– 9 –

SD-CX1W

Error Messages

When an error message is displayed, proceed as follows:

Error messages Meaning Remedy

BLANK MD Nothing is recorded. (Neither

music nor disc name is re-

corded.)

Replace it with another disc.

Can't COPY You tried to record from a

copy prohibited CD. Replace the CD.

Can't EDIT A track cannot be edited. Change the stop position of the

track and then try editing it.

Can't READ* The disc is damaged. Replace it with another disc.

(*: Number or

symbol) TOC information cannot be

read. Erase the disc and try recording

again.

MiniDisc not specified.

Can't REC Recording cannot be per-

formed correctly due to vibra-

tion or shock in the unit.

Re-record or replace the Mini-

Disc.

Can't T REC Timer recording is impossible

or there is no available space

on the MD.

Replace it with another record-

able disc.

The disc is out of recording

space.

Can't WRITE The TOC information could

not be created properly due to

a mechanical shock or to

scratches on the disc.

Set this unit to the stand-by

mode and try to write the TOC

again. (Remove any source of

shock or vibration whilst writing.)

CD NO DISC A CD has not been loaded. Load a CD.

The CD data cannot be read. Reload the CD.

DISC FULL The disc is out of recording

space. Replace the disc with another

recordable disc.

EDIT OVER You chose 21 or more tracks

for track editing. Decrease the number of tracks.

Er - MD ** A MiniDisc is not working

properly. Press the MD button.

(**: Number or

symbol) Set this unit to the stand-by

mode and turn the power on

again.

Error messages Meaning Remedy

MD NO DISC A MiniDisc has not been load-

ed. Load a MiniDisc.

The MiniDisc data cannot be

read. Reload the MiniDisc.

NAME FULL The number of characters for

the disc name or track name

exceeds 40.

Shorten the disc or track name.

NOT AUDIO Thedatarecordedonthisdisc

is not audio data. Replace the disc.

PLAYBACK MD You tried to record on a play-

back-only disc. Replace it with another record-

able disc.

POWER ? A MiniDisc is not working

properly. Set this unit to the stand-by

mode and turn the power on

again.

PROTECTED The disc is write protected. Move the write protection tab

back to its original position.

TEMP OVER The temperature is too high. Set this unit to the stand-by

mode and wait for a whilst.

TOC FORM ** TOC information recorded on

the MD does not match the

MiniDisc specifications or it

cannot be read.

Replace it with another disc.

(**: Number or

symbol) Erase the discand try recording

again.

TOC FULL There is no space left for re-

cording track numbers. Replace it with another record-

able disc.

TOC FULL 1 There is no space left for re-

cording character information. Replace it with another record-

able disc.

Erase the needless characters.

? MD DISC The data contains an error. Press the MD button.

MiniDisc not specified. Replace it with another disc

Troubleshooting Chart

Many potential "problems" can be resolved by the owner without calling a service

technician.

General

CD player

MiniDisc

Tuner

Remote control

Symptom Possible cause

"TIME ADJUST" appears when the

clock time is checked. Did a power failure occur? Reset the clock.

When a button is pressed, the unit

does not respond. Set this unit to the power stand-by mode and

then turn it back on.

