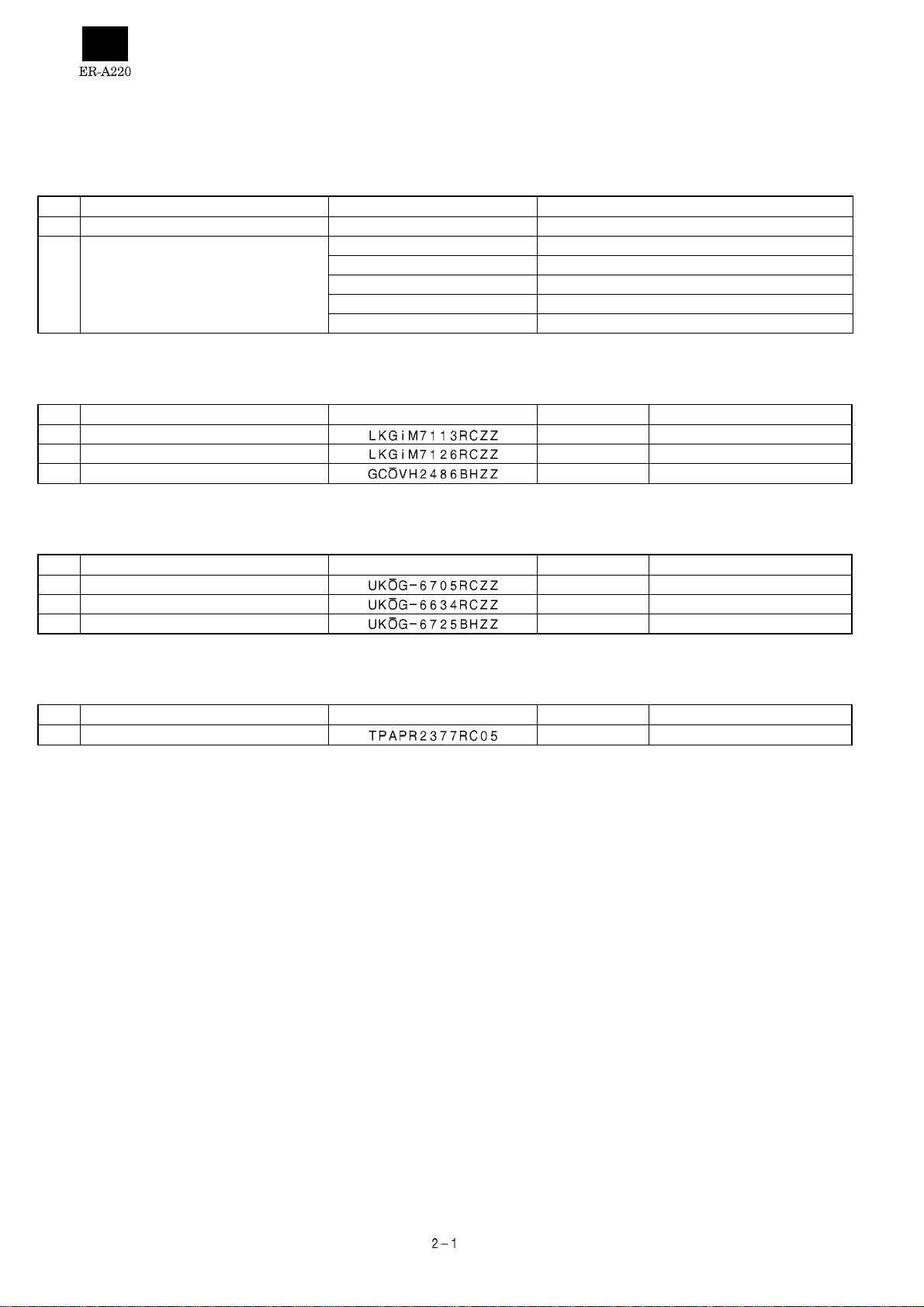

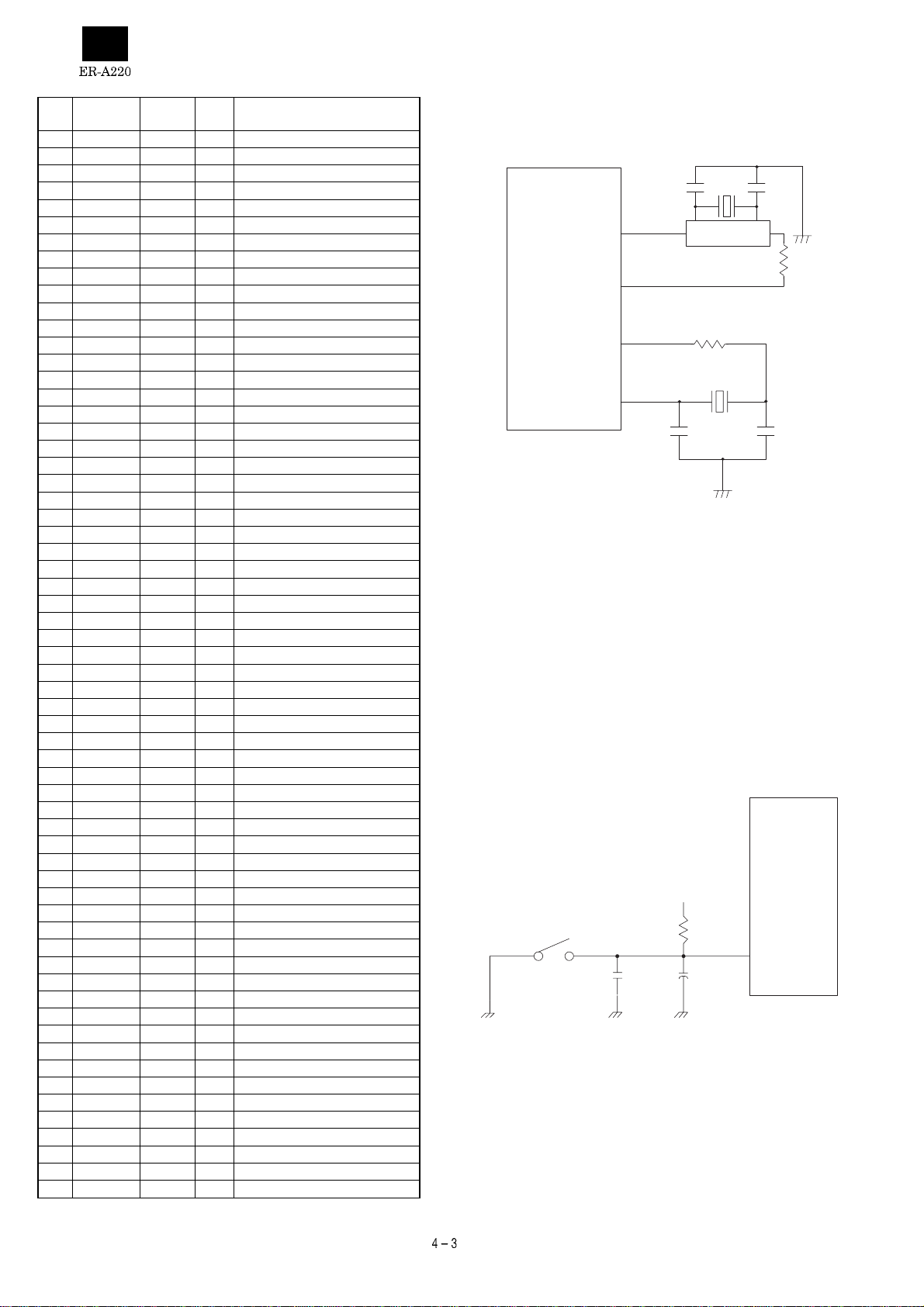

Pin

No. SYMBOL SIGNAL

NAME In/Out Function

39 CLKOUT /RDY In VCC

40 ALE NC Out NOT USE

41 /HOLD /HOLD In Controled by P71

42 /HLDA NC Out NOT USE

43 CBCLK NC Out NOT USE

44 /RD /RD Out Read

45 /BHE NC Out NOT USE

46 /WR /WR Out Write

47 /CS3 CS3 Out Display segment latch

48 /CS2 /RAS1 Out Chip select :for RAM

49 /CS1 BUSY In FMC :Busy

50 /CS0 /ROS1 Out Chip select :for ROM

51 A19 NC Out NOT USE

52 A18 NC Out NOT USE

53 A17 A17 Out Address bus :17

54 A16 A16 Out Address bus :16

55 A15 A15 Out Address bus :15

56 A14 A14 Out Address bus :14

57 A13 A13 Out Address bus :13

58 A12 A12 Out Address bus :12

59 A11 A11 Out Address bus :11

60 A10 A10 Out Address bus :10

61 A9 A9 Out Address bus :9

62 VCC VDD In VDD

63 A8 A8 Out Address bus :8

64 VSS GND In GND

65 A7 A7 Out Address bus :7

66 A6 A6 Out Address bus :6

67 A5 A5 Out Address bus :5

68 A4 A4 Out Address bus :4

69 A3 A3 Out Address bus :3

70 A2 A2 Out Address bus :2

71 A1 A1 Out Address bus :1

72 A0 A0 Out Address bus :0

73 D15 PH4 Out Paper feed motor :Phalse4

74 D14 PH3 Out Paper feed motor :Phalse3

75 D13 PH2 Out Paper feed motor :Phalse2

76 D12 PH1 Out Paper feed motor :Phalse1

77 D11 P13 Out Key/Display :Strobe3

78 D10 P12 Out Key/Display :Strobe2

79 D9 P11 Out Key/Display :Strobe1

80 D8 P10 Out Key/Display :Strobe0

81 D7 D7 InOut Data bus :7

82 D6 D6 InOut Data bus :6

83 D5 D5 InOut Data bus :5

84 D4 D4 InOut Data bus :4

85 D3 D3 InOut Data bus :3

86 D2 D2 InOut Data bus :2

87 D1 D1 InOut Data bus :1

88 D0 D0 InOut Data bus :0

89 AN7 DTS Out Printer head drive

90 AN6 LATCH Out Printer data latch

91 AN5 P105 Out Printer head voltage ON

92 AN4 P104 Out CG ROM Bank

