Shimadzu MOC-120H User manual

INSTRUCTION MANUAL

ELECTRONIC MOISTURE BALANCE

MOC-120H

321-56738-21F

DEC. 2008

READ AND UNDERSTAND THIS MANUAL BEFORE OPERATION.

SAVE THIS MANUAL.

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL

(

804

)

318-3686

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL

(

804

)

318-3686

I

RequestsFPL950701

Provide this manual to the next user in the event that the instrument is transferred.

To ensure safe operation, contact your Shimadzu Balance representative for installation, adjustment, or

reinstallation after moving the instrument to a different site.

NoticesFPL950701

The content of this manual is subject, without notice, to modifications for the sake of improvement.

Every effort has been made to ensure that the content of this manual was correct at the time of creation. However,

in the event that any mistakes or omissions are discovered, it may not be possible to correct them immediately.

The copyright of this manual is owned by Shimadzu Corporation. Reproduction and duplication of whole or part of

the content without permission of the company are strictly prohibited.

"Microsoft", "Windows", "Windows Vista" and "Excel" are registered trademarks of Microsoft Corporation of the

U.S.A. in the United States and other countries. All other company names and product names that appear in this

manual are trademarks or registered trademarks of the companies concerned. Note that TM and ®indications are

not used.

The company names, organization names and product names in this manual are trademarks or registered

trademarks of the companies and organizations concerned.

Shimadzu does not guarantee that the WindowsDirect communication function will operate without problems on all

PCs. Shimadzu will accept no responsibility for any trouble that arises as a result of using this function. You are

recommended to back up all important data and programs in advance.

©2004-2008 Shimadzu Corporation. All rights reserved.

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

Declaration of Conformity

Manufacturer’s Name: SHIMADZU CORPORATION

Analytical&MeasuringInstrumentsDivision

Address: 1,Nishinokyo-Kuwabara-cho, Nakagyo-ku,

Kyoto 604-8511, Japan

declares in sole responsibility that the following product

Product Name Electronic Moisture Balance

Model Name MOC-120H

P/N 321-63300-10

referred to in this declaration conforms with following directives and standards

Electromagnetic Compatibility 2004/108/EEC

EN61326-1:2006

Electrical equipment for measurement, control and laboratory use

EMCrequirements

Low Voltage Directive 2006/95/EC

EN 61010-1:2001

Safety requirements for electrical equipment for measurement,

controlandlaboratoryuse

Part1:Generalrequirements

The last two digits of the year in which CE marking was affixed for Low Voltage

Directive 2006/95/EC are 03.

Note 1) This declaration becomes invalid if technical or operational modifications are

introduced without manufacturer’s consent.

Note 2) This declaration is valid if this product is used alone or in combination with the

accessories of this product which are mentioned in attached Appendix 1 or

other instruments which fulfill with the requirement of mentioned directive.

Note3) Importer/Distributor and Authorised Representative in EU is as follows:

SHIMADZUEUROPAGmbH

Address :Albert-Hahn-Strasse 6-10, 47269 Duisburg, F.R. Germany

Quality Assurance Department

Analytical & Measuring Instruments Division

SHIMADZU CORPORATION

II

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

III

Action for Environment (WEEE)PL950701

To all user of Shimadzu equipment in the European Union:

Equipment marked with this symbol indicates that it was sold on or after 13th August 2005, which means it should

not be disposed of with general household waste. Note that our equipment is for industrial/professional use only.

Contact Shimadzu service representative when the equipment has reached the

end of its life.

They will advise you regarding the equipment take-back.

With your co-operation we are aiming to reduce contamination from waste electronic and

electrical equipment and preserve natural resource through re-use and recycling.

Do not hesitate to ask Shimadzu service representative, if you require further information.

WEEE Mark

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

IV

Electronic Moisture Balance Safety NotesFPL950701

Improper use of the electronic moisture balance in violation of the following safety notes may result in death, injury or

damage to property due to fire, etc. Furthermore, the electronic moisture balance has high temperature components which

can cause burns if proper safety guidelines are not followed.

Observe all safety guidelines

Carefully read and observe all safety notes included in this user’s manual.

Do not use the unit if it appears to be malfunctioning

If you suspect a problem or malfunction in the unit, discontinue use and immediately have the unit inspected by certified

service personnel.

