SGM Flasher DMX 1.5 User manual

professional strobe projector

rel. 1.00

user manual

Flasher

D

DMX 1.5

EN

appendice

page 1

IDFE

General warnings

Carefully read the warnings contained in this manual, since they supply important instructions concer-

ning safety of installation, use and maintenance.

It is very important that this manual be kept with the equipment for future consultation.

In case of sale or transfer of the equipment to another user, ensure that this manual always

accompanies the equipment to allow the new owner to obtain information about the operation

and the relevant warnings.

• Not for residential use.

• After unpacking check the integrity of the equipment. In case of doubt, do not use the equipment,

and contact an authorized SGM Technical Service Centre.

• The packaging materials (plastic bags, expanded polystyrene, nails, etc.) must be kept out of reach

of children since they are potential sources of danger.

• This equipment may only be operated by adults. Do not allow children to tamper with the machine

or play with the product.

• The electrical and mechanical work necessary for the installation of the equipment must be carried

out by a qualified electrician or by a competent person.

• Before connecting the unit, check that the data on the registration plate is the same as that of the

electrical grid.

• Avoid using the equipment:

- in places subject to excessive humidity

- in places subject to vibrations or knocks

- in places with temperatures higher than 45°C or lower than 2°C

- Protect the equipment from excessively humid conditions

(the optimum values are between 35 and 80%).

• Do not disassemble or modify the equipment.

• Prevent inflammable liquids, water or metallic objects from penetrating the equipment.

• In case of spilling liquid on the equipment, immediately disconnect the power supply of the mixer.

• The minimum distance between the projector and the surface to be illuminated must not be less

than 1.5 m.

• In case of serious functioning problems, switch off the equipment and contact the nearest SGM

retailer or the manufacturer directly for inspection.

• Avoid opening the equipment: there are no parts repairable by the user.

• Never try to repair the equipment alone. Repairs carried out by inexpert persons may cause damage

or serious malfunctioning. Contact the nearest authorised Technical Service Centre.

Always insist on original spare parts.

Protect the environment: do not throw the packaging in your dustbin,

but return it to your retailer or take it to a collection point for special

waste disposal.

