SGM LEKTRA KPT Guide

KPT

Miniature Pressure Transmitters

technical documentation EN Rev. of 28/06/2022

Page 2 of 20 www.sgm-lektra.com

KPT - contents

CONTENTS

1-WARRANTY

2-PRODUCT

3-FEATURES

4-DIMENSIONS

5-INSTALLATION

6-ELECTRICAL CONNECTIONS

7-DISPLAY

8-CONFIGURATION

9-FACTORY TEST AND QUALITY CERTIFICATE

page 3

page 4

page 5

page 6

page 8

page 9

page 10

page 14

page 20

Page 3 of 20

www.sgm-lektra.eu

KPT - warranty

Products supplied by SGM LEKTRA are guaranteed for a period of 12 (twelve) months from delivery date

according to the conditions specified in our sale conditions document.

SGM LEKTRA can choose to repair or replace the Product.

If the Product is repaired it will maintain the original term of guarantee, whereas if the Product is replaced it will have 12

(twelve) months of guarantee.

The warranty will be null if the Client modifies, repair or uses the Products for other purposes than the normal conditions

foreseen by instructions or Contract.

In no circumstances shall SGM LEKTRA be liable for direct, indirect or consequential or other loss or damage whether

caused by negligence on the part of the company or its employees or otherwise howsoever arising out of defective goods

1-WARRANTY

Page 4 of 20 www.sgm-lektra.com

KPT - product

2- PRODUCT

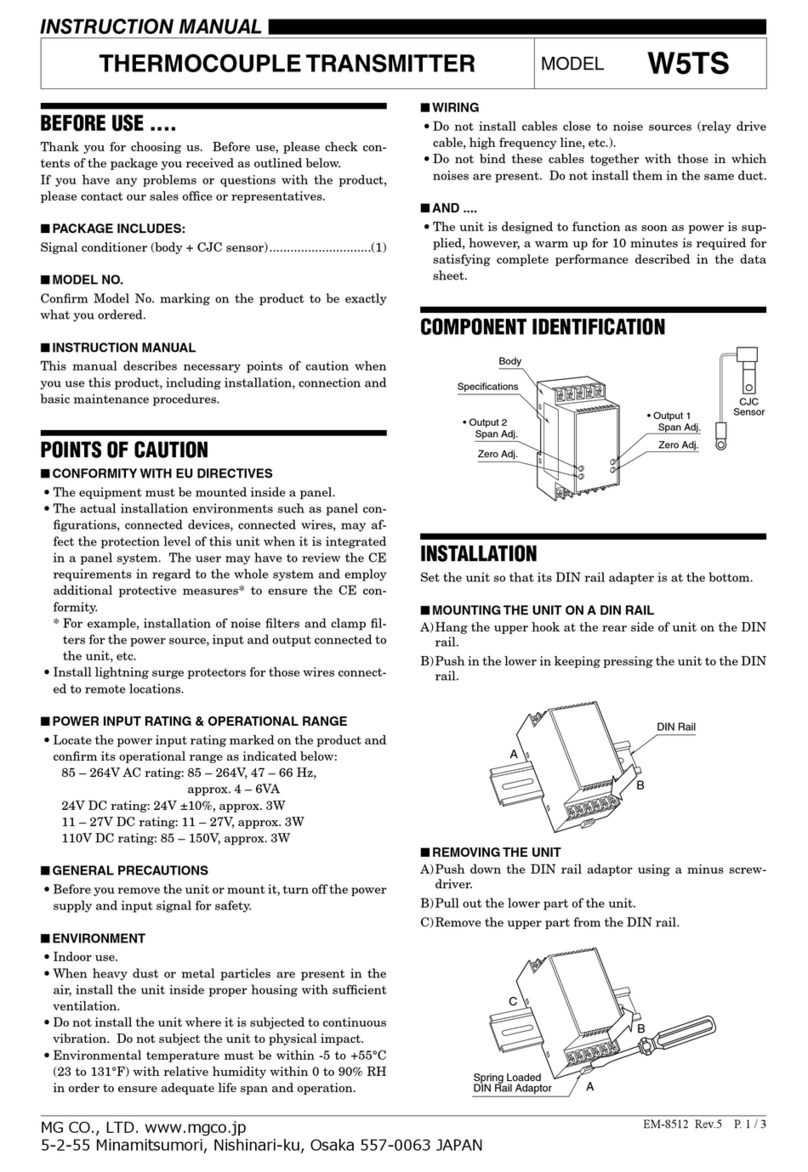

2.1 IDENTIFICATION

Each meter has an adhesive identification plate on which are indicated the meter main data.

The following picture describes the information on the identification plate.

KPLCMTFAG03

24Vdc 12÷42Vdc

PA0081604506

2

3

1Mod.

