4Product Version 1.0 | Revision E | Released 2022-12-09

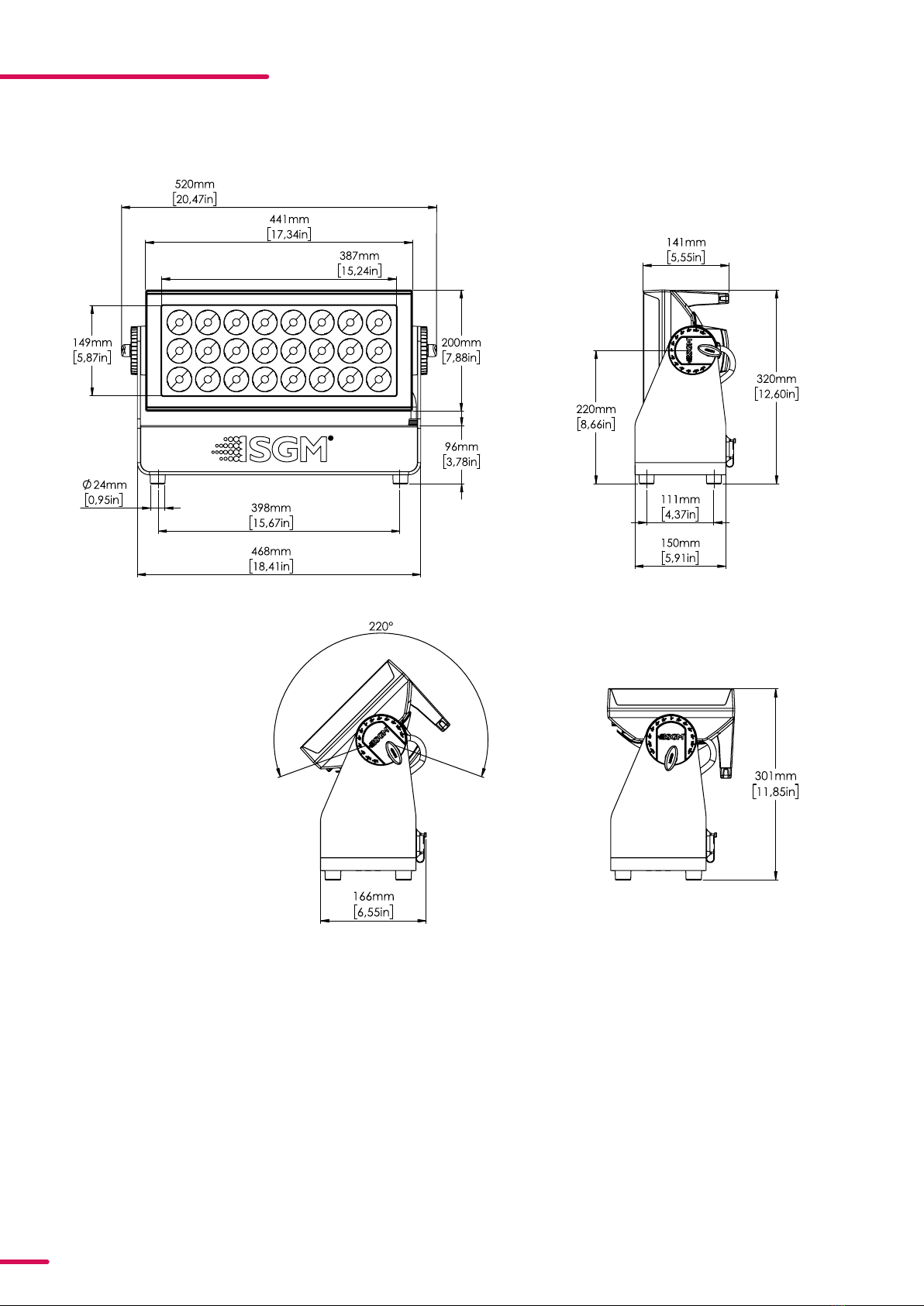

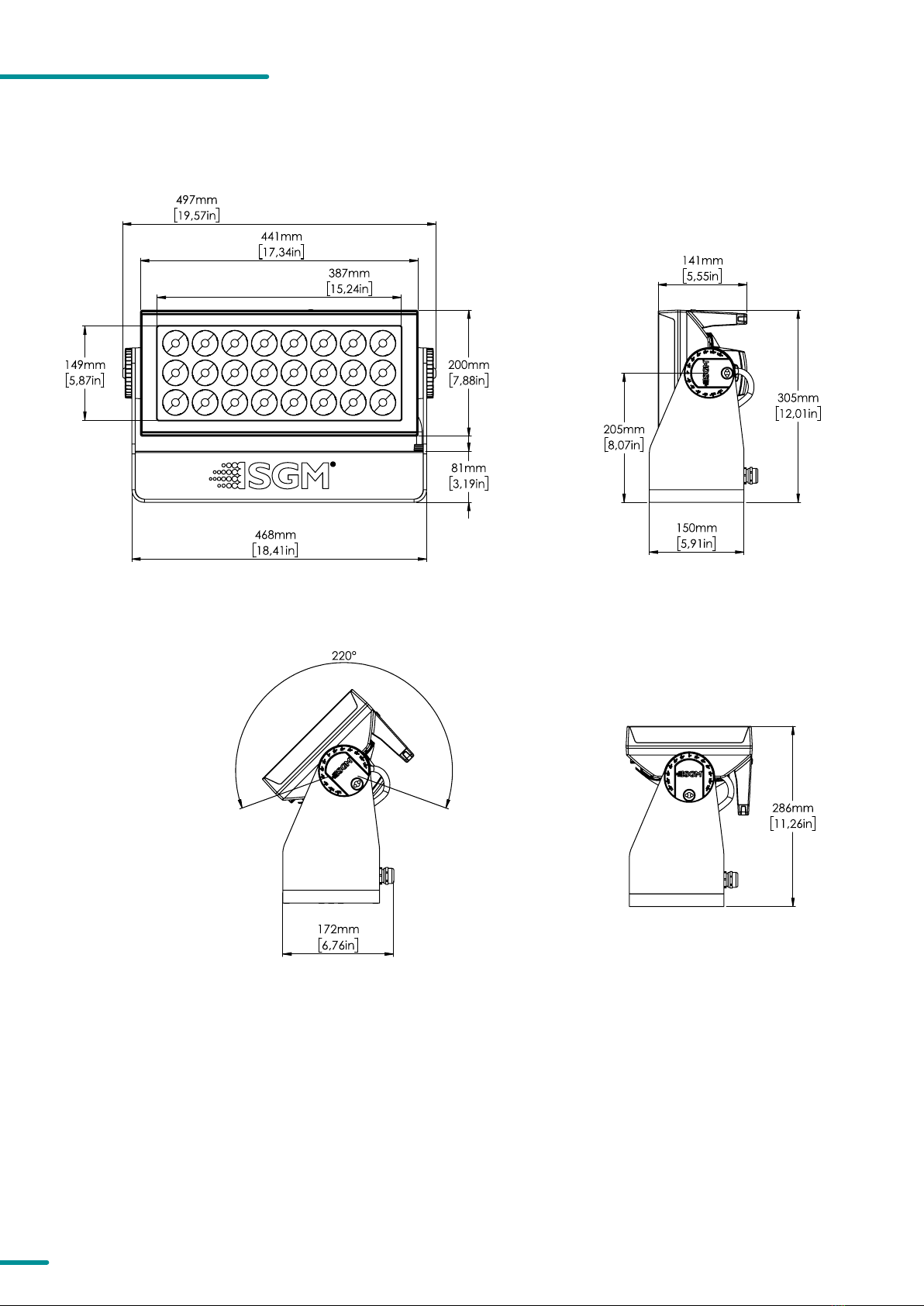

2 DIMENSIONS

2 Standard version

3 POI version /

6 SAFETY INFORMATION

7 BEFORE INSTALLING THIS PRODUCT

8 INSTALLATION STANDARD FIXTURE

8 Identication and terminology

9 Unpacking

9 Transport handling

9 Rigging

10 Rigging process using SGM Omega brackets

11 Tilt lock

11 Power requirements

12 Connecting power

12 Connecting data

12 Connecting a wireless transmitter

12 Signal priority

13 INSTALLATION POI FIXTURE

13 Identication and terminology

14 Unpacking

14 Application considerations

14 Connecting temporary Power

15 Connecting temporary signal

16 Settings and Fixture Defaults

17 Wireless Data Connection

17 LED Indicator Behaviour

18 Mounting

18 Brackets

19 Flat Bracket attachment

19 Omega Bracket attachment

20 Universal Bracket attachment

21 Wall Bracket attachment

22 POI TIlt Lock

23 Permanently Connecting Power & Data

24 USER INTERFACE

24 Using the display panel

24 Shortcuts

25 DISPLAY

25 Operational mode (A)

25 DMX Address (B)

25 External data indicator (C)

25 External data protocol (D)

25 Error Indicator

CONTENT