page 2

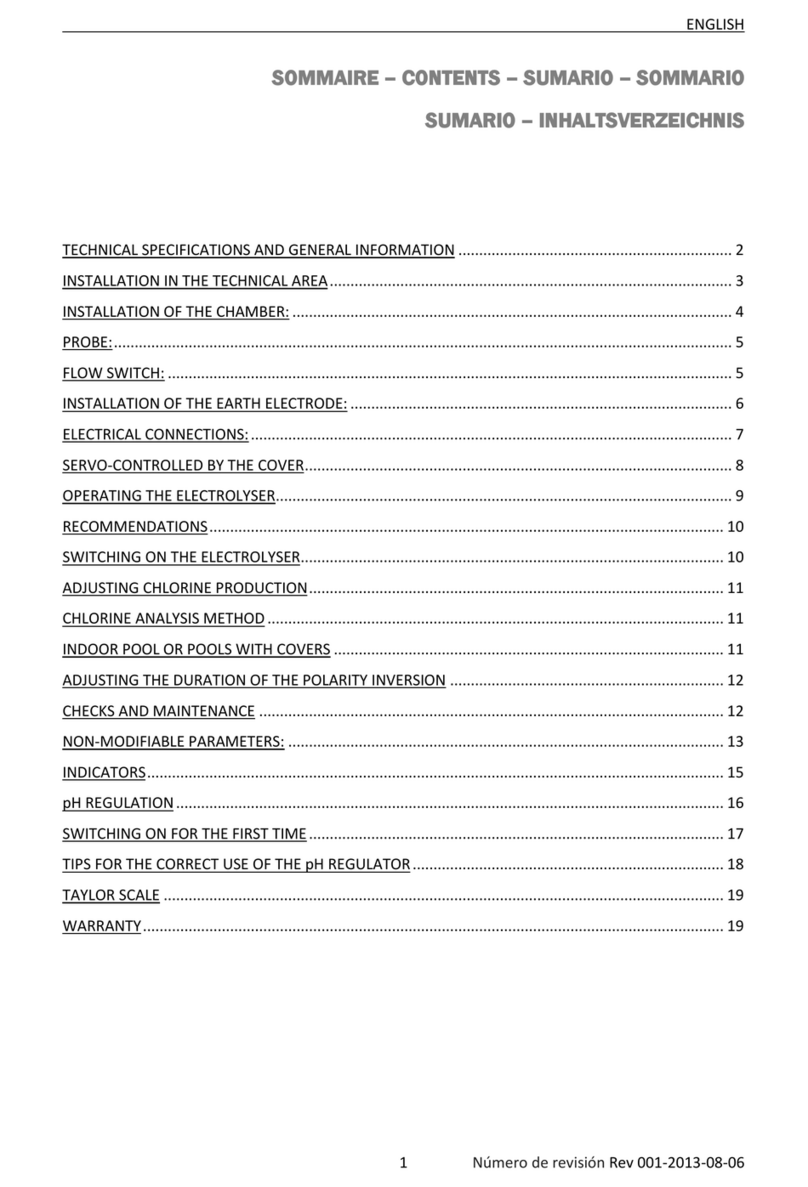

Index

1 General information

2 Index

3 Main features

3Lamp

3 Dimmer

3 Technical specifications

4 Positioning

4 Flasher DMX 1.5 maintenance

4 Access to internal components

4 Fitting the lamp and re-lamping

5 Cleaning the fixture / periodic checks

5 Switching the fixture on / fixture status

5 Start addresses

6 Connecting the Flashers

6 Control channels

6 ch 1 - dimmer

6 ch 2 -strobe

Made in Italy by SGM Electronic

Printed in July, 1998 • Rel. 1.00

EN

appendice

page 3

I D F E

Main features

SGM’s new Flasher DMX 1.5 strobe unit is another result of the firm’s lengthy experience in manufac-

turing this type of fixture. The quality and design philosophy are those which all SGM products have

had in common for years and the sophisticated electronics used combined with ground-breaking

performance earn it a rightful place at among the world’s top products.

In-depth function study, an on-going search for innovative materials, technical updating and constant

research aimed at ensuring even further safety have resulted in a truly unique product.

The mechanism and electronics were designed entirely by our in-house research labs, ensuring com-

plete command of all know-how and an optimum quality:price ratio.

Like all other SGM products, the Flasher passed the firm’s long trail period and strict tests brilliantly

before being put on the market, ensuring high quality and reliability up to the firm’s customary stan-

dards.

Particular care taken with the unit’s looks and optimisation of the outer structure to ensure functiona-

lity enable the fixture to be easily installed in any position and ensure extremely rapid maintenance.

The Flasher is built in compliance with current CE norms

Lamp

The Flasher is fitted with a Xenon XOP15 lamp with exceptional luminous output optimized by electro-

nic control.

Dimmer

The Flasher also has a dimmer function that enables flash power to be adjusted from zero to 100%.

Technical Specifications

Power required 90-260V, 50Hz, 60Hz - universal, automatic voltage changer

Lamp 1,500W - XOP15, special base

Power absorbed 400W

Reflector Polished aluminium with high transmission factor

Electronics Completely designed by SGM R&D lab engineers.

Main board (CS 0218), input board (CS 0217) and IGBT controller board (CS 0228).

Settings Via rotary dip switches for addressing the fixture’s control channels.

Input ch1 - dimmer / ch2 -strobe

Safety norms Protected to IP20. Automatic power cut-off in the event of overheating or

faulty cooling system operation.

Cooling Forced ventilation via an axial fan.

Body Sheet metal with epoxy powder finish

Mounting bracket Steel metal with epoxy powder finish

Dimensions 49 x 21 x 17 cm. Weight: 5.6kg.

SGM Elettronica reserves the right to carry out improvements or modifications on its products

without prior notice. Always consult the handbook of the unit being used to avoid errors and

any difference between actual functions and handbook contents.

Flasher DMX 1.5 maintenance

Access to internal components

The Flasher has a system for access to the fixture’s internal components, which prevents accidental

opening. To open the fixture, it must be dismantled from its operating position and disconnected from

the mains supply: screw 1 can then be unscrewed. Once side panel 2 has been removed, the front

glass (3) must be removed extremely carefully. If the fixture must be completely dismantled, screw 4

and side panel 5 must also be removed. The lamp and reflector can then be removed for access to the

electronics.

Fitting the lamp and re-lamping

ATTENTION: Before re-lamping, make certain that it’s really necessary and discon-

nect the fixture’s main power supply. If the unit has been used recently, wait for

the lamp and mechanical parts to cool before opening (10 - 30 minutes).

Be very careful to avoid touching the reflector and the actual lamp with your bare

hands, as any residue subject to high temperature burns, causing components to

blacken, and definitively damages the lamp. Fit the new lamp carefully.

After re-lamping, it’s always advisable to clean the fixture completely.