P. S .

S.N.

1. Product code 3. Serial number2. Power supply

1. connector

2. Display (opt.)

3. Process connection

4. Sensor

2

3

4

4

3

1

1

Page 5 of 20

www.sgm-lektra.eu

3-FEATURES

KPT - features

Measurement range

- Relative Pr.: Max. 0÷400bar (0÷40Mpa) Min. 0÷0,1bar (0÷10kPa)

- Absolute Pr.: Max. 0÷25bar (0÷2,5MPa) Min. 0÷1bar (0÷100kPa)

- Negative Pr.: Max. -1÷39bar (-0.1÷3.9MPa) Min. -1÷0 (-100÷0kPa)

Power Supply

12÷42Vdc (2-wire)

Output

4÷20mA

Max. Accuracy

±0.25%FS

Typical Stability

±0.5%FS for 3 years

Ambient temperature

-20° ÷ +100°C

Medium temperature

-30° ÷ +120°C

Storage temperature

-40° ÷ +125°C

Temperature compensation range

0° ÷ +80°C

Electrical connection

Connector Type A EN 175301-803 (DIN 43650)

Connector protection

IP65

Wet part protection

IP68

Diaphragm material

AISI 316

Process connection material

AISI 316

Diaphragm fill liquid

Silicone oil

Sensor housing material

AISI 304

Gasket material

NBR

Overload pressure / Burst pressure:

Range Code Range (bar) Overload P. Burst P. Range Code Range (bar) Overload P. Burst P.

C1 0÷0,25 R. 10bar 20bar C5 -1÷0 R. 10bar 20bar

C2 0÷0,4 R. 10bar 20bar D4 -1÷0,6 R. 20bar 40bar

C3 0÷0,6 R. 10bar 20bar D5 -1÷1,6 R. 20bar 40bar

D1 0÷1 R. 20bar 40bar F8 -1÷3 R. 75bar 150bar

D2 0÷1,6 R. 20bar 40bar F9 -1÷5 R. 75bar 150bar

D3 0÷2,5 R. 20bar 40bar FA -1÷9 R. 75bar 150bar

F1 0÷4 R. 75bar 150bar FB -1÷15 R. 75bar 150bar

F2 0÷6 R. 75bar 150bar FC -1÷24 R. 75bar 150bar

F3 0÷10 R. 75bar 150bar FD -1÷29 R. 75bar 150bar

F4 0÷16 R. 75bar 150bar FE -1÷39 R. 75bar 150bar

F5 0÷25 R. 75bar 150bar M1 0÷1,0 A. 20bar 40bar

F6 0÷30 R. 75bar 150bar M2 0÷1,6 A. 20bar 40bar

F7 0÷40 R. 75bar 150bar M3 0÷2,5 A. 20bar 40bar

G1 0÷60 R. 150bar 200bar O1 0÷4 A. 75bar 150bar

G2 0÷100 R. 150bar 200bar O2 0÷6 A. 75bar 150bar

H1 0÷160 R. 600bar 800bar O3 0÷10 A. 75bar 150bar

H2 0÷250 R. 600bar 800bar O4 0÷16 A. 75bar 150bar

H3 0÷400 R. 600bar 800bar O5 0÷25 A. 75bar 150bar

R. = Gauge Pressure - A. = Absolute Pressure

Page 6 of 20 www.sgm-lektra.com

4-DIMENSIONS

KPT - dimensions

4.1 MECHANICAL DIMENSIONS

Ex. with 1/2“ NPT female thread

1/2“ NPT male thread with

1/4” NPT female threaded

hole

M20x1.5 male thread

1/2”G male thread

ISO 2861 vacuum

connection max 2.5bar

1/4” NPT male thread

Page 7 of 20

www.sgm-lektra.eu

KPT - dimensions

Sanitary: DIN 32676 DN25 /

ISO 2852 DN 25; max 30bar

Sanitary: DIN 32676 DN40 /

ISO 2852 DN 38; max 30bar

Sanitary: DIN 32676 DN50 /

ISO 2852 DN 51; max 30bar

Ø56.5

Page 8 of 20 www.sgm-lektra.com

KPT - installation

5-INSTALLATION

5.1 APPLICATION EXAMPLES

Level measurement in beer silo Pressure measurement in pipe

mH

2

O

KPa

22 8

23 9

24 10

25 11

26 12

27 13

28 14

1 15

2 16

3 17

18

5 19

6 20

7 21

NO

NO

ALM1

ALM2

AC220V

mAin

Vin

++

-+

+

GND

OUT

DC24V

1

2

The transmitters KPT can be installed in a connection point of the under pressure pipe.

