Sharp AE-X26FR-N User manual

Other Sharp Air Conditioner manuals

Sharp

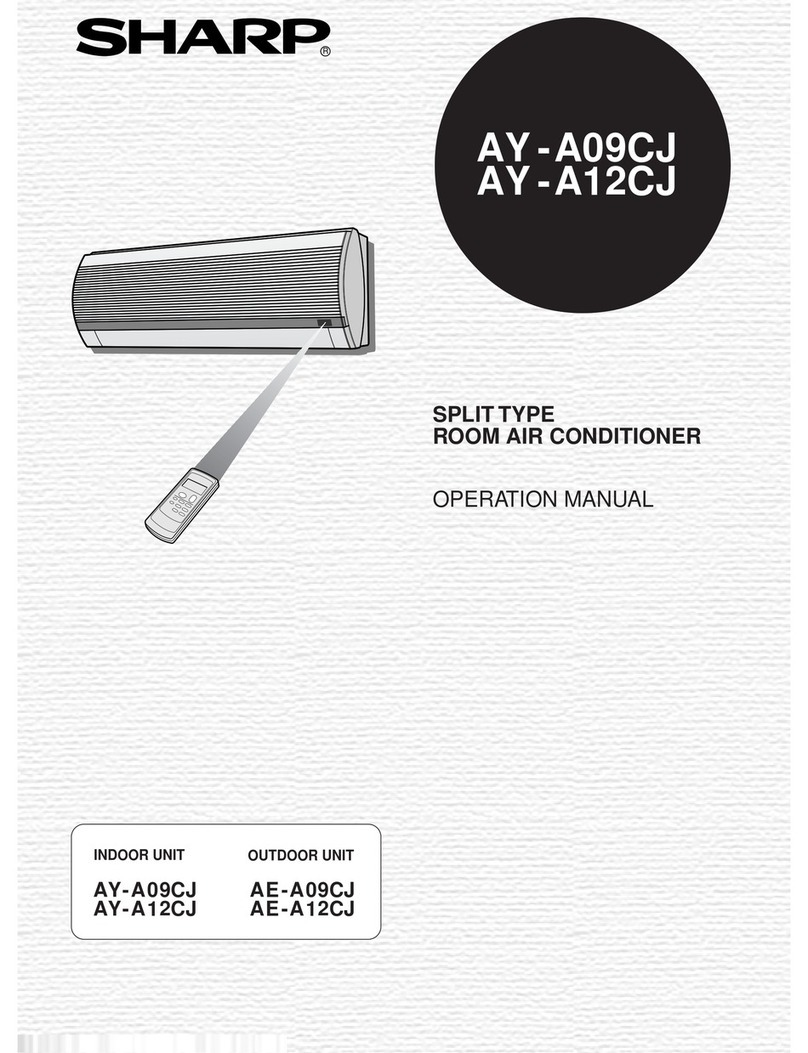

Sharp AE-A09CJ User manual

Sharp

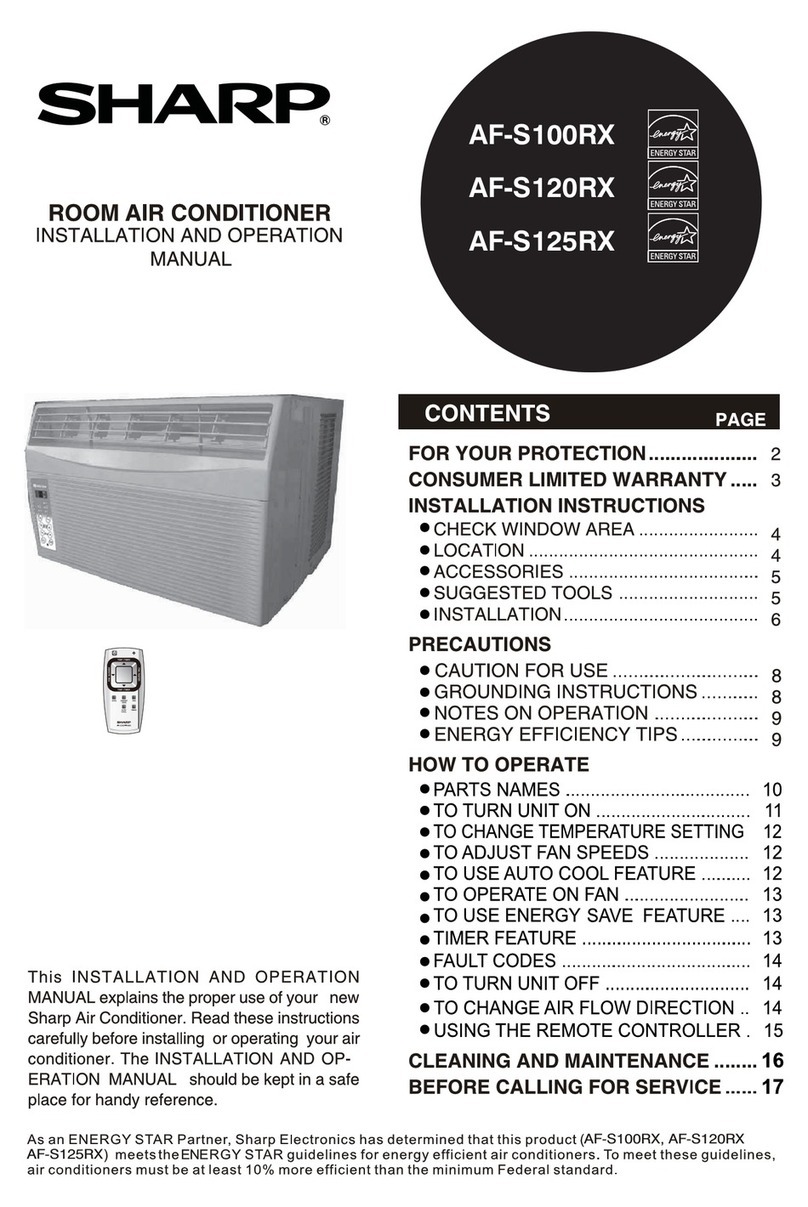

Sharp 2020215A0343 User manual

Sharp

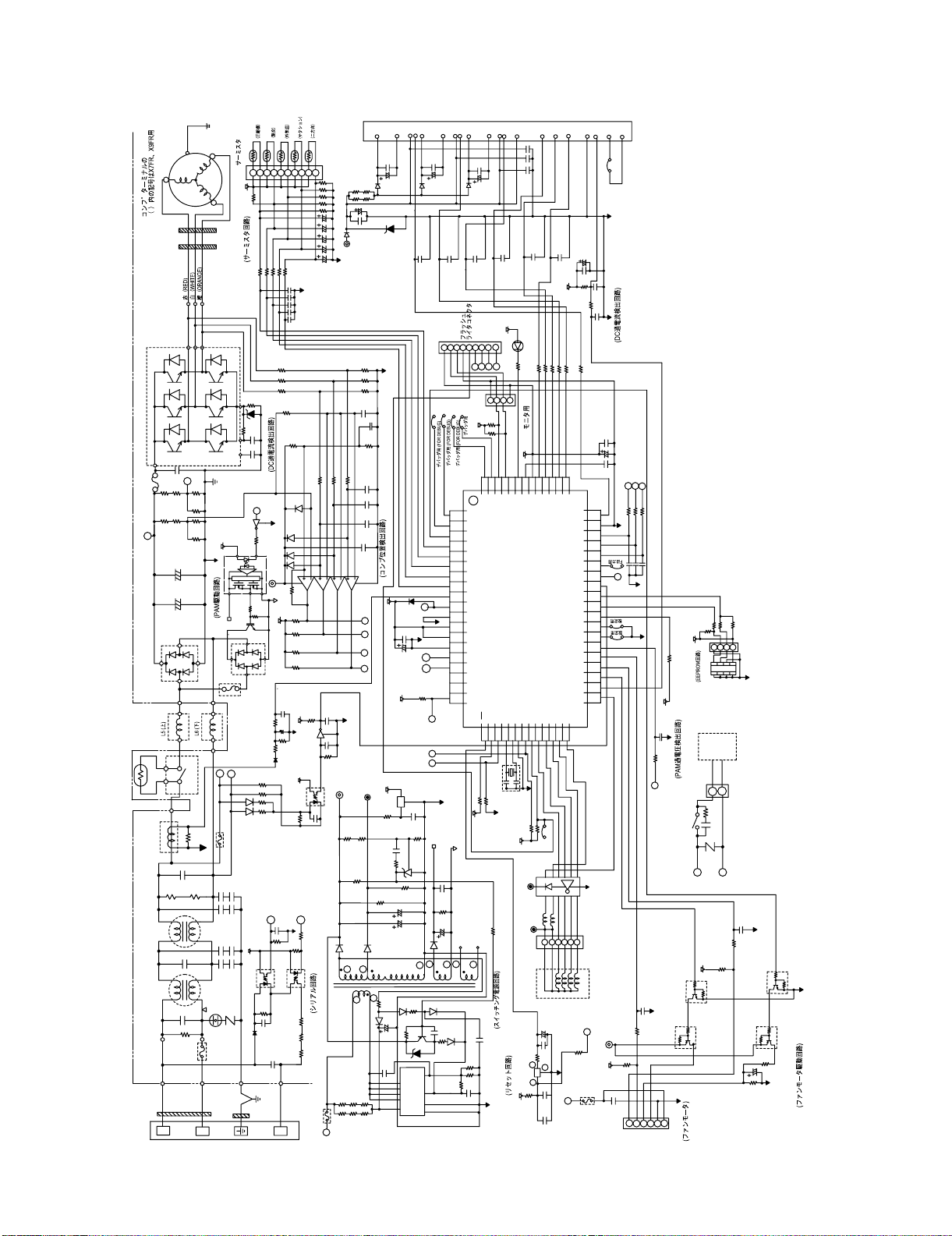

