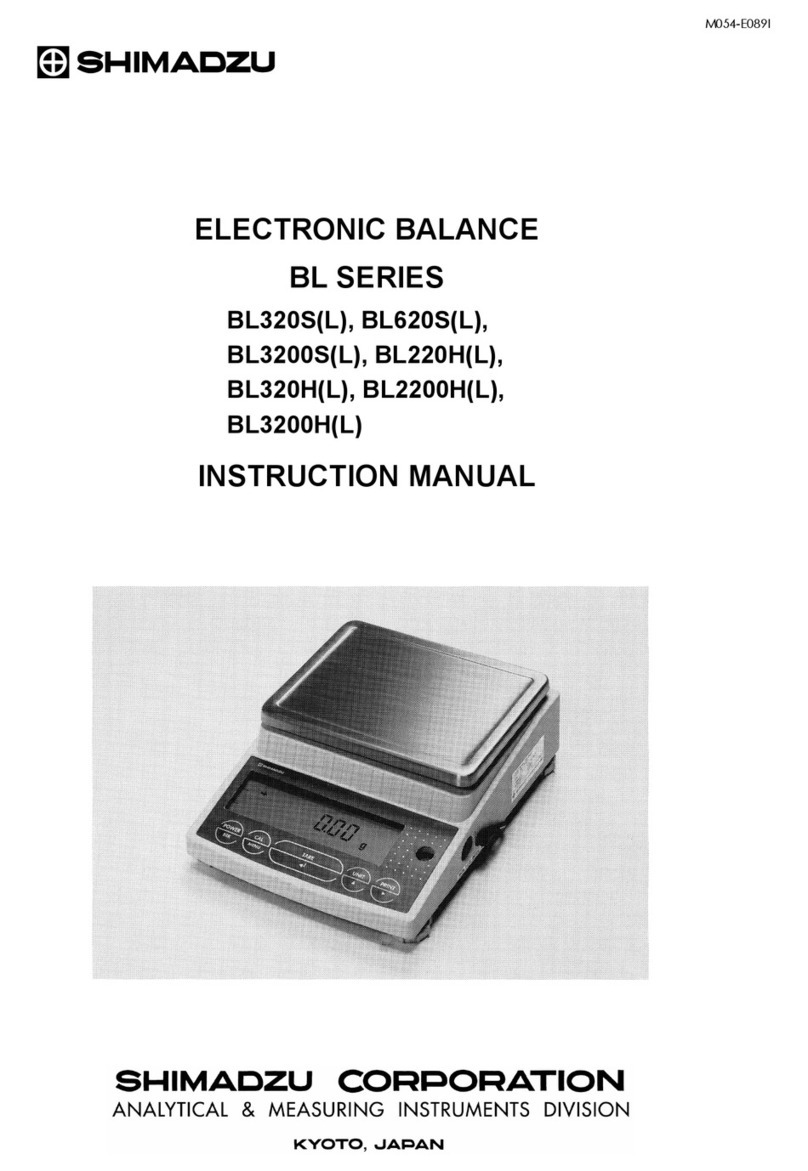

Shimadzu ATX224 User manual

Document No. 321-78009A

ElectronicAnalytical Balance

ATX /ATY Series

Service Manual

1

Table of Contents

1. OperationsforAdjustment.............................................................................................................................................1

1.1. Entering the Service Mode.....................................................................................................................................1

1.2. Contents of Service Menu......................................................................................................................................2

1.3. Service ModeFunctions........................................................................................................................................3

2.

