Page 17 of 36

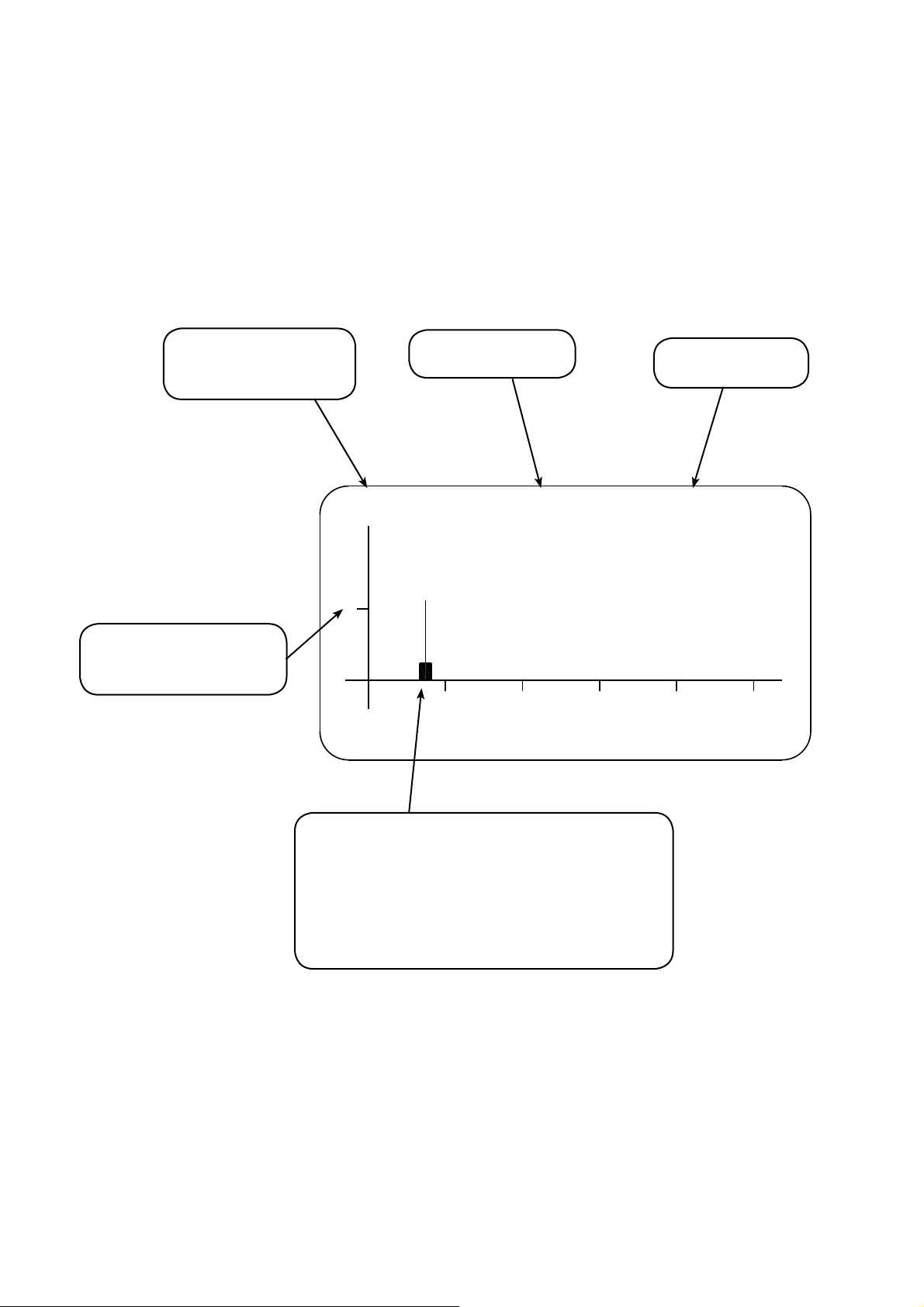

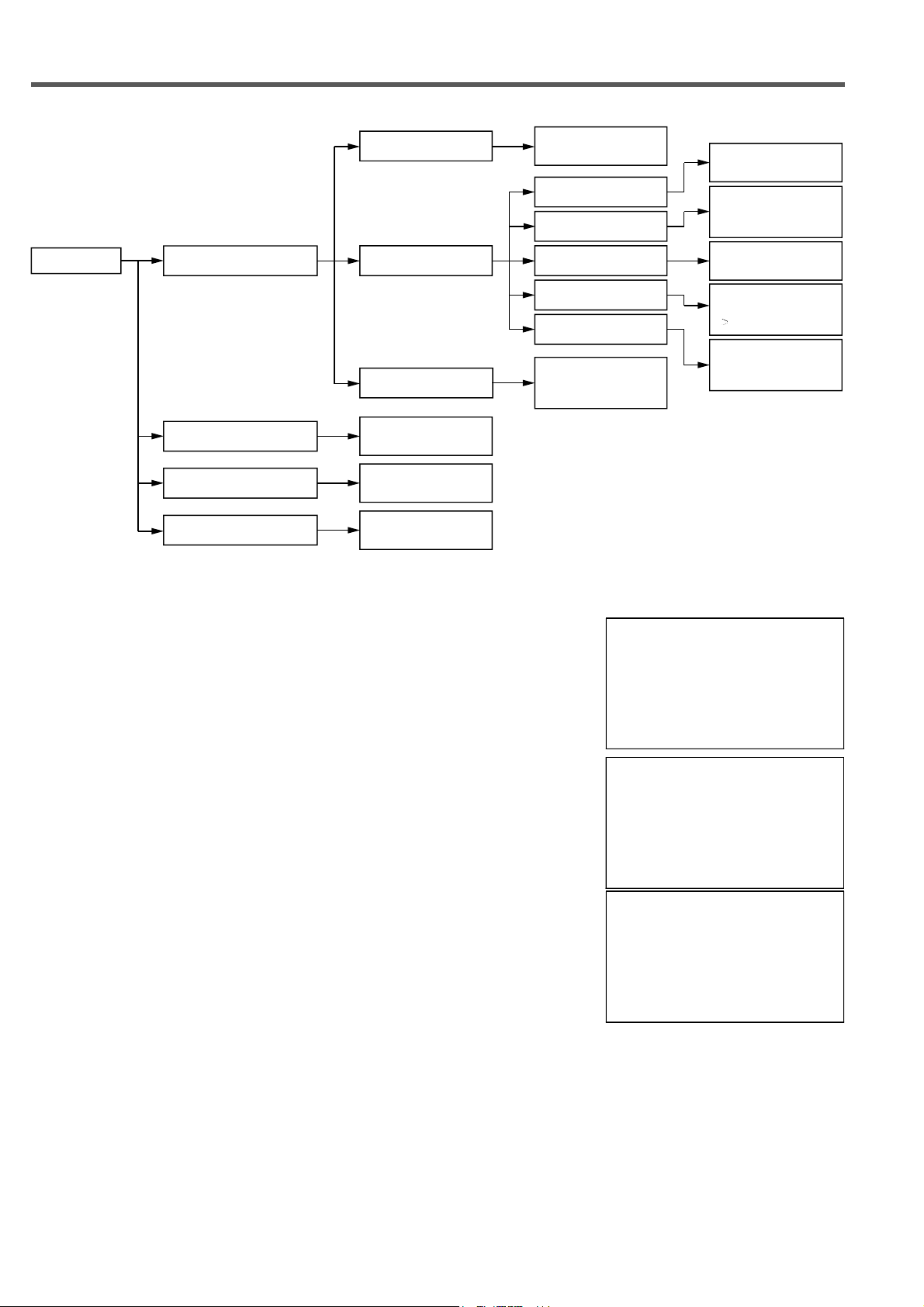

8.2.3.5 - RL2 DIAGNOSTIC

Position the cursor on RL2 DIAGNOSTIC, press ENTER to confirm

If it becomes necessary the FLOWMETER functional control, it’s possible

to enable the RL2 alarm output function. In this case, enabling the func-

tion,RL2 is energized in normal operation (RL2 LED on) and is de-ener-

gized(LED RL2 off, safety alarm) when at least one of the four conditions

mentioned below, shall be verified:

- TEMP. : temperature out of range

- ECHO : no echo is detected

- GAIN : the sensor’s gain exceed the value setted in Max Gain TH

- FLOW : the measured flow exceed the 120% of SET MAX FLOW in

setup

Press SCROLL button to select the operation mode.

Press ENTER to confirm. LEFT ARROW to exit without changes

Default value: DISABLE

NOTE: when an error occurs, a “!” is flashing on the display: press

SCROLL to show a message that indicate what kind of error is present.

The METER automatically returns to RUN mode..

