Shimadzu AA-7000 Series User manual

C122-E058G

Atomic Absorption Spectrophotometers

AA-7000 Series

Atomic Absorption Spectrophotometers

AA-7000 Series

Reaching Even Greater Heights

Enhanced Flame Analysis

World-Class High-Sensitivity Furnace

Improved Dual Atomizer System

Advanced Safety Technology

4

The AA-7000 Series can be upgraded by adding units to allow the system to handle the analysis targets.

The AA

-

7000 Series can be upgraded by adding units to allow the system to handle the analysis targets.

System Configuration can Evolve

with Your Needs

AA-7000 Series supports a wide range of

analysis applications.

Major Fields of Application Analysis Sensitivities

Concentration limit of detection

(ppm) (ppb)

H

Li NeFONCB

ArClSPAl

Ca Sc Ti Cr Mn Fe Co Ni Cu Zn KrBrSeGa

YZrNbMo

Tc Ru Rh Pd Cd XeTe IIn

Cs Ba La

Fr Ra Ac

Hf Ta W Re Os Ir AuPt Hg RnAtPoBiPbTl

Ce Pr Nd Pm Sm Eu Gd Tb LuYbTmErHoDy

Th Pa U Np Pu Am Cm Bk LrNoMdFmEsCf

He

Ag

a

Sn Sb

Si

V

Be

Na

Rb Sr

Mg

KGe As

* May differ according to coexisting substances in the sample.

AA-7000G GFA-7000A AA-7000G GFA-7000A Auto Sampler System

ASC

*2

Environment

Metals, Semiconductors, Ceramics

Petroleum, Chemicals, Polymers

Seawater, river water, effluent,

sludge, air-borne dust

Metals, minerals, glass,

ceramics, IC chips

Petroleum, oil, catalysts,

chemical products, biodiesel

Blood, animals, plants,

drugs, food products

Medical, Biology, Pharmaceuticals

Flame Furnace

AA-7000F Manual Burner System

AA-7000F

AA-7000F/AAC

AA-7000F/AAC Auto Burner System

GFA

ASC

*1

ASC

*1

*2

*3

AAC

AAC

5

Flame and Measurement Procedures

Flame Selection

Air-C2H2N2O-C2H2

HVG MVU

H

Be NeFONCB

Na Mg ArClSPAl

KCa Ti CrMnFeCoNiCuZn KrBrGa

Rb Sr Y Zr Nb Mo Tc Ru Rh Pd Cd XeITeIn

Cs Ba La

Fr Ra Ac

Hf Ta W Re Os Ir Pt Au RnAtPoBiPbTl

Ce Pr Nd Pm Sm Eu Gd Tb LuYbTmErHoDy

Th Pa U Np Pu Am Cm Bk LrNoMdFmEsCf

He

Ag

u

Ge

Si

V

Li

SeAs

Sb

Hg

Sc

Sn

H

HVG

AUTO

Graphite Furnace

Atomizer

GFA

AA-7000F/AAC Dual Atomizer System

Auto Atomizer

Changer

ASC

Autosampler

Dual Atomizer System

Automatic adjustment of atomizer

Automatic serach of burner height

AUTO

AAC

*1 Requires ASC stand kit.

*2 Requires ASK-7000.

*3 Automatic burner height search function can be used.

AA-7000F/AAC equips with AAC as standard.

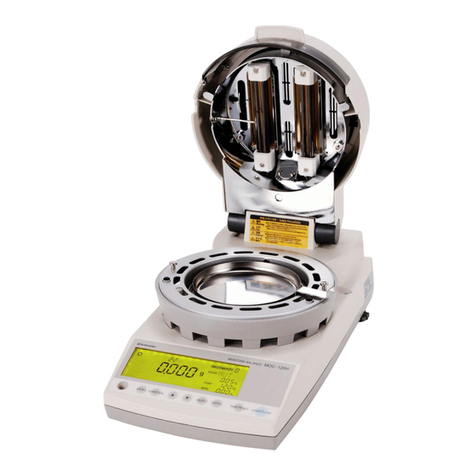

AA-7000F Flame Model

AA-7000G Furnace Model (with options attached)

Detector

Hollow cathode lamp

Beam splitter

Monochromator

D2 lamp

Chopper mirror

Burner head (or graphite tube)

Reference beam

Sample beam

6

Enhanced Flame Analysis

The AA-7000 Series incorporates newly developed 3D double-beam optics.