It is recommended that the combination of a closing valve to facilitate the operations of mechanical installation or maintenance.

The driof the Zero caused by the installation position can be easily eliminated by the calibration trimmer Zero.

If you want to calibrate the Zero or Span unscrew the top of the transmitter body.

Page 9 of 20

www.sgm-lektra.eu

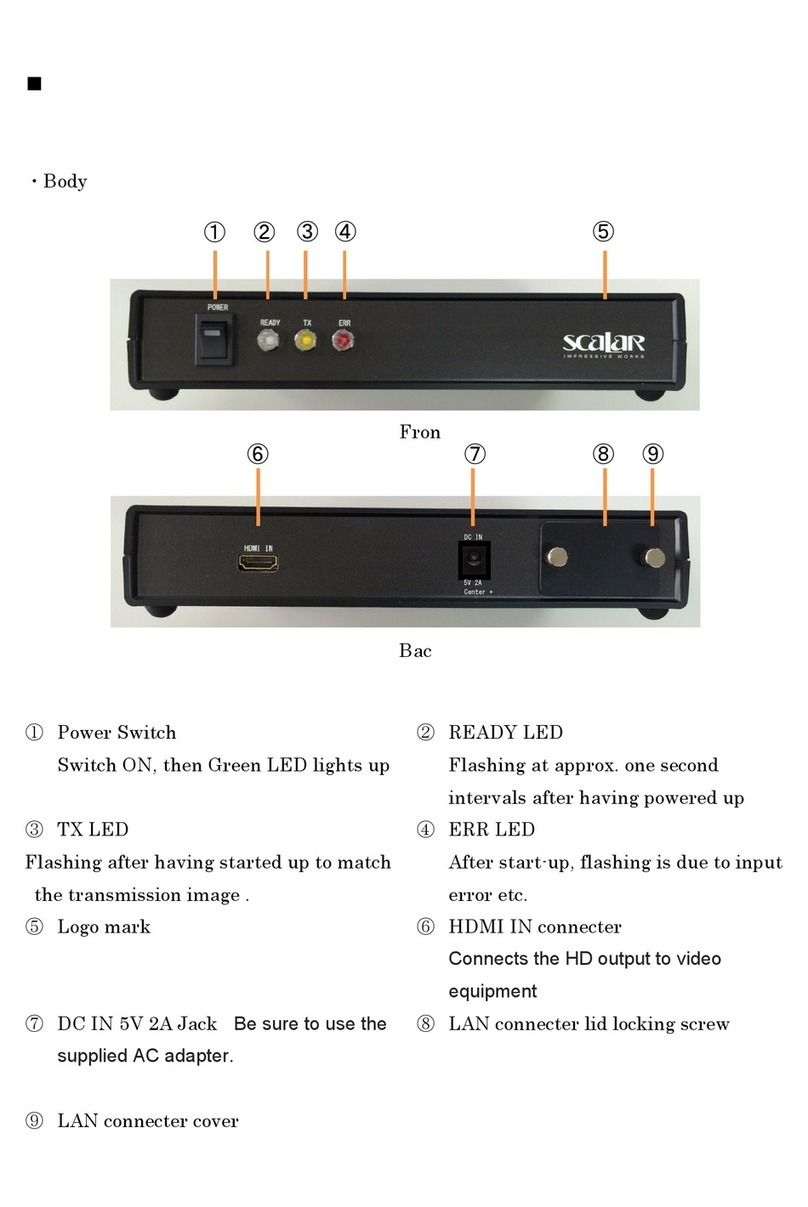

KPT - electrical connections

6-ELECTRICAL CONNECTIONS

6.1 CONNECTION

Two wires connection 4÷20mA

Type A connector EN 175301-803 (DIN 43650)

Terminal for 1.5mm2 max wires.

Cable gland: PG9 4.5÷7mm

10A

250V

12

3

3+PE

40

26.5

Connector pinout

PINS Function

1 Power + = +V

2 Power - = 0V

3-

Power+

Power-

Switch1

Ground

1

2

3

P+ P+

Power

S+ S-

Signal

K1+ K1-

Relay

K2+ K2-

Relay

Bland label

6.2 LCD Display, 2 way PNP output

Page 10 of 20 www.sgm-lektra.com

KPT - display

7-DISPLAY (optional)

The KPT pressure transmitter may be directly connected to the configurable LCD display.

The display is available for all KPT sensors.

The display main features are:

- dimensions 39x24

- blue backlight

- large, 9x5, and easily visible font of the measured value

- programmable pressure measure unit

- programmable display pressure range

- Access code for the programming protection

- display with a rotation of 350°

Measurement scale range Bargraph

Measuring range percentage value

Programming buttons

Measured value

Measure unit of the measured value

100% bar

16.0

Page 11 of 20

www.sgm-lektra.eu

7.1 MOUNTING

To mount the display on the KPT proceed as follows:

1) Unscrew the screw and remove the female connector.

