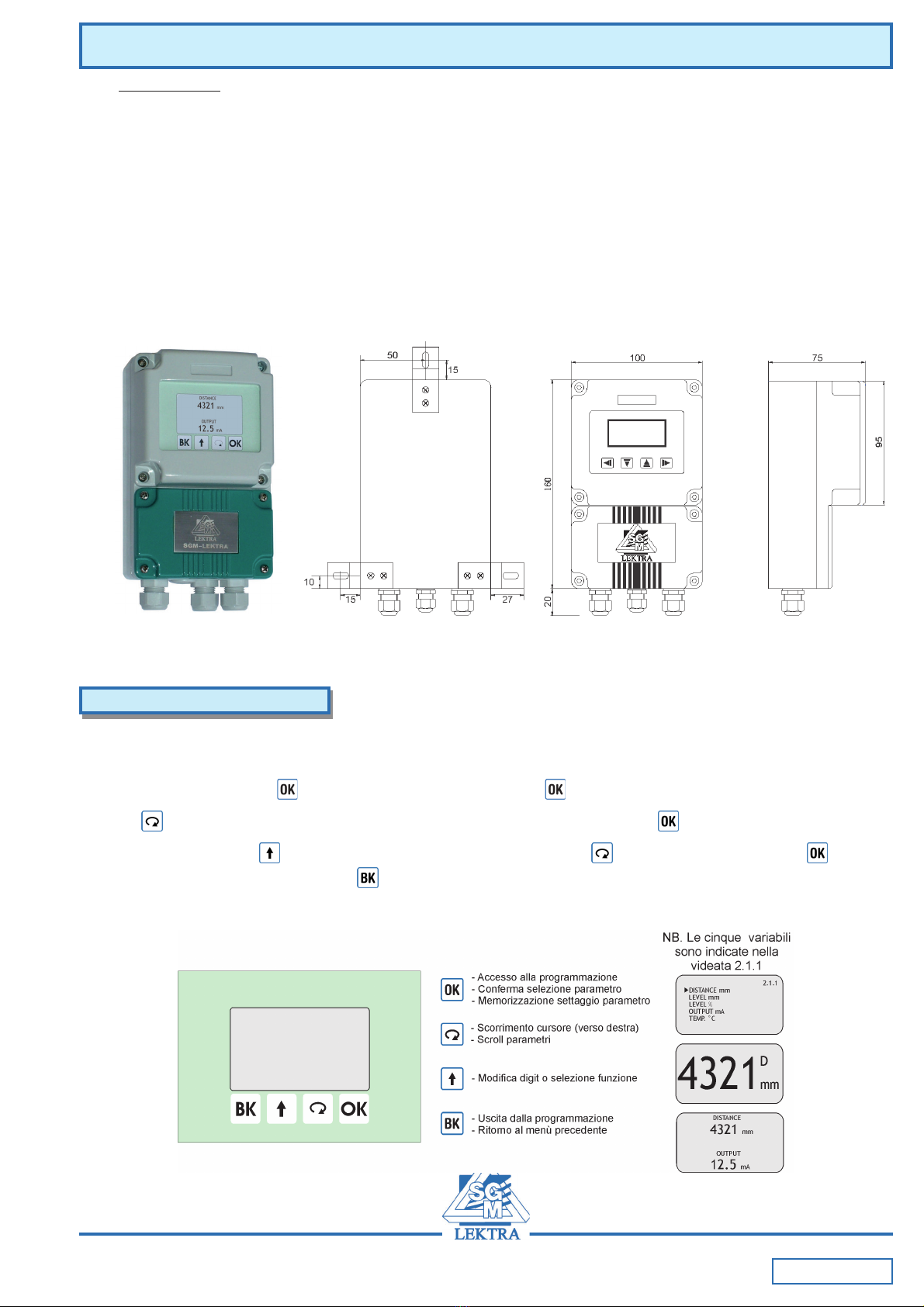

SGM LEKTRA PTU51 User manual

Table of contents

Other SGM LEKTRA Transmitter manuals

SGM LEKTRA

SGM LEKTRA PTU50 User manual

SGM LEKTRA

SGM LEKTRA FLOWMETER Guide

SGM LEKTRA

SGM LEKTRA RPL75 User manual

SGM LEKTRA

SGM LEKTRA METER Series Quick start guide

SGM LEKTRA

SGM LEKTRA PTU05 User manual

SGM LEKTRA