The optical system has been designed to produce its maximum performance for each measurement method through

optimal adjustment of the light beam and light beam digital filter, and by using optical components that restrict light

losses.

Double-Beam Optics and Stable Hardware Achieve Superior Stability

7

Advantages of the Double-Beam System

Support for Developing Analytical Conditions

Optional Autosampler Reduces Analysis Workload

Long-term stability

The graph shows the results of

measurements on 2 ppm copper (Cu)

conducted over at least one hour.

(The plot shows mean values for 11

repeated measurements.) Over the

course of more than 600

measurements, the instrument

achieved a relative standard

deviation within 1%.

High sensitivity

The graph shows the direct

measurement results for 0.1

ppm lead (Pb).

Automatic gas flow rate optimization

Automatic searching for optimal fuel gas flow rate (Japanese Patent 2099886). It is important

to determine the optimal gas flow rate for the flame when using an organic solvent or after

changing the burner height. The AA-7000F Series automatically optimizes the gas flow rate

by measuring the changes in absorbance between a blank and a standard sample. The

difference between the two is displayed on the screen. The gas flow rate achieving the

highest sensitivity is detected and this value is automatically set as the gas flow rate value.

Automatic burner height optimization (AA-7000F/AAC)

The absorption sensitivity for flame analysis is also affected by the burner height. This results

from variations in the flame temperature due to the burner height. The flame temperature is

also affected by the matrix components. AA-7000F/AAC adjusts the burner height in 0.5 mm

steps to automatically search for the optimal conditions.

AA-7000F enables above function by AAC-7000 (option).

Low carryover

Great care must be taken to avoid carryover during flame analysis. The new ASC-7000

autosampler rinses the nozzle at the rinsing port on the overflow mechanism after each

sample measurement is complete. This ensures 10

-4

max. carryover during the

measurements of multiple samples. The graph shows the results of consecutive analyses

of 10 ppm, 20 ppm, and 50 ppm sodium (Na) standard solutions in the EMISSION mode.

No carryover could be detected when measuring the 10 ppm standard sample

immediately after the measuring the 50 ppm Na standard sample.

Example of micro sampling analysis

Examples of the measured waveforms (overlaid) and calibration curve for micro

sampling analysis are shown to the right.

A 2-ppm Cu standard solution was prepared by auto-dilution using the autosampler.

The autosampler can also be used to conduct dilution measurements of the sample.

(Injection volume: 90 µL)

Trace Sample Analysis Using Micro Sampling

Micro sampling

At least 1 mL (1000 µL) volume of a liquid sample is required for the continuous intake of

sample during normal flame analysis. With micro sampling, however, approximately 50 to 90

µL of sample is injected in one shot into the flame and quantitation is based on the height

and area of the peak signal obtained. This method offers the advantages below.

Advantages

.

Permits analysis of small sample volumes

.

Multi-element analysis of small sample volumes

.

No blockage of burner slot with samples having a high salt concentration

.

Synchronized with the autosampler for auto-dilution measurements

*Synchronization with the autosampler requires the optional micro sampling kit.

Data Showing Long-Term Stability for

Flame Cu Measurements

0.1 ppm to 0.4 ppm Calibration Curve for Lead (Pb)

A

b

s

Conc(ppm)

Conventional method Overflow method

Discharge

Data showing low carryover

1. Sample injected into

micro sampling port.

2. Solenoid valve opens to inject sample

in one shot into the flame.