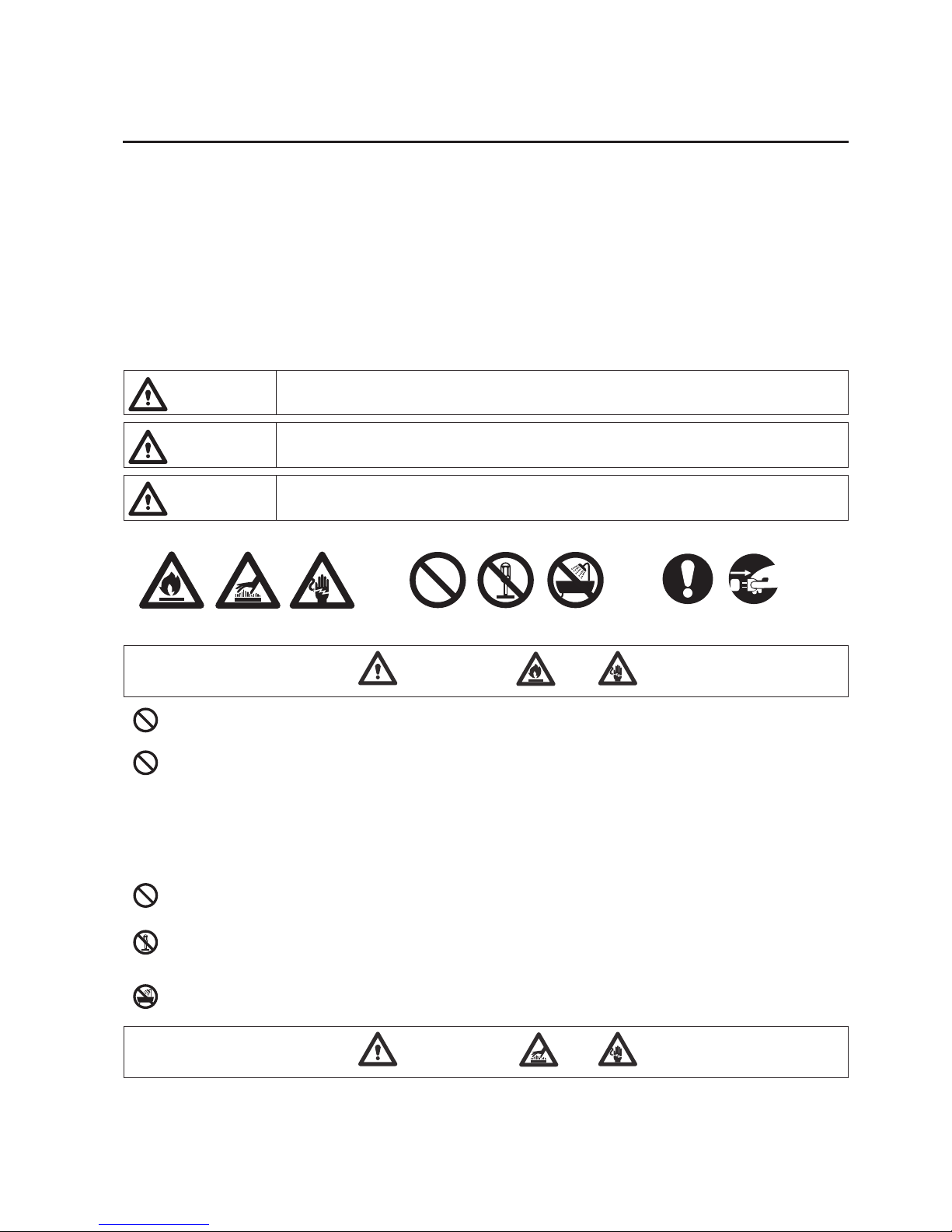

Meanings of Warning Indicators and Symbols

The following symbols are used in this operating manual and product to prevent accidents from occurring as a result of

improper usage or handling. The meaning of each symbol is as described below.

Failure to observe these items may lead to death or injury to the user.

Failure to observe these items may lead to injury to the user or damage to property.

Items which the user should be aware of in order to use the unit safety.

Caution Symbols Prohibition Symbols Symbol Requiring User Action

Fire Hazard Burn Hazard Electric Shock Prohibited Do Not Do not Expose Required Disconnect Plug

Hazard Disassemble to Water Action from Electrical Outlet

Do not attempt to measure samples which may undergo dangerous chemical reactions when heated as doing so

may result in explosion or release of toxic gas.

Do not place flammable materials near the electronic moisture balance.

Some parts of the electronic moisture balance become extremely hot during operation and could lead to fire if

flammable materials are placed nearby.

The heater inside the Electronic Moisture Balance reaches temperatures higher than the preset sample-heating

temperature.

The surface of the quartz tube of the heater reaches approximately 500°C (900°F) even during normal

measurements. In addition, the nickel-chromium resistance wire inside the heater reaches approximately 900°C

(1700°F) and is not airtight.

Never use with any power source for which the product was not designed.

Application of excessively high voltage may result in overheating to malfunction or fire.

Do not attempt to disassemble, modify or rebuild the electronic moisture balance.

Doing so may result in accident, electric shock, etc. If you believe the unit may be malfunctioning contact to an

authorized Shimadzu representative.

Do not allow the unit to come in contact with water.

The electronic moisture balance is not waterproof. Do not allow water or other liquids to get into the unit’s enclosure

as this may lead to electric shock or malfunction.

Do not touch the heat-dispersing component of the heater cover or sample pan with your bare hands, as doing so

might result in burns.

