SGM LEKTRA MTU5 User manual

MTU5

Ultrasonic level transmitter 825B136A

Process Control and Measurement

Factory Test Certificate

In conformity to the company and check procedures I certify that the equipment:

MTU5...................................... Production and check date: ................................

Serial n. .......................................................

is conform to the technical requirements on Technical Data and it is made in conformity to the SGM-LEKTRA procedure

Quality Control Manager .................................

Warranty

Products supplied by SGM LEKTRA are guaranteed for a period of 12 (twelve) months from delivery date according to

the conditions specified in our sale conditions document.

SGM LEKTRA can choose to repair or replace the Product.

If the Product is repaired it will mantein the original term of guarantee, whereas if the Product is replaced it will have 12

(twelve) months of guarantee.

The warranty will be null if the Client modifies, repair or uses the Products for other purposes than the normal conditions

foreseen by instructions or Contract.

In no circumstances shall SGM LEKTRA be liable for direct, indirect or consequiential or other loss or damage whether

caused by negligence on the part of the company or its employees or otherwise howsoever arising out of defective goods

Technical Data

Housing material: PC / PP wetted part

Mechanical installation: DN150 PP flange or bracket

Protection degree: IP67 / IP68 (sensor)

Electrical connection: Internal push connectors

Workingtemperature: -30÷+70°C;+80°C non-continuous

Pressure: from 0,5 to 1,5 bar (absolute)

Powersupply: 24Vdcor24,115,230Vac(specifyattheorder)

Power consumption: max 1,5W

Analog output: 4÷20mA, max 750ohm

Relays output: n°2 3A 230Vac (n.o.)

Digital communication: MODBUS RTU

Max measure range: max 0.5÷12m

[In case of non perfectly reflecting surfaces, the maximu

distance value will be reduced]

Blind distance: 0,5m

Temperature compensation: digital from -30 to 80°C

Accuracy: ±0,5% (of the measured distance)