2) connect the display female connector with the KPT

male connector.

KPT - display

Page 12 of 20 www.sgm-lektra.com

KPT - display

3) Unscrew the plastic ring nut, the male connector must not be rotated

to avoid damage to internal connections.

4) Carefully lithe male connector, be careful not to damage the internal

connection wires.

5) Tighten the inside screw.

Page 13 of 20

www.sgm-lektra.eu

KPT - display

6) Screw the plastic ring nut, the male connector must not be rotated to

avoid damage to internal connectionse.

7) Connect the female connector and lock it by tightening the screw.

Page 14 of 20 www.sgm-lektra.com

KPT - configuration

8.1 PARAMETERS SETTING

8.1.1 CLK - Access code

To access the parameters need to enter the access code 132.

Press Zto select the digit and Sto modify.

Press Mto confirm and go to the next parameter.

8-CONFIGURATION VIA DISPLAY

To configure the display parameters is sufficient to act on the 3 buttons:

Z- access to the parameter programming or select digit to be edited

S- change the selected digit or choice option

M - stores changes or moves to the next parameter

To access the parameter setting, press M

8.1.2 SLL - Begin scale value of the measuring range

PTo access the next parameter without changes, press M.

Set the value to be displayed when the analog signal is 4mA.

Press Zto select the digit and Sto modify.

Press Mto confirm and go to the next parameter.

NB - the decimal point position is in accordance with the setting in 8.1.6

SLL

0.0

100% bar

16.0

clk

132

8.1.3 SLH - End scale value of the measuring range

To access the next parameter without changes, press M.

Set the value to be displayed when the analog signal is 20mA.

Press Zto select the digit and Sto modify.

Press Mto confirm and go to the next parameter

NB - the decimal point position is in accordance with the setting in 8.1.6

SLH

16.0

8.1.4 UNI - Measure unit

To access the next parameter without changes, press M.

The available measure units are:

0 - None

1 - kPa; chiloPascal

2 - MPa; megaPascal

3 - Pa; Pascal

4 - bar; bar

5 - mbar; millibar

6 - psi; pounds per square inch

7 - mHO; meters of water column

8 - mmHO; millimeters of water column

9 - cmHO; centimeters of water column

10 - mmHg; millimeters of mercury column

11 - tor; torr

12 - atm; atmospheres

To select the unit of measurement set the corresponding number, es:

to select bar have to set the number 3.

Press Zto select the digit and Sto modify.

Press Mto confirm and go to the next parameter.

bar uni

3

Page 15 of 20

www.sgm-lektra.eu

KPT - configuration

8.1.5 PV-dISP - “Measured value” Displaying

To access the next parameter without changes, press M.

Set the measured value to be displayed.

The available options are:

00 - 4÷20mA analog signal value displaying, that KPT sensor is transmitting,

with three digits to the decimal point right

01 - KPT sensor measured pressure value displaying; the measure unit displayed

is in accordance with the setting in 8.1.4

02 - KPT sensor measured pressure range percentage displaying, with two digits

to the decimal point right

Press Zto select the digit and Sto modify.

Press Mto confirm and go to the next parameter.

pv disp

1

8.1.6 dECP - Decimal point

To access the next parameter without changes, press M.

Set the decimal point fixed position for the measured pressure displaying.

The available options are:

0 - no decimal point, eg.: 160

1 - one digit to the decimal point right, eg.: 16.0

2 - two digit to the decimal point right, eg.: 1.60

3 - three digit to the decimal point right, eg.: 0.160

Press Zto select the digit and Sto modify.

Press Mto confirm and go to the next parameter.

decp

1

8.1.7 Pb - Zero correction

To access the next parameter without changes, press M.

Set the Zero correction value.

Press Zto select the digit and Sto modify.

Press Mto confirm and go to the next parameter.

pb

0.0

8.1.8 KKI - Correction factor

To access the next parameter without changes, press M.

Set the correction factor value.

Press Zto select the digit and Sto modify.

Press Mto confirm and go to the next parameter.

kki

1.000

8.1.9 AOLC - Low alarm

To access the next parameter without changes, press M.

Set the low alarm threshold value in mA.

Press Zto select the digit and Sto modify.

Press Mto confirm and go to the next parameter.

ma aolc

3.500

8.1.10 AOHC -Higt alarm

To access the next parameter without changes, press M.

Set the higt alarm threshold value in mA.

Press Zto select the digit and Sto modify.