This electronic moisture balance is at high temperature during and immediately after making measurements,

When touching the unit, only use the specified control knobs and accessories.

Warning

Caution

Note

Warning

Fire Hazard Electric Shock Hazard

Caution

Burn Hazard Electric Shock Hazard

IV

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

V

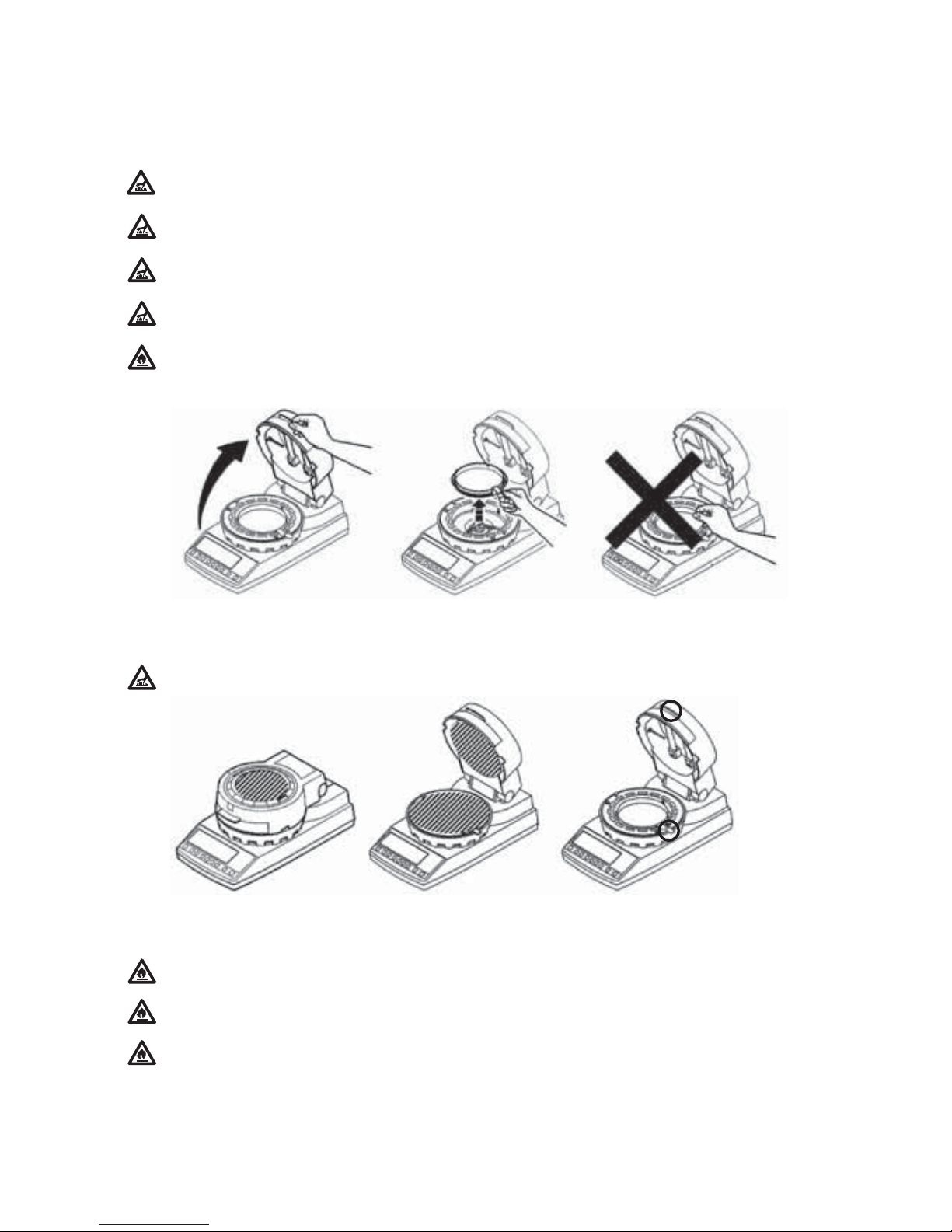

Follow operation instruction

Correctly set draft shield, sample pan supporter, sample pan handler and sample pan.

Hold the handle of heater lid when opening or closing heater lid.

Use sample pan handler when removing sample pan.

Never touch any metal parts of heater unit and surrounding parts when removing sample pan.

Cool the unit down to ambient temperature in a safe location after measurement.

Always make sure that the unit has cooled down sufficiently before covering it with a dust cover.

Warning on high temperature

The shadowed parts become especially hot during measurement. Only handle the parts marked with circles when

operating.

Do not measure hazardous samples

Use the Electronic Moisture Balance only for measuring the moisture content in a sample by moisture evaporation

through the heating process.

Set the drying temperature within the safe temperature range of each sample.

The heater inside the Electronic Moisture Balance reaches temperatures higher than the preset sample-heating

temperature.