Sampling port

Solenoid

valve

(opened)

Solenoid

valve

(closed)

Sampling port

Absorbance

Measurement time

Pb 0.08ppb

Mn 0.02ppb

0.05ppb

0.01ppb

Enhanced Sensitivity due to Graphite Furnace

Advances in optics and a new graphite furnace design achieve improved

lower limits of detection for furnace analysis (comparison with previous

Shimadzu models).

This superb analysis performance is possible in all fields.

Achieves World-Class Lower Limits of Detection

Previous New

8

World-Class High-Sensitivity Furnace

High-Performance Autosampler

High-Sensitivity Application Data (Analysis of Selenium (Se))

Mix and inject up to four sample types (diluted solution, standard solution,

sample, matrix modifier, etc.). (Of course, unmixed samples can also be injected.)

Select a fluororesin tube or pipette tip as the injection nozzle.

Automatic dilution and re-analysis if the calibration curve concentration is exceeded.

Independent control of the gas flow through the graphite tube during

atomization achieves extremely high-sensitivity measurements.

(Japanese Patent 2067563)

Digital temperature control and electronic gas flow control enhance stability

Combination of a high-sensitivity optical sensor and unique digital temperature control

technology achieves highly accurate temperature control in all temperature regions from

drying to atomization. An electronic flow controller can precisely control the inner gas

flow rate in 0.01 L/min units. These control techniques significantly enhance both the

sensitivity and the data stability.

Example of Automatic Dilution and Re-Analysis

Analysis of cadmium (Cd): The maximum concentration of the calibration curve has been set to 1ppb. At 1.8ppb, the sample of [003] has exceeded the

maximum concentration. As a resultit has been automatically diluted by 4 times and re-measured.

* Depending on the state of the sample, some other combinations may be appropriate.

High-density graphite tube

(P/N 206-50587)

Pyro-coated graphite tube

(P/N 206-50588)

Platform tube

(P/N 206-50887-02)

Selecting the Graphite Tube

Effective for elements that readily form

carbides (Ni, Fe, Cu, Ca, Ti, Si, V, Mo, etc.).

Restricts chemical interference due to

coexisting substances. Effective for the

analysis of environmental samples and

biosamples, such as sea water and

industrial waste.

Can be used for all elements. Especially

effective for low-boiling point elements

(Cd, Pb, Na, K, Zn, Mg, etc.).

Measurement Example Showing High Sensitivity

Analysis of 0 to 5 ppb selenium (Se): Sensitivity is adequate for 1 ppb measurements.

(20 µL injected volume, Pd modifier, pyro-coated graphite tube)

Measurement Example Showing High Stability

Analysis of 0.5 ppb lead (Pb): Approx. 5% relative standard deviation after 5 repeated

measurements is adequate for quantitative analysis.

9

AA-7000F/AAC creates an integral burner and furnace that remains permanently installed in the combustion chamber.

It supports both flame analysis of high concentration samples and furnace analysis of trace samples, without changing

the atomizer unit. The integral construction with the atomizer saves space.

AA-7000F enables above function by AAC-7000 (option).

* The AAC-7000 cannot be attached to an AA-7000G instrument.

Single Unit Handles High Concentration to Trace Analysis Samples

10

Improved Dual Atomizer System

The new drive mechanism halves the switching time between flame and furnace measurements

(comparison with previous Shimadzu models).

Smallest footprint for a full system Easily attach an autosampler

Direct connection of the autosampler

to the AA instrument minimizes the

installation footprint and simplifies

maintenance.

Lamp house

Just slide the cover to the side for

easy replacement of the hollow

cathode lamps through the large

opening.

New Atomizer Design Permits Easy Switching Between Flame and Furnace Measurements

Slim, Easy-to-Use Design

The atomizer unit is switched automatically by software

operation. No troublesome replacement of the atomizer

unit is required. No need to disconnect pipes or wires.

In case of the flame measurement of high-concentration

sample, offsetting the burner head from the light axis,

instead of angle adjustment, allows to adjust the

sensitivity.

Flame measurement: Burner head

intersects the light axis (red line).

Furnace measurement: Furnace

intersects the light axis (red line).

