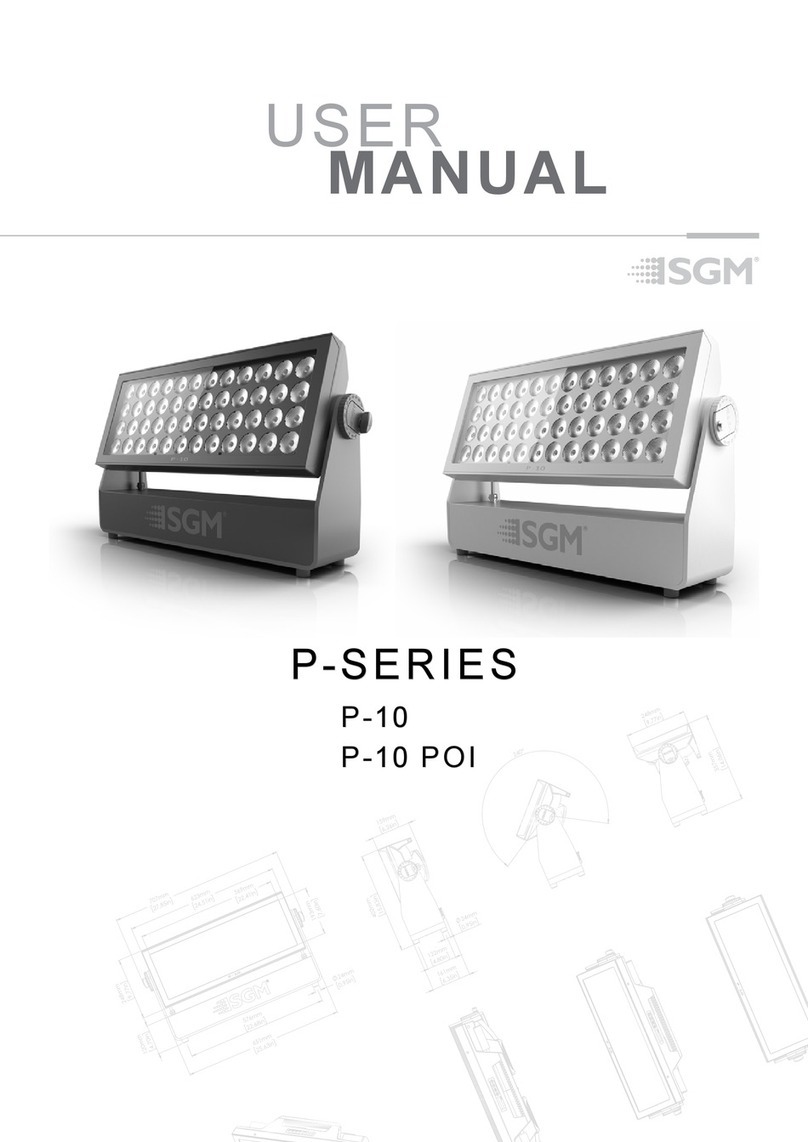

SGM P-3 User manual

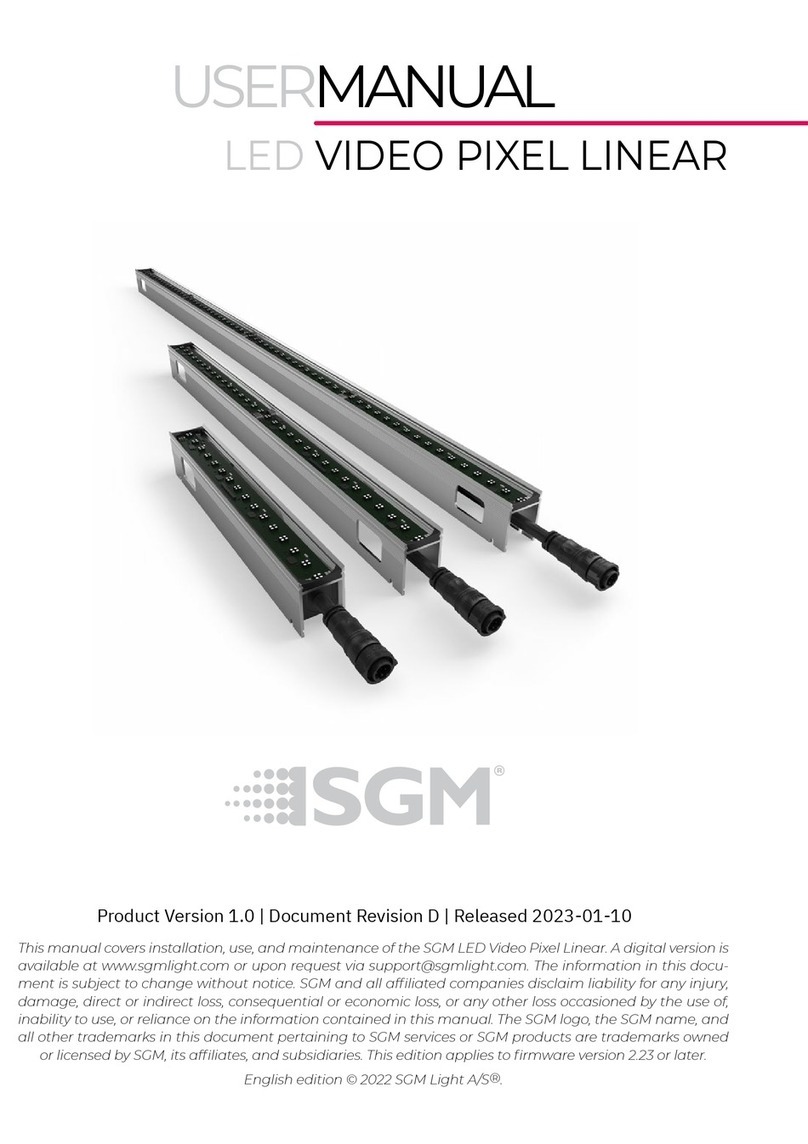

USERMANUAL

P-3

Product Version 1.0 | Document Revision A | Released 2023-10-19

PRELIMINARY

2Product Version 1.0 | Revision A | Released 2023-10-19

P3 VISION DIMENSIONS

All dimensions in millimetres and inches. Drawing not to scale

This manual covers installation, use, and maintenance of the P-3 SGM Series. A digital version is available at

to change without notice. SGM and all affiliated companies disclaim liability for any injury, damage, direct

or indirect loss, consequential or economic loss, or any other loss occasioned by the use of, inability to use, or

reliance on the information contained in this manual. The SGM logo, the SGM name, and all other trade-

marks in this document pertaining to SGM services or SGM products are trademarks owned or licensed by

SGM, its affiliates, and subsidiaries. This edition applies to firmware version 1.17 or later.

English edition © 2023 SGM Light A/S®.