DisassemblingandAssembling the Balance.............................................................................................................5

2.1. Precautions...............................................................................................................................................................5

2.2. Inspecting the Balance Interior (Removing the Caseand PanSupporter)...................................................6

2.3. Replacing Components..........................................................................................................................................8

2.3.1. ReplacingtheFrontGlassASSY(C8).................................................................................................................................8

2.3.2. ReplacingtheSideGlassASSY(C6,C7)...........................................................................................................................9

2.3.3. ReplacingtheRoofGlassASSY(C5).................................................................................................................................9

2.3.4. ReplacingtheDisplayBoardASSY(B2).............................................................................................................................9

2.3.5. ReplacingthePowerBoardASSY(B4)........................................................................................................................... 10

2.3.6. ReplacingtheAnalogBoardASSY(B3)........................................................................................................................... 10

2.3.7. ReplacingtheWeightLoaderASSY(27)..........................................................................................................................11

2.3.8. ReplacingtheUnitASSY(1)............................................................................................................................................. 12

2.3.9. ReplacingtheDetectorASSY(U11).................................................................................................................................13

2.3.10. ReplacingtheForceCoilASSY(L1).................................................................................................................................13

2.3.11. ReplacingtheStopperPlate(U14)................................................................................................................................... 16

2.3.12. ReplacingtheStopperLever(U15)................................................................................................................................... 16

3.

Checking the Electronic Board................................................................................................................................... 17

3.1. DisplayBoardASSY (B2).................................................................................................................................... 17

3.2. Analog Board ASSY (B3)..................................................................................................................................... 17

3.3. Preamp BoardASSY (B1)................................................................................................................................... 18

3.4. PowerBoardASSY (B4)...................................................................................................................................... 18

4.

HardwareAdjustment................................................................................................................................................... 19

4.1. Adjusting the DetectorASSY(U11)Height...................................................................................................... 19

4.2. Adjusting the Tilt Error........................................................................................................................................ 20

4.3. Adjusting the Balance......................................................................................................................................... 21

4.4. Adjusting the Cornerload Error ......................................................................................................................... 22

5.

SoftwareAdjustment.................................................................................................................................................... 23

5.1. EEPROM Initialization.......................................................................................................................................... 23

5.2. Model Selection.................................................................................................................................................... 23

5.3. Releasing and Setting the Setting Information Lock..................................................................................... 25

5.3.1. ReleasingtheSettingInformationLock............................................................................................................................ 25

5.3.2. SettingtheSettingInformationLock.................................................................................................................................25

5.4. Inputting Weight Valuesfor LinearityAdjustment.......................................................................................... 25

ii

5.5. LinearityAdjustment............................................................................................................................................ 26

5.6. Internal Weight Calibration (PCAL)(ATX Only)............................................................................................... 27

5.6.1. OperationProcedureandProcess................................................................................................................................... 27

5.7. Sensitivity Calibration.......................................................................................................................................... 28

5.7.1. ExternalWeightCalibrationECAL.................................................................................................................................... 28

5.7.2. SensitivityCalibrationUsingInternalWeight(ATXOnly).................................................................................................29

5.8. Weight LoaderMechanism Operation Check................................................................................................. 31

5.8.1. OperationProcedureandProcess................................................................................................................................... 31

5.8.2. Errors.................................................................................................................................................................................. 31

6.

EEPROM......................................................................................................................................................................... 32

6.1. PRINT Operations................................................................................................................................................. 32

6.2. Data Edit(EDIT) Operations................................................................................................................................ 33

6.3. Backup(BKUP)Operations................................................................................................................................ 33

6.4. Download (RESTR) Operations......................................................................................................................... 33

6.5. All Initialization(INIT)Operations...................................................................................................................... 34

6.6. EEPROM Data Editing Software........................................................................................................................ 34

7.

Updating the Program.................................................................................................................................................. 36

7.1. Programming Tools............................................................................................................................................. 36

7.2. Programming........................................................................................................................................................ 36

7.2.1. DownloadingtheProgramtotheTool............................................................................................................................... 36

7.2.2. PreparingtheTool.............................................................................................................................................................. 40

7.2.3. Programming..................................................................................................................................................................... 41

8.

Performance Inspection............................................................................................................................................... 43

8.1. Reproducibility...................................................................................................................................................... 43

8.2. CornerloadError................................................................................................................................................... 43

8.3. Linearity.................................................................................................................................................................. 43

8.4. Tilt Error.................................................................................................................................................................. 43

9.

Problemsand Solutions .............................................................................................................................................. 45

9.1. General Problem Solutions ................................................................................................................................ 45

9.2. ErrorDisplay.......................................................................................................................................................... 46

9.2.1. UserModeErrors.............................................................................................................................................................. 46

9.2.2. ServiceModeErrors.......................................................................................................................................................... 47

10.