Flame measurement Furnace measurement

A single autosampler can be used for both flame and

furnace measurements. Simply slide it left or right. No

need to purchase two autosamplers.

* Dimensions do not include ASC-7000. Height (H) does not include protrusions.

AA-7000F/AAC Dual Atomizer System

AA-6300

11

The system with a dual atomizer fits into a 960 mm width

(including power supply for the graphite furnace atomizer),

achieving the world's smallest installation footprint* for a full

system.

* Shimadzu in-house investigation. Current as of November 2008.

Safety is an extremely important consideration for flame atomic absorption spectrophotometers using acetylene gas.

The AA-7000 Series instruments are the first* ones in the world fitted with a vibration sensor as standard. They also

incorporate a comprehensive range of safety mechanisms, including gas leak detectors.

* Shimadzu in-house investigation. Current as of November 2008.

Comprehensive Safety Functions in Every System

12

Advanced Safety Technology

World first! –– flame extinguished automatically by vibration sensor

The flame is automatically extinguished when the new built-in sensor detects vibrations.

Instruments are completely safe during severe shaking caused by earthquakes.

Multimode automatic gas leak check

The fuel gas pipes inside the instrument gas controller are automatically

checked for gas leaks when the power is turned on and when the flame is

extinguished. Should a gas leak be detected, a warning buzzer sounds and a

warning is displayed on the screen.

Flame-retardant materials

UL 94V-0-rated flame-retardant materials

are used for the instrument external

covers and atomizer unit. This superior

design pays due consideration to safety.

Safe ignition switches

The switches perfectly fit finger contours and are positioned

near the window.

To prevent inadvertent operation, both switches must be

pressed simultaneously to start ignition.

Durable pipes and reliable couplings

All pipes are selected for durability and

used with highly reliable couplings.

Clear window

The large window permits observation of the flame, and the

burner can be easily accessed through the large opening.

The window closes when released to eliminate the chance

of it being left open.

Automatic flame ignition and extinguishing

Flame ignition and extinguishing operations are extremely simple. The

Air-C

2

H

2

flame priority ignition mechanism prevents flashback.

Automatic Air-N

2

O switching system with acetylene flow-rate monitor

After the ignition of an Air-C

2

H

2

flame, the flame automatically switches to

an N

2

O-C

2

H

2

flame.

If the C

2

H

2

flow rate does not increase due to solenoid valve trouble, for

example, switching to the support gas is disabled to prevent flashback.

Pressure monitor prevents flashback Automatic gas shut-off by flame monitor

Sudden power interruption detection and re-ignition safety measures

Drain tank level monitor

Mechanism to prevent misuse of the burner

Safety Functions for Flame-Specification Instruments

Safety Functions for Furnace-Specification Instruments

The connected options and operation of safety mechanisms are

checked during instrument initialization.

Cooling water flow rate monitor Argon gas pressure monitor Furnace cooling check

Overcurrent protection unit (double-checked by circuit protector and optical sensor)

Safety-Conscious Design

13

The optimal background correction methods are installed as standard:

high-speed self-reversal method (SR method) and deuterium lamp method (D2method).

Dual-Background Correction Functions

SR (high-speed self-reversal) method –– accurate background correction over a wide range

Samples with a complex matrix

(Containing a large quantity of a specific element as the main component)

Purified water, tap water, environmental water, etc.

Samples with a relatively simple matrix

Samples suitable for the SR method Samples suitable for the D2method

These functions can correct for spectral interference in flame measurement.

Selecting the optimal background correction method for each sample ensures

accurate and reliable analysis results.

1. High-speed self-reversal (SR) correction is generally more accurate than deuterium lamp (D

2

) correction. As both atomic absorption and background

absorption can be measured using a single lamp, the correction errors due to light-axis misalignment are extremely small. This is ideal for the quantitation

of trace components in a matrix exhibiting complex background absorption, such as bio-samples and metals.

2. Permits background correction over the entire wavelength range from 185 nm to 900 nm.

3. This method can correct for spectral interference due to neighboring lines that can occur when a resonance line for another element exists near the

analytical line for the target element. (See table on next page.)