11,417in

290mm

9,915in

251,85mm

6,063in

154mm

11,024in

280mm

4,882in

124mm

6,618in

168,1mm

9,892in

251,25mm

180°

11,417in

290mm

9,915in

251,85mm

6,063in

154mm

11,024in

280mm

4,882in

124mm

6,618in

168,1mm

9,892in

251,25mm

180°

3Product Version 1.0 | Revision A | Released 2023-10-19

P3 WASH DIMENSIONS

All dimensions in millimeters and inches. Drawing not to scale

11,417in

290mm

9,915in

251,85mm

6,063in

154mm

11,024in

280mm

6,618in

168,1mm

9,892in

251,25mm

180°

11,417in

290mm

9,915in

251,85mm

6,063in

154mm

11,024in

280mm

6,618in

168,1mm

9,892in

251,25mm

180°

4Product Version 1.0 | Revision A | Released 2023-10-19

2 P-3 VISION DIMENSIONS

3 P-3 WASH DIMENSIONS

6 SAFETY INFORMATION

7 BEFORE INSTALLING THIS PRODUCT

8 OVERVIEW

8 Fixture Types

8 Cabling on Wash and Vision

8 Control Options

9 INSTALLATION P-3

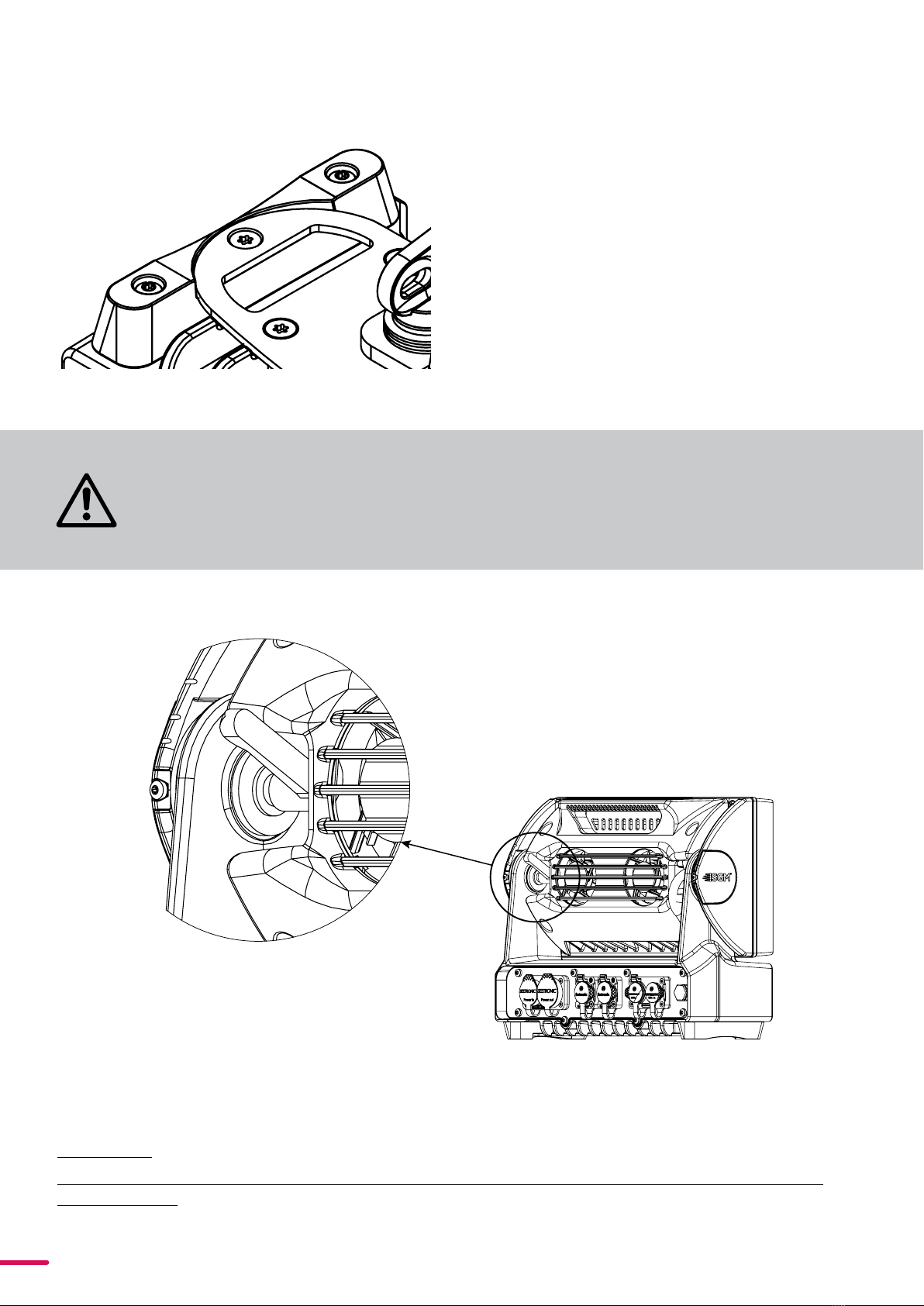

9 Identication and terminology of P-3 Vision

10 Identication and terminology of P-3 Wash

11 Unpacking

11 Application considerations

11 Handling and Transportation

12 RIGGING

13 Omega bracket

14 Safety Wire

14 Tilt Lock

15 Arraying

16 POWER AND DATA

16 P-3 Vision and Wash Power

16 P-3 Vision and Wash Data

17 DMX

17 Ethercon

17 Connecting a wireless transmitter

1 7

Signal priority

18 USER INTERFACE

18 Using the display panel

18 Shortcuts

19 DISPLAY

19 Operational mode (A)

19 Fixture Universe (B)

19 DMX Address (C)

19 External data protocol (D)

19 External data indicator (E)

19 Next available address (F)

19 Information panel (G)

19 Warning Indicator

20 CONFIGURATION

20 About DMX

20 DMX Start address

20 Setting Universe and address

CONTENT

5Product Version 1.0 | Revision A | Released 2023-10-19

21 MANUAL OPERATION

21 USING STANDALONE OPERATION

22 CONFIGURATION WITH DMX/RDM ADDRESSING TOOL

23 FIXTURE PROPERTIES AND DEFAULT SETTINGS

23 Individual Fixture Settings

23 LED Engine

23 Beam Angle

24 RDM

24 Supported RDM functions

24 Sensors

25 CONTROLLING P-3 VISION

25 Operation from a single controller

26 Operation from two controllers using Hybrid Mode

29 ACCESSORIES

29 Arraying bracket

29 Filter frame

30 MAINTENANCE

30 Firmware Updates

31 Cleaning

31 SGM Vacuum Test kit

32 TROUBLESHOOTING

33 FIXTURES AND ACCESSORIES

33 Ordering information

34 SUPPORT HOTLINE

34 APPROVALS AND CERTIFICATIONS

35 USER NOTES

CONTENT

6Product Version 1.0 | Revision A | Released 2023-10-19

SAFETY INFORMATION

SGM fixtures are intended for professional use only. They are not suitable for household use.

Les fixtures SGM sont impropre à l’usage domestique. Uniquement à usage professionnel.

This product must be installed in accordance with the applicable installation code by a person

familiar with the construction and operation of the product and the hazards involved.

Ce produit doit être installé selon le code d’installation pertinent, par une personne qui connaît

bien le produit et son fonctionnement ainsi que les risques inhérent.

DANGER! RISK OF ELECTRIC SHOCK DO NOT OPEN THE DEVICE!

• Do not open the device; there are no user-serviceable parts inside.

• Disconnect power before installing or servicing to avoid electrical shock.

• Ensure that the device is electrically connected to earth (ground).