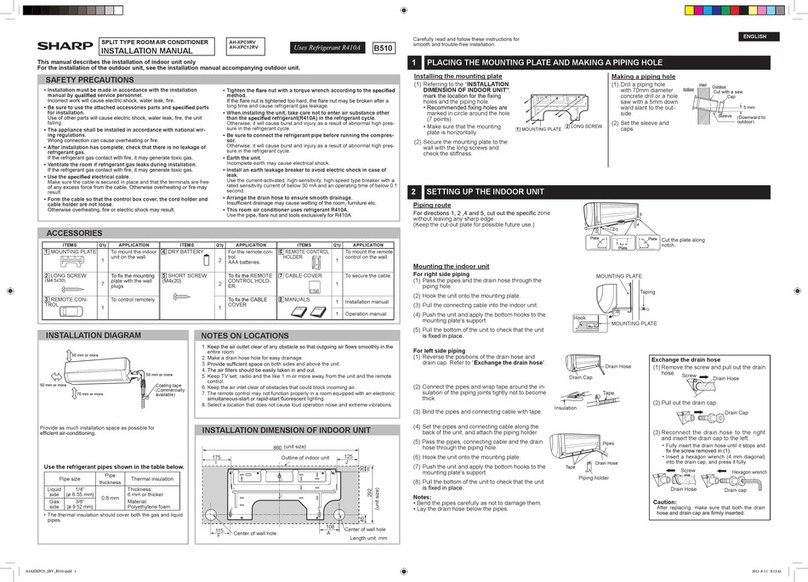

Sharp AH-XPC9RV User manual

Sharp

Sharp AY-AP9KR User manual

Sharp

Sharp AH-AP18DR User manual

Sharp

Sharp AU-1802Y User manual

Sharp

Sharp CV-13NH User manual

Sharp

Sharp AF-06CSL User manual

Sharp

Sharp AE-X2M14LR User manual