Troubleshooting............................................................................................................................................................ 48

10.1. DisplayWon'tAppear...................................................................................................................................... 48

10.2. Key Operation DoesNotWork...................................................................................................................... 49

10.3. "ERRC"IsDisplayed...................................................................................................................................... 50

10.4. "ERRH"IsDisplayed...................................................................................................................................... 52

10.5. When Power is Switched On,Display Stops at or "Software Version".................................................. 53

10.6. Troubleof Weight Loader............................................................................................................................... 54

iii

11.

ComponentsList........................................................................................................................................................... 55

11.1. ATX/ATY Series Exploded View..................................................................................................................... 55

11.2. ATX/ATY SeriesMaintenance Parts.............................................................................................................. 60

11.3. ATX/ATY Series Dedicated Jigs..................................................................................................................... 62

1

1. Operations forAdjustment

Forthegeneraloperationsmethod,seetheUser's ManualfortheATXSeries.

1.1. Entering the Service Mode

Move from user modeto servicemode as follows.

(1)Inthe usermodemassdisplaystate,keeppressing [POWER]and[PRINT]keys.

(2)Releasethekeys.

(3) Press downonthe[CAL]and[MENU] keys.

(4)The password input displayappears. Flashing

Use the arrowkeys to input numbers.

Input00321asthedisplaymaintenancemodepassword,andpress the[→O/T←]key.

(5)Whenthepasswordis approved,theservicemodeopens.

Alternately, you can enter service mode byinputting the displaymaintenancemode command "@SVC=321"

from thePC.

2

1.2. Contents of Service Menu

Theservicemodeconfiguration(menuconfigurationdiagram)isshownbelow.

DisplayExample

[NormalRange(guideline)]

Spanafteraging

ppm/C

0 to±2

Spanbeforeaging

ppm/C

0 to±20

Zeroafteraging

g/C

0.000to± 0.0050

Zerobeforeaging

g/C

0.000to± 0.0100

Zero

Span

WAD

500,000 - 700,000

100g:2,400,000-2,600,000

200g: 4,200,000-4,600,000

300g: 6,100,000-6,500,000

TAD

25,000–38,000

OAD

0± 10(g)

Weighingcapacity

±30 (g)

LAD

WG

Not appear when [LOCK] is ON.

If no error has occurred,

"NOERR" isdisplayed.

Pressthe[→]keytodisplay

the last five errors recorded

in the log, in order of

occurrence.

TYPE Display

SHIP Display

Software Version

AD Display WAD *

TAD *

OAD *

LAD *

WG *

CR *

Select Type Type list

Set Shipment Japan

SI

EXP

ASIA

TA

Sirial NO. Input UP 5div Input

DOWN 5div Input

OEM Setting ON Weight Input

Min Input

Lock Setting

NVRAM PRINT

EDIT

BACKUP

Download

INITIAL

END

Ok?

Ok?

Edit Run

Input

Input

Input

Input

Linear Adjust Run

Setting Weight Input

Ok?

(Maintenance Mode) * Marking mean going buck to Measure Mode

AD

Error Log

After Ageing

Span(ppm/C)

After Ageing

ZERO Drift(g/C)

Before Ageing

Span(ppm/C)

Before Ageing

ZERO Drift(g/C)

Ok?

Weight Loader HOME POSITION

LOAD,UNLOAD

Aftertheexecutionoftheitemsmarkedwithanasteriskmark,themodereturnstothemass displaystate.

SerialNo. Input

UP5dig.Input

DOWN 5dig.Input

3

Items in the figure framed in thick lines denote execution items, while those framed in thin lines denote menu

items.

Shaded itemsarenotdisplayedwhen thesetting informationlock ison.Usethearrowkeys to movebetween

items.

Key

Explanation

→

Move to an item in a subordinate menu. If the menu item to the left of the arrow has no asterisk mark and is also

shaded, pressing the [Enter] key on that item opens a subordinatemenu item. (In other words, if the higher menu

acceptsthe[Enter]keyevenifithasnoenable/disableswitch,pressingthe[Enter]keyopensthesubordinatemenu.)