• Do not apply power if the device or mains cable is in any way damaged.

• Do not immerse the fixture in water or liquid.

WARNING! TAKE MEASURES TO PREVENT BURNS AND FIRE!

• Install in a location that prevents accidental contact with the device.

• Install only in a well-ventilated space.

• Install only in accordance with applicable building codes.

• Do not paint, cover, or modify the device, and do not filter or mask the light.

• Keep all flammable materials well away from the device.

ALLOW THE DEVICE TO COOL FOR 15 MINUTES AFTER OPERATION BEFORE TOUCHING IT

CAUTION: EXTERIOR SURFACE TEMPERATURE AFTER 5 MIN. OPERATION = 42°C 108°F.

STEADY STATE = 48°C 118°F.

WARNING! TAKE MEASURES TO PREVENT PERSONAL INJURY. DO NOT

LOOK DIRECTLY AT THE LIGHT SOURCE FROM CLOSE RANGE.

• Take precautions when working at height to prevent injury due to falls.

• For Permanent Outdoor Installations (POI), ensure that the fixture is securely fastened to

a load-bearing surface with suitable corrosion-resistant hardware.

• For elevated installations, secure the fixture with suitable safety cables, and always com-

ply with relevant load dimensioning, safety standards, and requirements.

WARNING! READ THE FOLLOWING SAFETY PRECAUTIONS CAREFULLY BE-

FORE UNPACKING, INSTALLING, POWERING OR OPERATING THE DEVICE.

Please visit www.sgmlight.com for the latest version of this user manual / safety information

leaflet. Due to continuous improvements, the instructions may change without notice. SGM al-

ways recommends the latest available firmware version from www.sgmlight.com.

7Product Version 1.0 | Revision A | Released 2023-10-19

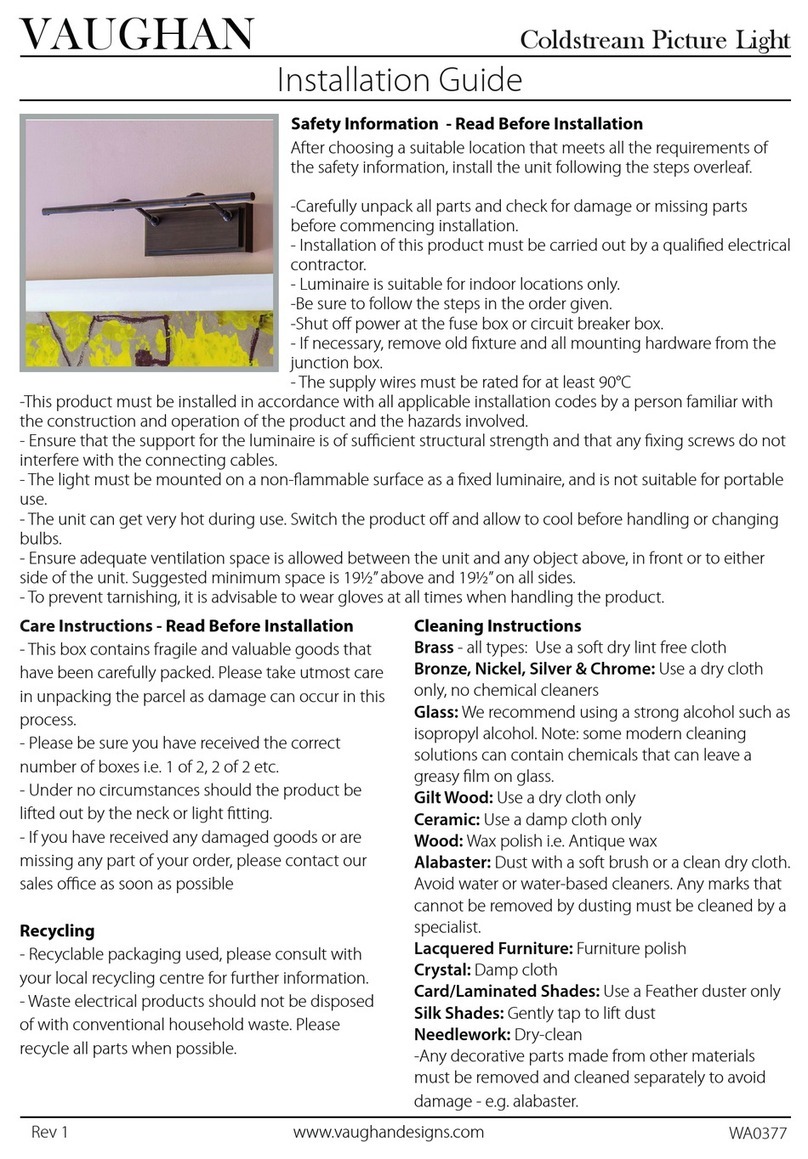

BEFORE INSTALLING THIS PRODUCT

VISUAL INSPECTION

All users of the SGM fixtures should regularly clean those parts of the fixture directly exposed to

the elements, such as the external housing and front lenses. Additionally, all owners of the SGM

fixtures must periodically check the external housing of the fixture for structural breaks, deteri-

oration, cracked lenses, or loose screws. To ensure proper operation, but also to prevent the risk

of potential accidents, do not use the fixture if the lens, housing, or power cables are damaged.

If parts of the fixture appear to be missing, cease use immediately and contact SGM support.

WIRING

When installing fixtures in a permanent installation, ensure power and data cable leads are in-

stalled as a service loop to an appropriately rated junction box using suitable cable strain reliefs/

glands. All installed fixtures must be securely mounted, and service loop appropriately protect-

ed for installation location. All electrical wiring and connections should be completed by a qual-

ified electrician.

Separation of field installed power limited circuit (dimming/control) wiring from the branch

circuit wiring in the outlet box are to be made in accordance with local and/or national electrical

installation codes.

SAFETY PRECAUTIONS

When using electrical equipment, basic safety precautions should always be followed including

the following:

• Do not mount near gas or electric heaters.

• Permanently installed equipment should be mounted in locations and at heights where

it will not readily be subjected to tampering by unauthorized personnel.

• The use of accessory equipment not recommended by the manufacturer may cause an

unsafe condition.

• Do not use this equipment for other than intended use.

• Refer service to qualified personnel or authorized service centres.

• Do not look directly into the beam for long periods of time, when the fixture is on.

• The fixture shall, under no circumstance, be covered with insulating material of any kind.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

8Product Version 1.0 | Revision A | Released 2023-10-19

OVERVIEW

The P-3 series of fixtures are designed to provide even and powerful washes over various flat surfaces such as stages

and building facades. The range features multiple beam angles, LED engines and control protocols. P-3 is an exterior,

IP66 rated product intended for permanent or temporary mounting.