4. As no polarizer is used, measurements are possible with low light losses and a high S/N ratio.

5. The rapid lamp lighting permits accurate measurement unaffected by emission noise in the atomizer.

* Hollow cathode lamp L-2433 is required to use the SR method. Hollow cathode lamp L-2433 can also be used for the D

2

method.

Features

Principle

Background absorption

Background

Atomic absorption

Background

Atomic absorption

Time

Lamp current

IH spectrum

IH

IL IL spectrum

(Lamp energy) (Sample measurement) (Energy component ratio)

Atomic

absorption

WavelengthWavelength Atomic

absorption

Absorption

layer

A small current IL (approx. 10 mA) and a large current IH (approx. 500

mA) are alternately passed through the hollow cathode lamp. The

lamp emission spectrum when the large current flows has a depression

in the center (self-reverse), due to self-absorption of the large number

of sputtered atoms in the atom cloud, as shown in the diagram to the

left. No significant atomic absorption is apparent and background

absorption mainly occurs. Conversely, the lamp emission spectrum

when the small current flows comprises a single narrow peak resulting

from both atomic absorption and background absorption. By

determining the difference between the two types of absorption, it is

possible to accurately correct for the background absorption and

measure the true atomic absorption.

Examples suitable for SR method (where differences result between SR and D

2

methods)

Example: Measurement of trace levels of zinc in iron (analysis of Zn in Fe solution)

BGC-SR method BGC-D2method

The identical 0.5 ppm Zn solution is accurately corrected to

the same absorbance at (2) and (6).

Due to inadequate correction, the absorbance is higher at

(6) than at (2) for the identical 0.5 ppm Zn solution.

Zn 0.25ppm

Zn 0.50ppm

Fe 0.1%

Fe 0.5%

Fe 0.5% Zn 0.25ppm

Fe 0.5% Zn 0.5ppm

Fe 0.75% Zn 0.3ppm

Atomic absorption signal

Background signal

14

Atomic absorption signal

Background signal

D

2

(deuterium lamp) method –– highly sensitive background correction

1. Detection sensitivity is superior to the SR method. Therefore, this method is suitable for the analysis of samples with a simple matrix requiring high

sensitivity, such as the measurement of trace levels of impurities in ultrapure water or environmental analyses.

2. As the lighting frequency is higher than with the SR method, it can eliminate noise due to emission components of the flame or graphite tube to permit

accurate atomic absorption measurements.

3. The original hollow cathode lamp can be used.

Features

Principle

The deuterium lamp method involves lighting the hollow cathode lamp and the

deuterium lamp alternately at high speed. After separation by the monochromator,

the light from the deuterium lamp has a bandwidth from 0.1 to 5 nm. Therefore, an

atomic absorption with a line width of only about 1/1000 nm is almost unobservable

compared to the background absorption due to wide-bandwidth molecular

absorption. However, as the light from the hollow cathode lamp has approximately

the same bandwidth as the atomic absorption band, the total of the atomic

absorption and the background absorption can be observed. With the deuterium

lamp (D

2

) method, light from both sources passes through the atomizer. The

difference in absorbance is determined to conduct background correction.

The SR method is suitable for samples containing elements that cause

problems with spectral interference, as shown in the table to the left.

Measured Element

Al

Analytical Line (nm) Coexisting Element Absorption Line (nm)

309.28 Mg 309.30

As 193.76 Fe 193.73

Ca 422.67 Fe 422.64

Cd 228.80 Ni 228.84

Cu 324.75 Fe 324.73

Ga 294.36 Ni

285.18

Mg 285.21 Fe

Fe

Fe

Fe

Fe

Fe

294.39

Ni 232.00 232.04

Pb 217.00 216.95

Sb 217.58 217.55

Se 196.03 196.05

Si 251.61 251.69

FeZn 213.856 213.8589

Examples of elements and wavelengths causing spectral

interference problems due to neighboring lines

Atomic absorption + background absorptionHollow cathode lamp spectrum

Atomic absorption

D2lamp spectrum Background absorption

Examples suitable for D

2

method (where no difference results between SR and D

2

methods)

Example: Measurement of trace levels of lead in 2% NaCl solution by molecular absorption (analysis of Pb in 2% NaCl solution)

BGC-SR method BGC-D2method

It can be seen that the sensitivity is higher with the BGC-D

2

method.

Background signal

Atomic absorption signal

15

D

D

2

(deuterium

la

mp

)

method

––

hi

gh

ly

sensitive

bac

kg

round

correction

Features

Fe

Spike 0ppb 2ppb 4ppb

Spike 0ppb 2ppb 4ppb

Features of the WizAArd Software

The WizAArd software used with the AA-7000 runs under Windows 7/ Vista/XP.

Wizard Functions Make Setting the Conditions So Simple That Even a Novice Can Do It.

Measurement Screen Layout Shows Measurement Status at a Glance

Just set the measurement conditions using WizAArd to

complete the general settings.

The initial settings can also be completed simply

by following the Wizard procedures.

Lamp History Function Assists with Lamp Management

The accumulated operation time for each lamp displayed on the lamp

registration screen assists with lamp service life management. Multiple

lamps for the same element are differentiated using lamp IDs.

Select element.

Start Wizard.

Set calibration curve and sample parameters.

Set monochromator parameters.

Connect to instrument.

16

The

WizAArd

software

used

with

the

AA

-

7000

runs

under

Windows

7

/

Vista/XP

.

Wizard Functions Make Setting the Conditions So Simple That Even a Novice Can Do It.

Wizard Functions Make Setting the Conditions So Simple Tha

Measurement Screen Layout Shows Measurement Status at a Glance

M

easuremen

t

S

creen

L

a

y

ou

t

Sh

ows

M

easuremen

t

St

a

t

us a

t

Just

set

the

measurement

conditions

usi

ng

WizAArd

to

Jus

ts

et

the

me

asu

rem

ent

co

ndi

tio

ns

usi

ng

Wiz

AAr

dt

o

complete the

g

eneral settin

g

s.

T

he initial settin

g

s can also be completed simpl

y

by following the Wizard procedures.

L Hit F ti A it ithL M t

L

amp

Hi

s

t

or

y

F

unc

ti

on

A

ss

i

s

t

s w

ith

L

amp

M

ana

g

emen

t

T

he accumulated operation time for each lamp displa

y

ed on the lamp

r

e

g

istration screen assists with lamp service life mana

g

ement. Multiple

l

amps for the same element are differentiated usin

g

lamp IDs.

Select

ele

m

e

n

t

.

Sta

r

t

Wiz

a

r

d

.

S

et ca

l

i

b

ration curve an

d

samp

l

e parameters.

S

et monochromator

p

arameters.

Co

nn

ect

to

in

st

r

u

m

e

n

t

.

p

Features of the WizAArd Software

1

6

Clear, Easy-to-Use Software

Features

of

the

WizAArd

Software

The WizAArd software used with the AA 7000 runs under Windows 7

/

Vi

st

a/

XP

Signal profile display

Measured element

Real-time signal monitor

MRT (Measured Results Table)

The worksheet shows sample names,

absorbance, concentrations,

and correction calibration results.

Calibration curve display

Software Provides Comprehensive Information Displays and Flexible Settings

Identical software operation for flame and furnace measurements

Combining a high-performance autosampler simplifies advanced settings

Even if the calibration curve is created after sample measurements,

concentration calculations can be conducted on past data. This

allows trial measurements to be directly used as actual

measurements.

Extrapolation of calibration curve range. If the sample concentration

exceeds the calibration curve range, additional measurements can be

performed on standard solutions to re-calculate the concentration.

Use existing calibration curves for measurements. Useful for sample

concentration order checks and for checking the instrument

sensitivity.

One-touch re-measurement operation. No need to repeat the

measurement from the beginning.

Create and save multiple calibration curves on a single worksheet.

