SHAREBOT Kiwi-3D User manual

USER’S MANUAL

SHAREBOT Kiwi-3D

4

ATTENTION – EXTRUDER

The fusion and extrusion system of the thermoplastic lament requires a heated end up to tempera-

tures of 250 degrees and more. The contact, even for a very limited time, with the heated part causes

burns. You must avoid to put your hands or other body parts in the printing area when printing and

for minutes aer the printing process is over. The current temperature of the extruder is indicated on

the LCD screen.

5

Summary 5

Chapter 1 – Preliminar operations 11

Open the package

Positioning the printer

Assembling the reel-carrier

Unlocking the extruder

Chapter 2 – Process of 3D Printing 17

Model

Downloading from internet

From a 3D model to a printing le

A good STL, a good slicing, a good print

Printing le

Storing the les

Chapter 3 – LCD Panel 22

Informative mode

The control knob

Access to principal menu

“Prepare” menu

“Adapt” menu

6

Chapter 4 – Setting the printer 26

Loading the lament

Preparing the printing plate

Learning to set up the plate

- Calibration

- Regulating nal leg of axis Z

Calibrating axes X and Y

- Recovering of scraps and usage of M99

- Squaring o axes X and Y

Putting in tension the extruder’s rubber bands

Chapter 5 – Our first print from a SD Card 31

SD Card

Printing proles

Starting the print

Stopping the print

Modifying printing parameters

Detaching the 3D printed object

Capitolo 6 - Creiamo i nostri gcode 35

Slic3r

Conguring Slic3r

Loading the model to print

Basic parameters of Slic3r

Slicing

7

Chapter 7 – Material and printing plate 40

How ABS entails

How PLA entails

How other materials entai

Capitolo 8 – Considerations about the model orientation 40

Orientation

Just one object?

Supports

Printing details

Capitolo 9 – Ordinary manutention 44

Cleaning the printer

- Printing bed

- Stretcher

- Nozzle

Lubrication

Putting in tension the belts

A correct ventilation

Updating the rmware

Chapter 10 – General information about security 46

8

Support Policies

If you have any problems in using our printers, the procedure to be followed is as fol-

lows:

Check the manual and guides available on the web site;

Contact the dealer from which you purchased the machine

Contact technical support by lling out the form beside remember to ll in all elds. Our

techni- cians will ricontatteranno within 3 working days.

In case your printer should re-enter in the factory to be repaired, our technical support

will give as- sign a le number to return and we will provide all the additional informa-

tion required.

Attention: the package should be the original one, penalty forfeiture of the guarantee

Upon receiving your printer, our technicians will assess whether the problem stems from

a failure, in this case the repair under warranty will be carried out for free, or by improp-

er use of the printer or by an improper use of material not approved by Sharebot: in the

latter case we will provide

you with a quote to request your consent to repair. For out-of-warranty printers may be

required a quote for the inspection.

Troubleshooting is a very important task for us and we think is necessary to share ex-

periences, problems and solutions. Because of that please give priority to the use of the

forum that will also allow others to take advantage of our and your eorts. Each month

we will evaluate who gave the best suggestions or reporting an issue with its solution,

we will reward with a surprise! Visit our website for more information.

9

10

Technical characteristics

Printing technology: Fused Filament Fabrication

Mono extruder printing volume: 140 x 100 x 100 mm +/- 5mm

Theorical positioning resolution axes X and Y: 0,06 mm

Positioning resolution axis Z: 0,0025 mm

Extruder hole diameter: 0, 35 mm

Filament to be extruded diameter: 1,75 mm

PLA best extruding temperatures: 200-230°

Tested and supported printing lament: PLA

Experimented printing laments: Cristal Flex, PLA Thermosense, Thermoplastic

Polyurethane, PLA Sand, PLA Flex, PET

External Dimensions: 310 x 330 x 350 mm

Weight: 10kg

Consumption: 65 watt

Electronical card compatible with Arduino Mega 2560 with Firmware Open Source

Marlin https://github.com/Sharebot3D/Marlin

LCD Screen of 20 x 4 with an encoder menu of navigation

Presetted printing values for PLA

Extruder block with regulation pressure upon lament

11

Chapter 1

Preliminar Operation

Anatomy of a Sharebot NG

Your professional 3D printer Sharebot Kiwi-3D is a tool of precision, ideated, developed and assem-