The surface of the quartz tube of the heater reaches approximately 500°C (900°F) even during normal

measurements. In addition, the nickel-chromium resistance wire inside the heater reaches approximately 900°C

(1700°F) and is not airtight. Measurements of combustible or flammable samples pose a risk of fire.

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

VI

Do not measure any sample which might explode, ignite or produce toxic substances under high temperature.

Do not measure any sample which might cause chemical reaction under high temperature.

Do not measure any sample of unknown property.

Do not measure any sample whose surface hardens or solidifies by heating causing high inner pressure.

Immediately turn the power off if the sample should catch fire during measurement.

Use with adequate ventilation and appropriate venting for sample type.

Do not place flammable objects near the unit

The unit becomes very hot during and after measurements. Do not place any flammable objects near it as they may

catch fire.

Do not place near any objects which are not heat resistant. They may be damaged or deformed.

Never place anything on top of the heater unit.

Immediately turn the power off and disconnect power cable when any emergency occurs, such as abnormal smell,

smoke or fire.

Key and Power Switch Operation

Do not turn the power on while pressing any keys.

Do not operate any keys except as instructed in this manual.

Turn the power off and disconnect power cable when lightning is expected.

Emergency Stop

[Start/Stop] key is always effective during measurement. Press it immediately when any danger or abnormality occurs.

Installation, Transportation and Storage

Avoid locations subject to extremely high or low temperature, high humidity, direct sun light, electro-magnetic noise,

corrosive gas or dust.

Install on a vibration-free, level surface.

For transportation, hold the unit level as much as possible.

Do not drop or impact the unit.

Do not pull the cable - hold the connecter when disconnecting the power cable or RS-232C cable.

Turn the power switch off and disconnect from the power source when not using for a long time or lighting is expected.

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

VII

Others

After a power outage, turn the power back ON.

When a power outage occurs, the power is shut off automatically. Therefore, once turn off the power switch, then

begin operation from 7.1"Turn on the power switch" (☞page 12) again.

Do not connect anything other than peripheral devices specified by Shimadzu to the moisture balance's connector.

If you do, the balance may stop working normally.

In order to avoid trouble, always connect peripheral devices in accordance with the directions in this manual.

If you detect anything abnormal (e.g. a burning smell) disconnect the AC power cord immediately.

Continuing to use the balance with an abnormality could lead to fire or an electric shock.

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

Contents

1. Introduction............................................................................................... 1

2.

Description of Features and Principles of Operation .................................

2

2-1 Principles of Operation ............................................................................................. 2

2-2 Features ................................................................................................................... 2

2-3 Applications (i.e., materials which can be measured) ............................................. 2

3. Specifications ........................................................................................... 3

4. Names of Individual Parts and Components ......................................... 4

4-1 Names of Parts of Main Unit .................................................................................... 4

4-2 Parts and Accessories.............................................................................................. 5

5. Display and Control Panel ....................................................................... 6

5-1 Display ......................................................................................................................6

5-2 Control Panel Operations ......................................................................................... 7

6. Assembly and Installation of Main Unit.................................................. 8

7. How to Conduct Measurements .............................................................. 12

8. Specifying Measuring Conditions........................................................... 15

8-1 Selecting Temperature Display Mode ...................................................................... 15

8-2 Types of Settings ...................................................................................................... 16

8-3 Descriptions of Individual Measuring Condition Settings......................................... 16

8-3-1 Selecting the CONDITIONS (Measuring conditions storage area) ............. 17

8-3-2 Selecting the MODE (Measuring mode) ...................................................... 18

8-3-3 TEMP (Drying temperature) Setting ............................................................ 27

8-3-4 Bias Setting .................................................................................................. 28

9. Menu Settings ........................................................................................... 29

9-1 Types of Menu Settings............................................................................................ 29

9-2 Descriptions of Individual Menu Items ..................................................................... 29

9-2-1 Selecting a measurement base and switching the % display ..................... 30

9-2-2 Specifying the type and format of output ..................................................... 31

9-2-3 Specifying sample codes ............................................................................. 34

9-2-4 Setting the date and time ............................................................................. 35

9-2-5 CAL (Balance calibration) ............................................................................ 36

9-2-6 Specifying a device ID ................................................................................. 37

9-2-7 Specifying a password ................................................................................. 38

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

10. Error Messages......................................................................................... 39

11. Precaution on Conducting Measurements ............................................ 40

12. Predictive Measurements ........................................................................ 41

12-1 A Description of Predictive Measuring ..................................................................... 41

12-2 Procedure for Obtaining Predicted Measurements.................................................. 43

12-2-1 Calculating the bias to be specified when operating in predictive

measurement mode ..................................................................................... 43

12-2-2 Evaluating Predictive measurements .......................................................... 45

12-2-3 Performing Predictive measurements ......................................................... 46

13. Temperature Calibration (Option required) ............................................ 47

14. Printing Output to a Printer (Option) ...................................................... 49

14-1 Printer Output Sample .............................................................................................. 49

