MD-X60H

– 2 –

CAUTION-INVISIBLE LASER RADIATION WHEN OPEN. DO NOT STARE INTO

BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD. STIRRA

EJ IN I STRALEN OCH BETRAKTA EJ STRALEN MED OPTISKA INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING VED ABNING. SE IKKE IND I

STRALEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

VARO! AVATTAESSA OLET ALTTIINA NAKYMATON LASERSATEILYLLE.

ALA TUIJOTA SATEESEEN ALAKA KATSO SITA OPTISEN LAITTEEN LAPI.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD.

STIRRA EJ IN I STRALEN OCH BETRAKTA EJ STRALEN GENOM OPTISKT

INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING NAR DEKSEL APNES. STIRR IKKE

INN I STRALEN ELLER SE DIREKTE MED OPTISKE INSTRUMENTER.

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT SÄTT ÄN I

DENNA BRUKSANVISNING SPECIFICERAS. KAN

ANVÄNDAREN UTSÄTTAS FÖR OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN FÖR LASERKLASS 1.

CAUTION -INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED

AVOID EXPOSURE TO BEAM .

VARNING - OSYNLIG LASERSTR LNING N R DENNA DEL R PPNAD OCH SP RRAR

R URKOPPLADE. STR LEN R FARLIG.

ADVARSEL - USYNLIG LASERSTR LING N R DEKSEL PNES OG SIKKERHEDSL S

BRYTES. UNNG EKSPONERING FOR STR LEN.

VARO! AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

N KYM T N LASERS TEILYLLE. L KATSO S TEESEN.

VARNING - OSYNLIG LASERSTR LING N R DENNA DEL R PPNAD OCH SP RREN

R URKOPPLAD. BETRAKTA EJ STR LEN.

ADVARSEL - USYNLIG LASERSTR LING VED BNING N R SIKKERHEDSAFBRYDERE

ER UDE AF FUNKTION. UNDG UDSETTELSE FOR STR LING.

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT SÄTT ÄN I

DENNA BRUKSANVISNING SPECIFICERAS. KAN

ANVÄNDAREN UTSÄTTAS FÖR OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN FÖR LASERKLASS 1.

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

CAUTION

Use the MD/CD component system only in accordance with the instruc-

tions given in this manual and do not attempt to interfere with the in-

terlock switch or make any other adjustment as this may result in

exposure to hazardous radiation.