Press Mto confirm and go to the next parameter.

ma aolc

23.000

Page 16 of 20 www.sgm-lektra.com

8.2.1 SP1: threshold 1 upper limit

To move to the next parameter press M, otherwise:

press Zto edit the parameter; the least significant digit can

be edited by pressing S.

To confirm the change and move to the next digit press Z;

to confirm and go to the next menu press M.

8.2.2 RP1: threshold 1 lower limit

To move to the next parameter press M, otherwise:

press Zto edit the parameter; the least significant digit can

be edited by pressing S.

To confirm the change and move to the next digit press Z;

to confirm and go to the next menu press M.

8.2.3 SPDT1: threshold 1 activation delay (0.0 ÷ 60.0 sec.)

To move to the next parameter press M, otherwise:

press Zto edit the parameter; the least significant digit can

be edited by pressing S.

To confirm the change and move to the next digit press Z;

to confirm and go to the next menu press M.

8.2.4 RPDT1: threshold 1 de-activation delay (0.0 ÷ 60.0 sec.)

To move to the next parameter press M, otherwise:

press Zto edit the parameter; the least significant digit can

be edited by pressing S.

To confirm the change and move to the next digit press Z;

to confirm and go to the next menu press M.

8.2.5 MOD1: setting the intervention mode of threshold1

To go back to the operational interface press M, otherwise:

press Zto edit the parameter; the indicative digit of the activation

mode can be edited by pressing S.

To confirm the change and move to the operational interface press M.

8.2 THRESHOLD N ° 1SETTINGS

From the operational interface, press M+ Zsimultaneously for at least 5 seconds.

KPT - configuration

SP 1

0.000

RP 1

0.000

5 SPDT 1

0.1

5 RPDT 1

0.1

NUL MOD 1

0.0

Page 17 of 20

www.sgm-lektra.eu

KPT - configuration

8.4MEANING OF INTERVENTION MODES:

MODx Activation mode

0 No output, threshold not active.

1Active threshold (with SPDTx delay) when the measured value exceeds the SPx value;

threshold not active (with RPDTx delay) when the measured value falls below RPx

2Threshold not active (with RPDTx delay) when the measured value falls below RPx;

active threshold (with SPDX delay) when the measured value falls below RPx

3

Active threshold (with SPDTx delay) when the measured value is between RPx and SPx;

threshold not active (with RPDTx delay) when the measured value is not included between

the RPx ÷ SPx interval

4Active threshold (with SPDTx delay) when the measured value is outside of interval RPx ÷ SPx;

threshold not active (with RPDTx delay) when the measured value is within the interval RPx ÷ SPx

8.3.1 SP2: threshold 2 upper limit

To move to the next parameter press M, otherwise:

press Zto edit the parameter; the least significant digit can

be edited by pressing S.

To confirm the change and move to the next digit press Z;

to confirm and go to the next menu press M.

8.3.2 RP2: threshold 2 lower limit

To move to the next parameter press M, otherwise:

press Zto edit the parameter; the least significant digit can

be edited by pressing S.

To confirm the change and move to the next digit press Z;

to confirm and go to the next menu press M.

8.3.3 SPDT2: threshold 2 activation delay (0.0 ÷ 60.0 sec.)

To move to the next parameter press M, otherwise:

press Zto edit the parameter; the least significant digit can

be edited by pressing S.

To confirm the change and move to the next digit press Z;

to confirm and go to the next menu press M.

8.3.4 RPDT2: threshold 2 de-activation delay (0.0 ÷ 60.0 sec.)

To move to the next parameter press M, otherwise:

Press Zto edit the parameter; the least significant digit can

be edited by pressing S.

To confirm the change and move to the next digit press Z;

to confirm and go to the next menu press M.

8.3.5 MOD2: setting the intervention mode of threshold 2

To go back to the operational interface press M, otherwise:

press Zto edit the parameter; the indicative digit of the activation

mode can be edited by pressing S.

To confirm the change and move to the operational interface press M.

8.3 IMPOSTAZIONI SOGLIA N°2

From the operational interface, press M+ Ssimultaneously for at least 5 seconds.

SP 2

0.000

RP 2

0.000

5 SPDT 2

0.1

5 RPDT 2

0.1

NUL MOD 2

0.0

Page 18 of 20 www.sgm-lektra.com

KPT - note

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

Page 19 of 20

www.sgm-lektra.eu

9-FACTORY TEST AND QUALITY CERTIFICATE

Documentation subject to technical change with no prior warning

SGM-LEKTRA S.r.l.

Via Papa Giovanni XXIII, 49

20090 Rodano (MI) - ITALY

tel: ++39 02 95328257

fax: ++39 02 95328321

e-mail: info@sgm-lektra.com

web: sgm-lektra.com

In conformity to the company and check procedures I certify that the equipment:

is conform to the technical requirements on Technical Data and it is made in conformity to the procedure

Quality Control Manager: .......................................................... Production and check date: .................................................