Toopenthemenufromthemassdisplaystate,usethe[MENU]keyinsteadofthe[→] key.

←

Returntotheiteminthehighermenu.

↓

Movetoitemsinorder.

↑

Movetoitemsinreverseorder.

*Forthereleasemethodof settinginformationlock,see"5.3.1 Releasing the Setting Information Lock."

1.3. Service Mode Functions

Servicemodefunctionsareshownbelow.

Function

Outline

Error display

Displays error codes for errors that have occurred in user

mode.

If no errors have occurred when service mode is opened,

the errordisplaydoes notappear.

Model namedisplay

Displays themodelname setting.

Destination display

Displays thedestinationsetting.

Ex.: JPN= Japan

SI = Countries and regions that recognize SI units

only

EXP= Overseas(excludingSoutheastAsia)

ASIA= SoutheastAsia

TA = TypeApproval

SoftwareVer. display

Displays thecurrentlymountedsoftwareversion.

Ex.:1.00,##,XX

Inprinciple,1.00istheversionnumberforhardwarechanges.

Next, ## is the version number for manuals and other documentation

changes.

Finally,XXistheversionnumberforbugfixesandotherminorchanges.

Spantemperature coefficientdisplay

Displays the span temperature coefficient for before and

afteraging.

Zerodrift display

Displays theamountof zerodriftbeforeandafteraging.

ADvalue

display

Mass data(WAD) display

Displays mass data as received from ADconverter. (Data

subjectedto smoothing)

Temperaturedata(TAD)

display

Digitally displays voltage of temperature sensor mounted

onUniBlocmagnetor loadcell.

Temperature-corrected mass

data(OAD) display

Displays WAD mass data subjected to temperature

correction.(Datasubjectedtosmoothing)

Linear-corrected mass data

(LAD) display

Displays OADmassdatasubjectedtolinearitycorrection.

Absoluteload(WG)display

Displays mass values shown in g units that are subjected

to all correction processing. Displays mass values not

subjectedto zerosettingor tareweight.

Sensitivitycalibration

Executes sensitivity calibration using the same operation

asuser mode.

Weight loader

check

Return to initial position

Internal weight loadersystem returnstoinitial position.

Loadand unload

Internal weight isloadedor unloadedtounitASSY.

Linearity

adjustment

Linearityadjustment

Executes the adjustment operation for calculation of the

linearitycorrectioncoefficient.

Weight value input for linearity

adjustment

Inputs the reference weight value used for linearity

adjustment.

4

Function

Outline

Modelselection

Selection of the model nameautomatically sets the basic

information for weighing capacity, minimum display, and

referencemassforadjustment.

Shipping

settings

Unitfor Japan

Set the units users can use, depending on shipping

destination.

Initialsetting = Unit for Japan

SI unit

Overseas unit

UnitforAsia

TypeApproval

Serial No.

input

Top5digits

Input thetop 5digits of serial No.

Bottom 5 digits

Input thebottom 5digits ofserial No.

OEM

On

Sets toOEMmodel.

Weighing capacity

Changes the weighingcapacity.

Minimum display

Changes theminimum display.

Setting informationlock (errorcheck)

Prevents changes to the model, OEM, shipping, and S/N

settings. When the lock is active, all error checks are

enabled.

NVRAM

Dataprint

OutputsdatasavedinEEPROMtoa dedicatedprinter.

Data edit

EditsdatasavedinEEPROMonbalancedisplayunit.

Backup

Of the data saved in EEPROM, backs up temperature

correction coefficient, linearity correction coefficient, and

modelsettingstatusdata to aFlashmemory.

Download

Writes to EEPROM the data backed up on a Flash

memory.

Allinitialize

Initializes all datasavedinEEPROM.

END

Endsservicemode.

5

2. Disassembling and Assembling the Balance

2.1. Precautions

1) Pull theconnectorstraight outwhendisconnecting.Neverpull itoutat abentangle.

* Pulling out at a bent angle could bend the terminal pins, making it difficult to re-insert the

connector.