not better than ±3mm

Resolution: 1mm

Calibration: 4 buttons or by MODBUS RTU

Warm-up: 5 minutes typical

LCDDisplay: Plug-indisplay/keyboard4buttonsmatrixLCD

Page 2 of 28

MTU5 - Safety / Mechanical installation

2. INSTALLATION

2.1 MECHANICAL DIMENSIONS

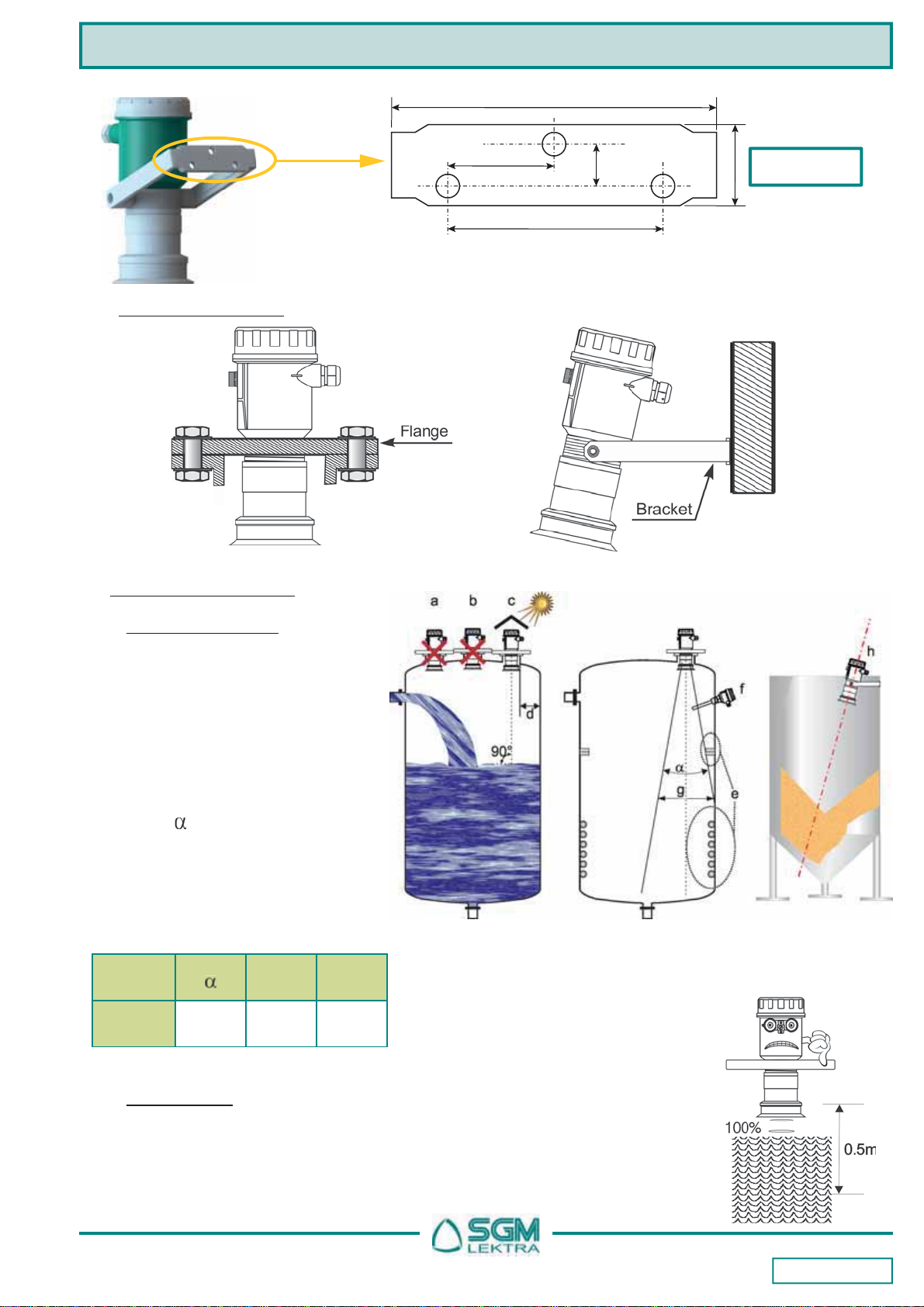

The MTU5 transmitter has the DN150 PN6 UNI 1092-1/PP flange or bracket connection.

1. SAFETY

1.1 Installation precaution

a) Installation shall only be performed by qualified personnel and in accordance with local governing regulations.

b) Make sure that the working temperature is between -30 and +70 ° C, +80 ° C non-continuous.

c) Installthetransmitterina its physicalcharacteristicsand housing/sensorconstructionmaterials compatibleenvironment.

d) The transmitter must be used safety warnings observance.

e) Improper transmitter use would cause serious damage to people, to the product and connected equipment.

Fig.3

The non intrusive system application is now preferred in the level measurements field. For this reason the

SGM-LEKTRA developed the MTU5 unity to best meet the “GENERAL-PURPOSE” application requests. The MTU5 unit

offers, together with its compact size, a complete versions range that makes the MTU5 very versatile for the most varied

applications, including areas with explosion hazard and chemically aggressive environments. MTU5 is an ultrasonic level

transmitter, temperature-compensated and suitable for connection with MODBUS RTU acquisition systems. MTU5 is a

compact unit which in addition to an analog output includes two freely addressable relay.

Non-contact level measurements

Suitable for liquids and granulates level

measurement

Integrated digital temperature sensor

to compensate the measure

MODBUS RTU com. protocol

24Vdc or 24, 115, 230Vac power s.

Mechanical protection: IP67 / IP68 (sensor)

Output: 1 4÷20mA analog output

2 relays output

DN150 flange

(Cod.2)

Fig.1 Fig.2

Anticondensation

filter (M/N code)

Drilling template

view (fig.3)

Bracket

(Cod.4)

Page 3 of 28

MTU5 - Mechanical installation

2.3.1 Blind distance

During installation is important to remember that in the sensor vicinity there is a blind

zone (or BLIND DISTANCE) of 0.5m where the sensor can not measure.

2.3 Mounting precautions

2.3.1 Mounting position (Fig.6)

- With cambered roof, Do not install the

sensor in the tank center (b).

Leave a 500mm minimum distance

between the sensor and the tank

smooth wall (d).

- Use a protective cover to protect the

sensor fromweatheranddirectsunlight(c).

- Donotinstallthesensorneartheloadzone(a).

- Make sure that in the sensor emission

beam(lobe“ ”)therearenoobstacles

(f,s) that can be intercepted as level.

- Make sure that there is not foam

presence on the product surface to be

measured

Tab.1

Liquids Bulk solids

Fig.6

Lobo

“ “ Lg

MTU5 10° 12m 2m

(12m)