Select the appropriate calibration curve for the sample concentration

and composition.

Real-time drying and ashing progress display for furnace

measurement

A higher temperature cleaning operation than the cleaning stage

can be added for each measurement. This reduces the graphite tube

memory effect. Tube deterioration is reduced by minimizing the

cleaning operations.

Add optional autosampler rinsing operations to ensure adequate

rinsing of the autosampler after completing the measurement of

high-concentration samples.

Set up sample dilution and spike-and-recovery tests on the same

screen.

Overlay function allows size and shape comparison of peak profiles.

Large-volume injection permits high-sensitivity measurements.

Precision control of drying and ashing temperatures reduces analysis

time.

17

Identical software operation for flame and furnace measurements

Identical software operation for flame and furnace measurem

Combining a high-performance autosampler simplifies advanced settings

Combining a high-performance autosampler simplifies advan

E

ven

if

t

h

e ca

lib

rat

i

on curve

i

s create

d

a

f

ter samp

l

e measurements,

if h lib i i df l

concentration calculations can be conducted on past data. This

a

llows trial measurements to be directl

y

used as actual

m

easurements.

E

xtrapolation o

f

calibration curve ran

g

e. I

f

the sample concentration

exceeds the calibration curve ran

g

e, additional measurements can be

p

er

f

ormed on standard solutions to re-calculate the concentration.

U

se existing calibration curves

f

or measurements. Use

f

ul

f

or sample

concentration order checks and

f

or checking the instrument

s

ensitivity.

One-touch re-measurement operation. No need to repeat the

m

easurement

f

rom the be

g

innin

g

.

Create and save multiple calibration curves on a single worksheet.

Select the a

pp

ro

p

riate calibration curve for the sam

p

le concentration

and com

p

osition.

Real-time dr

y

in

g

and ashin

g

pro

g

ress displa

y

f

or

f

urnace

m

easuremen

t

A

h

i

gh

er temperature c

l

eanin

g

operation t

h

an t

h

e c

l

eanin

g

sta

g

e

can be added

f

or each measurement. This reduces the

g

raphite tube

m

emor

y

e

ff

ect. Tube deterioration is reduced b

y

minimizin

g

the

c

l

eanin

g

operations.

Add optional autosampler rinsin

g

operations to ensure adequate

r

insin

g

of the autosampler after completin

g

the measurement of

h

i

g

h-concentration samples.

Set up samp

l

e

d

i

l

ution an

d

spi

k

e-an

d

-recovery tests on t

h

e same

s

creen.

Overla

y

f

unction allows size and shape comparison o

f

peak pro

f

iles.

Large-volume injection permits high-sensitivity measurements.

Precision control of drying and ashing temperatures reduces analysis

ti

m

e

.

Software Provides Comprehensive Information Displays and Flexible Settings

17

171717

17

17

17

1

Sof

ftware

Provides

Comprehensive

Information

Displays

and

Flexible

Settings

Sof

g

p

FDA 21 CFR Part 11 Compliance

FDA 21 CFR Part 11 Compliance

Supports System Management andAccuracy

FDA

21

CFR

Part

11

Compliance

A combination of enhanced WizAArd software with Shimadzu's network-compatible CLASS-Agent data

management software supports FDA 21 CFR Part 11 Compliance.

WizAArd used alone provides comprehensive system policy setting, user management, log browser, audit trail,

and electronic signature system management functions.

Hardware validation software installed as standard.

Comprehensive Data Management Functions

User Management

User management restricts the users of

the system. It registers each user to

determine how each one uses the

software.

System Policy

The system policy settings allow advanced

password and lockout settings. The levels

can be set in stages from "unrestricted"

to "Part 11 compatible".

CLASS-Agent (Option)

Connection to CLASS-Agent permits

efficient, long-term database

management of large amounts of analysis

data.

Log Browser

The log browser easily displays a variety of logs to check the

system modification history and other log information.