Fig.2-1

2) When assembling the base unit ASSY (2) and case ASSY (3), check that the power board ASSY (B4)

connectoris firmlyinserted.

* An insufficiently inserted connector could lead to instabilityin thedisplay.

Fig.2-2

3) When performing disassembly and assembly of the unit ASSY (1), insert the lever fixing pin (J1) into the

leverfixing holeonthe top oftheOPF.

* Lift up on the lever ASSY (1) to insert the pin. Proceed carefully to avoid scratching the elastic

support.

4) Use acontrolledtorquedrivertotightenthescrewstothetorquesshown inthetablebelow.

Screw

Torque[kgf•cm]

M2

1

M2.5

2.5

M3 panhead

9

M3hexagonalsocketheadbolt

15

M4 panhead

18

M4 hexagonalsockethead bolt

30

M5 hexagonalsockethead bolt

35

Connector

6

2.2. Inspecting the BalanceInterior(Removing the Caseand Pan Supporter)

[Disassembly]

1) ExtracttheAC adapter andremovethepan(6), pansupporterASSY(4),and wind shieldring(7).

2) Remove the screws on the back surface of the balance (truss M3 × 5 (4 screws)), and remove the rear cover

(13).

3) Remove the screw covers (B24), and the screws (2 screws) on the back of the balance, and remove bolt

P4M4×25 (2 bolts).

* To remove the screw covers (B24), insert something with a sharp tip (tweezers, etc.) into the

screw cover (B24) hole, and then lift up.

* When removing the screw covers (B24), be careful to avoid damaging the case (C1) and the

screw covers (B24).

Fig.2-3 Fig.2-4

4) RemovescrewP3 M4 ×20 (2 screws)(B23) onthebottom and frontof thebalance.

Fig.2-5

5) With the case ASSY (3) lifted up, extract the connector inserted into the switch board ASSY (C4), and

removethecaseASSY(3).

* Be carefulto avoid deformingthe case (C1) when positioning.

Be careful to avoid deforming the rib on the inside.

Be careful to avoid deforming the front display.

* The display board ASSY (B2) and power board ASSY (B4), etc., can be inspected while in this

position.

Fig.2-6

6) RemovescrewP4 M4 ×8(7 screws), and remove theunitcover(B5).

* The unit ASSY (1), analog board ASSY (B3), and the weight loader ASSY (27), etc., can be

Connector

Screw cover

Hole

BoltP4M4 ×25

7

inspectedwhile inthisposition.

[Assembly]

1) Withtheunitcover(B5)asthe base,usescrewP4M4 ×8(7 screws) to tighten.

* With the unit cover (B5) rear screw as the base, align with the center of the pan supporter axis

and the 15.5-dia. hole to amount the otherscrews. (Fig.2-7)

* Mount the unit cover (B5) so that the cable is flat. At this time, be careful to avoid pinching the

cable.

* Check that there is no gapbetween thebase ASSY (B1) and the unit cover (B5).

Fig.2-7 Fig.2-8

2) With the case ASSY (3) lifted up, insert the connector into the switch board ASSY (C4), and set the case

ASSY (3) intothe baseunitASSY(2).

* Be careful to avoid damaging the power board ASSY (B4) and cable when covering the base

unit ASSY (2) with the caseASSY (3).

* Be careful to ensure that the case ASSY (3) does not touch the pan supporter axis when

covering the base unit ASSY (2) with thecaseASSY (3).

* Checkthe connector connection conditionson thepower boardASSY(B4).

3) Tighten the case ASSY (3) and base unit ASSY (2) in two locations in back (bolt P4 M4 × 25) and two

locations onthebottomfrontside(P3M4×20).

4) Attachthescrewcovers (B24)in twolocationsonthebackof thebalance.

* When attaching the screw covers (B24), insert the protrusion on one side of the screw cover

(B24) into thecase(C1) hole and then push downon the top of the screw cover(B24) to attach.

* Attach so that thescrew cover (B24) hole is on the back side.

Fig.2-9 Fig.2-10 Fig.2-11

5) Mounttherearcover(13) (trussM3 ×5(4screws)).