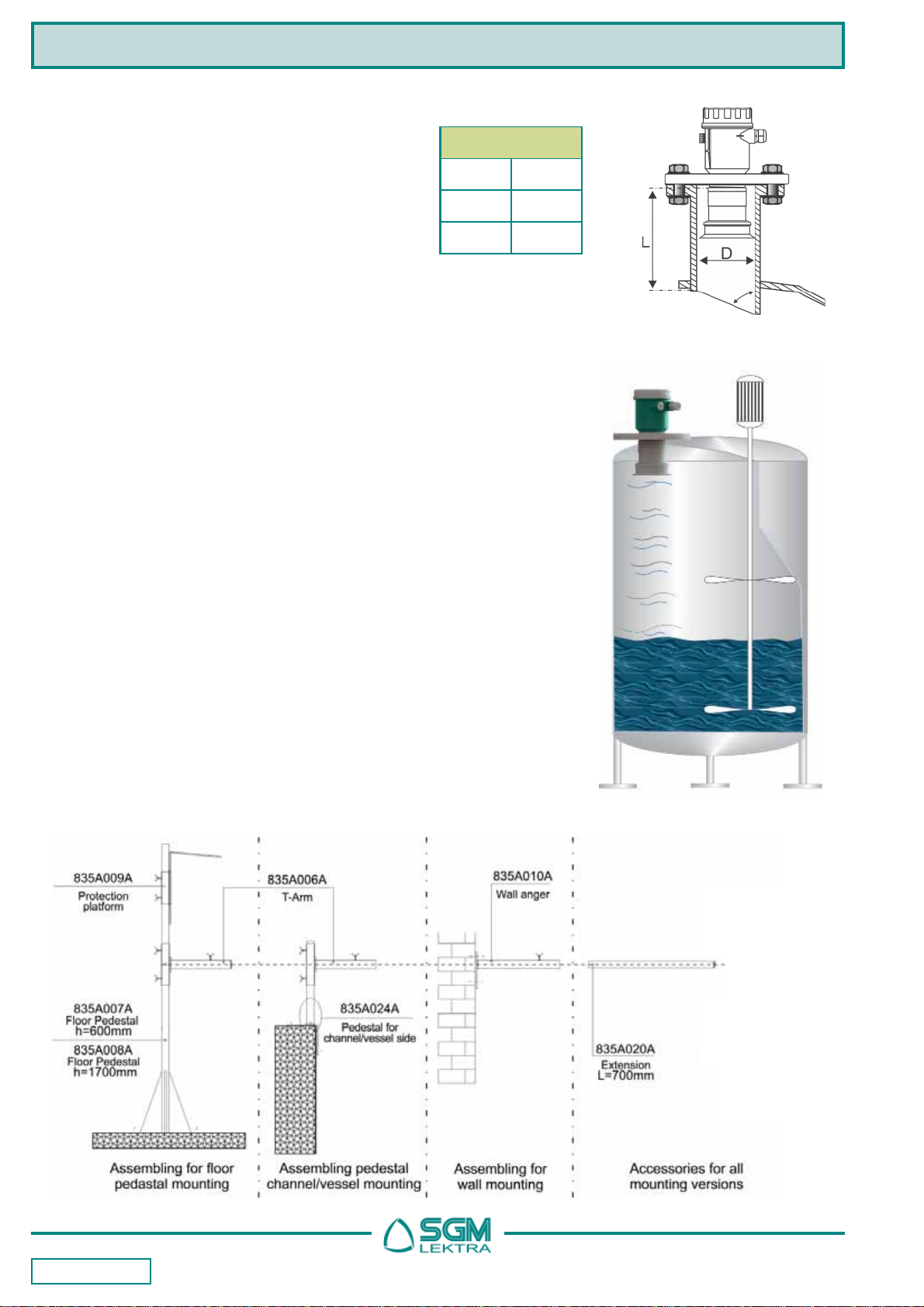

2.2 Mounting examples

Fig.4

Fig.5

Drilling template

view

Fig.7

75mm

37.5mm

20mm

122mm

35mm

Fig.3

Page 4 of 28

MTU5 - Mechanical installation

2.3.6 Mechanical installation accessories

Fig.10

2.3.5 Agitators presence

The level measurement is possible thanks to the Auto-Tuned statistical filter.

Should rarely need to adjust the filter setting by editing 2 MTU5 sensor

programming parameters:

- FILTER; this parameter is present in the Quick Setup menu (page 9)

and in the Advanced Configuration “SETUP” menu (page 16);

increasing the parameter value, decreases the sensor sensitivity to the

level measurement sudden variations.

- F-WINDOW; this parameter is present in the Advanced Configuration

“SERVICE” menu (page 26); decreasing the parameter programmed

value, increases the sensor immunity to false echoes.

Fig.9

MTU5 can be installed in an extension pipe

(see Figure 8) to turn away the sensor from

the maximum level point. The extension pipe

must be flat and without joints (welds, etc..),

also, the pipe terminal part must be cut at 45°

and with the borders without burr.

MTU5

D (mm) Lmax(mm)