(Miniature Pressure Transmitters)

Table of contents

Other SGM LEKTRA Transmitter manuals

SGM LEKTRA

SGM LEKTRA PTU51 User manual

SGM LEKTRA

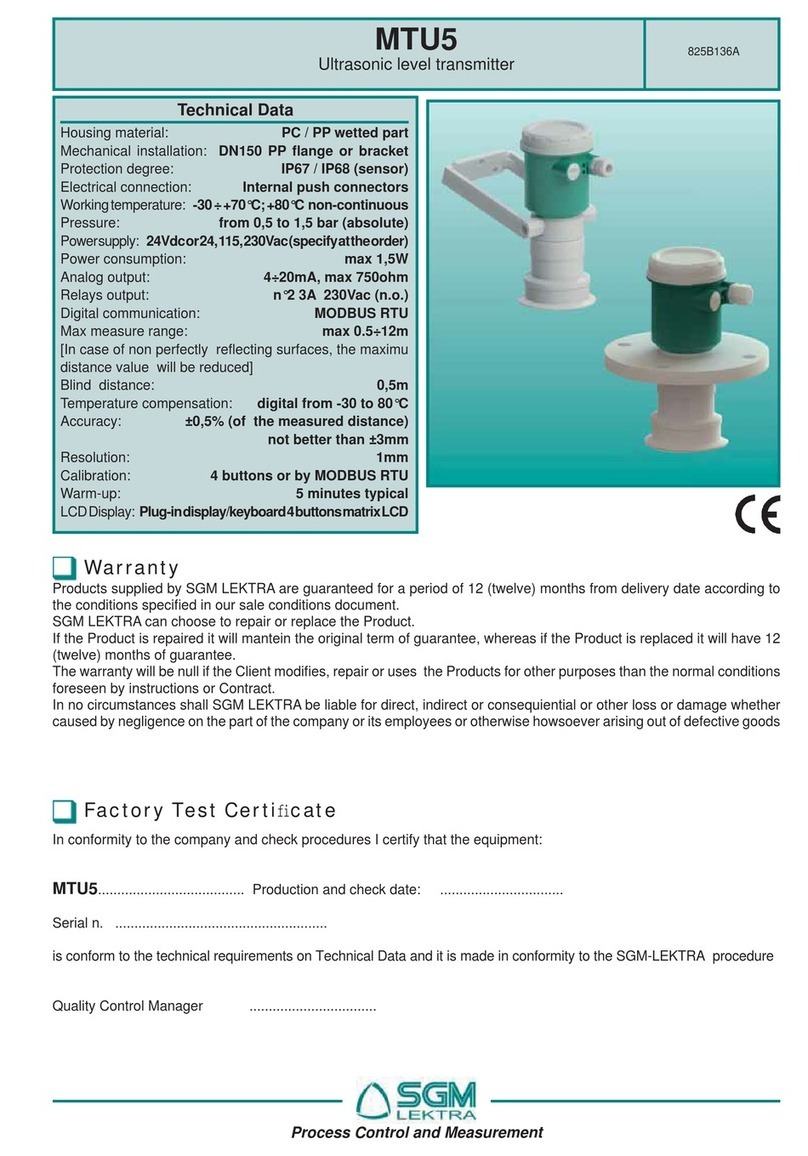

SGM LEKTRA MTU5 User manual

SGM LEKTRA

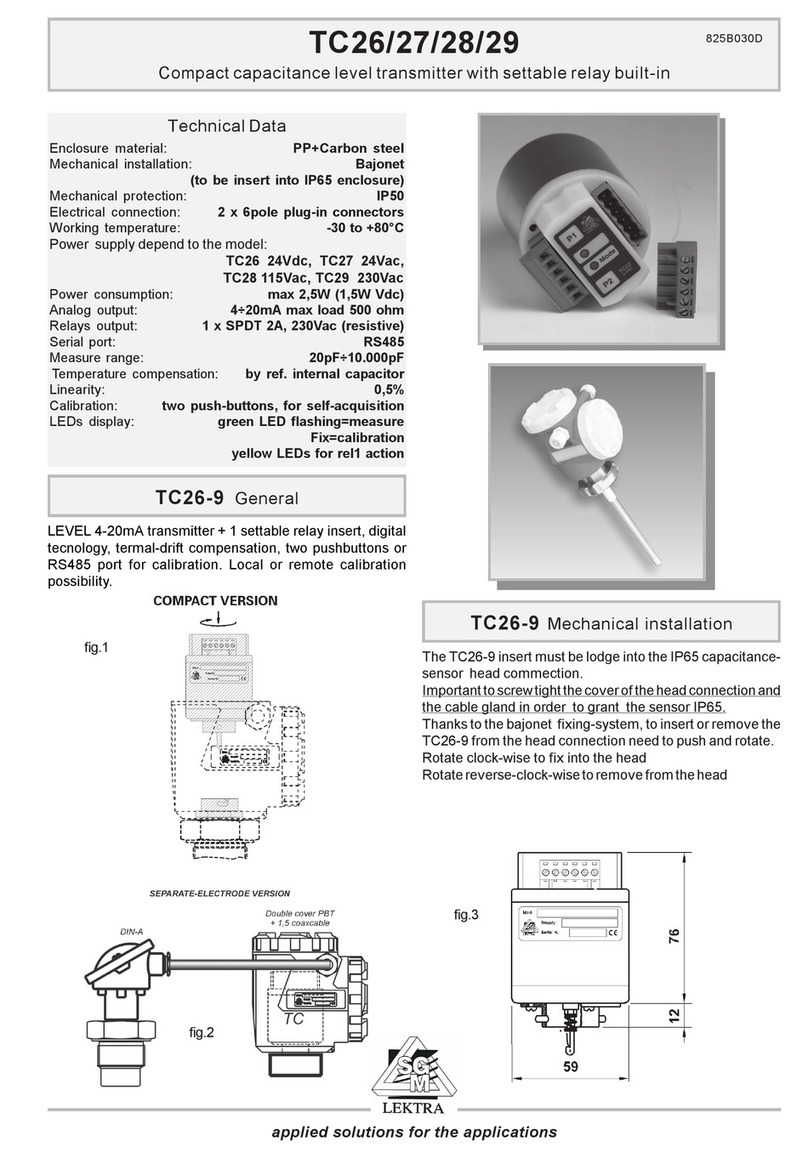

SGM LEKTRA TC26 User manual

SGM LEKTRA

SGM LEKTRA METER Series Quick start guide