6) Align the anti-blow ring (11) and the center of the pan supporter axis, andmount the anti-blow ring (11) and

windshieldplate(12).(Fixingscrew: Anti-blowring(11)→ScrewP3M2.5×6(2 screws),Windshield plate

(12)→ Screw P4M3× 6(2 screws))

Fig.2-12

Unit cover assembly

basescrew

Alignwiththecenter.

Screw cover

Hole

Protrusion

Hole

Alignwiththecenter.

Wind shield plate

fixingscrew

Anti-blow ring fixing

screw

8

7) Setthepan(6), pan supporterASSY(4),and wind shield ring (7).

8) Perform horizontal adjustment, and connecttheAC adaptor.

2.3. Replacing Components

2.3.1. Replacing theFront GlassASSY(C8)

1) ExtracttheAC adaptor, andremove thepan(6), pansupporterASSY(4), and windshieldring(7).

2) Remove the insideknob (C10), andremove theroof glassASSY(C5) andsideglassASSY(C6, C7).

* While supporting thefront glass ASSY(C8), removethe screws.

3) Remove the screws on thebackof the balance(truss M3 ×5(4 screws)), and remove therearcover (13).

4) Remove the two cover screws (B24) on the back side of the top of the balance, remove the screw P4

M4 ×12 (2screws),andremove thecaseroof (C3).

* After removing thecase roof (C3), take care to prevent the front glass ASSY (C8) from falling.

5) RemovethefrontglassASSY(C8).

6) If the cushion (C13) adhering to the front pillar (C12) is damaged, replace it with a new cushion (C13), (4

cushions).

Fig.2-13

7) Followthisprocedureinreverse tomountthe newfrontglassASSY (C8).

* Insertintothecaseroof(C3) groovesothatthecushion adhesionsidefacestowardthefront.

Fig.2-14

Cushions

Frontpillar

Cushion tape

Cushion

Frontglass

Frontpillar

Cushion

Front

Side

9

2.3.2. Replacing theSideGlassASSY(C6,C7)

1) ExtracttheAC adaptor, and remove theinsideknob(C10).

2) Removetheside glassASSY (C6, C7).

3) Insertthe newsideglassASSY(C6, C7),andmount theknob (C10).

4) Open the side glass ASSY (C6, C7), and coat lubricant (OT1) on the upper and lower glass edges (5cm

from theedge).

Fig.2-15

2.3.3. ReplacingtheRoof GlassASSY (C5)

1) ExtracttheAC adaptor, and remove the insideknob(C10).

2) Remove theroofglassASSY(C5).

3) Insertthe newroof glassASSY(C5), andmountthe knob(C10).

2.3.4. Replacing the Display Board ASSY (B2)

1) Use the procedures in "2.2 InspectingtheBalance Interior"toremove asfar asthe caseASSY(3).

2) RemovetheconnectorinsertedintothedisplayboardASSY (B2).

(ATXseries:4locations,ATYseries: 2locations)

3) Loosen the screw P3 M3×8 (4 screws) fixing the display board ASSY (B2) in place, and remove the

displayboardASSY(B2).

4) Use thescrewP3M3×8(4screws)totemporarilytightenthenewdisplayboardASSY(B2).

5) Adjustthemountingpositionfor the displayboard ASSY (B2). Align the leftand right directions to theedges

of board mounting surfaces on the mount, display board (B8). For the front-to-back direction, align the

displayboardASSY(B2) toapressed-forwardposition,andattachthescrewP3 M3×8(4 screws).

* Alignthe display board ASSY(B2) height position to left and right.

Fig.2-16

6) Assemblethe balancein thereverseproceduretothesteps1)and 2).

Lubricant (OT1) coating

Aligntheheight.

10

2.3.5. Replacing the Power BoardASSY (B4)

1) Use the procedures in "2.2 InspectingtheBalance Interior"toremove asfar asthe caseASSY(3).

2) Removethe connectorinsertedintothe power boardASSY(B4).(1location)

3) Loosen the bolt P3 M3 ×8 (4 bolts) fixing the power board ASSY (B4) in place, and remove the power

boardASSY(B4).

