CONTENTS

[ 1 ] GENERAL

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Target users . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

3. Major features . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

4. Environment conditions . . . . . . . . . . . . . . . . . . . 1-1

5. Basic specification matrix . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Operation specifications . . . . . . . . . . . . . . . . . . 2-1

3. Copy performance . . . . . . . . . . . . . . . . . . . . . . . 2-3

4. Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

[ 3 ] CONSUMABLE PARTS

1. Supply system table . . . . . . . . . . . . . . . . . . . . . 3-1

2. Production control number (lot No.) . . . . . . . . . 3-3

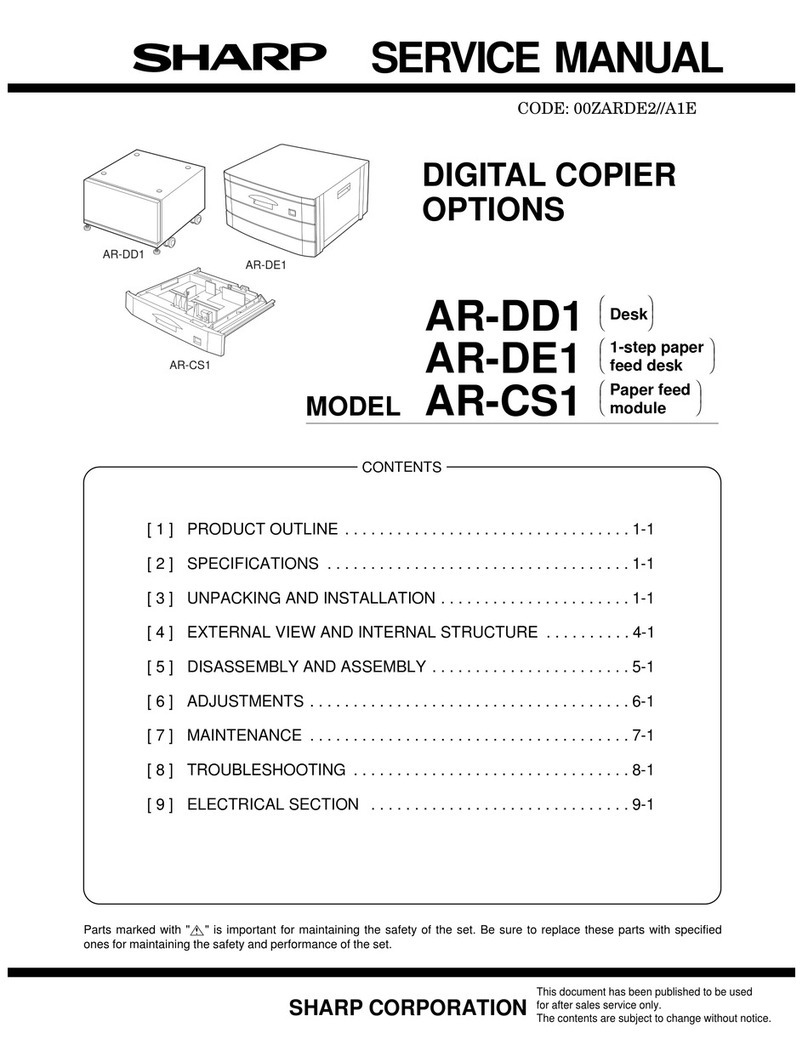

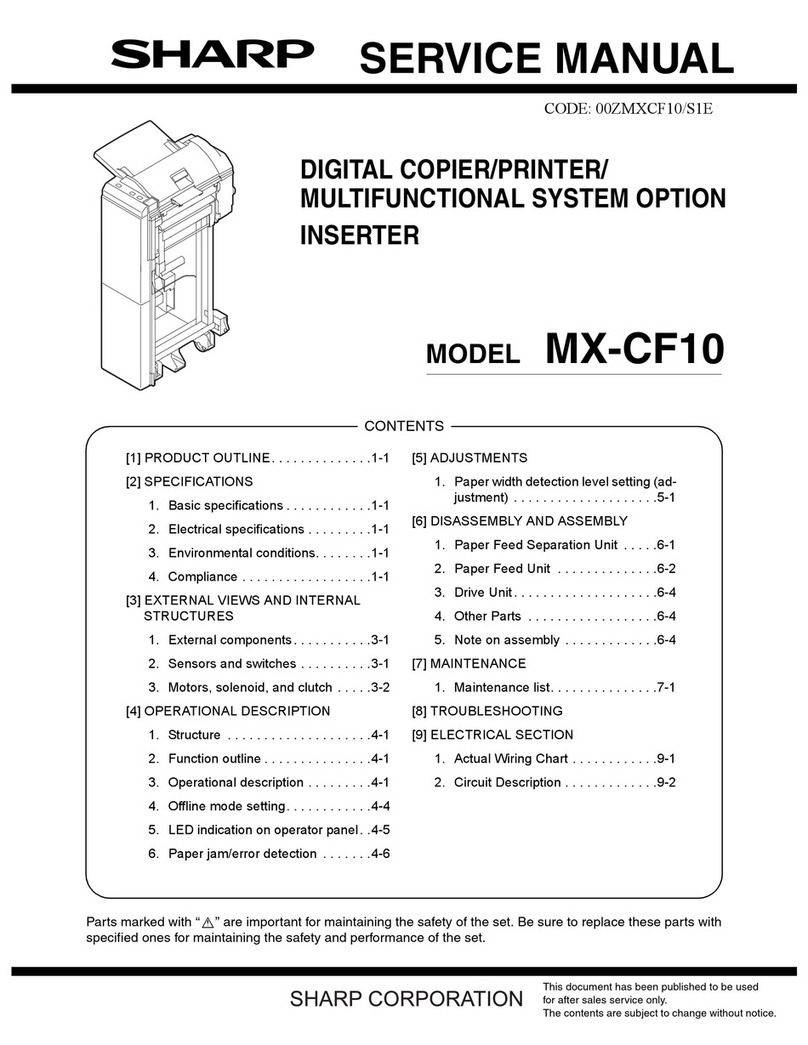

[ 4 ] EXTERNAL VIEWS AND INTERNAL

STRUCTURE

1. Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

3. Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4. Motors and solenoids . . . . . . . . . . . . . . . . . . . . 4-4

5. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

[ 5 ] UNPACKING AND INSTALLATION

1. A word on copier installation . . . . . . . . . . . . . . 5-1

2. Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3. Installing procedure . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] COPY PROCESS

1. Copy process composition . . . . . . . . . . . . . . . . 6-1

2. Image forming process steps . . . . . . . . . . . . . . 6-2

3. Description process . . . . . . . . . . . . . . . . . . . . . . 6-3

4. Transition of OPC drums surface potential . . . 6-3

5. OPC drum membrance decrease correction . . 6-3

[ 7 ] OPERATION DESCRIPTIONS

7-1. Optical system . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2. Fuser section . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7-3. Paper feed section and

paper transport section . . . . . . . . . . . . . . . . 7-5

7-4. New drum cartridge detection system . . . . 7-8

[ 8 ] DISASSEMBLY AND ASSEMBLY

1. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

3. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

4. Tray paper feed/transport section . . . . . . . . . . . 8-8