80 240

100 300

Tab.2

Fig.8

Page 5 of 28

MTU5 - Connections and Configuration

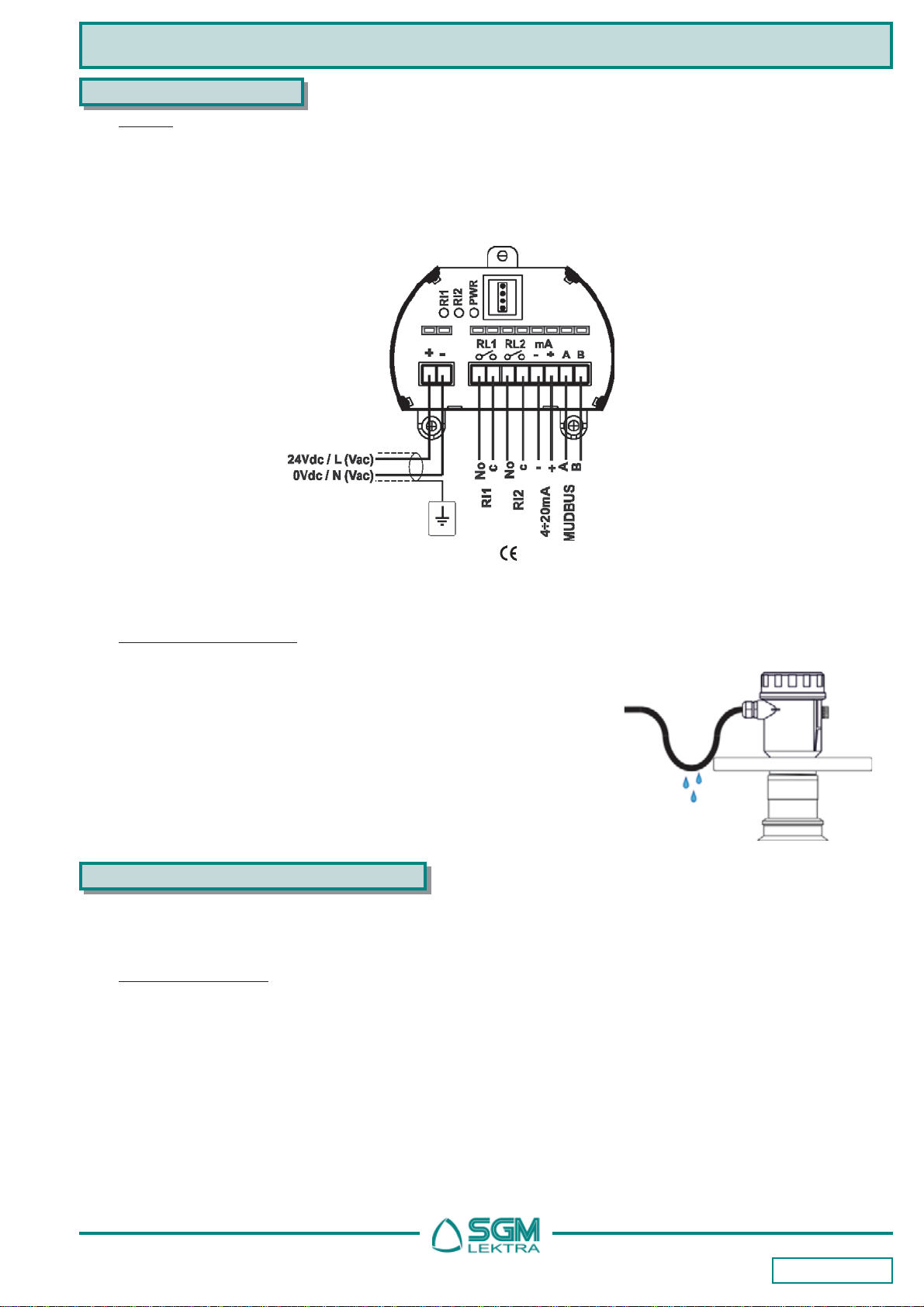

3. CONNECTIONS

3.1 Wiring

1) Separate the engine control cables or power cables from the MTU5 connection cables..

2) Open the cap by unscrewing.

3) Lead the cables into the transmitter through the glands.

4) Do not use sleeves terminals, because they might interfere with the VL601 module insertion

5) Close the cap and tighten the cable glands.

3.2 Humidity infiltrations

4. CONFIGURATION MODES

The MTU5 have 2 configuration/calibration modes:

- via MODBUS RTU, by PC, for 4-wires versions

- via VL601 programming module

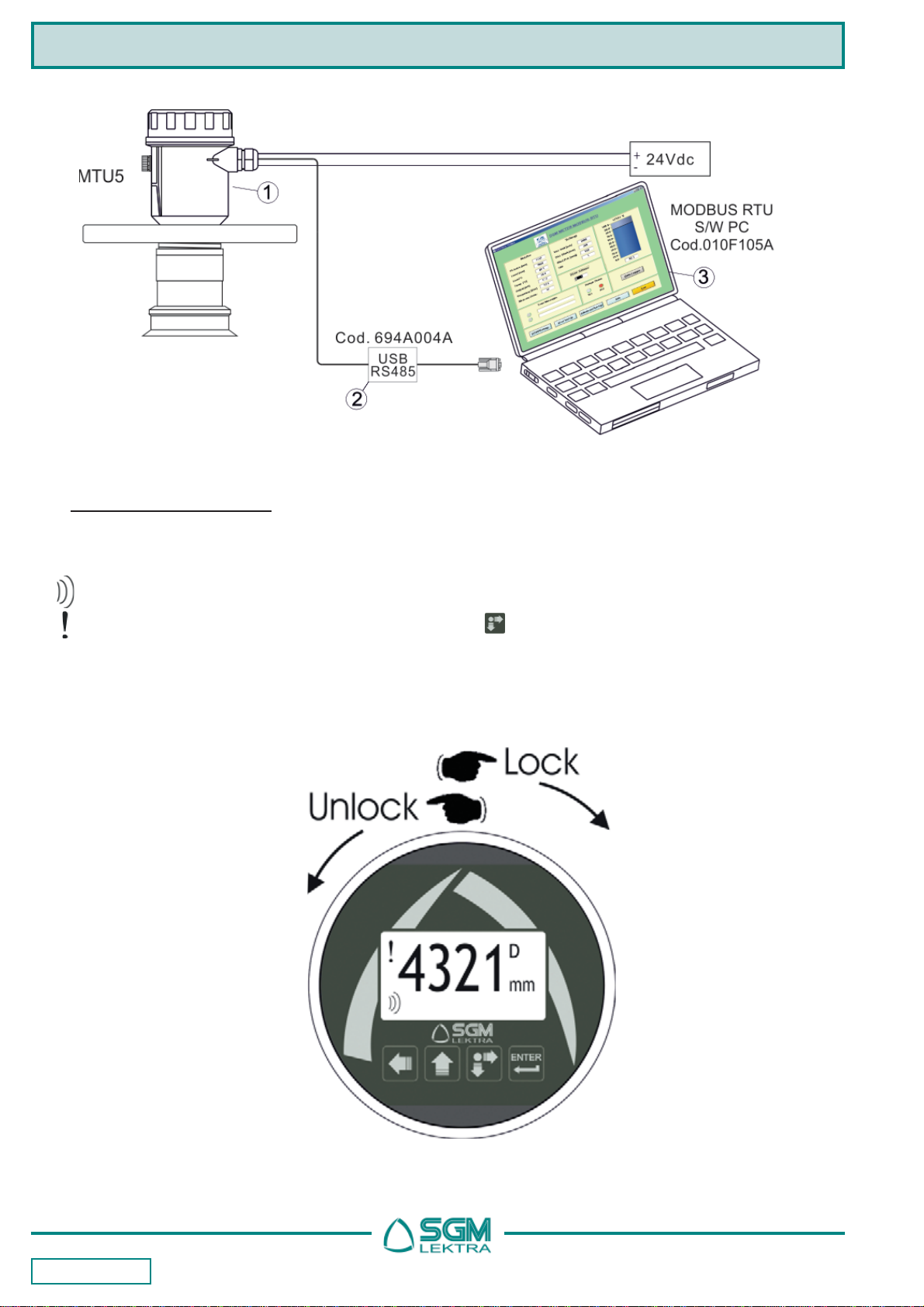

4.1 Via MODBUS RTU

4.1.1 MODBUS RTU PC connection (fig.13)

1) MTU5 with MODBUS RTU communication protocol

2) USB/RS485 interface module, cod.694A004A

3) MODBUS RTU communication S/W, cod.010F105A (3), for MTU5 transmitter

With this software is possible:

- connect, by selecting the UID address, the MTU5 transmitters in MODBUS RTU network

- read on your PC monitor all measures in reading and MTU5 operation data

- programming all MTU5 configuration parameters

- storing on files, data logger function; MTU5 measures in reading and operating states

To avoid the humidity infiltration inside the housing is recommended:

- forelectricalconnections, usea cablewith a 6÷12mm outer diameterand

fully tighten the M20 cable gland

- fully tighten the cap

- position the cable so that it forms a downward curve at the M20 output

(Fig. 12); in this way the condensation and/or rain water will tend to drip

from the curve bottom

For installations with a strong humidity/vapor presence the version with

the optional anti-condensation filter (cod.M/N) is available Fig.12

The immunity to electromagnetic interference complies with Directives

Fig.11

Page 6 of 28

4.3 via VL601 configuration

The VL601 programming module can be mounted and removed from the MTU5 without affecting the unit operation.

Unscrewing the cap, the VL601 module can be mounted (by clockwise rotation until it clicks) or dismounted (by

rotation counterclockwise) as shown in Fig.14. The VL601 module is equipped with matrix LCD.

displayed at the bottom indicates the correct echo signal reception

displayedat thetop alertsthat thereis ageneric error;press to showthe messagethat indicatesthe present

error type.

The MTU5 returns automatically to RUN mode.