Sharp

Sharp AF-100DX User manual

Sharp

Sharp AY-XP7FR User manual

Sharp

Sharp AF-A9LA User manual

Sharp

Sharp Eco Inverter AH-XP18MV User manual

Sharp

Sharp UHL Series User manual

Sharp

Sharp AF-S60PX User manual

Sharp

Sharp AH-A09BF User manual

Sharp

Sharp AH-A18LCA User manual

Sharp

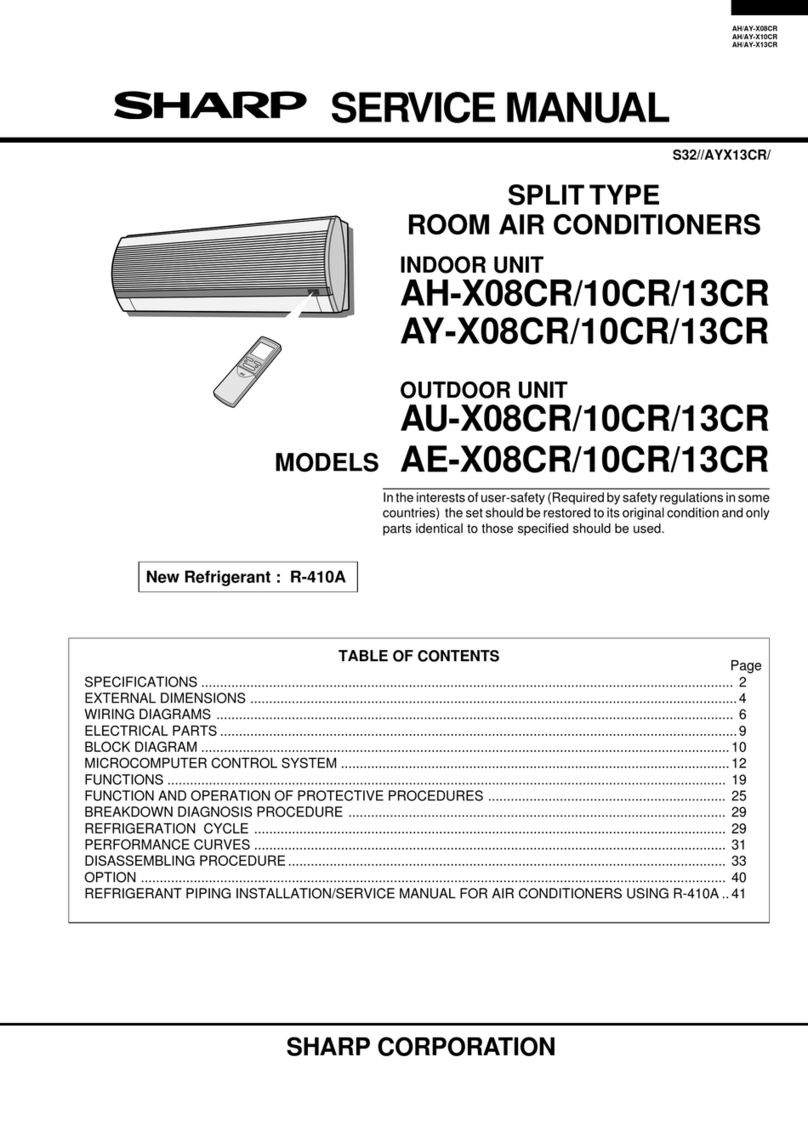

Sharp AH-X08CR User manual

Sharp

Sharp AF-S60RX User manual

Sharp

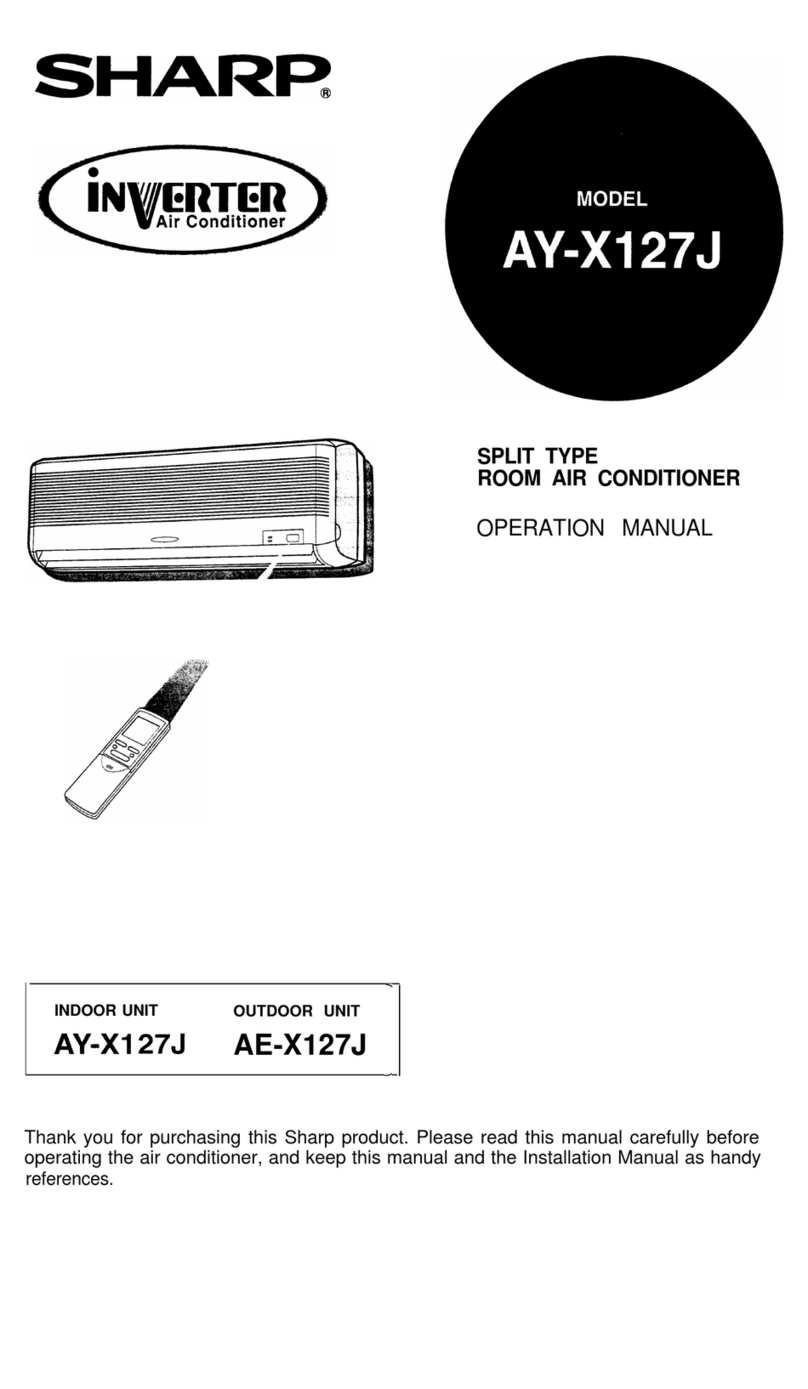

Sharp AE-X127J User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions