ER-A520U/ER-A530U HARDWARE DESCRIPTION

– 8 –

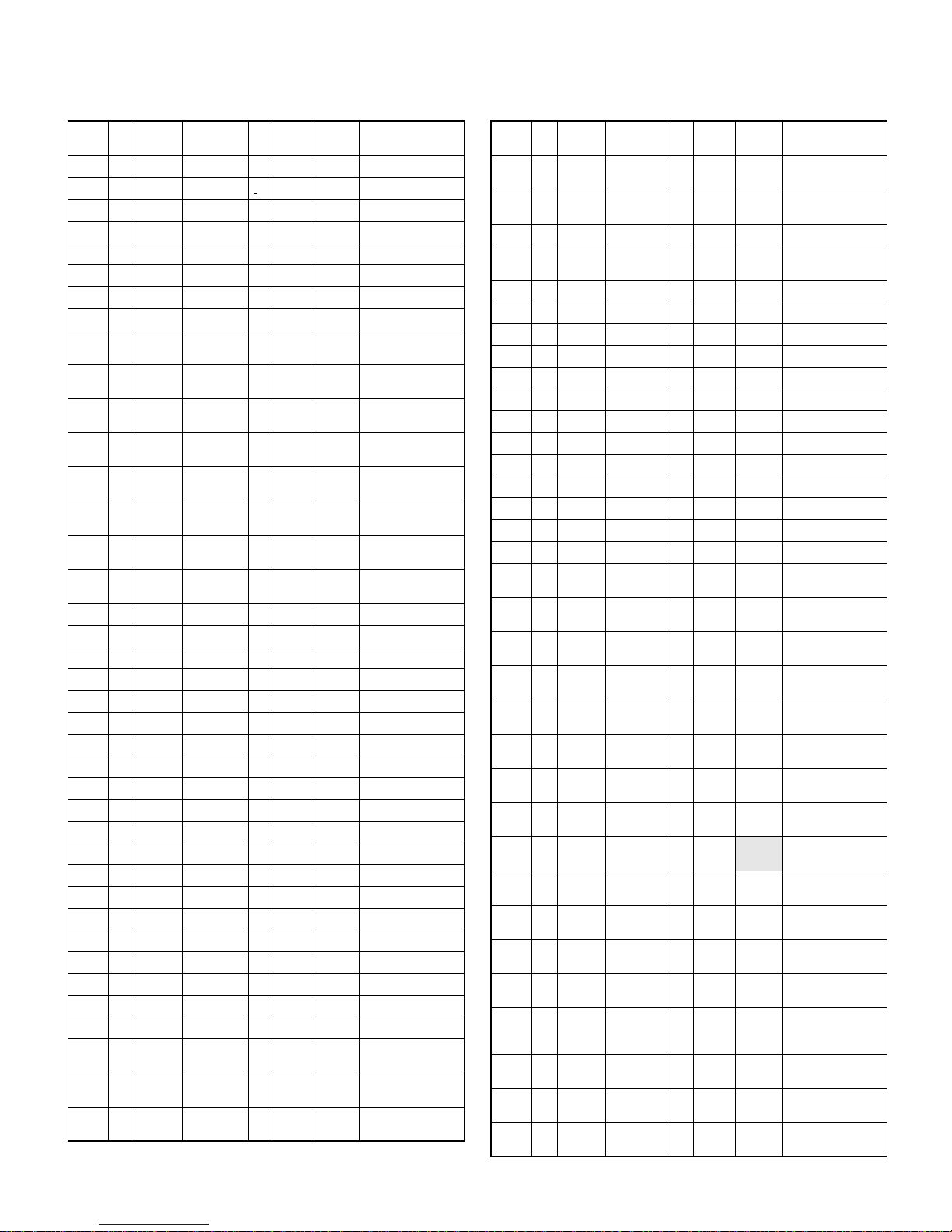

3. CPU PIN TABLE

M16C/80 PORT USED IN PROCESSOR MODE: MICROPROCESSOR MODE (SEPARATE BUS 8bit WIDTH)