bled in Italy by qualied sta. Before leaving the factory it was submitted to a quality control and to a

quality test that guarantees its operation. It’s very imporant, before you can use the printer, knowing

all the technical terms used in this handbook and identify all the specical components that form a

Sharebot Kiwi-3D.

1. Carriage of axis Z

2. Glass printing bed

3. Printing bed rubber bands

4. Printing bed regulation screws

5.LCD Panel

6. Interruttore “On / O”

7. Extruder’s cables

1

2

3

7

3

4

56

12

1. Extruder

2. Extruder’s cables

3. Printing strand’s power hole

4. Material fan of cooling

5. Printing bed regulation screws

1

2

3

4

5 5

5

13

1. SD Card entry

1

14

1. Power cable socket

2. Label with Identication Code

12

15

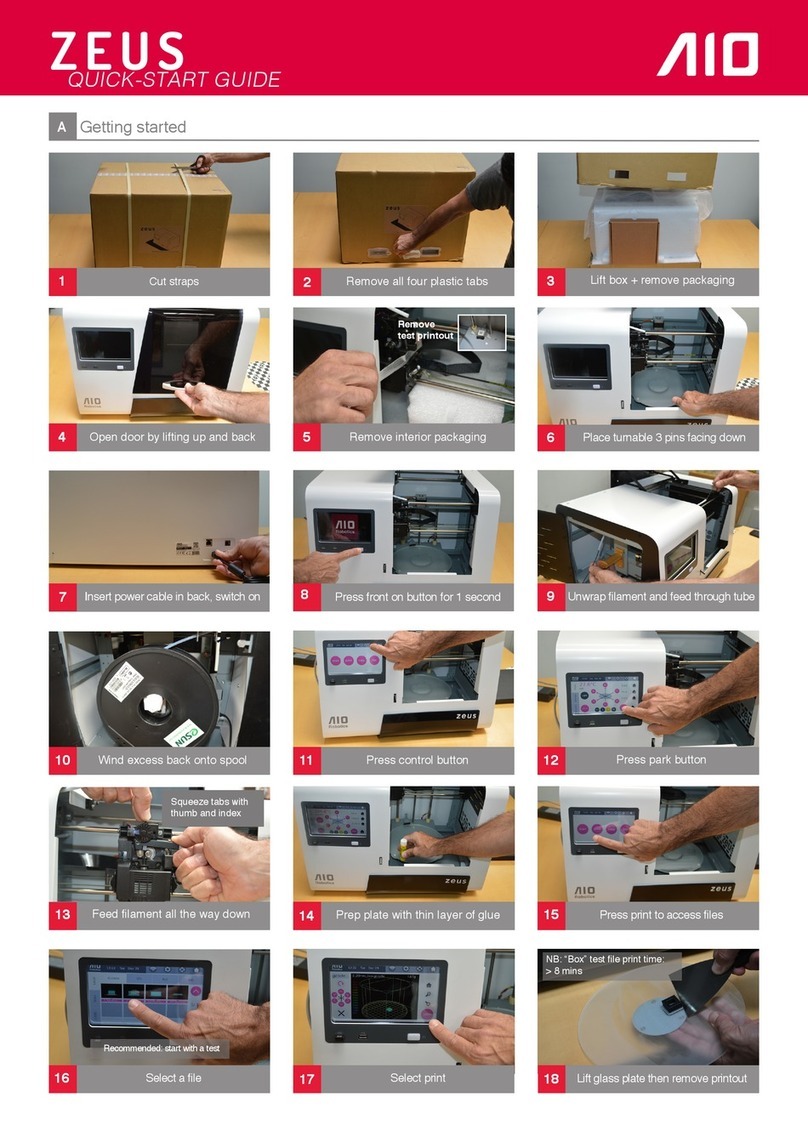

Opening the package

Your Sharebot Kiwi-3D is equipped with a series of accessories that allow you to make it immediately