4) Use abolttotemporarilyfix thenewpowerboardASSY(B4) in place.

5) Use theprocedures in"2.2InspectingtheBalanceInterior"toassemble thecaseASSY (3).

6) Use the I/F board mounting jig (J6) to adjust and fix the position of the power board ASSY (B4). With the

centers of the two connectors, and of the jig ATX for board mounting (J7) holes, in aligned positions, adjust

the boardpositionsothat itcomes tothefarthest outsideposition.

Fig.2-17

7) Mount therear cover (13).

2.3.6. Replacing theAnalog BoardASSY (B3)

1) Use theprocedures in "2.2 Inspecting the Balance Interior"toremove asfar as the unitcover(B5).

2) Insertthe leverfixing pin(J1) intotheleverfixing holeonthetopoftheOPF.

3) Remove the connector on the upper side of the board inserted into the analog board ASSY (B3). (3

locations)

Fig.2-18

4) RemovetheconnectorinsertedintothedetectorASSY(U11).(1location)

* When removing, use caution to ensure that it does not come into contact with the lever ASSY

(U7) andscratch the elastic support.

Fig.2-19

Connector(3locations)

Connector

JigATX forboardmounting

Connector

Connector

11

5) Loosentheclamp,E-20-3C (B10)mountedtothebaseunitASSY (2), andremove the wire.

Fig.2-20

6) Loosen thescrewP4M4×8and flatwasher M4 (2 locations) fixingthe mount, analog board (B11) in place,

and remove themount, analog board(B11).

7) Loosen the screw P3 M3×8 (4 screws) fixing the analog board ASSY (B3) in place, and remove the

analogboardASSY (B3).

8) Removetheconnector(for thecoil)insertedintotheanalogboardASSY (B3).

9) Use theaboveprocedure inreversetomountthenewanalogboardASSY (B3).

2.3.7. Replacing the Weight Loader ASSY (27)

1) Use theprocedures in "2.2 InspectingtheBalanceInterior"toremoveas faras the unitcover(B5).

2) Loosen the screw P4 M4 × 8(2 screws) and flat washer M5 (2 locations), remove the weight stopper (W3),

andremovethe weight.

* When removing the weight (W4), be careful to avoid damaging the unit ASSY (1). (Be careful to

avoid letting the weight stopper (W3) rotating in tandem and coming into contact with the pan

supporter axis.)

* When performing re-assembly, be careful to avoidletting dust settleon theweight (W4).

3) LoosenthescrewP4M4×8(4screws),andremove the weightloaderASSY(27).

4) Use theaboveprocedure inreversetomountthenewweight loaderASSY (27).

* Mount the weight loader ASSY (27) on cell width of the unit ASSY (1) in the balance left and right

directions.

* Be carefulto avoid letting the weight loadermechanism comeinto contact with the lever.

* When mounting,press the weight loaderASSY(27) forward forthemounting position.

Fig.2-21

Sameinterval

Pressforward.

Clamp

12

2.3.8. Replacing theUnitASSY (1)

1) Use theprocedures in "2.2 Inspecting the Balance Interior"toremove asfar as the unitcover(B5).

2) Loosen the screw P4 M4 × 8(2 screws) and flat washer M5 (2 locations), remove the weight stopper (W3),

andremovethe weight.

3) Insertthe leverfixing pin(J1) intotheleverfixing holeonthetopoftheOPF.

* Lift up on the lever ASSY (U7) to insert the pin. Proceed carefullyto avoid scratching the elastic

support.

4) RemovetheconnectorinsertedintothedetectorASSY(U11).(1location)

* When removing, use caution to ensure that it does not come into contact with the lever ASSY

(U7) andscratch the elastic support.

5) Stand the back of the base ASSY (B1) on the floor, loosen the bolt P3 M5×12 (3 bolts) on the bottom of

thebaseASSY(B1),andremove the unitASSY(1).