MTU5 - Configuration

Fig.13

Fig.14

Page 7 of 28

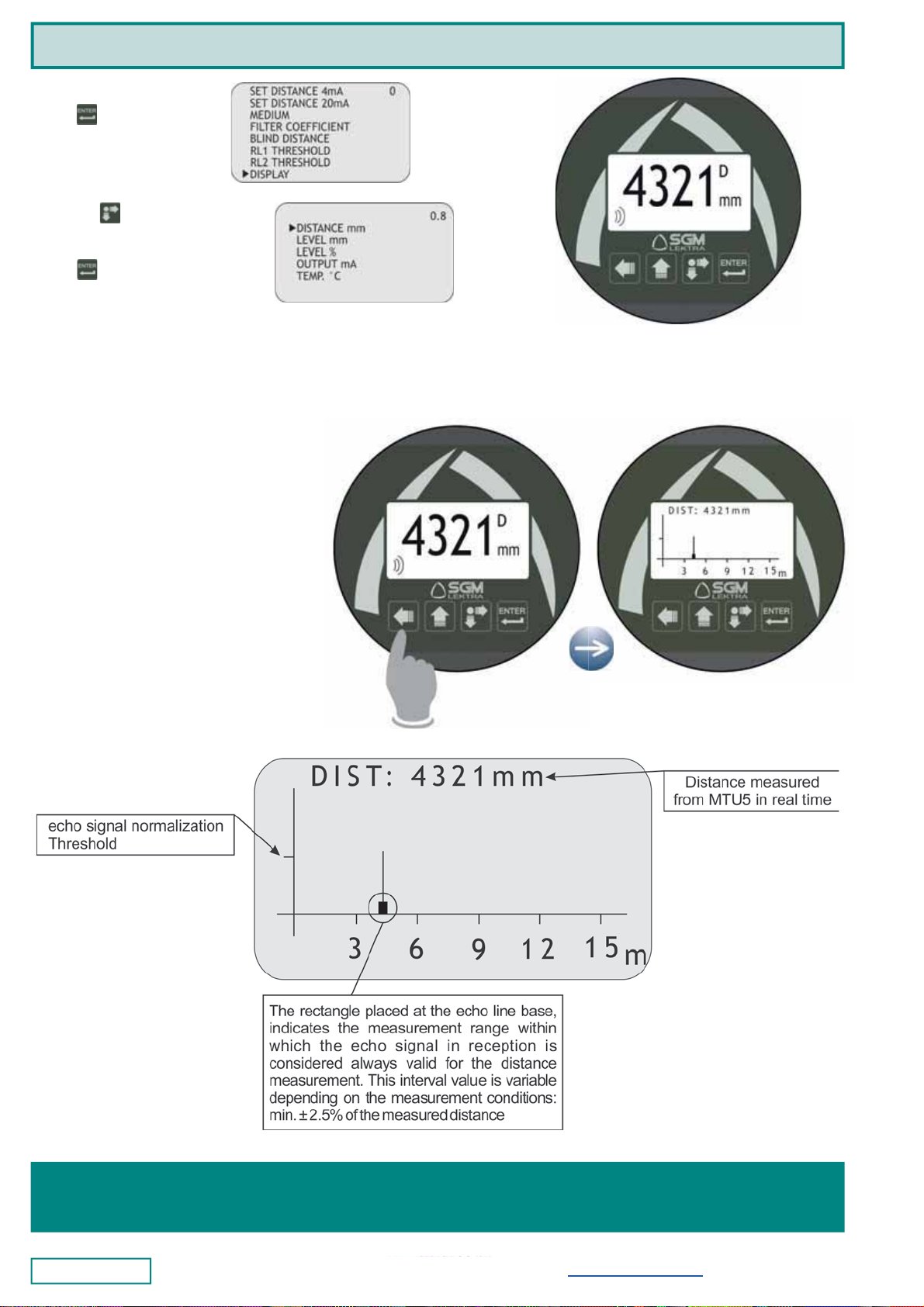

The VL601 program module has 4 buttons (fig. 15) which allow to perform all operational, control and programming

instrument functions.

In the configuration menus, is possible:

a) Submenus and parameters access; press to select and press to access.

b) Parameter options choice: Press to select the option and press to store the option.

Press to exit without storing

c) Configure the parameter values; in some parameters the configuration is done by setting a value (eg., in the

SET DISTANCE 4mA parameter is possible to change the the corresponding distance value, in mm): press to

select the digit to be modified (the digit is highlighted in inverse ), press to change the highlighted digits

number, press to save the set value and exit automatically. Press to exit without storing .

In the display top right, during the settings, there is always a number, eg. “1.2”. This number is the menu or

parameter index that’s displayed. The menu structure is represented on page 8 and on pages 13÷14.

MTU5 - Configuration

Fig.15

WiththeVL601 module is possible to access two configuration modes for the MTU5 setting:

QUICK START - Menu with easy access for quick basic parameters configuration.

To access: from “RUN” mode press to the quick setup menu mode access, to exit

ADVANCED CONFIGURATION - Full menu with access to all parameters, including functional parameters.

It is recommended to carefully read the complete documentation before accessing.

To access: from “RUN” mode, holding down , press to the advanced configuration mode access, to exit

WARNING! -The documentationprovidedwiththeMTU5containthemostfrequently

used indications. If it’s necessary refer to the full manual, it can be downloaded from

our website www.sgm-lektra.com , in the products section.