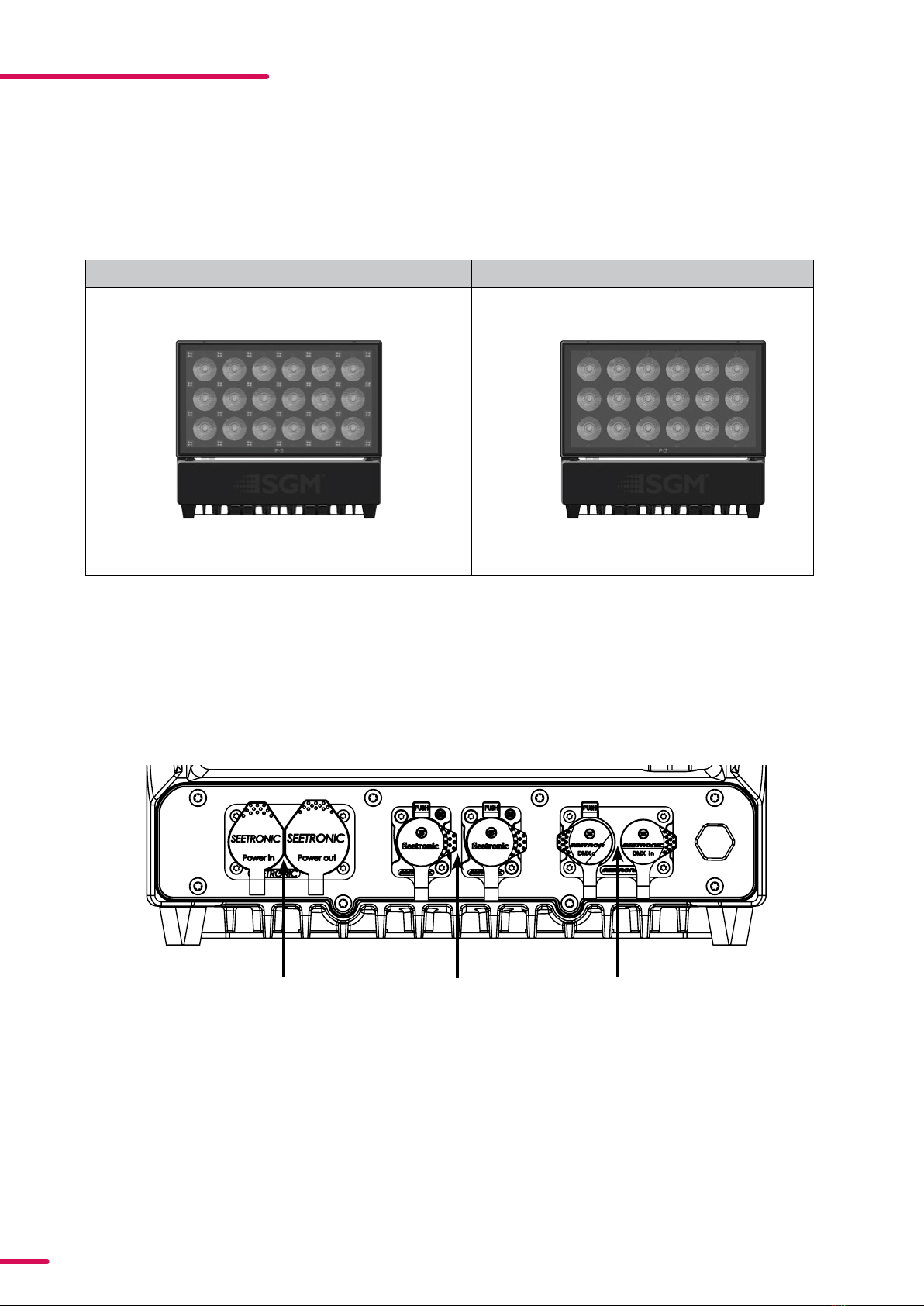

FIXTURE TYPES

CABLING ON WASH AND VISION

CONTROL OPTIONS

P-3 VISION P-3 WASH

Power In/Out Ethernet In/Out DMX In/Out

• DMX

• sACN

• Art-Net

• Wireless DMX (CRMX)

9Product Version 1.0 | Revision A | Released 2023-10-19

INSTALLATION P3

Illustrations might vary from received products. This is subject to change without notice.