PORT PIN

No. Pin

name Signal

name I/O Initial

value After

POFF Function

P00 122 D0 D0 I/O −In DATA BUS D0

P01 121 D1 D1 I/O−In DATA BUS D1

P02 120 D2 D2 I/O −In DATA BUS D2

P03 119 D3 D3 I/O −In DATA BUS D3

P04 113 D4 D4 I/O −In DATA BUS D4

P05 112 D5 D5 I/O −In DATA BUS D5

P06 111 D6 D6 I/O −In DATA BUS D6

P07 110 D7 D7 I/O −In DATA BUS D7

P10 109 P10 RAS O L Out L RECEIPT

PAPER FEED A

P11 108 P11 RBS O L Out L RECEIPT

PAPER FEED B

P12 107 P12 RCS O L Out L RECEIPT

PAPER FEED C

P13 106 P13 RDS O L Out L RECEIPT

PAPER FEED D

P14 105 P14 JAS O L Out L JOURNAL

PAPER FEED A

P15 104 P15

/INT3# JBS O L Out L JOURNAL

PAPER FEED B

P16 103 P16

/INT4# JCS O L Out L JOURNAL

PAPER FEED C

P17 102 P17

/INT5# JDS O L Out L JOURNAL

PAPER FEED D

P20 101 A0 A0 O −Out L Address Bus A0

P21 100 A1 A1 O −Out L Address Bus A1

P22 99 A2 A2 O −Out L Address Bus A2

P23 98 A3 A3 O −Out L Address Bus A3

P24 97 A4 A4 O −Out L Address Bus A4

P25 96 A5 A5 O −Out L Address Bus A5

P26 95 A6 A6 O −Out L Address Bus A6

P27 94 A7 A7 O −Out L Address Bus A7

P30 92 A8 A8 O −Out L Address Bus A8

P31 85 A9 A9 O −Out L Address Bus A9

P32 84 A10 A10 O −Out L Address Bus A10

P33 83 A11 A11 O −Out L Address Bus A11

P34 82 A12 A12 O −Out L Address Bus A12

P35 81 A13 A13 O −Out L Address Bus A13

P36 80 A14 A14 O −Out L Address Bus A14

P37 79 A15 A15 O −Out L Address Bus A15

P40 78 A16 A16 O −Out L Address Bus A16

P41 77 A17 A17 O −Out L Address Bus A17

P42 75 A18 A18 O −Out L Address Bus A18

P43 73 A19 A19 O −Out L Address Bus A19

P44 72 A20

/CS3# A20 O −Out L Address Bus A20

P45 71 A21

/CS2# A21 O −Out L Address Bus A21

P46 70 A22

/CS1# A22 O −Out L Address Bus A22

P47 69 A23#

/CS0# A23# O −Out L Address Bus A23

P50 65 WR# WR# O −Out L WRITESTROBE

SIGNAL

P51 64 BHE# BHE# O −Out L NOT USED

P52 63 RD# RD# O −Out L READ STROBE

SIGNAL

P53 62 BCLK BCLK O −Out L BCLK CLOCK

P54 55 HLDA# HLDA# O −Out L NOT USED

P55 54 HOLD# HOLD# I −In NOT USED

P56 53 ALE ALE O −Out L NOT USED

P57 52 RDY# RDY# I −In NOT USED

P60 47 RTS0# RS2# O H In RS-232 RS2

P61 46 CLK0

CI2#

I−In RS-232 CI2

P62 45 RxD0 RD2 I −In RS-232 RD2

P63 44 TxD0 TD2 O H In RS-232 TD2

P64 43 RTS1# RS1# O H In RS-232 RS1

P65 42 CLK1 CI1# I −In RS-232 CI1

P66 40 RxD1 RD1 I −In RS-232 RD1

P67 38 TxD1 TD1 O H In RS-232 TD1

P70 37 P70/

TA0out KR0# I −In KEY RETURN

SIGNAL 0

P71 36 P71/

TA0in KR1# I −In KEY RETURN

SIGNAL 1

P72 35 P72/

TA1out KR2# I −In KEY RETURN

SIGNAL 2

P73 34 P73/

TA1in

KR3#

I−In KEY RETURN

SIGNAL 3

P74 33 P74/

TA2out KR4# I −In KEY RETURN

SIGNAL 4

P75 32 P75/

TA2in KR5# I −In KEY RETURN

SIGNAL 5

P76 31 P76/

TA3out KR6# I −In KEY RETURN

SIGNAL 6

P77 30 P77/

TA3in KR7# I −In KEY RETURN

SIGNAL 7

P80 29 P80/

TA4out BUZZER O L In BUZZER SIG-

NAL

P81 28 P81/

TA4in DSEN I −In DRAWEROPEN

SENSE SIGNAL

P82 27 P82/

INT0# POFF# I −In P-OFF SIGNAL

P83 26 P83

/INT1# SHEN# I −In

UP-P16DP

SHEN# SINGNAL

P84 25 P84

/INT2# I−In NOT USED

P85 24 P85

/NMI# NMI# I −In NMI (CON-

NECTED TO

VDD)

P86 18

P86/

Xcout

Xcout O −Out SUB CLOCK

(32.768kHz)

P87 17 P87/

Xin Xcin I −In SUB CLOCK

(32.768kHz)

P90 7 P90/

CLK3 SCK O L Out L UP-P16DP

CLOCK SIGNAL

PORT PIN

No. Pin

name Signal

name I/O Initial

value After

POFF Function