SGM LEKTRA

SGM LEKTRA METER Guide

SGM LEKTRA

SGM LEKTRA FLOWMETER Guide

SGM LEKTRA

SGM LEKTRA RPL81 User manual

SGM LEKTRA

SGM LEKTRA RPL75 User manual

SGM LEKTRA

SGM LEKTRA RPL81 User manual

SGM LEKTRA

SGM LEKTRA PTU50 Guide

Popular Transmitter manuals by other brands

WIKA

WIKA A-10 operating instructions

WisyCom

WisyCom MTP41 user manual

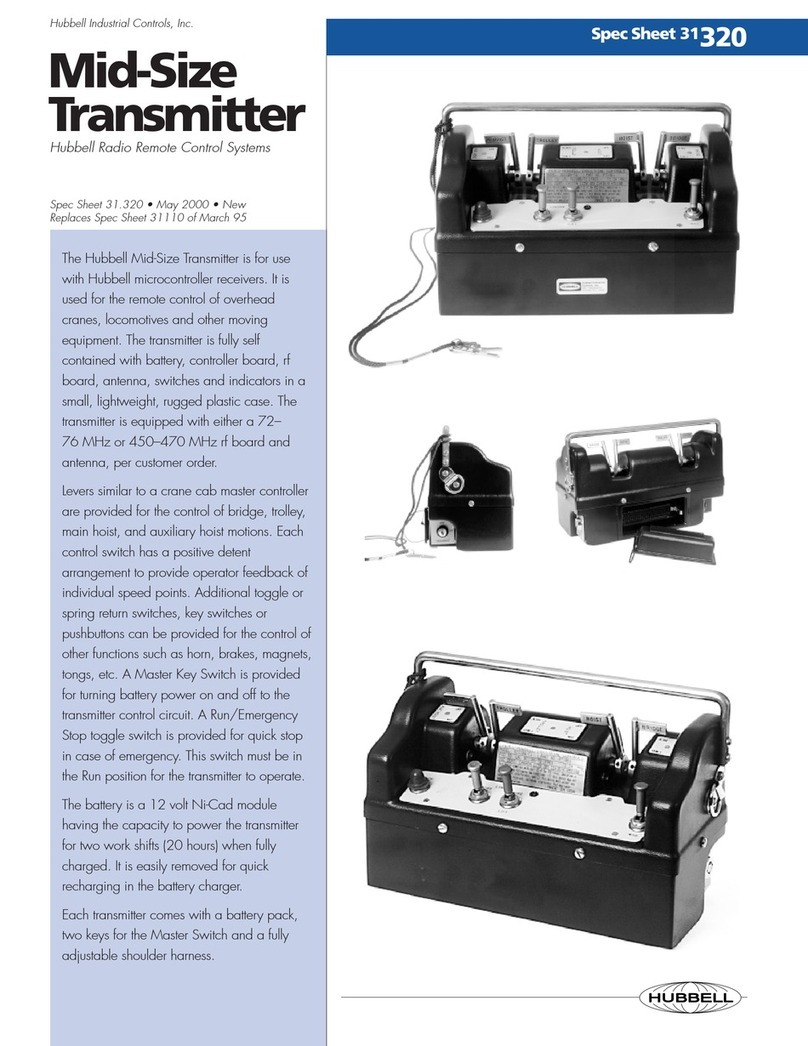

Hubbell

Hubbell Mid-Size Transmitter 31.320 Specification sheet

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS ALPHA TDS 190 18 DIN TOTAL DISSOLVED SOLIDS... instruction manual

NKE

NKE STBD-PR user manual

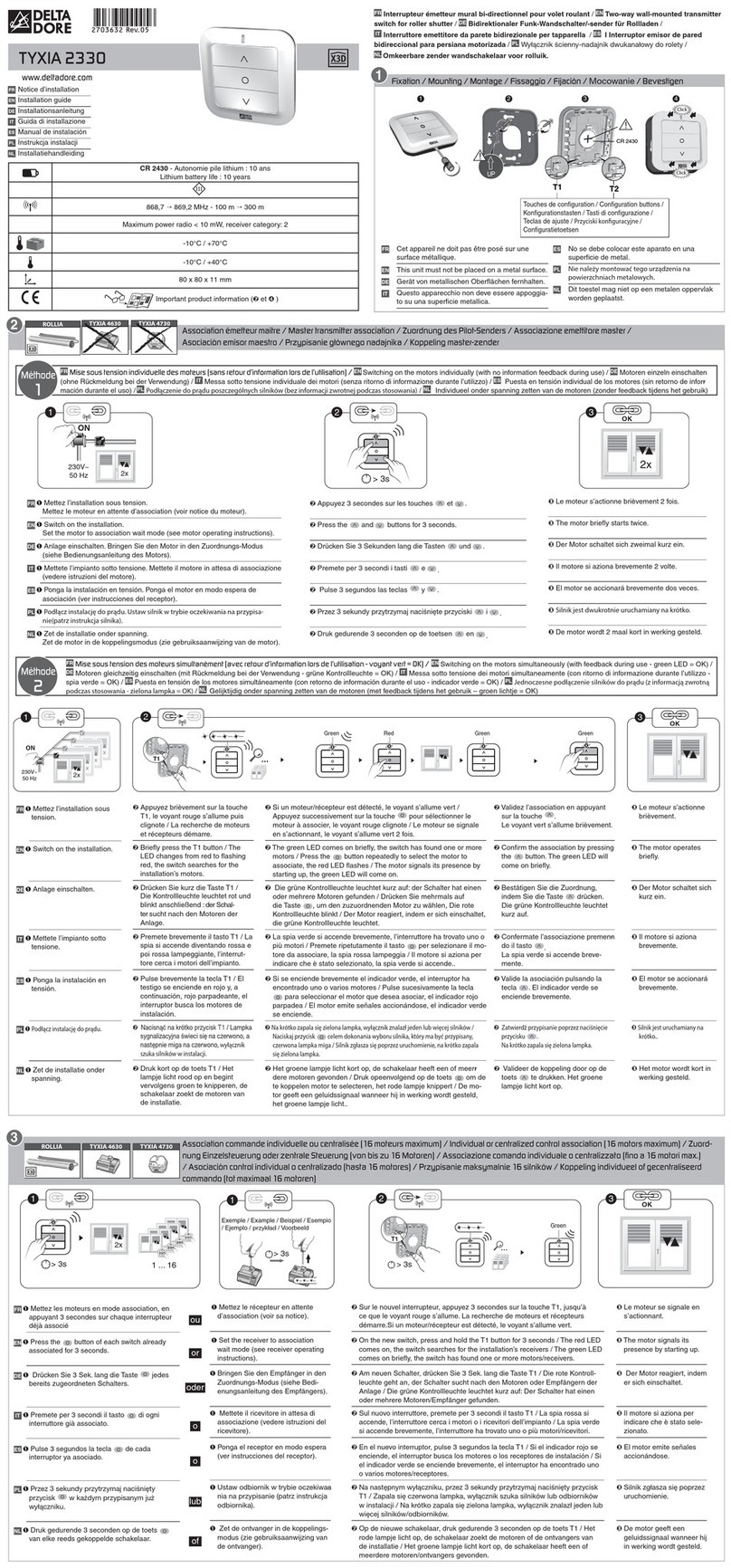

DELTA DORE

DELTA DORE TYXIA 2330 installation guide