RL1 COUNTER

RL2 THRESHOLD

RL2 DIAGNOSTIC

Ź

DISABLE

ANABLE

Ź

FLOWMETER - configuration

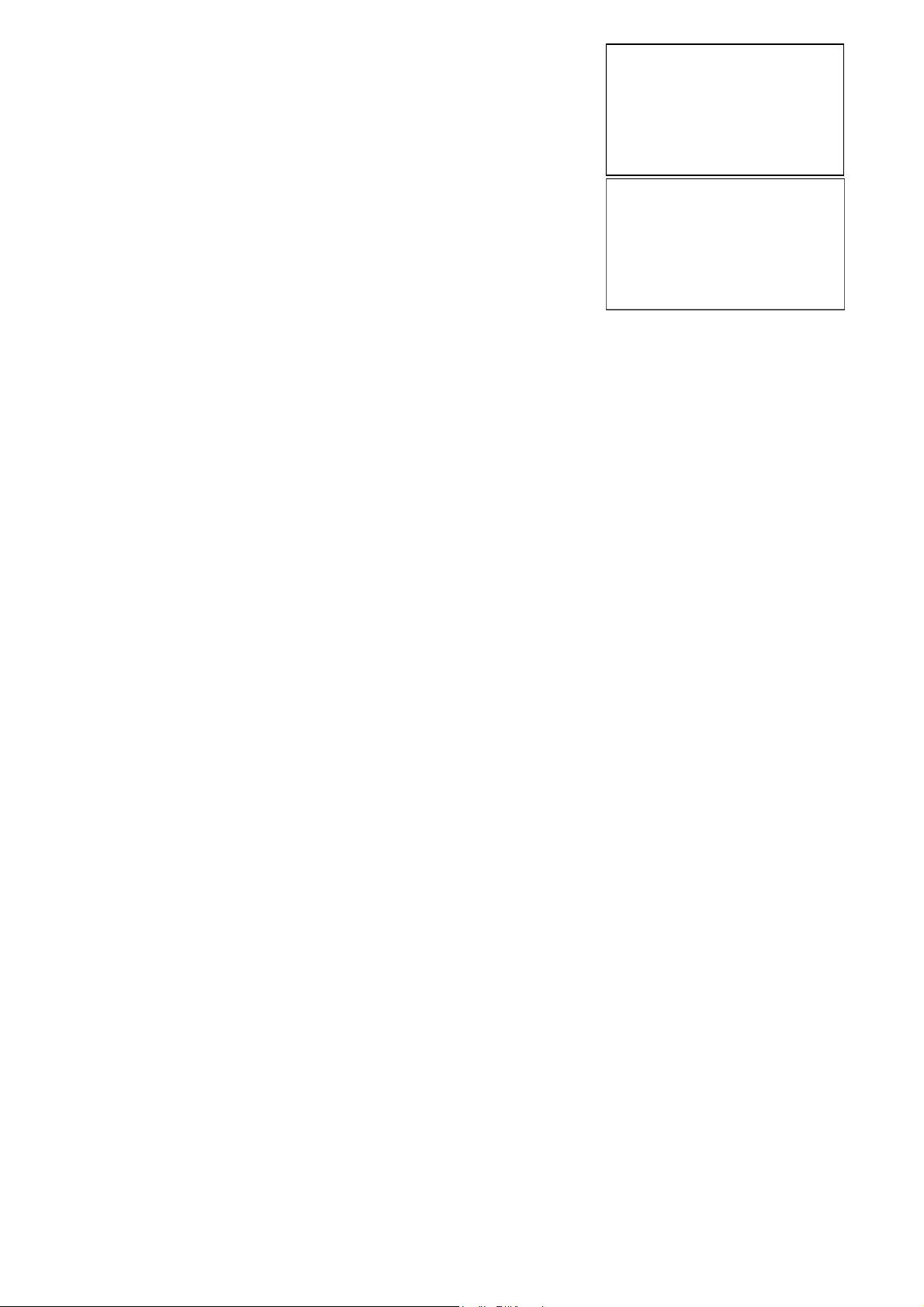

8.2.4 - SET MAX FLOW

Position the cursor on SET MAX FLOW, press ENTER to confirm

In this sub-menu it’s possible to setup the MAX flow rate value associated

with 20mA.

Use UP ARROW and SCROLL to modify the value.