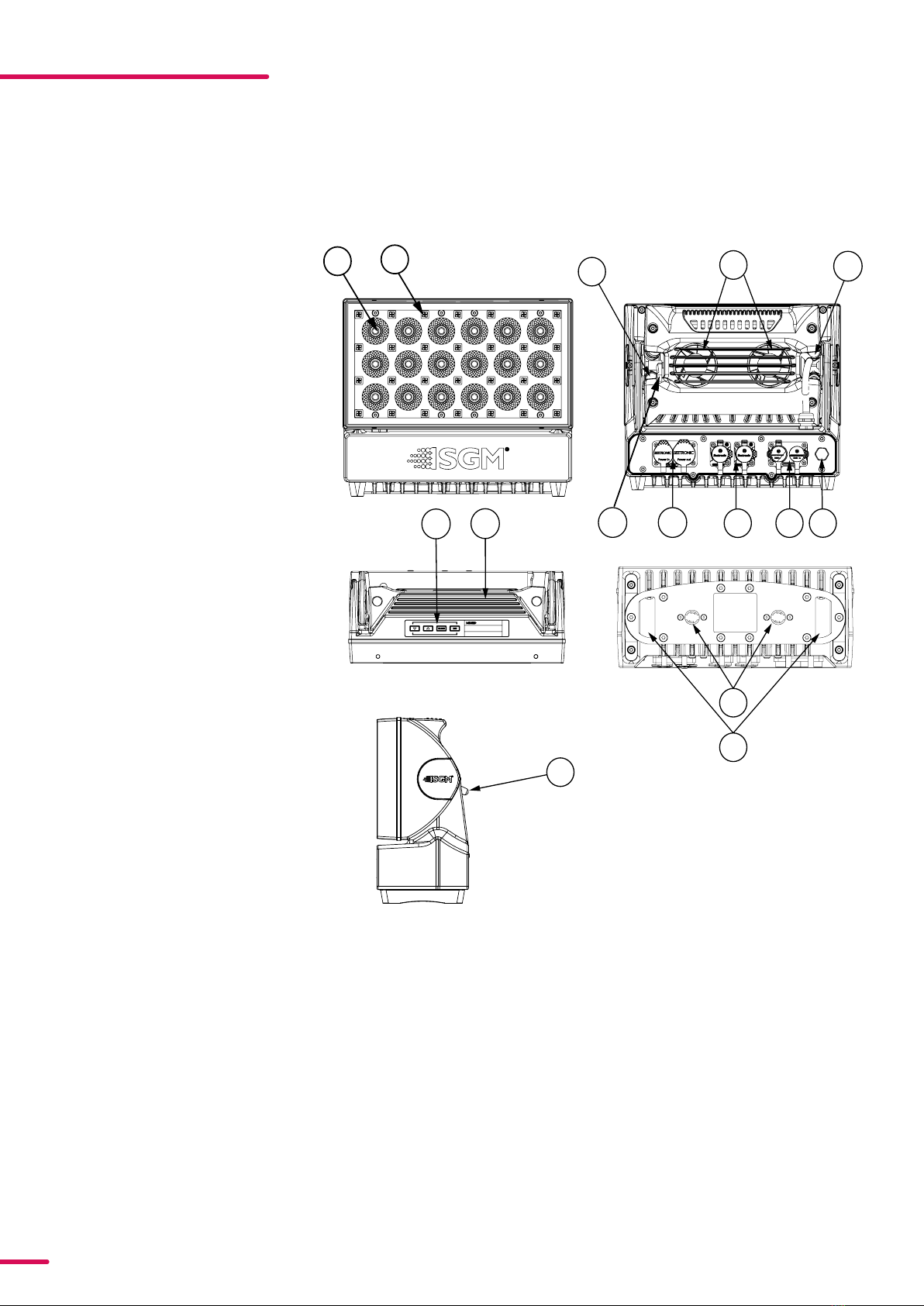

IDENTIFICATION AND TERMINOLOGY OF P3 VISION

AB

A: 24 x RGBW LEDs

B: 28 x RGB pixels

C: GORE-TEX membrane

D: Cooling fans

E: Dehumidifier

F: Control Panel

G: Handle

H: Tilt Lock

I: Power In/Out

J: Ethernet In/Out

K: DMX In/Out

L: Holes for Omega bracket

M: Safety wire attachment point

D

C

JC

K

L

M

I

F

E

G

H

H

10 Product Version 1.0 | Revision A | Released 2023-10-19

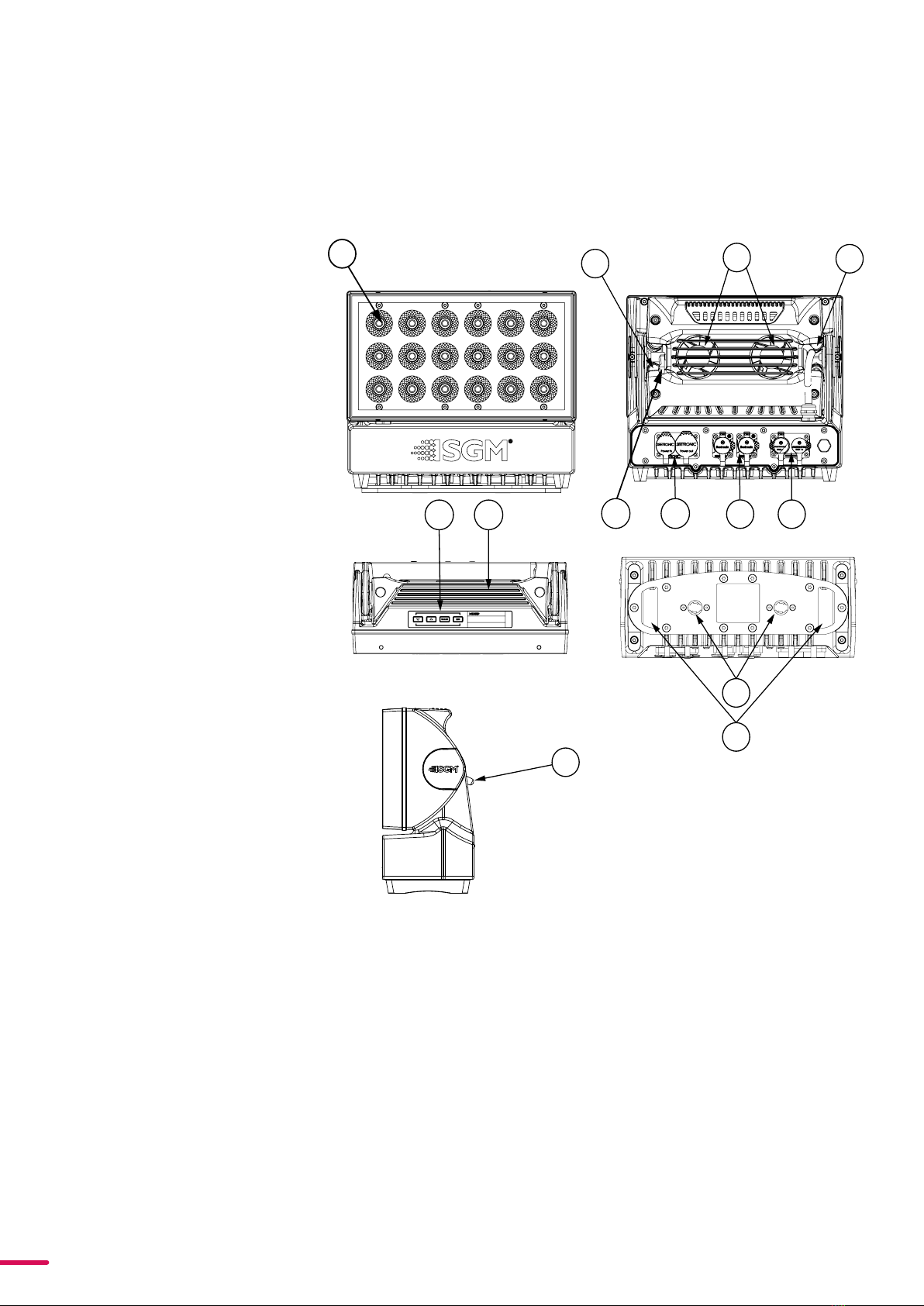

IDENTIFICATION AND TERMINOLOGY OF P3 WASH

AB

A: 24 x RGBW LEDs

B: GORE-TEX membrane

C: Cooling fans

D: Dehumidifier

E: Control Panel

F: Handle

G: Tilt Lock

H: Power In/Out

I: Ethernet In/Out

J: DMX In/Out

K: Holes for Omega bracket / M-10 screws (x2)

L: Safety wire attachment point

K

L

FI

G

G

HJ

E

CD

11 Product Version 1.0 | Revision A | Released 2023-10-19

UNPACKING

Before permanent mounting, ensure the fixture is not visibly damaged and that all parts and components are pres-

ent. Testing the fixture for proper function is also recommended. During testing, configuration and addressing can

be done. The P-3 is an addressable product and is most efficiently configured before installation. This is especially true

in installations where the fixtures will be in inaccessible areas.

Configuration can be done either via the display or by using SGM Configuration software. This PC based software is

available for download from the SGM website. Once all fixtures, parts and software are available, configuration and

installation can begin.

APPLICATION CONSIDERATIONS

When selecting a location for the device, ensure that:

• It is situated away from public thoroughfares and protected from contact with people.

• It is not immersed in water.

• It has adequate ventilation

The standard fixture is IP66-rated and is designed for both indoor and outdoor events. This means that it is protected

from:

• Dust, to the degree that dust cannot enter the fixture in sufficient quantities as to interfere with its operation.

• Lower pressure water jets from any direction.

When using standard fixtures outdoors or in wet locations, ensure that:

• The DMX connection out of the last fixture in a chain is properly sealed, in accordance with the ingress protec-

tion (IP) requirements.

• The DMX out of the last fixture is terminated with a 120 Ohm resistor between pin 2 and 3 (as per RS485 stand-

ards).

HANDLING AND TRANSPORTATION

Always use the supplied packaging or suitable flight case for transportation and storage. Never carry the fixture by

connected cables or wires.

12 Product Version 1.0 | Revision A | Released 2023-10-19

RIGGING

The P-3 can be installed in any orientation, in any free-air cooled application. There are numerous mounting options

via 3 adjustable brackets.

Start the standard rigging process by blocking the lower working area, and make sure the work is performed from a

stable platform.