ATTENTION: T

HIS TYPE OF LAMP MUST ONLY BE REPLACED BY QUALIFIED PERSONNEL SUF

-

FICIENTLY INFORMED ON RISKS AND METHODS OF OPERATION

.

Cleaning the fixture / periodic checks

Cleaning the glass and reflector (inside and out) is decisive for the utmost lumi-

nous output and must be carried out periodically. Cleaning frequency depends

2

3

5

1

4

page 4

Positioning

To position the fixture, set the channels as follows:

Channel 1 dimmer 100% open

Channel 2 strobe positioned at 128 (ref. scale 0÷255)

Position the fixture by turning it on the support bracket and locking in the required position using the

bolts supplied.

Flasher does not require focussing.

Trouble-free horizontal, vertical or tilted positioning is possible, provided sufficient space is left round

the unit for air circulation.

EN

appendice

page 5

I D F E

above all on the surroundings in which the unit is used: damp, smoky or dusty surroundings in particu-

lar favour a greater build-up of dirt on the unit’s glass.

Clean using a soft cloth and normal glass cleaning products or methylated spirits, always being certain

to dry the parts. Clean the outside of the glass at least every 15/20 days and the inner group at least

every 40/60 days.

To ensure utmost fixture efficiency, it’s advisable to carry out a general periodic check-up every 700

running hours. Electrical and mechanical components must be checked by qualified technical person-

nel.

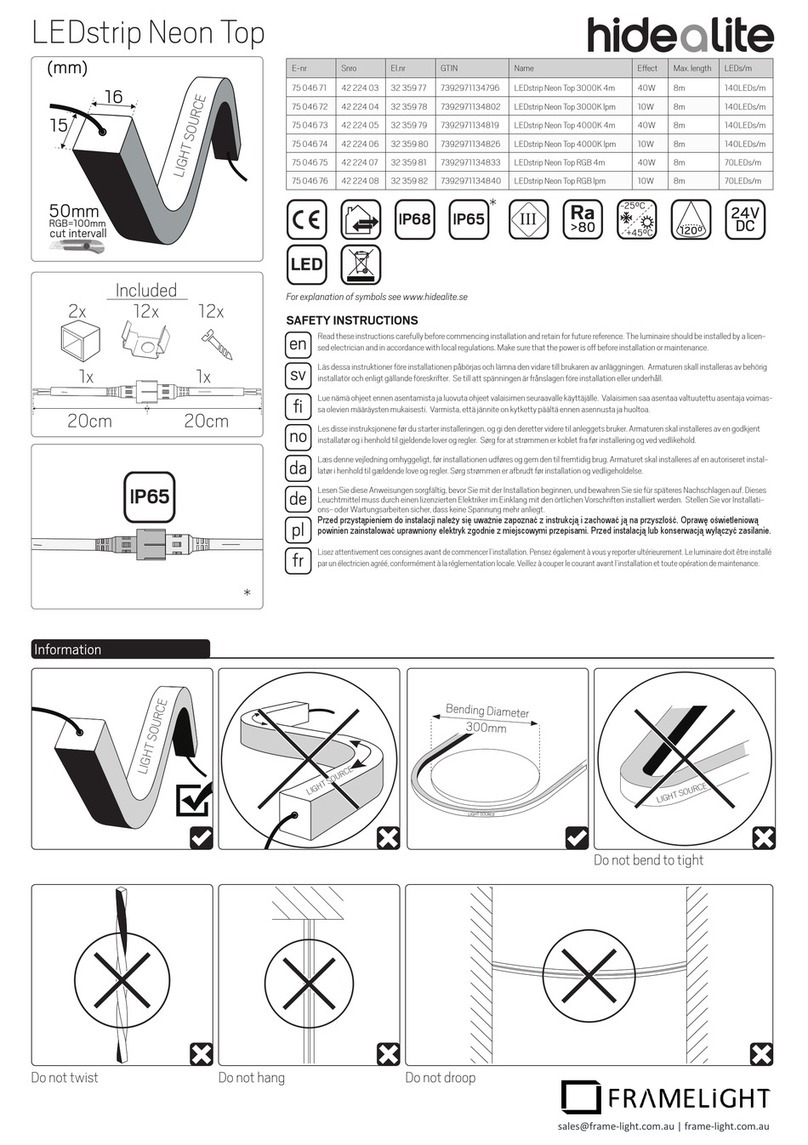

Start addresses

When connecting, each fixture must be appropriately configured.

The start address is set using the rotary dip switch located on the rear of the fixture. The address can

be changed even when the fixture is on.

The lowest start address is 001. When 000 is used as the address, as in the following example, the

Flasher’s built-in computer uses 001 anyway.

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

Flasher #1 (ch 1 ÷2)

Flasher #2 (ch 3 ÷4)

Flasher #3 (ch 5 ÷6)

x 100 x 10 x 1

Switching the fixture on / fixture status

The Flasher doesn’t have a manual switch for turning it on. In fact its special electronics check the

DMX signal line continually and only turn on the fixture when the control signal is sent.

In particular, when channel 2 (see further ahead) is set at 0 (zero), the fixture automatically goes into

stand-by.

The power supply connector is used as a local cut-out. The red pilot light below the connector indica-

tes that there is voltage on the in-coming power line.

The green “DMX OK” LED indicates that the connection of the DMX network is operating and the

signal matches protocol specs.

The red “SYSTEM FAILURE” LED lights up when the lamp doesn’t light up, in spite of the DMX com-

mand. Striking lasts for a very short period (approx. 1 sec.).

In this case, call the nearest assistance centre, disconnect the fixture from the mains supply

and carry out a check.

page 6

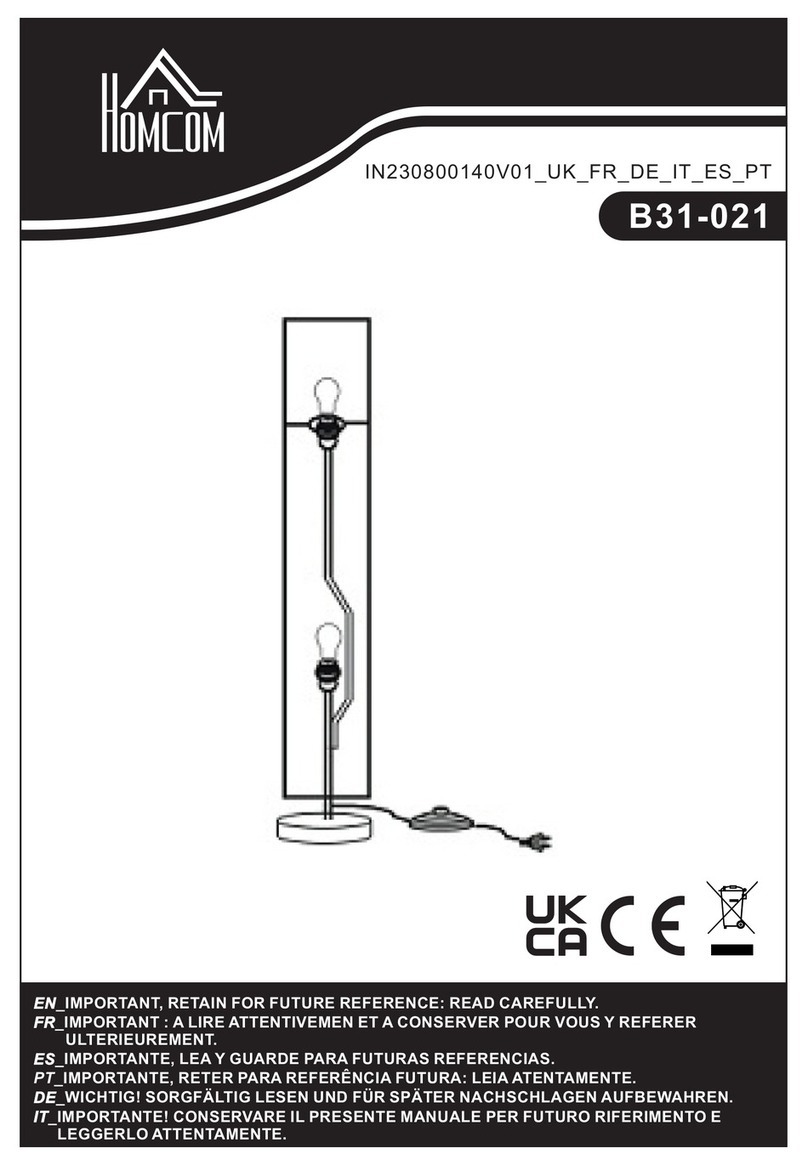

Control channels

dimmer

Channel 1 allows linear control of luminous intensity from zero to 100%.

When channel 2 (strobe) is set at 0 (zero), channel 1 enables SINGLE SHOOT use.

In this case, a single flash is given at the power required by the operator: it’s sufficient to use the

channel 1 slider on the desk or the controller starting from 0 and stopping at the value of the required

scale (parameter 0÷10, 0÷255 or 0÷100, according to the controller used).