SGM LEKTRA PTU50 Guide

SGM LEKTRA

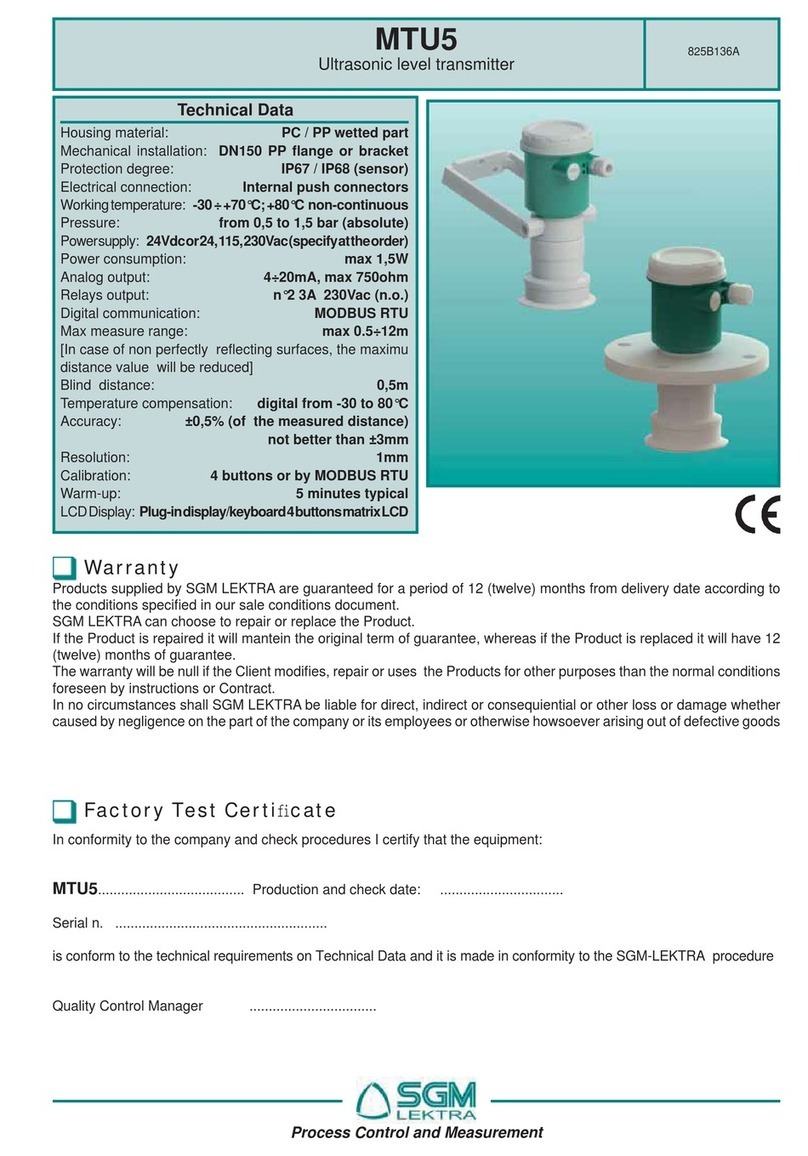

SGM LEKTRA MTU5 User manual

SGM LEKTRA

SGM LEKTRA RPL81 User manual

SGM LEKTRA

SGM LEKTRA METER Guide

SGM LEKTRA

SGM LEKTRA RPL75 User manual

Popular Transmitter manuals by other brands

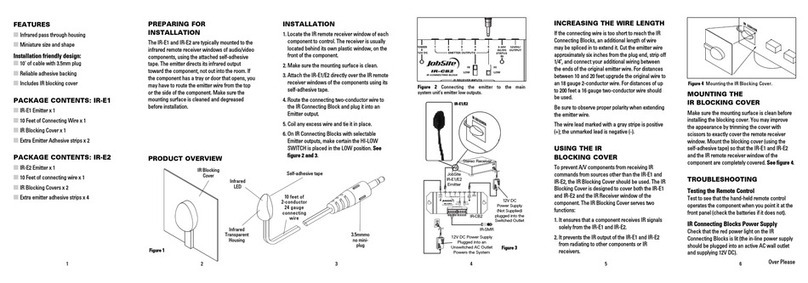

Jobsite

Jobsite IR-E1 Installation & user guide