5. Manual paper feed section . . . . . . . . . . . . . . . 8-10

6. Rear frame section . . . . . . . . . . . . . . . . . . . . . 8-13

7. Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

[ 9 ] ADJUSTMENTS

1. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Copy density adjustment . . . . . . . . . . . . . . . . . 9-18

3. Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

[10] SIMULATION

1. Entering the simulation mode . . . . . . . . . . . . . 10-1

2. Simulation list . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

3. Contents of simulation . . . . . . . . . . . . . . . . . . . 10-3

4. Toner save mode setting and cancel . . . . . . 10-9

5. AE level adjustment . . . . . . . . . . . . . . . . . . . . 10-9

6. Self diag list . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

[11] USER PROGRAMS . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ELECTRICAL SECTION

1. Block diagram

A. Overall block diagram . . . . . . . . . . . . . . . . 12-1

B. Main PWB block diagram

(load drive block diagram) . . . . . . . . . . . . 12-1

2. Circuit descriptions

A. Main PWB . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

B. Operation panel section . . . . . . . . . . . . . 12-12

C. DC power operational description . . . . . 12-12

3. Circuit diagram

A. MAIN PWB CIRCUIT . . . . . . . . . . . . . . . 12-15

B. OPERATION PWB CIRCUIT . . . . . . . . . 12-22

C. DL PWB CIRCUIT . . . . . . . . . . . . . . . . . . 12-25

D. BL PWB CIRCUIT . . . . . . . . . . . . . . . . . . 12-26

E. SENSOR PWB A/B . . . . . . . . . . . . . . . . . 12-27

F. SENSOR PWB C . . . . . . . . . . . . . . . . . . 12-28

G. AC POWER SUPPLY CIRCUIT . . . . . . . 12-29

H. DC POWER SUPPLY CIRCUIT . . . . . . . 12-35

4. ACTUAL WIRING DIAGRAM . . . . . . . . . . . . 12-39

5. TIMING CHART

A. Warm-up . . . . . . . . . . . . . . . . . . . . . . . . . . 12-41

B. Tray paper feed . . . . . . . . . . . . . . . . . . . . 12-41

C. Manual multi paper feed . . . . . . . . . . . . . 12-42

D. Manual single paper feed . . . . . . . . . . . . 12-42

www.freeservicemanuals.info

Published in Heiloo, Holland.