14-2 Outputting Stored Measurement Data ..................................................................... 52

15. Computer Interface................................................................................... 53

15-1 RS-232C Interface Specifications ............................................................................ 53

15-2 Setting Up and Transmitting Data ............................................................................ 54

15-2-1 Connecting the RS-232C cable ................................................................... 54

15-2-2 MOC-120H settings ..................................................................................... 54

15-2-3 Setting Up the Computer ............................................................................. 54

15-2-4 Starting Up the Computer ............................................................................ 56

15-3 Computer Output Format ......................................................................................... 57

16. Maintenance .............................................................................................. 59

16-1 Performing Maintenance .......................................................................................... 59

16-2 Replacing Fuses ...................................................................................................... 60

17. Parts List ................................................................................................... 61

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

1

1. Introduction

Thank you for choosing the Shimadzu Electronic Moisture Balance MOC-120H. MOC-120H has high

reliability by employing the UniBloc cell, introduced for use in electronic balances by Shimadzu in 1989.

It provides WindowsDirect functions for transfer of measurement results to personal computer without

installing software. This and other various functions can be used to meet the operator's objectives.

In order to make full use of the functions and performance provided in the MOC-120H, please read this

instruction manual before using the balance and keep the manual for future reference.

For information on the following points, please contact your Shimadzu Balance representative.

Product warranty

After service

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

2

2. Description of Features and Principles of Operation

2-1 Principles of Operation

This unit determines the moisture and solid contents of samples by heating them using infrared

illumination and measuring changes in mass due to evaporation. This is referred to as the drying

loss method and is the simplest method for determining moisture content and thus mandated by

many public regulations related to measurement standards.

2-2 Features

UniBloc sensor

The core mechanism of the internal precision balance is the UniBloc*1cell which provides excellent responsiveness,

temperature characteristics, and shock resistance. This UniBloc*1sensor ensures excellent reliability in moisture

content measurements over a long period of use.

New Auto Taring Function

The MOC-120H comes with an internal Auto Taring Function which makes it possible to perform reset correction while

performing measurements, thus eliminating drift of the balance even when performing measurements over a long time

and making it possible to obtain extremely reliable measurements.

Mid-infrared quartz heating lamp

The MOC-120H uses a mid-infrared quartz heating lamp (with a central wavelength of 2.6 +m). This heater provides

excellent drying efficiency over a wide range of different types of sample, minimizes the differences in heating due to

the different colors of samples, and eliminates the overheating of sample surfaces, thus making it possible to obtain

ideal drying conditions.

What‘s more, this heating lamp also provides a long service life 5 to 10 times greater (20,000 to 30,000 hours) than

older infrared or halogen lamps.

A wide selection of measuring modes

The MOC-120H provides a wide selection of measuring modes (automatic operation mode, timed operation mode, high-

speed drying mode, low-speed drying mode, stepped drying mode, and predictive measuring mode) which makes it

possible to perform measurements under the best drying condition for each sample.

The ability to store measuring conditions

The MOC-120H provides 10 measuring conditions storage areas which may be used to store sets of measuring

conditions to be used for different types of samples, thus reducing the work of programming settings before each

measurement.

Data memory

The MOC-120H is able to store up to 100 pieces of measurement data in memory, making it possible to output large

batches of data all at one time.

Printer port

The MOC-120H is equipped with a printer port which may be used to connect to the optional printer, thus making it

possible to print out text or graph data showing final measurements or intermediate drying states while performing

measurements.

The ability to display changes in moisture content (6M) in a numeric and bar graph display

The change 6M in moisture content over 30-second intervals is displayed in a numeric and bar graph display, thus

making it easier to estimate when a measurement should be completed. This feature is also useful in helping to

determine measurement completion conditions.

2-3 Applications (i.e., materials which can be measured)

Materials for which water is the only or main component which evaporates as a result of

heating

Materials for which no dangerous chemical reactions or other changes occur as a result of

heating

* Measurements can be performed with virtually any material meeting these conditions.

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

3

3. Specifications

Measurement format : Evaporation weight loss method (Heat drying and weight loss method)

Sample weight : 0.5g - 120g

Minimum display : Moisture content: 0.01%

Weight: 0.001 g

Measurable quantities : Moisture content (wet base & dry base), weight, solid content

Reproducibility (Standard deviation)*1

: Samples with a weight of 5 g or higher less than 10g: 0.05% *1

Samples with a weight of 10 g or higher: 0.02% *1

Measurement modes : Automatic operation mode

Timed operation mode (with measurement times of 1~240 minutes or

continuous measurement mode, with a maximum measurement time of

12 hours)

High-speed drying mode (may be used with either automatic or timed

operation mode)

Low-speed drying mode (may be used with either automatic or timed

operation mode)

Stepped drying mode (performs drying in 5 steps)

Predictive measuring mode

Heater temperature range : May be set within a range of 30 to 200°C in 1°C increments (sample

position temperature)