93 AN3 P103 In Head rank

94 AN2 Vref In Base voltage :2.495V

95 AN1 P101 In Printer head voltage check

96 AVSS GND In GND

97 AN0 TH In Print head temperature check

98 VREF VDD In VDD

99 AVCC VDD In VDD

100 SIN4 P97 In Key return :7

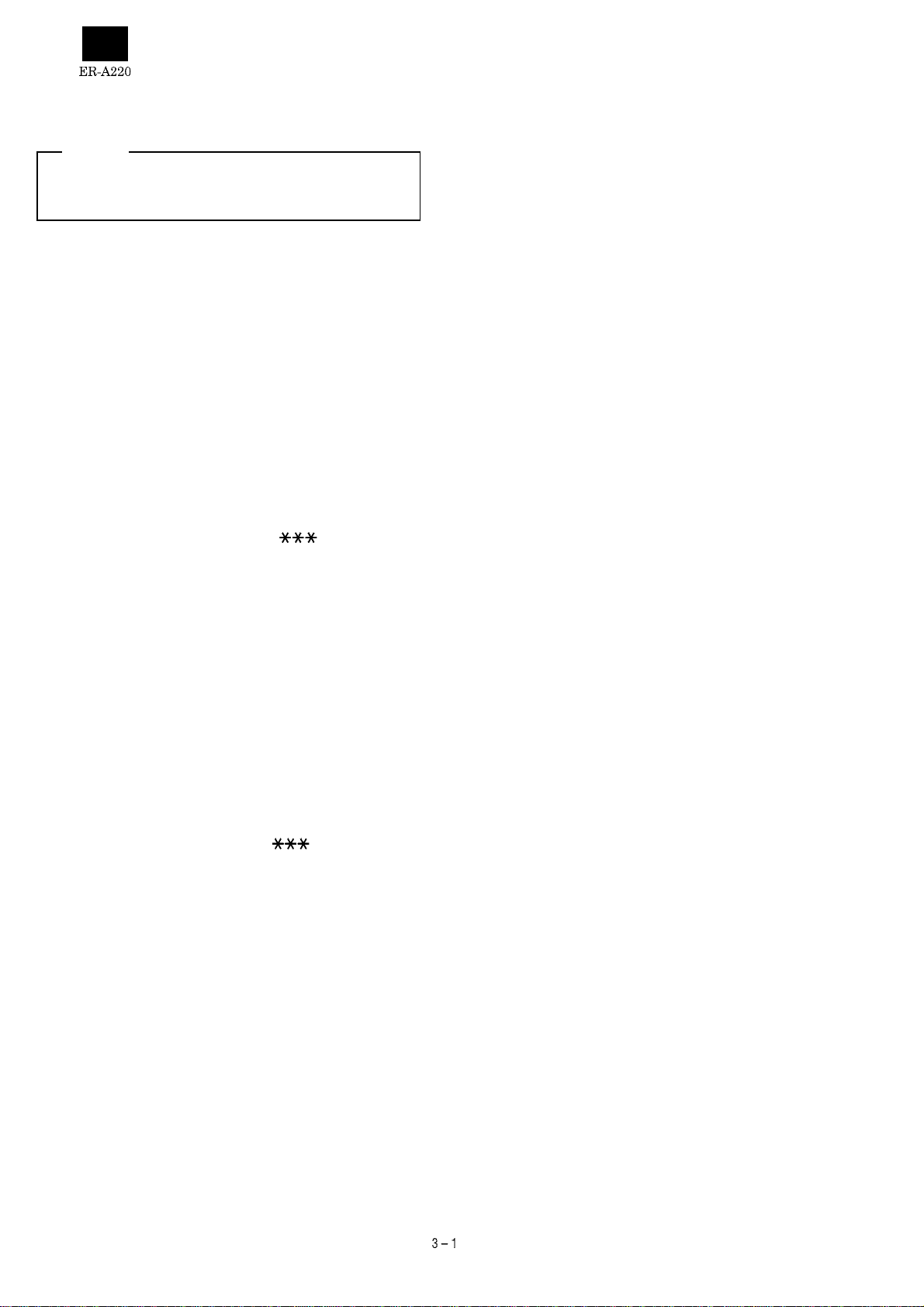

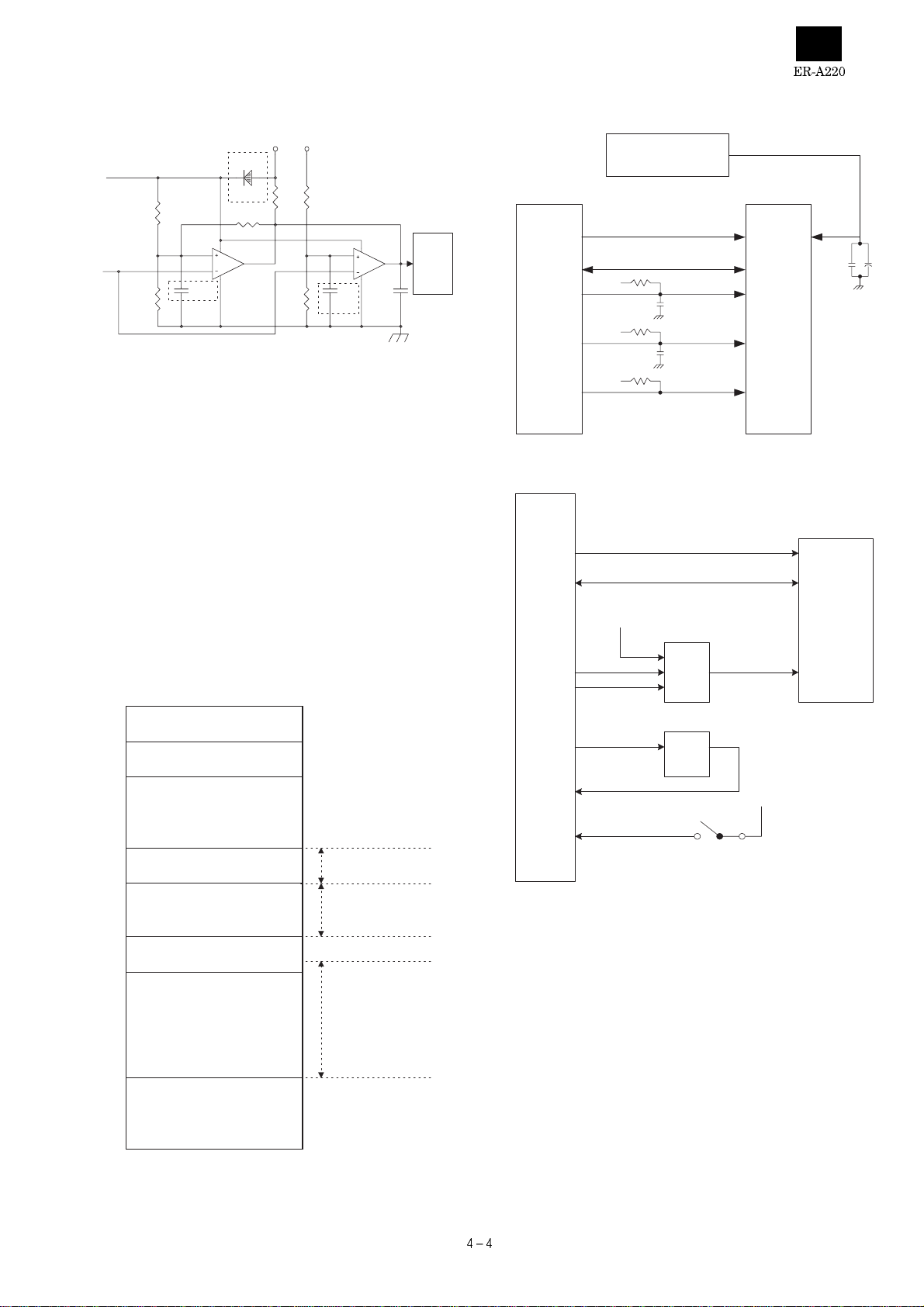

3. Clock generator

1) CPU

Two oscillators are connected to the CPU.

The basic clock X3 is supplied from a 12MHz oscillator.

The 12Mhz basic clocks are formed by X3 and W42C21 and inputted

to the Xin pin of the CPU.

If the CPU was not operating properly, the signal does not appear on

this line in most cases.

The sub-clock X1 generates 32.768KHz which is primarily used to

update the internal RTC (real time clock).

During the standby mode, it keeps oscillating to update the clock and

monitoring the power recov-ery.

4. Reset circuit

When the mode switch is placed in the "SRV" position, the reset signal

is sent to the CPU to reset the hardware.

11

10

27P

C135

CPU

XIN

X3

12MHz

X1

32.768KHz

12

18P

C134

14

XOUT

XCOUT

XCIN

R110

330

W42C3103G

IC9 R109

0

CPU

R47

/RESET

C14C104

MODE SWITCH

SRV' position

VDD

11

+