3,150in

80mm

4,882in

124mm

4,173in

106mm

10,079in

256mm

11,417in

290mm

2,441in

62mm

A

Figure 1 : Dimensions for base locking points

All SGM fixtures have locking points in the base for installation and rigging. In both standard and POI fixtures, the

distance between the points from center to center is always 106 mm. Standard versions include 1/4 turn fasteners to

mount SGM omega brackets. POI versions come with M-10 captive nuts for M-10 screws.

Always use the supplied omega bracket to rig a standard fixture. Lock the bracket with the 1/4-turn fasteners.

PLEASE NOTE! 14TURN FASTENERS ARE ONLY LOCKED WHEN TURNED FULLY CLOCKWISE. DEPENDING ON

THE STRUCTURE, PLEASE USE APPROPRIATE AND SECURE METHODS FOR MOUNTING THE OMEGA BRACKETS.

13 Product Version 1.0 | Revision A | Released 2023-10-19

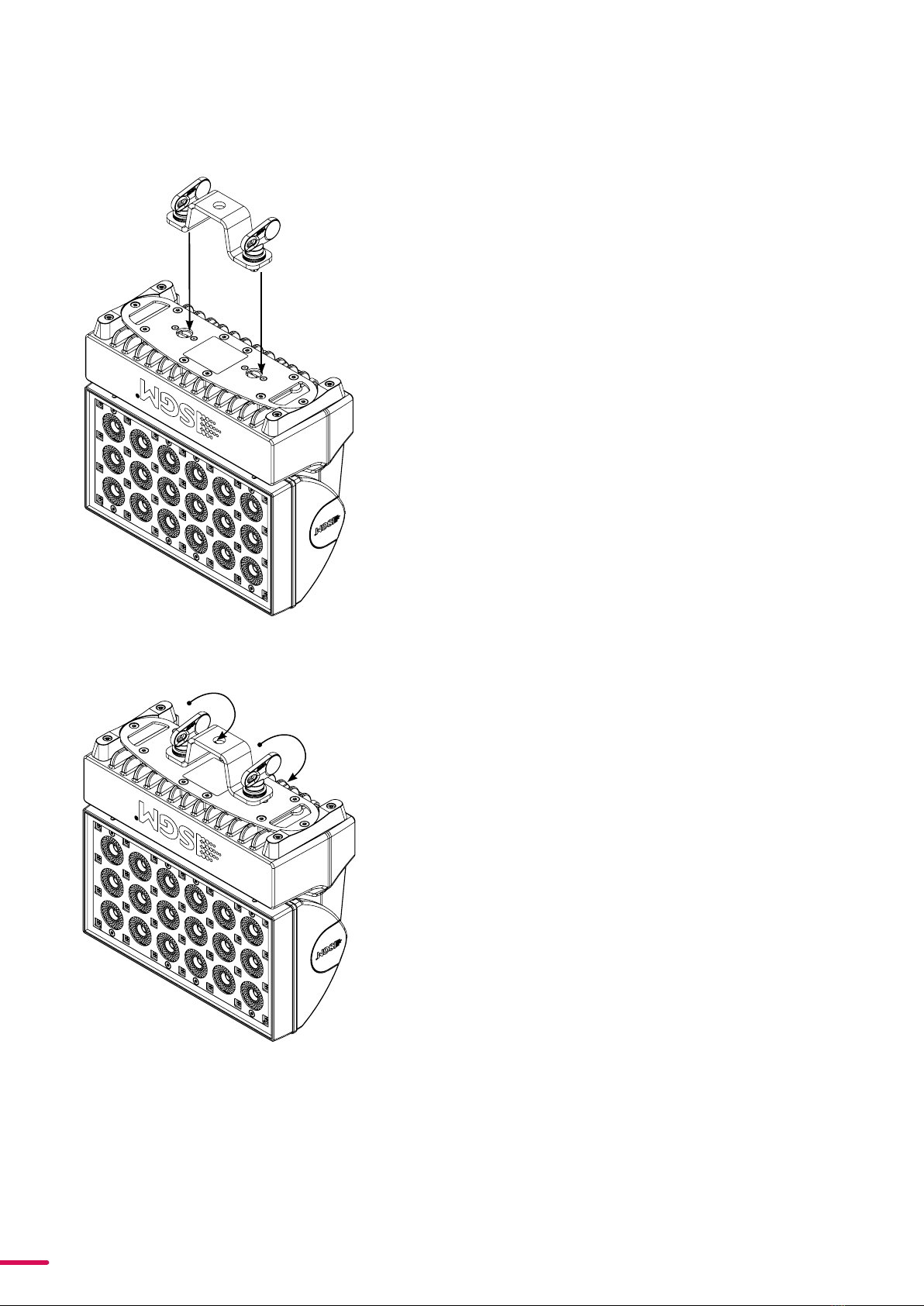

Step 1. Check that the clamp/bracket is undam-

aged. Supporting structure should be capable of

bearing at least 10 times the weight of all installed

fixtures, lamps, cables etc.

Step 2. Bolt a clamp or bracket securely to the ome-

ga bracket with a M12 bolt (min. grade 8.8) and a

lock nut. For longer term installations, choose out-

door-rated hardware.

Step 3. Align the omega bracket with the fixture

base. For standard Omega Bracket, insert the fas-

teners into the fixture base bracket, and turn both

levers a full 1/4 turn clockwise to lock. (When using

the POI Omega Bracket, insert the included M-10

screws through the bracket holes and tighten

them with a M-10 key until they are fully attached

to the base.

Step 4. Hang the fixture on a truss or other struc-

ture. Tighten the clamp/bracket.

Step 5. Verify that there are no combustible materi-

als, cables, or surfaces to be illuminated within 0.3

m (12 in.) of the fixture.

Step 6. Check that there is no risk of the head/yoke

colliding with other fixtures or structures.

Figure 3 : Installing the P-3

Figure 2: Installing the P-3

OMEGA BRACKET

14 Product Version 1.0 | Revision A | Released 2023-10-19

Fasten a safety wire (not shown) between the load-bear-

ing support structure and the safety wire attachment

point on the device.

The safety cable (not included in the package) must:

• Bear at least 10 times the weight of the device

(SWL).

• Have a minimum gauge of 4 mm.

• Have a maximum length (free fall) = 30 cm (12 in.).

SAFETY WIRE

SAFETY WIRE

Figure 4 : Safety wire attachment point

Pushing the lever on the left hand side of the fixture will tighten the tilt. it may take several rotations to fully lock the

fixture head in place.

CAUTION!

ALWAYS LEAVE A FIXTURE TO COOL OFF FOR 15 MINUTES AFTER OPERATION BEFORE

HANDLING.

SAFETY WIRE

TILT LOCK

WARNING! ALWAYS SECURE AN ELEVATED FIXTURE WITH A SAFETY WIRE.

ALWAYS USE A SAFETY WIRE OF A GRADE AISI 316 STEEL. MAKE SURE THE

SLACK OF THE SAFETY WIRE IS AT A MINIMUM. NEVER USE THE YOKE/

HANDLE FOR SECONDARY ATTACHMENT.

Figure 5: Tilt Lock

15 Product Version 1.0 | Revision A | Released 2023-10-19

ARRAYING

PLEASE NOTE! APPLICABLE TO P3 VISION AND WASH VARIANTS ONLY.

The P-3 Vision and Wash are designed to work with an arraying bracket which locks the fixtures together in x and y

axis. This bracket aligns the fixtures only, they are not designed to be self-supporting.

