– i –

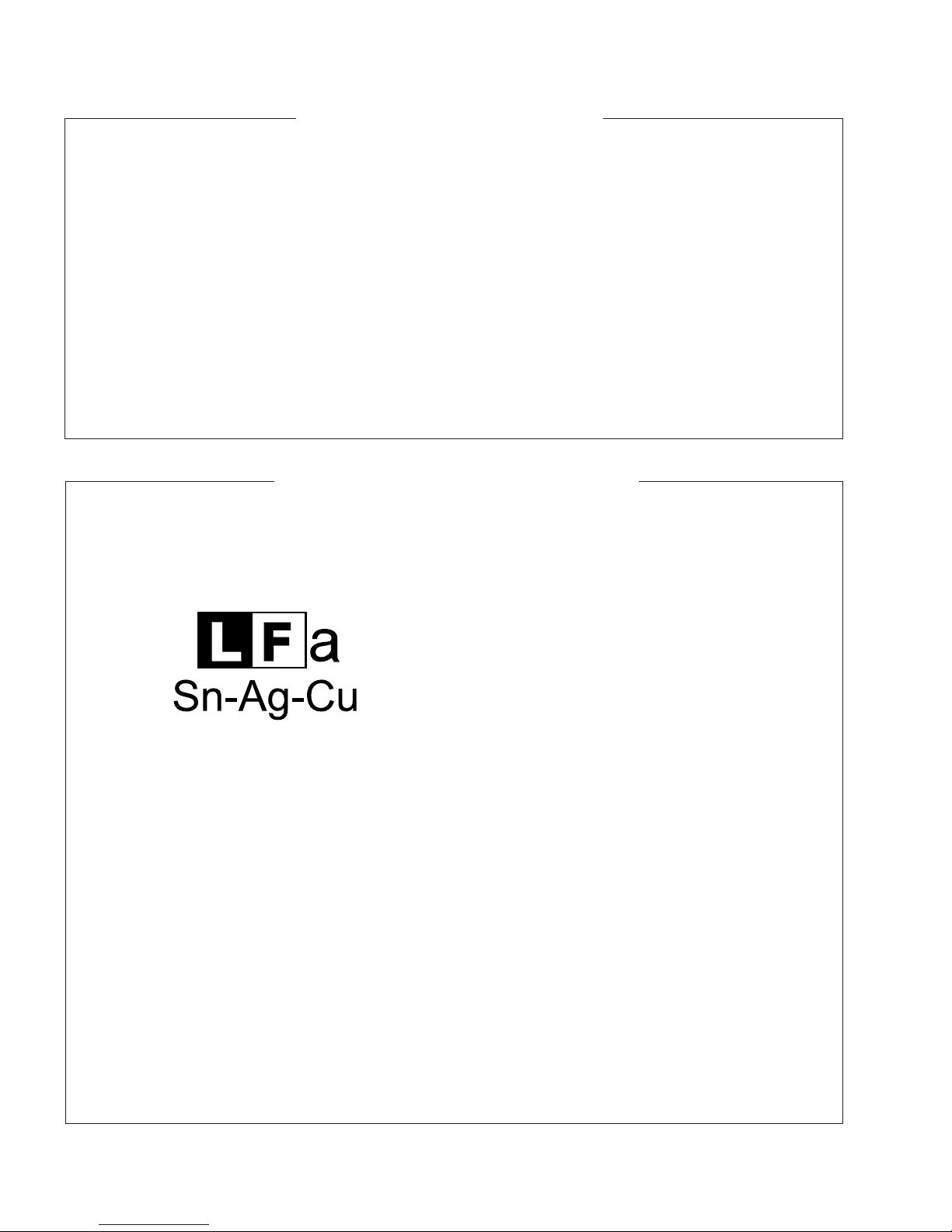

1. Employing lead-free solder

The TEL/LIU PWB and Operation Panel PWB of this model employs lead-free solder.

This is indicated by the "LF" symbol printed on the PWB and in the service manual.

The suffix letter indicates the alloy type of the solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free solder

When repairing a PWB with the "LF" symbol, only lead-free solder should be used. (Using normal tin/lead alloy solder may

result in cold soldered joints and damage to printed patterns.)

As the melting point of lead-free solder is approximately 40°C higher than tin/lead alloy solder, it is recommended that a

dedicated bit is used, and that the iron temperature is adjusted accordingly.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is higher and has poorer melting point (flow), to prevent damage to the

land of the PWB, extreme care should be taken not to leave the bit in contact with the PWB for an extended period of time.

Remove the bit as soon as a good flow is achieved.

The high content of tin in lead free solder will cause premature corrosion of the bit.

To reduce wear on the bit, reduce the temperature or turn off the iron when it is not required.

Leaving different types of solder on the bit will cause contamination of the different alloys, which will alter their

characteristics, making good soldering more difficult.

It will be necessary to clean and replace bits more often when using lead-free solder. To reduce bit wear, care should be

taken to clean the bit thoroughly after each use.

PRECAUTIONS FOR USING LEAD-FREE SOLDER

(Danish) ADVARSEL !

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the equipment manufacturer.

Discard used batteries according to manufacturer's instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

(French) ATTENTION

Il y a danger d'explosion s' il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d'un type recommandé par le constructeur.

Mettre au rébut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfare vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anweisungen.

CAUTION FOR BATTERY REPLACEMENT

UX-P115U