Display : Backlit LCD display (137 x 43 mm)

External output : RS-232C interface

Communications : Allows for data output using WindowsDirect function

Storage of measurement conditions

: Allows for storage of 10 sets of measurement conditions

Data memory : Allows for storage of 100 pieces of data

Temperature/humidity operating range

: 5~40°C, maximum of 85% RH

Heat source : Medium frequency infrared quartz heater (maximum 625W)

Power supply : AC 100~120/220~240V (50/60 Hz)

Power consumption : Maximum of 640W

Weight and external dimensions

: 4.5 kg, 220 x 415 x 190 mm (W x D x H)

Sample pan : SUS sample pan (Diameter: 130 mm; Depth 13 mm)

Items included : 2 sample pans, 2 sample pan handler, wind shield, sample pan

supporter, spoon, spatula, 2 spare 8A-fuses, 20 aluminum foil sheets,

power cord, three-prong plug adapter, Instruction manual

Optional equipment : Printer set (includes DPU-414 printer, printer interface cable printer

paper 1roll, and AC adapter), printer paper (10 rolls), package of

aluminum foil sheets (500 sheets), RS-232C cable, Temperature

calibration kit

*1When using Shimadzu standard samples and measuring conditions. It is not applied to and not

garanteed with all samples or conditions.

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

4

4. Names of Individual Parts and Components

4-1 Names of Parts of Main Unit

Heater lid

Handle (Observation window)

Temperature sensor

Display

Level

Heater

Wind shield

Sample pan

Sample pan handler

Control panel

Power conversion switch Power switch

Power inlet

Fuse holder

RS-232C port

Height adjustment legs

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

5

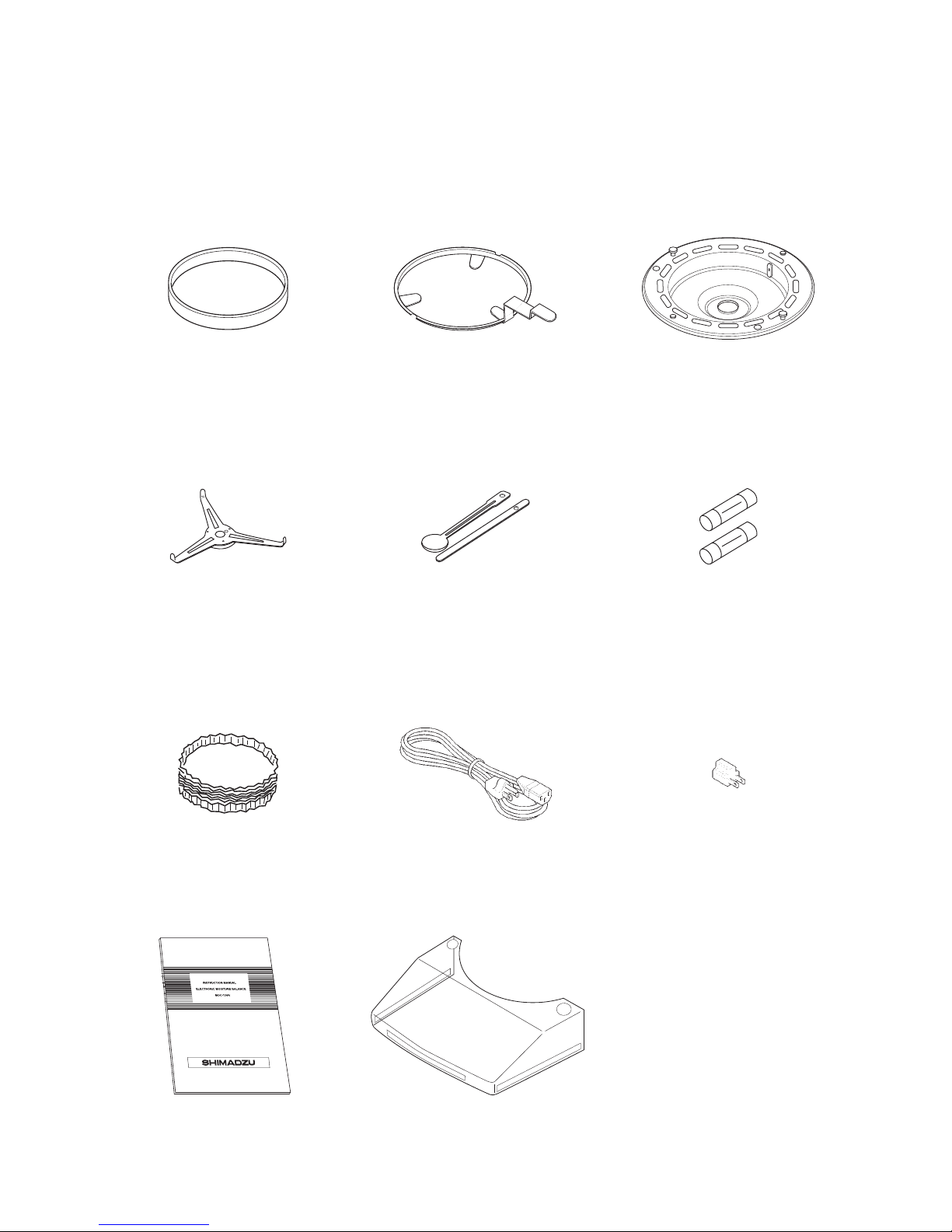

4-2 Parts and Accessories

Sample pan (2) Sample pan handler (2) Wind shield

Sample pan supporter Spoon and spatula (1 each) Spare 8A-fuses (2)

Aluminum foil sheets (20) Power cord Three-prong plug adapter

Instruction manual Protection Cover

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

6

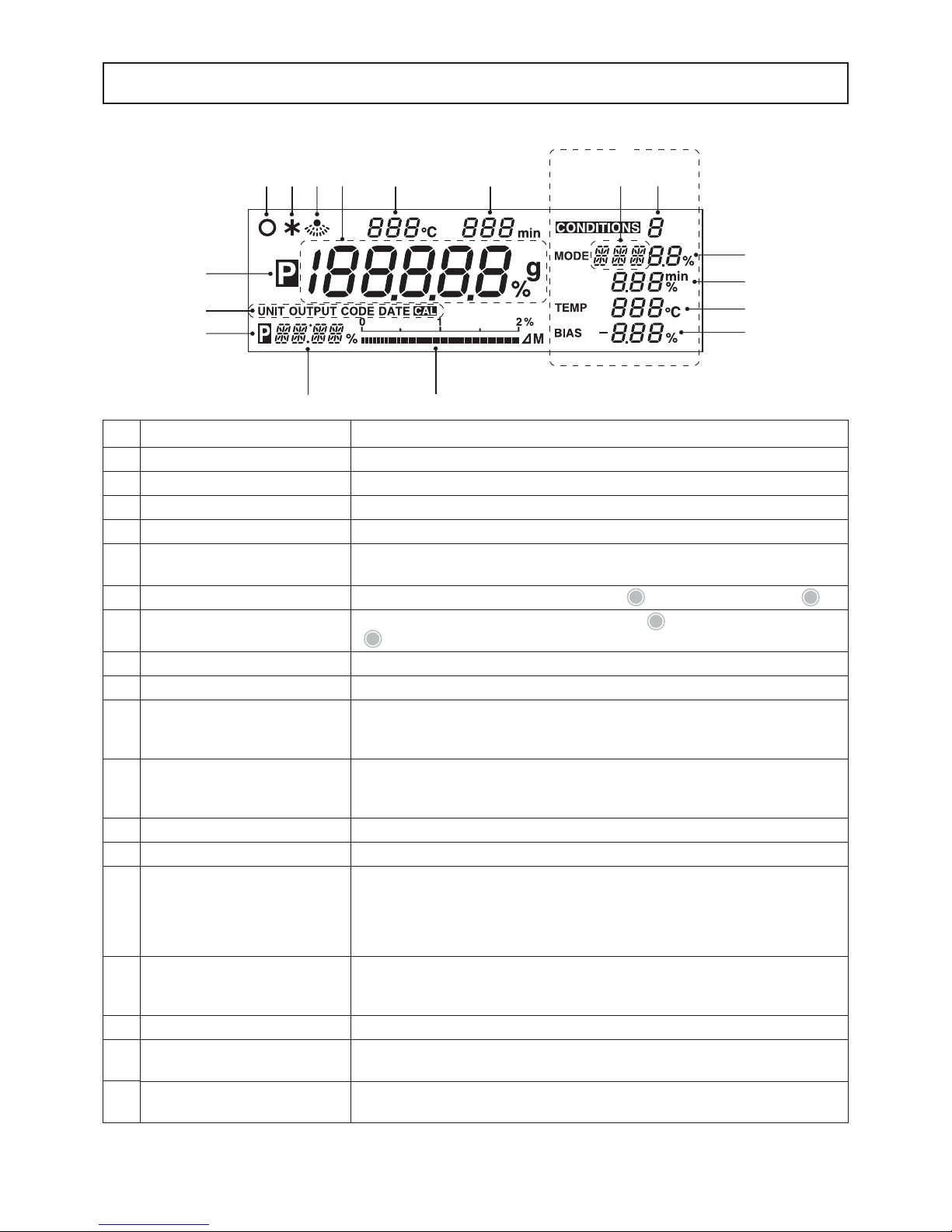

5. Display and Control Panel

5-1 Display

12 3D E F 9 8

GH

4

6

5

0

A

B

C

Display as it appears with the power on.

(All display items shown.)