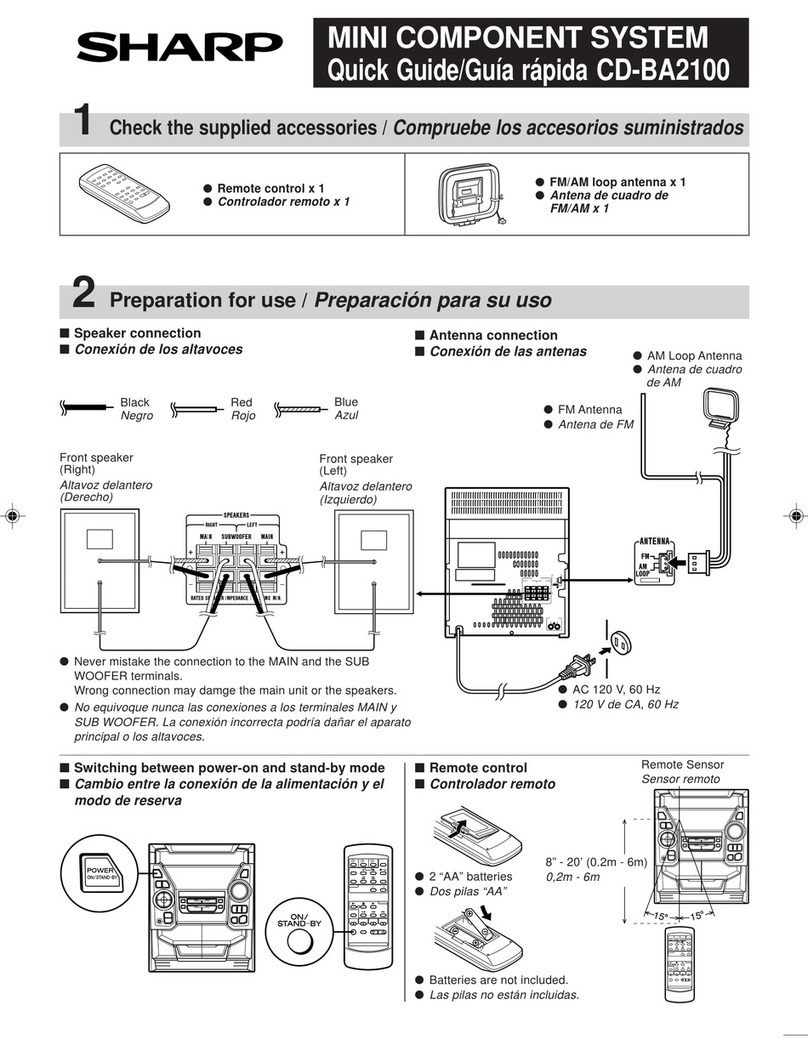

No sound is heard. Is the volume level set to "0"?

Are the headphones connected?

Are the speaker wires disconnected?

The picture on the TV screen is dis-

torted. When a radio or TV which uses an indoor

aerial is placed near the unit, the picture on

the TV screen may be distorted or the radio

may not function properly.

It is recommended that you use an external

aerial.

Symptom Possible cause

Eventhoughadischasbeenloaded,

"CD NO DISC" or "Can't READ" is

displayed.

The disc is very dirty.

Is the unit located near excessive vibrations?

Has condensation formed inside the unit?

Playback does not start. The disc is loaded upside down.

Playbackstopsinthemiddleorisnot

performed properly. The disc does not satisfy the standards.

The disc is distorted or scratched.

Playback sounds are skipped, or

stopped in the middle of a track. Is the unit located near excessive vibrations?

The disc is very dirty.

Has condensation formed inside the unit?

Symptom Possible cause

A recording cannot be made. Is the MiniDisc protected against accidental

erasure?

Did you try to make recording on a playback-

only MiniDisc?

Can you see the "DISC FULL" or "TOC

FULL" message in the display?

Eventhoughadischasbeenloaded,

"MD NO DISC" or "Can't READ" is

displayed.

The disc is very dirty.

Is the unit located near excessive vibrations?

Playback sounds are skipped. Has condensation formed inside the unit?

Symptom Possible cause

Radio makes unusual noise consec-

utively. The stereo system is placed near the TV or

computer.

FM/AM loop aerial is not placed properly.

Move the AC power lead away from the aeri-

al if located near.

The preset channel cannot be re-

called. Did a power failure occur?

Preset the channel again.

Symptom Possible cause

The remote control does not oper-

ate. Is the AC power lead of the stereo system

plugged in?

The battery polarity is not correct.

The batteries are dead.

Incorrect distance or angle.

Does the remote control sensor receive

strong light?.