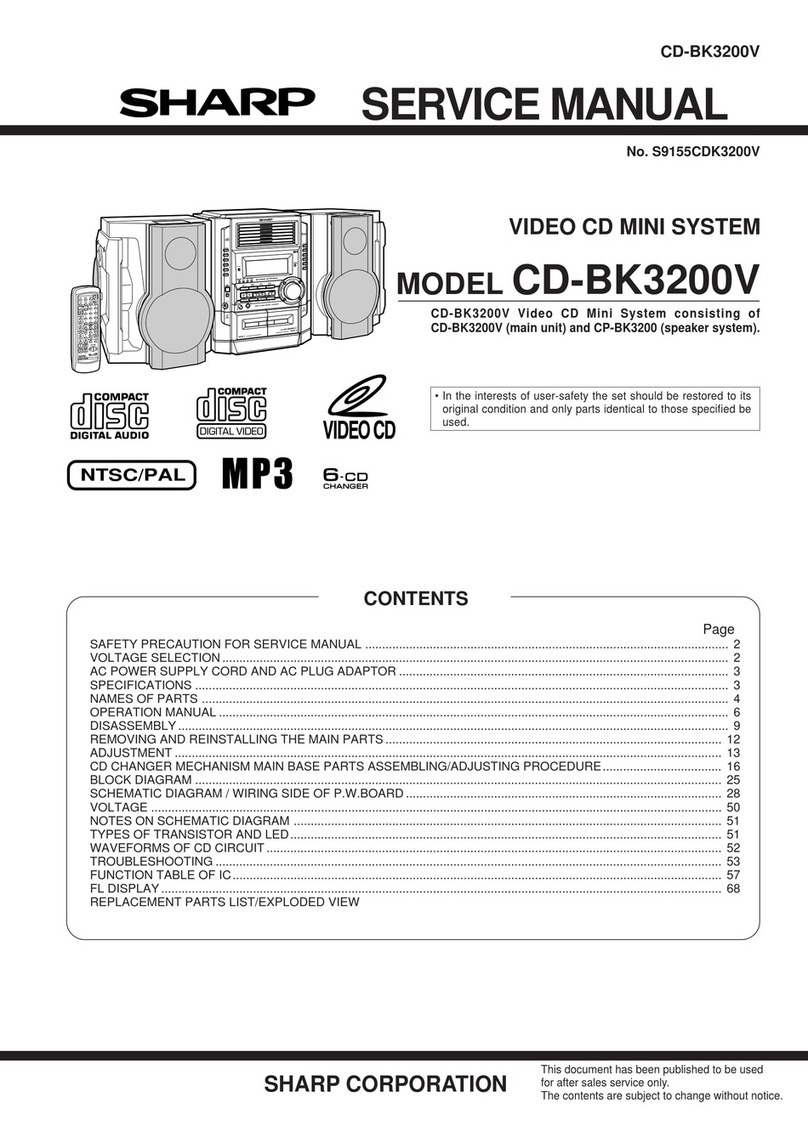

SAFTY ORECAUTION FOR SERVICE MANUAL

WARNINGS (CD)

THEAEL(ACCESSIBLEEMISSIONLEVEL)OFTHELASER

POWEROUTPUTISLESSTHANCLASS1BUTTHELASER

COMPONENT IS CAPABLE OF EMITTING RADIATION

EXCEEDING THE LIMIT FOR CLASS 1. THEREFORE IT IS

IMPORTANTTHATTHEFOLLOWINGPRECAUTIONSARE

OBSERVED DURING SERVICING TO PROTECT YOUR

EYES AGAINST EXPOSURE TO THE LASER BEAM.

1-WHEN THE CABINET IS REMOVED, THE POWER IS

TURNEDON WITDOUTA COMPACTDISC INPOSITION

ANDTHEPICK-UPISONTHEOUTEREDGETHELASER

WILL LIGHT FOR SEVERAL SECONDS TO DETECT A

DISC. DO NOT LOOK INTO THE PICK-UP LENS.

2-THE LASER POWER OUTPUT OF THE PICK-UP UNIT

AND REPLACEMENT SERVICE PARTS ARE ALL

FACTORY PRE-SET BEFORE SHIPMENT.

DO NOT ATTEMPT TO RE-ADJUST THE LASER PICK-

UP UNIT DURING REPLACEMENT OR SERVICING.

3-UNDER NO CIRCUMSTANCES STARE INTO THE PICK-

UP LENS AT ANY TIME.

4-CAUTION-USEOF CONTROLSOR ADJUSTMENTS,OR

PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN

HAZARDOUS RADIATION EXPOSURE.

WARNINGS (MD)

The AEL (ACCESSIBLE EMMISSION LEVEL) of the laser

power output is less than class 1 but the laser component is

capable

ofemittingradiationexceedingthelimitforclass1.Therefore

it is important that the following precautions are observer

during

servicing to protect your eyes against exposure to the laser

beam.

1) When the unit case cover is removed and LOADING SW

(SW 1956) is turned on and then PLAY SW (SW 1954

mechanism PWB) is turned on in a few second.

The laser will light for several second to detect a disk.

2)The laserpoweroutputofthepickupunit andreplacement

service parts are all factory pre-set before shipment.

Do not attempt to re-adjust the laser pick-up unit during

replacement or servicing.

3) Under no circumstances stare into the pickup lens at any

time.

4) If laser optical unit becomes faulty, replace the complete

laser optical unit.

5)CAUTION-USEofcontrolsoradjustments,orperformance

ofproceduresotherthanthosespecifiedhereinmayresult

in hazardous radiation exposure.

VARO ! Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä katso säteeseen.

VARNING! Osynlig laserstralning när denna del är öppnad och spärren är urkopplad. Betrakta ej strälen.

(FOR U.K. ONLY)