PLEASE NOTE: NEVER RIG FIXTURES FROM THE ARRAYING BRACKET WITHOUT A SUPPORTING STRUCTURE.

Step 2:

Attach fixtures to the arraying brackets using

the quarter turn fasteners one line at a time. This

is so that all fixtures can be configured and veri-

fied via the control screen and keypad.

Step 3:

Cable each line of fixtures and verify boot and

configuration settings are correct.

Repeat steps 2 and 3 for grid style and other x &

y axis shapes.

Step 1:

Create a substructure which is spaced appropri-

ately to have the arraying brackets connected

together in the shape desired.

All connecting hardware must be sized and rat-

ed to safely hold the weight of the fixture and

the arraying bracket together.

Figure 6: Installation with arraying brackets

16 Product Version 1.0 | Revision A | Released 2023-10-19

Color

Black

White

green/yellow

Conductor

live

neutral

ground (earth)

Symbol

or

L

N

Wire

(L2)

Figure 8: Connecting AC Power/P-1 power cable 8 mm

P3 VISION AND WASH POWER

P3 VISION AND WASH DATA

The power cable color coding is given in figure 8:

• Connect the black wire to live

• Connect the white wire to neutral

• Connect the green/yellow wire to ground (earth)

The power cable must be fitted with a grounded connector intended for exterior use.

PLEASE NOTE! PROTECTIVE CAPS MUST BE SECURELY MOUNTED ON ANY UNUSED CONNECTORS, IN ORDER TO

MAINTAIN INGRESS PROTECTION IP RATING.

CAUTION! DO NOT CONNECT THE FIXTURE TO AN ELECTRICAL DIMMER SYSTEM, AS DOING

SO MAY CAUSE DAMAGE

The fixture is controllable using a DMX, sACN or Art-Net control device, and can be connected using either a DMX

cable, Ethercon style cable, or via the fixture’s built-in CRMX wireless receiver system.

POWER AND DATA

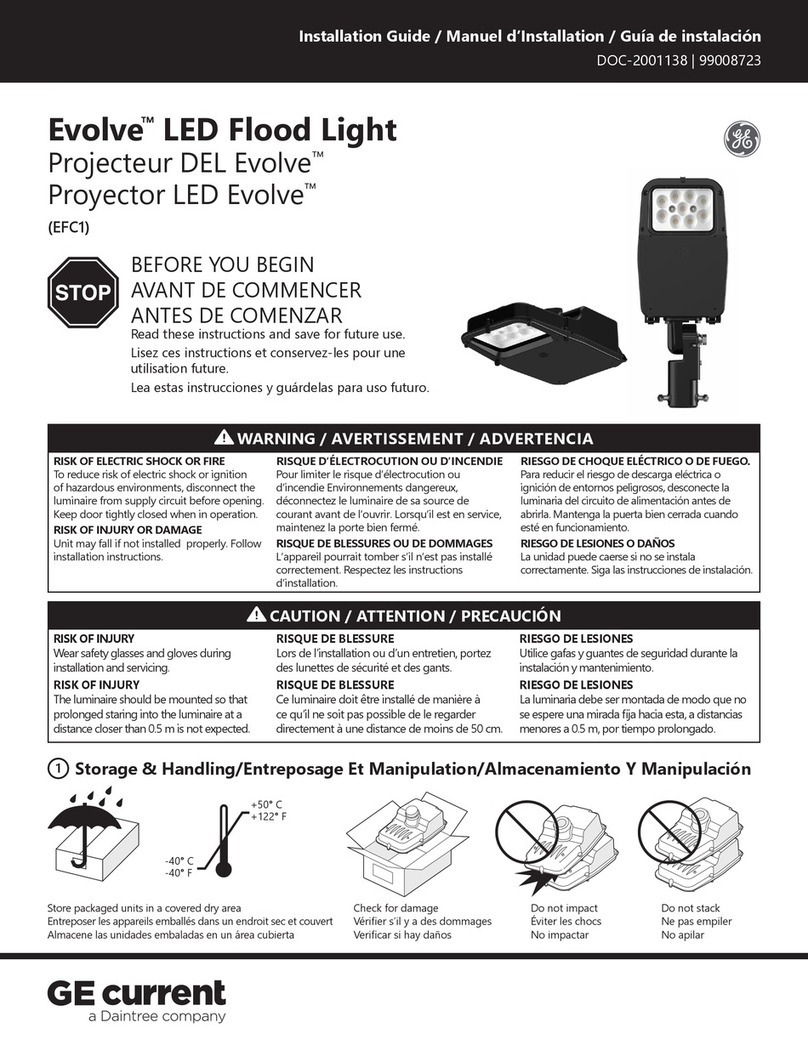

The P-3 series has cable and connectors for power and signal located on the back.

The power input required is 100–277 V, 50/ 60 Hz AC mains power supply, and draws a maximum of 360 Watts (P-3

Vision) or 330W (P-3 Wash) . Both are connected to power via “Powercon” type connectors. Power plug is as per local

code.

Power In/Out Ethernet In/Out DMX In/Out

Figure 7: Power and Data connectors

17 Product Version 1.0 | Revision A | Released 2023-10-19

CONNECTING A WIRELESS TRANSMITTER

The fixture is designed to look for wireless transmitters in ‘connect’ state when this option is not yet enabled. The fix-

ture comes tested for wireless functionality from the factory, therefore the beginning of the pairing process is discon-

nect from the factory wireless DMX transceiver.

To connect the fixture to a wireless transmitter:

1. Log off the currently paired wireless transmitter. Go to SETTINGS → WIRELESS DMX → LOG OFF in the menu.

Fixture confirms logged off.

2. Initialize connection on the wireless transmitter.

3. Confirm that the fixture has paired with the wireless transmitter.

SIGNAL PRIORITY

The fixture can be paired to an active wireless transmitter while also being connected to a cabled DMX or ethernet

signal. By default, the fixture will prioritize cabled DMX signal. If there is not cabled DMX signal, it will use the ethernet

signal. If it is also not receiving any ethernet signal, it will switch to wireless DMX.

Through the Settings menu in the display or RDM, this can be changed so that the fixture will prioritize wireless DMX

over Cabled DMX and ethernet.

The active input type is displayed in the top right corner of the display. The wireless signal strength can be checked

from the System menu in the display or via RDM by using an external RDM device.

DMX

When using a cabled DMX system, connect the DMX-In cable to the input connector and DMX-Out cable to the out-

put. Both are located on the rear of the fixture’s base (chassis mounted male and female 5-pin XLR plugs).

For outdoor installations, use only IP65-rated XLR connectors suitable for outdoor use. Terminate the DMX out cable

of the last fixture in the data link with a 120-ohm DMX termination.

PLEASE NOTE! SGM FIXTURES PROVIDE A PASSIVE DMX THRU SIGNAL AS DMX OUT, INSTEAD OF AN ACTIVE

OUTPUT SIGNAL.

ETHERCON

Using sACN or Art-Net is done through the ethernet connectors. These are compatible with all Ethercon or RJ45 style

connectors. The 2 ethernet ports can serve in either a daisy chain topology or can be fed directly with the ethernet

lines, providing a double input for ethernet protocols. For outdoor installations, use only IP65-rated XLR connectors

suitable for outdoor use. In a setup where the ethernet ports are in a daisy chain, the fixture will still pass through the

ethernet signal in the event the fixture loses power.

18 Product Version 1.0 | Revision A | Released 2023-10-19

USER INTERFACE

The fixture can be set up by using the control panel and OLED multi-line display on fixture’s head or through RDM.

The OLED display shows the current status and menu of the fixture. It is used to configure individual fixture settings

and read error messages. The complete list of the menu and all commands available are listed in “Control menu”.

Before turning on the fixture, make sure the power cable is properly connected. When the fixture is powered on it will

boot and reset before displaying the selected operating mode and DMX start address. Navigate through the menus

and options using the arrow buttons, and select items using the ENTER button.

USING THE DISPLAY PANEL

• Press the ‘ENTER’ button to access the menu or make a selection.

• Press the arrow buttons to scroll up and down in the menus.

• Press the ‘ESC’ button to take a step back in the menu.

Lorem ipsum dolor sit

6CH CTC MODE 101 (107)

DMX

ESC ENTER

Figure 9: OLED display and control panel

SHORTCUTS

• ESC + ENTER: Press ENTER to confirm factory defaults.

• ESC + UP: Press ENTER to start LED test.

• UP + DOWN arrows simultaneously = flip the display upside-down.

• ENTER + DOWN (hold down for 10 sec): Keypad unlock

19 Product Version 1.0 | Revision A | Released 2023-10-19

DISPLAY

OPERATIONAL MODE A

Displays the current mode (quick color, stand-alone, or

DMX mode). The fixture is set by default to be controlled

in DMX mode.

FIXTURE UNIVERSE B

Displays the current fixture universe. The universe is al-

tered directly from this view.

DMX ADDRESS C

Displays the current DMX address. The DMX address is al-

tered directly from this view.

Figure 10: Display

EXTERNAL DATA PROTOCOL D

Shows the external data protocol.

• When ‘DMX’ is displayed: the fixture responds to data received through cabled DMX.

• When ‘CRMX’ is displayed: the fixture responds to data received through wireless DMX.

• When ‘ART’ is displayed: the fixture responds to data received through Art-Net.

• When ‘sACN‘ is displayed: the fixture responds to data received through sACN.

When ‘-H‘ is shown after one of the above protocols this is an indication that Hybrid Mode is enabled.

EXTERNAL DATA INDICATOR E

The DMX signal indicator will flash when the DMX signal is received.

NEXT AVAILABLE ADDRESS F

The next available DMX address will show immediately, depending on the fixture’s DMX footprint.

INFORMATION PANEL G

The information panel is accessed by pressing ESC. It functions

as a way to quickly get an overview of errors, notifications and

important settings. Errors will always be shown first, followed

by a divider line. All other information such as custom PWM

frequency, Vision universe and address, ... will be shown below

the divider line. The current page and the total amount of pag-

es of information is shown in the top right corner of the display.

WARNING INDICATOR

If any errors are detected, the exclamation point will alternate

with the current display for easy detection.

To read the error message,do to the information panel by

pressing ESC.

A

G

B C D

F

E

Figure 11: Information panel

Figure 12: Warning indicator

20 Product Version 1.0 | Revision A | Released 2023-10-19

P-3 Vision and Wash are configured using either the user interface or SGM software; the SGM software, the SGM RDM

Addressing Tool. This software is Windows® PC based and connects to the fixtures via DMX512/RDM using the SGM

USB uploader cable.

ABOUT DMX

The fixture can be controlled using signals sent by a DMX controller on a number of DMX channels.

DMX is the USITT DMX512-A standard, based on the RS-485 standard. The signal is sent as DMX data from a console

(or a controller) to the fixtures via a shielded twisted pair cable designed for RS-485 devices.

The cables can be daisy chained between the fixtures, and up to 32 fixtures can be connected on the same DMX link.

Up to 300 m. (~1000ft.) of cable is achievable with high quality DMX cables. All DMX links must be terminated by con-

necting a DMX termination plug to the last fixture´s 5 pin DMX out connector.

PLEASE NOTE! STANDARD MICROPHONE CABLE IS NOT SUITABLE FOR TRANSMITTING DMX. UP TO 32 FIXTURES

CAN BE LINKED TO THE SAME DMX CHAIN. ADDITIONAL FIXTURES WILL OVERLOAD THE LINK.

DMX START ADDRESS

The fixture can be operated in different DMX modes. For any of the modes, the first channel used to receive data from

a DMX control device is known as the DMX start address.

For independent control, each fixture must be assigned its own DMX start address. For example, if the first RGBW

fixture is set to 6ch CTC DMX mode with a start DMX address of 101, the following RGBW fixture in the DMX chain

should then be set to a DMX address of 107. As the first fixture uses all the first 6 DMX channels, including channel 101,

the next available channel is 107 (101+6=107 >> 107).

If two or more fixtures have the same DMX start address, they will behave identically. Incorrect settings will result in

unpredictable responses from the lighting controller. Address sharing can be useful for diagnostic purposes and sym-

metrical control.

SETTING UNIVERSE AND ADDRESS

The fixture universe and address are shown on the

OLED display in the control panel. To change the

universe and address, start by pressing the up or

down button once. Use the up and down button to

first change the universe. When the desired uni-

verse is shown press ENTER to start changing the

address by using the up and down buttons. Once

the correct address is shown press ENTER to store

the universe and address. Note that if the fixture is

controlled through cabled/wireless DMX, the universe setting has no effect. The universe is only used if the fixture is

controlled via Art-Net or sACN using the ethernet port. For your convenience, the next available DMX address is dis-

played in the bottom right corner of the display. See "User Interface" on page 18 for instructions on using the display

panel. The fixture also offers the option to set the universe and address through RDM.

CONFIGURATION

AddressUniverse

Next available

Address

SETTING DMX MODE

From firmware version 3 onwards, a legacy and standard set of DMX modes are available. To select the DMX mode of

choice, a menu layer is implemented. To access the modes:

1. Press [ENTER]

2. “MODE” is displayed, Press [ENTER]

3. “Select Mode” and current DMX mode is displayed.

4.Press [Up] or [Down] to enter DMX Operation

Mode.

5. Press [ENTER]

6. Press [Up] or [Down] to select “Standard” or “Lega-

cy” DMX modes.

7. Press [ENTER]

8. Press [ESC]

9. Press [Up] or [Down] to navigate to list of DMX

modes.

10. Press [ENTER]

11.Navigate to DMX mode of choice by pressing [UP]

or [DOWN]

12. Press [ENTER]

PLEASE NOTE: DMX CHARTS FOR ALL MODES ARE AVAILABLE FOR DOWNLOAD AT WWW.SGMLIGHT.COM OR

BY EMAILING SUPPORT AT SUPPORTSGMLIGHT.COM

Figure 13: Setting universe and address

Table of contents

Other SGM Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Vision & Control

Vision & Control A-DIF-60x90-IR850-SL Instructions for use

Gradus Group

Gradus Group Impact FF-OSB60 instructions

GARANT

GARANT 081448 200 user guide

Daintree

Daintree GE current Evolve EFC1 Series installation guide

Pentair

Pentair SOLEO CL Installation and user guide

unios

unios Linear Series quick start guide