Press ENTER to confirm. LEFT ARROW to exit without changes

Default value: 0

00100.00

SET MAX FLOW

m³/h

RELAYS

SET MAX FLOW

FILTER COEFFICIENT

BLIND DISTANCE

Ź

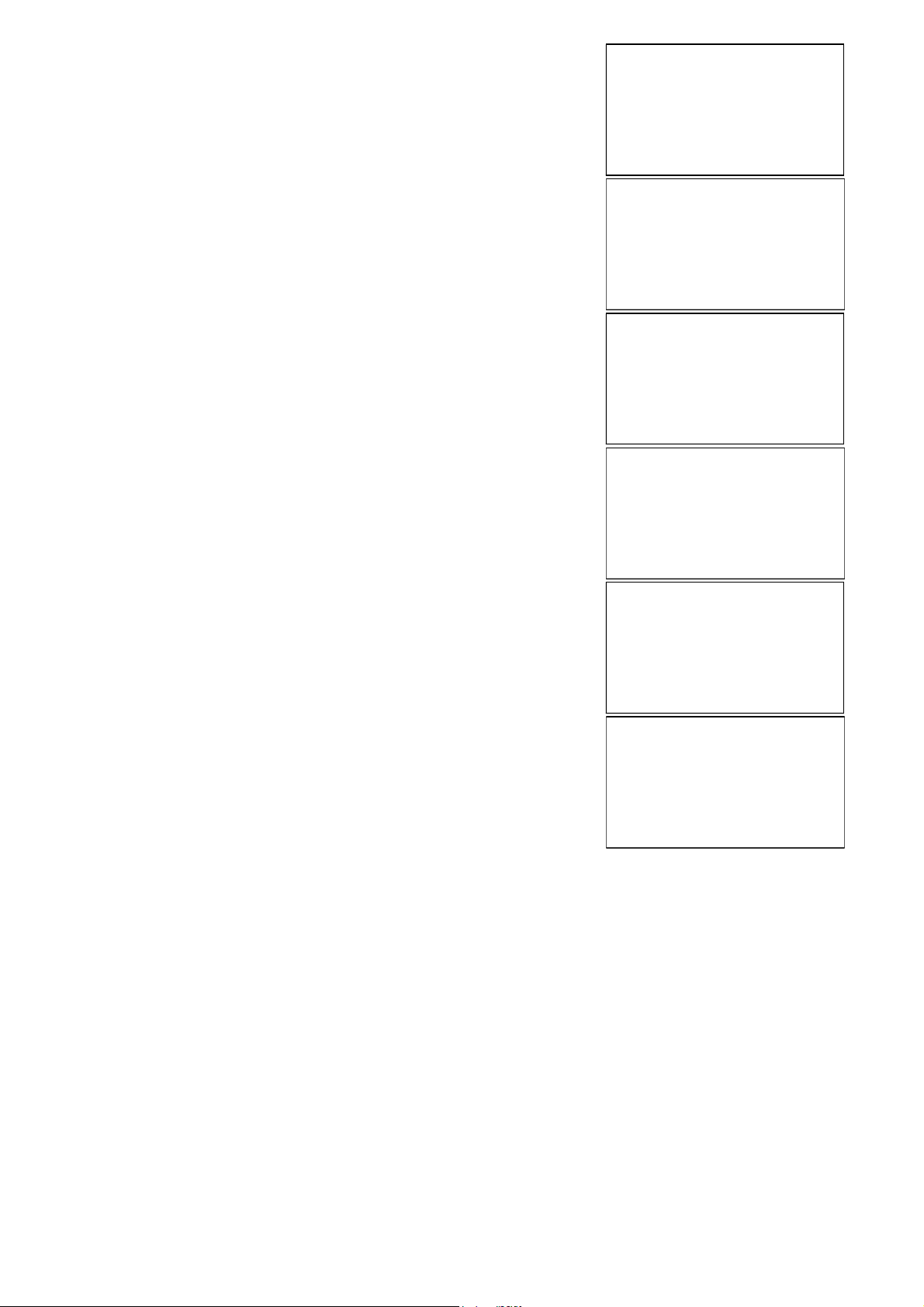

8.2.5 - FILTER COEFFICIENT

Position the cursor on FILTER COEFFICIENT, ENTER to confirm

Enter a value from 1 to 99: 1 = maximum speed, 99 = maximum slowness.

The function is deactivated with 0 (immediate response)

Use UP ARROW and SCROLL to modify the value.

Press ENTER to confirm. LEFT ARROW to exit without changes

Default value: 20 020 s

FILTER COEFFICIENT

RELAYS

SET MAX FLOW

FILTER COEFFICIENT

BLIND DISTANCE

Ź