Page 8 of 28

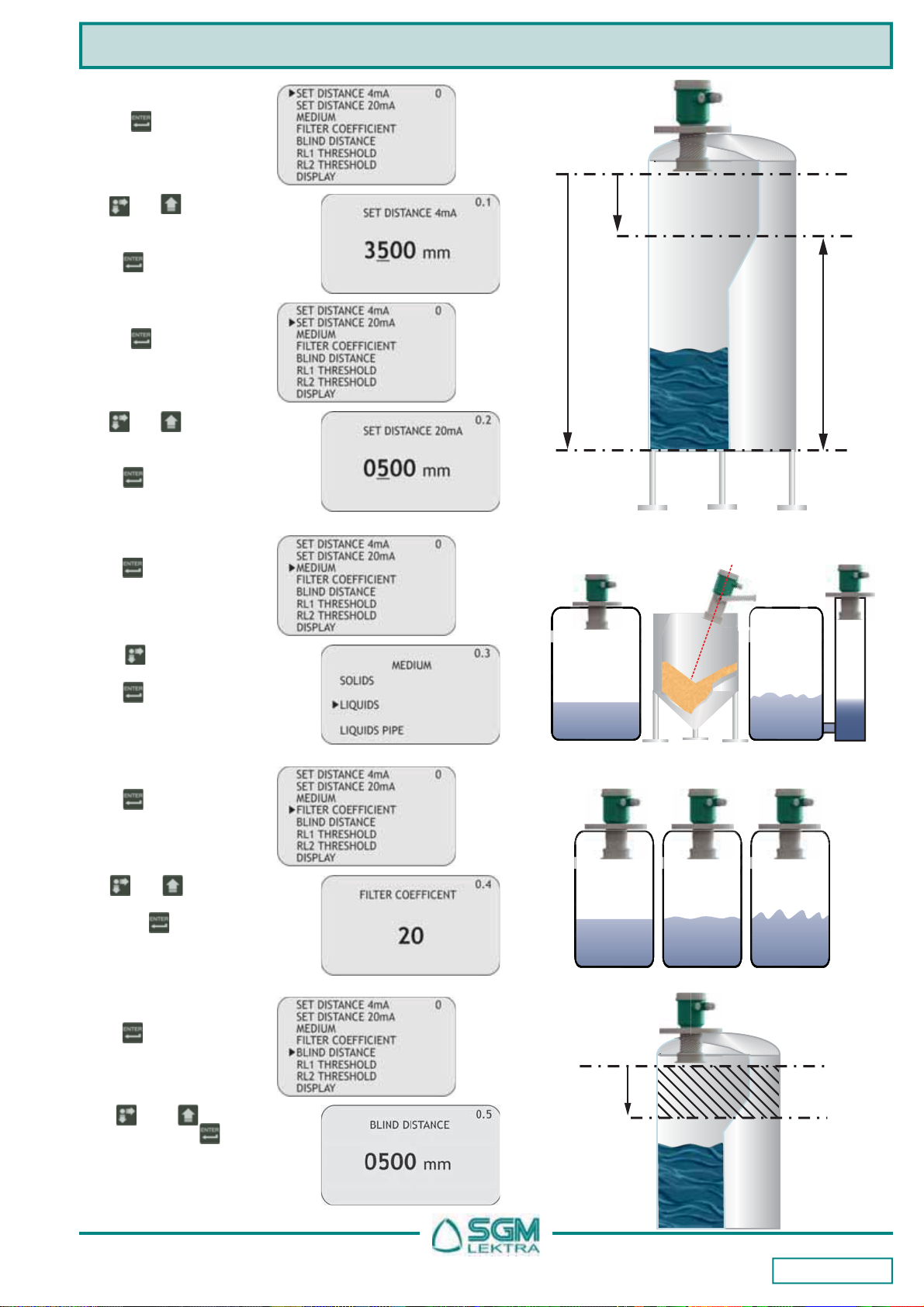

5. QUICK START MODE

MTU5 - Quick Start

From “RUN” mode press

to access the Quick

Setup menu

Select the parameters by

moving the cursor with ,

and confirm with ;

press to exit

5.1 Quick Setup menu structure

Page 9 of 28

MTU5 - Quick Start

4mA distance

20mA distance 100%

0%

Level

measurement

MTU5

reference point

t

t

t

t

Fig.16

5.2.3 MEDIUM

5.2.5 BLIND DISTANCE

5.2.4 FILTER COEFFICIENT

5.2.1 SET DISTANCE 4mA

Press to display the

distance value associated

with 4mA output.

5.2.2 SET DISTANCE 20mA

Press to display the pre-

vious setting

Press to select the me-

dium type.

Press to confirm.

In fig.17 product selection

example.

Press .TheBLIND ZONE

is used to avoid undesi-

red measures near to the

transmitter

Use and to modify

the value. Press to con-

firm. The minimum value is

500mm.

Press . Increasing the

valueslows down the sensor

response speed.

Use and tomodify the

value.Input a value from 1to

99. Press to confirm.

In fig.18 value choice exam-

ple.

Use and tomodifythat

value;in the Fig.16 example,

the4mAdistanceis3500mm.

Press to confirm.

Press to display the

distance value associated

with 20mA output.

Use and tomodifythat

value;in the Fig.25 example,

the20mAdistanceis500mm.

Press to confirm.

SOLIDS

LIQUIDS

LIQUIDS

PIPE

Fig.17

Fast resp.

5÷10 Normal resp.

20 Slow resp.

40÷100

Fig.18

BLIND

DISTANCE

BLIND

ZONE

MTU5

reference point

t

t

t

Fig.19

Page 10 of 28

MTU5 - Quick Start

5.2.6 RL1 THRESHOLD

Press to display the

previous setting. Set the

distance from the sensor

Use and tomodify the

value; in the fig.20 example

the RL1 max. level threshold

distance is 700mm.

Press to confirm.

NB-RL1 inactive with

0000mm

When confirming with the button the maximum level threshold value storage, in the example 700m (figures 20 and

21), the MTU5 activates RL1 with the following default settings for level alarm threshold:

1) MIN / MAX = MAX; maximum level alarm

2) DELAY = 0 sec.; no switching delay

3) SECURITY = YES; relay de-energized, and contact open, during the maximum level alarm

4) ENABLE / DISABLE = ENABLE; alarm threshold function enabled

To change these relay settings is necessary to access the advanced setup menu (pag.16) and any subsequent changes

to the RL1 threshold value not affect the relay custom settings.

RL1

THRESHOLD

Max level

alarm zone

MTU5

reference

point

700mm

Fig.20

RL1

SET

RL1 "ON"

RL1 "OFF"

RL1 RL1

Level

RL1, MAX LEVEL ALARM

RL1 RL1

RL1

RL1

Max

Alarm Max

Alarm

MTU5

reference

point

RL1

THRESHOLD

Max. level

alarm zone

700mm

RL1

Fig.21

Page 11 of 28

MTU5 - Quick Start

5.2.7 RL2 THRESHOLD

Press to display the

previous setting. Set the

distance from the sensor

Use and tomodify the

value; in the Fig.22 example

the RL2 min. level threshold

distance is 9000mm.

Press to confirm.

NB-RL2 inactive with

0000mm

When confirming with the button the maximum level threshold value storage, in the example 3000mm (figures 22 and 23),

the MTU5 activates RL2 with the following default settings for level alarm threshold:

1) MIN / MAX = MIN; minimum level alarm

2) DELAY = 0 sec.; no switching delay

3) SECURITY = YES; relay de-energized, and contact open, during the maximum level alarm

4) ENABLE / DISABLE = ENABLE; alarm threshold function enabled

To change these relay settings is necessary to access the advanced setup menu (pag.16) and any subsequent changes

to the RL2 threshold value not affect the relay custom settings.

MTU5

reference

point

RL2

THRESHOLD Min. level

alarm zone

3000mm

Fig.22

RL2 RL2

SET

RL2 "ON"

RL2 "OFF”

RL2 RL2

Level

RL2, MIN. LEVEL ALARM

RL2 RL2

RL2 RL2

Min.

Alarm Min.