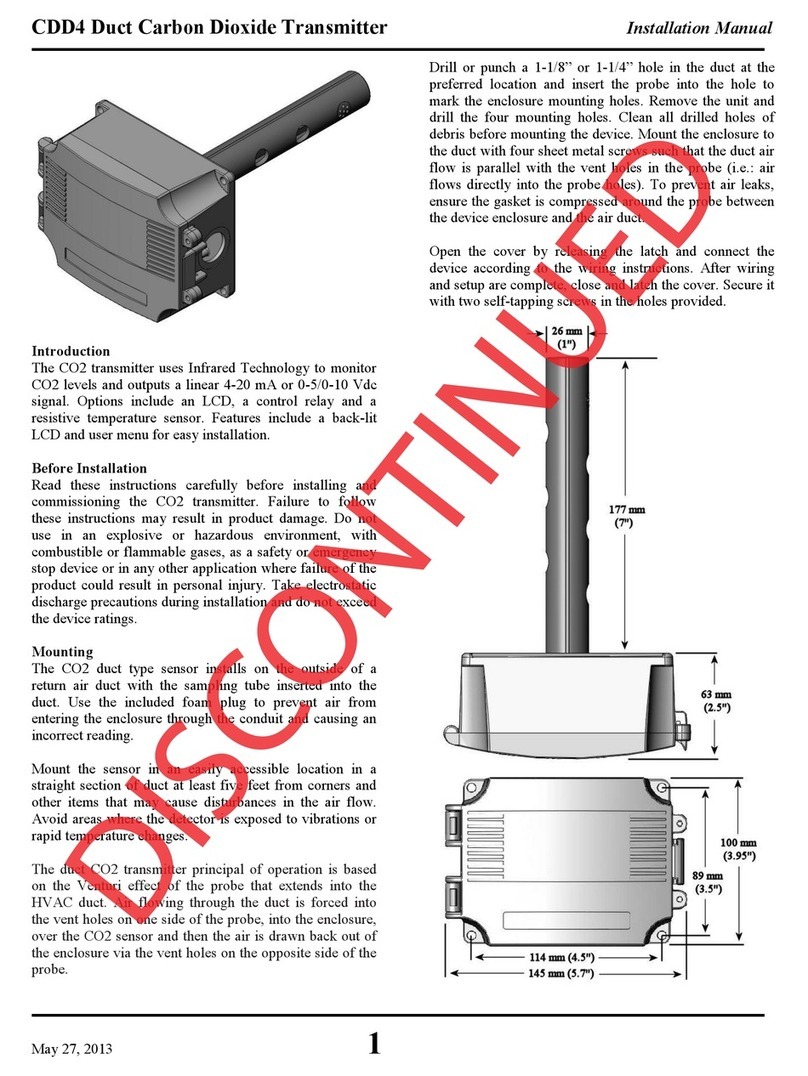

Greystone Energy Systems

Greystone Energy Systems CDD4 installation manual

IMI SENSORS

IMI SENSORS HT640B01 Installation and operating manual

Becker

Becker Centronic EasyControl EC415A-III Assembly and operating instructions

Tyco

Tyco Visonic PowerCode MCT-241 user guide

Omega

Omega MT12TX Series user guide