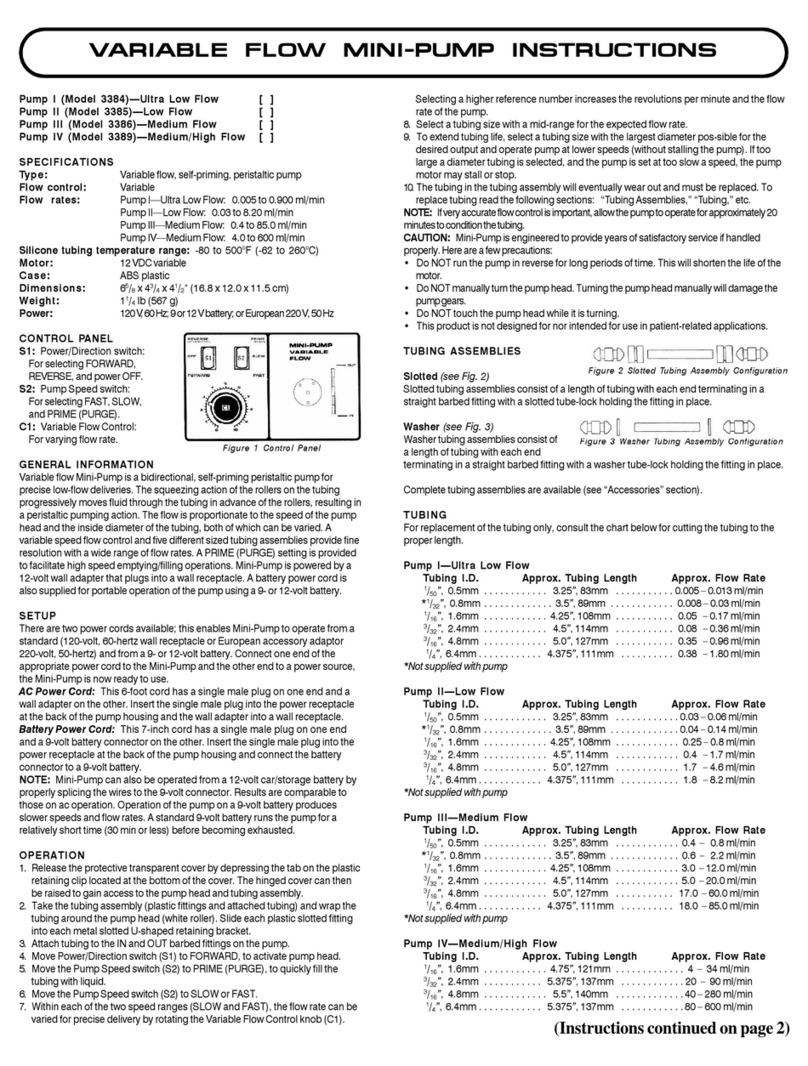

Control Company

Control Company 3385 instructions

Aurora

Aurora 330 Instruction and repair manual

Samoa

Samoa 560 230 Technical service guide

REMS

REMS Push instruction manual

Goulds Pumps

Goulds Pumps VMP Installation, operation and maintenance instructions

Armstrong

Armstrong Design Envelope 4302 Installation & operating instructions

Lumax

Lumax LX-1300 quick start guide