18

Log

Log

Br

Br

ows

ows

er

er

Use

Use

rM

r

M

ana

ana

gem

gem

ent

ent

t

o

"P

art

11

com

p

at

ibl

e

"

.

d

at

a

C

o

mp

p

p

p

re

h

ens

i

ve

D

a

t

a

M

ana

g

g

g

emen

t

F

unc

ti

on

s

Management

Accuracy Management (QA/QC) Functions Permit User Level Management, Audit Trail, and Electronic Signatures

QA/QC compatibility

The QA/QC functions permit accuracy

management.

Hardware validation software installed as standard

The hardware validation software makes it simple to evaluate the instrument

performance. When combined with the autosampler, it automatically determines

the wavelength accuracy, noise level, baseline drift, absorbance and repeatability,

and prints out the results of comparison with the pass criteria.

* Data from all Shimadzu analytical instruments can be centrally managed by CLASS-Agent.

s

st

an

d

da

d

rd

19

A

ccurac

y

y

y

y

y

M

ana

g

g

g

g

g

emen

t

(Q

(

A/

QC

)

F

unc

ti

ons

P

erm

it

U

ser

L

eve

l

M

anagemen

t,

Standard Parts / PC / Software

20

* The PC, monitor, printer, hollow cathode lamps, high-temperature burner head, pressure regulator and compressor are not included in the standard configuration.

Part Name Quantity P/N

071-60821-08 (120 V), 071-60825-51 (230 V)1

206-52046-911

1 206-97176

Common to All AA-7000 Series Models

1 206-97225

1 228-30164

1 037-70238-01

1 221-40500

3 206-57770

206-777041

206-77551-121

206-84934-671

AA-7000G Standard Parts List

Part Name Quantity

1

1

2

1

2

1

1 (0.3 m)

1 (2.4 m)

1

1

1

206-50389-91

206-50389-92

037-61019

201-79229-01

204-05899-01

206-50772-91

200-31328-01

016-43201-02

206-77413-41

206-50442-91

206-77243-92

AA-7000F, AA-7000F/AAC Standard Parts List

1 206-84934-66/-68

1 206-77551-02/-22

* Windows is a registered trademark of Microsoft Corp., U.S.A.

Operating system

CPU

RAM

Monitor

Storage device

I/O port

Microsoft Windows 7 Professional (32 bit) Vista Business or XP Professional

Intel®Celeron 420 (1.60 GHz) or higher

1 GB or higher (Vista) or 512 MB or higher (XP)

XGA (1024 × 768 dots) or higher

One CD-ROM drive (for installing software) Requires 60 MB min. hard disk space for installation

One serial port (for AA control)

Personal Computer / Monitor

Cable set

Cards (set of 10)

Instruction manual

Safety inspection sheet (safety instruction)

Declaration of conformity, explanatory notes (ISO-9001)

Warranty label

Registration form

Serial number label

Hose ASSY (for air supply)

Hose ASSY (for C2H2gas supply)

Hose clamp (16 mm)

Cleaning wire

Sampling tube (PTFE)

Sampling tube (for organic solvent samples)

Polyethylene tubing, No. 3

Polyethylene tubing, 8 × 1 (drain tubing)

Drain ASSY

Grease (in cup)

Funnel

Declaration of conformity, English version (ISO-9001)

Inspection report

P/N

Part Name Quantity P/N

Declaration of conformity, English version (ISO-9001)

Furnace mounting plate

Inspection report

* GFA-7000A is not included in the standard configuration.

Table of contents

Other Shimadzu Measuring Instrument manuals

Shimadzu

Shimadzu UV-2401 PC User manual

Shimadzu

Shimadzu PDA-7000 User manual

Shimadzu

Shimadzu UV-1800 User manual

Shimadzu

Shimadzu MOC63 User manual

Shimadzu

Shimadzu GCMS-QP2010 Series User manual

Shimadzu

Shimadzu AGS-X Series User manual

Shimadzu

Shimadzu MOC63u User manual

Shimadzu

Shimadzu UV-1700 series User manual

Shimadzu

Shimadzu IRAffinity-1 User manual

Shimadzu

Shimadzu MOC63u User manual