operative; there is no soware because it is open source and constantly updated. Soware must be

downloaded from the website of Sharebot to always have the latest version.

With care and without damaging the packaging remove the various parts and elements that x the

printer inside the cardboard and then, by the internal metal frame, pull it out.

Do NOT pull the so black lead from the le side and comes to the extruder: it is a power cord and NOT

handle. Proceed with the recovery from the packaging of all the parts and check that the material listed

below are all in the package:

WARNING: Do not throw away the original package. You could use it if you have to send it or move it.

In the package you’ll nd:

1. Reel-carrier in assembly kit

2. Power cable

3. SD Card with a few object that we loaded for you

4. USB cable

5. Spay

6. Glass printing bed

Positioning the printer

For proper operation, the printer must work in a clean and dust-free, with an ambient temperature

between 5° C and 35° c. It is also preferable to a position away from dras or air conditioning.

In front is the power switch, while at the bottom, in the center of the printer is the electronic part’s aera-

tion nozzle from which depends the correct circuit cooling: this must be le unobstructed.

Remember that the wire is usually in a spool and that this should be positioned on the reel-carrier in-

cluded in the packaging. The recommended position is behind the printer, on the same oor, but there

are alternative positions that depend on the presence of any walls or shelves near the machine. The

important thing is that the wire is easily accessible and you can even put multiple spools on the reel-

carrier without any hindrances or preventing the entrainment of the wire by the extruder.

For this reason, the printer may not be placed on a shelf that is at least 35 cm free space around the rear

or side.

16

Assembling the reel-carrier

For assembling the reel-carrier please see chapter 3, gures 9, 10 and 11 of the manual Assembly,

recalling that the wire must carry out unhindered and in the direction of the extruder.

Unlocking the extruder

To avoid damage during transport, the blocking of the extruder is secured with clamps. The clamps

must be carefully cut and removed to allow the extruder to move freely. DO NOT feed the printer until

you have done this step otherwise you will damage the motors and mechanics.

Remove all packaging inside the machine.

17

Chapter 2

Process of 3D Printing

Before you start printing with your Sharebot NG it is important to understand how you arrive at a

nished object. This allows you not only to know what you need to do to give form and substance to

your ideas, but it helps you to identify any constraints and limitations of the technology used by this

printer.

In the table we summarized the steps required to obtain a 3D printing:

Model

It all starts with creating or downloading a three-dimensional model of the object that you want

to print in 3D. The creation is done through one of the many modeling programs available over the

internet as freeware, shareware or soware for a fee. There are many and each of them has specic

characteristics. In this respect it is worth noting that you can have dierent modeling requirements

and this is reected in the variety of applications. Some are more suited to mechanical design, other

artistic modeling, other than architecture.

Remember that 3D modeling was primarily used to create projects or for rendering. In the rst case

the model was thought to be accomplished physically and therefore is subject to a series of specica-

tions and constraints that allow the project to be turned into something real. In the latter, the aim is

to create an image for certain requirements: the model might then be awless as display but physi-

cally impossible.

When you choose the program that you want to use for your models you must then ensure that it is

able to create a le suitable for the production (especially 3D printing) so those programs that oer

features of rendering or animation driven.