Alarm

MTU5

reference

point

RL2

THRESHOLD

Min. level

alarm zone 9000mm

Fig.23

Page 12 of 28

MTU5 - Quick Start

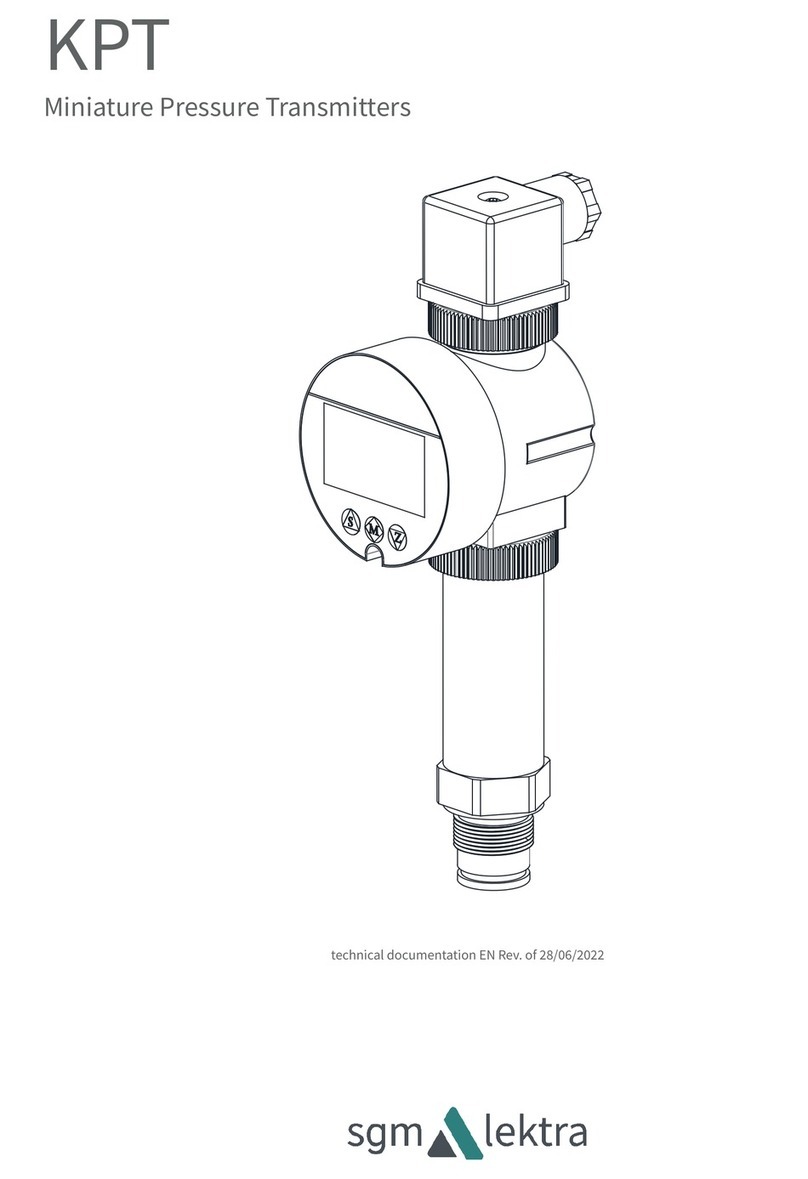

5.2 ECHO MAP

Pressing the BK, from RUN mode, to access

directly to the echoes digital map display,

which are in MTU5 receiving (Fig.25).

This function is useful for:

- properly orient the transducer

pointing.

- verify the echoes in acquisition

correctness.

- identify any false echo signals

that may cause measurement

errors.

Fig.24

Fig.25

Documentation subject to technical change with no prior warning

SGM-LEKTRA S.r.l. Via Papa Giovanni XXIII, 49 - 20090 Rodano (MI) - ITALY-

tel: ++39 0295328257 fax: ++39 0295328321

web: www.sgm-lektra.com e-mail: [email protected]

Pagesfrom13to28(fullmanual)canbedownloadedfromourwebsitewww.sgm-lektra.comintheproductssection

5.2.8 DISPLAY

Press to access the set-

tings change.

With the button is pos-

sible to select the data to

display

Press to confirm.

Table of contents

Other SGM LEKTRA Transmitter manuals

SGM LEKTRA

SGM LEKTRA PTU51 User manual

SGM LEKTRA

SGM LEKTRA PTU50 User manual

SGM LEKTRA

SGM LEKTRA METER Guide

SGM LEKTRA

SGM LEKTRA RPL81 User manual

SGM LEKTRA

SGM LEKTRA FLOWMETER Guide

SGM LEKTRA

SGM LEKTRA KPT Guide

SGM LEKTRA

SGM LEKTRA TC26 User manual

SGM LEKTRA

SGM LEKTRA RPL75 User manual

SGM LEKTRA

SGM LEKTRA PTU50 Guide

SGM LEKTRA

SGM LEKTRA RPL81 User manual

Popular Transmitter manuals by other brands

Danfoss

Danfoss AKS 32 installation guide

Cooper Menvier

Cooper Menvier 705r installation guide

Omega

Omega TX31 user guide

ZachTek

ZachTek WSPR quick start guide

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS ALPHA TDS 200 TOTAL DISSOLVED SOLIDS... instruction manual

Panasonic

Panasonic Ramsa WX-RP410 operating instructions