7

Item

1

2

3

4

5

6

7

8

9

0

A

B

C

D

E

F

G

H

Name

Stability indicator

Measuring completion indicator

Heater indicator

Predictive measurement indicator

Preparatory measurement indicator

Menu display (during menu selection)

Measuring conditions display (during

condition setting)

Measuring conditions storage display*

Measuring mode display*

Predictive measurement convergence

conditions display*

End conditions display*

Drying temperature display*

Bias display*

Moisture/Solid/Weight display

Temperature display

Measuring time display

Change in moisture (solid) content

display

Change in moisture (solid) content

scale display

Description

This indicator lights up when the balance is stable.

This indicator lights up when measuring has been completed.

This indicator flashes whenever the heater is on.

This indicator lights up when performing predictive measurements.

This indicator lights up when measuring has been completed after performing a preparatory

measurement.

Displays individual menu items in sequence each time the

SELECT

key is pressed after pressing the

MENU

key.

Flashes to display individual items in sequence each time the

SELECT

key is pressed after pressing the

CONDITION

key. Values may be specified for a given item when it is flashing.

Displays the reference number of the currently selected measuring conditions program.

Displays the currently selected measuring mode.

Displays the conditions for convergence of measured values when operating in predictive or

comparative mode. When operating in high-speed drying mode, used to display the conditions required

in order to maintain a temperature of 180°C.

Displays the currently selected end conditions. When the value is displayed as a percentage, it indicates

that measuring will end automatically, and when value is displayed in minutes, it indicates that

measuring will end when the specified amount of time is reached.

Displays the currently selected drying temperature.

Displays the moisture (or solid) bias.

When measuring weight (i.e., when in idling mode), used to display the weight in grams. When

performing measurements, used to display the moisture content and solids content as percentages.

When measuring weight, this display is also used to display ‘oL’ (overload) when the weight exceeds

the maximum measurable weight and to display ‘–oL’ (negative overload) when the weight does not

reach the minimum measurable weight.

When 'TT' mode is selected, displays the temperature near the heater with °C symbol illuminated. When

'ST' mode is selected, displays the sample position temperature with °C symbol blinking.

*Refer to 8.1 for the details of 'ST' and 'TT' modes.

Displays the amount of elapsed time during measuring.

Displays the change 6M in moisture (or solid) content at 30-second intervals during measurement.

Displays the change 6M in moisture (or solid) content in scalar format. The scale may display a

maximum change of 2 percent/30 seconds.

* Items marked with an asterisk display as flashing items during condition setting.

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

7

5-2 Control Panel Operations

The control panel keys are used to perform the following operations.

Name

START/STOP key

TARE/RESET key

ENTER key

SELECT key

UP key / DOWN key

CONDITION key

MENU key

Operation

Used to start measuring or to abort a measuring operation.

Also used to turn off the alarm which sounds to indicate that a measuring operation has been

completed.

Used to deduct the tare weight.

Also used to perform a reset after an error has occurred.

Also used to return to display of weight after completion of measurement.

Used to confirm currently selected settings during menu selection.

When further settings must be specified, pressing the ENTER key causes the next specifiable

item choice to be displayed.

Used to display the selectable items or for setting values during menu selection or condition setting.

Used for numerical settings.

Pressing the key causes the value to increase, and pressing the key causes the value to

decrease.

Used to enter and exit the measuring condition setting mode.

Used to enter and exit the menu selection mode.

MENU CONDITION SELECT ENTER TARE/RESET START / STOP

TARE/RESE

T

START / STOP

ENTER

SELECT

CONDITION

MENU

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

8

6. Assembly and Installation of Main Unit

1Opening the package

Open the package and check to make sure all listed

items are included.

2Installing the main unit

Place the main unit on a flat, stable surface where it

will not be subject to vibrations or exposed to drafts

or breezes.

3Removing the protective sheet

When using the unit for the first time after purchase,

remove the protective sheet attached to pan

supporter column.

Not level Level

Bubble

Height

adjustment

legs

▲Level is located to the left of the control panel.

4Ensuring that the unit is level

Turn the two height adjustment legs located at both

sides of the lower rear of the unit to adjust until the

level bubble falls within the red circle.

* The level is located to the left of the control panel. The

instrument is level if the bubble appears in the center

of the red circle when viewed from directly above.

Protective sheet

Pan supporter column

SALES & TECHNICAL SUPPORT

QAQC LAB www.qclabequipment.com TEL (804) 318-3686

Other manuals for MOC-120H

1

Table of contents

Other Shimadzu Measuring Instrument manuals

Shimadzu

Shimadzu MOC63 User manual

Shimadzu

Shimadzu MOC63u User manual

Shimadzu

Shimadzu PDA-7000 User manual

Shimadzu

Shimadzu MOC63u User manual

Shimadzu

Shimadzu IRAffinity-1 User manual

Shimadzu

Shimadzu GCMS-QP2010 Series User manual

Shimadzu

Shimadzu UV-1700 series User manual

Shimadzu

Shimadzu AGS-X Series User manual

Shimadzu

Shimadzu UV-1800 User manual

Shimadzu

Shimadzu TOC-V CPH User manual