Working enviroment

Common used CAD soware

Common used CAD soware

Soware: Slic3r

3D printer: Sharebot Kiwi-3D

Operation

Design the object

Import/save file in .stl format

(or .obj)

Generate command file for

3D printer

Select file and preloaded

filament profile

Output

Common used format for your file

File .stl

File .gcode

Printed object

18

Downloading from internet

The net oers many ready-made 3D models, but also in this case there are dierences between the

models that you “see ne” and those who “print well”. A good indicator of the ability to print the

pattern is of the form: the most popular 3D printing is STL (sites that intend to oer printable objects

use this format). If there is no STL it is likely that the intended use is dierent and the result on a 3D

printer is not guaranteed.

19

From a 3D model to a printing le

The real “secret” of three-dimensional printing is the transformation of three-dimensional object

into a sequence of two-dimensional slices that overlaping, reconstruct the object. Imagine a series

of slices of bread: If the stack rebuilt the loaf from which they were cut.

In the case of 3D printing every slice may consist of two-dimensional shapes not connected together

as it is their sum to create the nished object.

Thanks to this breakdown, the object can be complex as desired because the printer will draw with

the plastic one layer aer another without overlap; a square or a doodle for the printer have the

same diicult

The most important work the soware makes is starting from the 3D model – usually a mesh of

triangles in space called mesh – and transforms it into a sequence of slices according to a number

of parameters (slicing). Because the process is completed correctly the mesh should be closed and

not have triangles that are oriented incorrectly confusing the “inside” and “outside”. It happens that

some model is made to art: at this point or the soware that does the slicing manages to repair the

mesh or the result of errors that will prevent the correct reproduction of the object.

A good STL, a good slicing, a good print

The STL le is the starting point for the entire procedure, so from the le should be removed anything

you don’t want to print (hidden objects, etc.).

The 3D drawing must be a solid and not a solid sum interpenetrate or match. Similarly, the design

must be as clean and precise as possible: articles must have an inside and an outside well dened

so that the surfaces perfectly match each other without leaving holes. most 3D design soware gives

you the possibility to carry out an analysis of borders to check for holes.

The 3D drawing must be oriented in such a way as to have a face adjacent to the XY plane of your

drawing soware: in other words, the design should not “oat in a vacuum”, otherwise the machine

will not print.

If you’re working on a STL downloaded from internet or given to you by a client, there are free so-

ware for checking and correction of STL as Netfabb.

The “slices” are printed in a specic format (called G-Code); This format is nothing more than a set of

instructions for moving the instrument (cutter, laser or extruder head) along a path X, Y, and Z axes.

Each slice contains the movements on two axes, moving the press plane and motor commands that

extrudes the molten plastic to create one aer another the layers that make up the object. At the end

of each layer le commands move the Z-axis by lowering the print of that plan just enough to add

the new layer.

Every 3D object can be transformed with the process of slicing in a variety of G-Code les, each dier-

ent from the others because slicing parameters generated using dierent: for example the slices have

the inside full, empty or partially empty, or the walls are made with one, two, three or more passes.

20

Even the thickness of each layer is one of the parameters. The same object can be printed full, empty,

with 100 or 200 slices and more or less robust and sti despite having all versions a similar appear-

ance.

Printing le

The G-Code les, containing instructions for navigating the various mechanical parts of the printer

according to specic parameters and settings has a limited compatibility between dierent print-

ers. While the STL le of the template can be used by anyone with a 3D printer to create a printing

G-Code, a G-Code les is denitely running for the printer for which it was created but could be unus-

able with other printers. If it is not clearly compatible with NG Sharebot there try to print les that

you nd on the net because they may have malicious entries to your printer.

The le also contains the heated printing bed temperatures and those of the extruder, tying the le

not only to the printer but also to the material to be used. As we shall see in the following pages,

with the LCD Panel it is possible to modify some parameters when printing: Sharebot NG oers you

the possibility to edit the G-Code in order to adapt it to dierent materials without having to redo the

process of slicing.

Other manuals for Kiwi-3D

1

Table of contents

Other SHAREBOT 3D Printer manuals