When the value of channel 1 or channel 2 is 0 (zero), the fixture automatically goes into standby: the

Flasher doesn’t in fact have a power switch, which is replaced by the control electronics.

strobe

Channel 2 allows the flash rate of the Flasher to be regulated continuously.

The range goes from zero to 50 flashes per second, i.e. from off to continuous light.

When channel 1 or channel 2 are set at 0 (zero) the fixture automatically goes into standby: the Flasher

doesn’t in fact have a power switch, which is replaced by the control electronics.

Setting the strobe at 0 (zero), enables SINGLE SHOOT use (see channel 1 - dimmer).

ch 2

ch 1

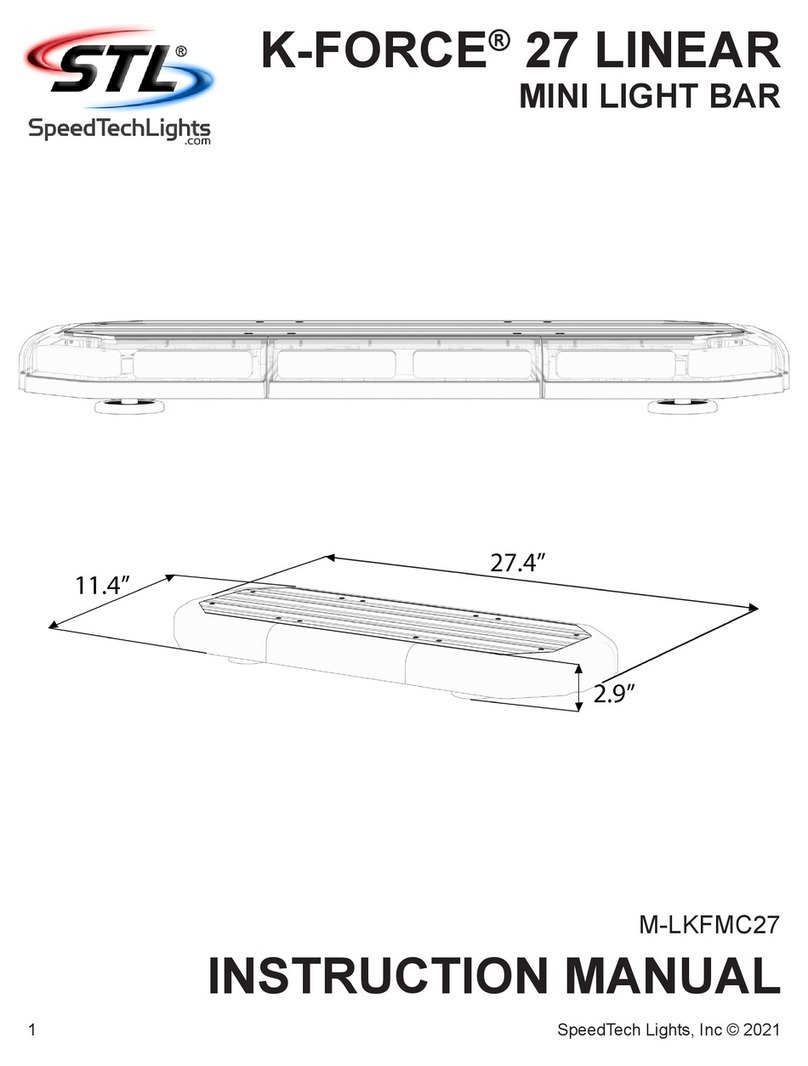

Connecting the Flashers

The fixture has DMX 512 input/output.

For connection, always use quality balanced microphone cables

such as RF 60/12 2x0.25mm2or similar to avoid faulty fixture

operation.

To reduce interference, it may be necessary to fit the last fixture

in the DMX chain with a system terminator, made using a

120Ohm 1/4W resistor between pins 2 and 3 on the DMX con-

nector.

Attention: the cable screen (sheath) must NEVER be con-

nected to the system’s ground as this would cause faulty

fixture and controller operation.

Flasher Flasher Flasher

DMX512 line

Flasher #1 Flasher #2 Flasher #n

DMX socket pin out

pin 1

comm

12

3

outputinput

12

3

4

5

4

5

pin 2

- DMX

pin 3

+ DMX

Via Pio La Torre, 1 • 61010 TAVULLIA (PS) • ITALY •

Tel. +39 0721476477 • Fax +39 0721476170

cod. M001165

Table of contents

Other SGM Lighting Equipment manuals