Fig.2-22

6) After setting the new unit ASSY (1), usethebolt P3 M5 × 12 (3 bolts) on the bottom of the base ASSY (B1)

to temporarily fix the unit ASSY (1), then use the unit ASSY positioning pin(J2) and plate (J8) to adjust the

position,andtighten.(35 kgf·cm)

* When lifting up on the new unit ASSY (1), do not hold it by the parallel guide and movable pillar

part.

* When setting the unit ASSY positioningjig (J2),be carefulto avoid damagingtheunitASSY (1).

Fig.2-23

7) See 2.3.7 tomount theweightloaderASSY (27).

* Mount the weight loader ASSY (27) on cell width of the unit ASSY (1) in the balance left and right

directions.

* Be carefulto avoid letting the weight loadermechanism come into contact with the lever.

8) Check repeatability and cornerload error, and then perform linearity, calibration of internal weight (ATX

series only), and sensitivity adjustment. (See "4.4 Adjusting the Cornerload Error," "5.5 Linearity

Adjustment," "5.6InternalWeightCalibration(PCAL)," and "5.7 SensitivityCalibration.")

9) Use theabove procedures 1) to 4) inreversetorestore the original state.

* Input the attached EEPROM data to the balance. Temperature Coefficients at Address Numbers

004 to 05A.

Bolt (3bolts)

UnitASSYpositioning jig

13

2.3.9. Replacing theDetectorASSY(U11)

1) Insertthe leverfixing pin(J1) intotheleverfixing holeonthetopoftheOPF.

* Lift up on the lever ASSY (U7) to insert the pin. Proceed carefullyto avoid scratching the elastic

support.

2) See 2.3.8 toremove theunitASSY(1).

3) Removethesolder onthetemperaturesensorcableconnectedto thedetectorASSY (U11).

* MT:Yellow line,MG:blue line

Fig.2-24

4) RemovethescrewP3M3×8(2screws), andremovethedetectorASSY(U11).

Fig.2-25

5) Use theaboveprocedures 3) to4) inreversetomountthedetectorASSY(U11).

6) Perform "4.1Adjusting theDetectorASSY (U11)Height."

7) Use theabove procedures 1) to 2) inreversetorestore the originalstate.

2.3.10.Replacing theForceCoilASSY(L1)

1) See 2.3.8 toremove theunitASSY(1).

2) Insertthe leverfixing pin(J1) intotheleverfixing hole on thetop surface.

* Lift up on the lever ASSY (U7) to insert the pin. Proceed carefullyto avoid scratching the elastic

support.

3) See 2.3.9 toremovethedetectorASSY (U11).

4) Removethesolder ontheleverASSY (U7)sideofthetwoPt-Ni bands (U17).

* Do notbreak orscratchthe Pt-Ni band (U17).

5) Remove the pan head screw M3 ×6 (2 screws) and flat washer M3 (2 locations), and remove the stopper

plate(U14).

6) RemovethepanheadscrewM2.5×5(4 screws), andslidethemagnet lid(U16)horizontallytoremove.

Fig.2-26

Screw P3 M3 ×8

Slide

Yellow

Blue

14

BoltM3 ×40

Springwasher

Flatwasher

Flatwasher

NutM3

Magnetside

Topview

7) Remove the socket head bolt M3 × 40 (2 bolts) fixing the lever ASSY (U7) in place, spring washer M3 (2

locations), flat washer M3 (4 locations),and nutM3 (2 locations), and remove the lever ASSY (U7) from the

top surface.

8) Remove thesolder on thetwistcable(L7)for theforcecoilASSY(L1)terminalplate.

9) Remove the pan head screw M2.5 ×6 fixing the force coil ASSY (L1), washer PB M2.6, and washer

CC-2605-08 inplace,andremove theforcecoilASSY (L1).

10) Use the pan head screw M2.5 × 6, washer PB M2.6, and washer CC-2605-08 to lightly tighten the new

force coil ASSY (L1) to the lever ASSY (U7), and solder the twist cable (L7) to the force coil ASSY (L1)

terminalplate.

* When viewed from thelever ASSY (U7) mounting side, left: blue line, right: yellow line

Fig.2-27

11) Insert the lever ASSY (U7) from the top of the unit, and temporarily fix in place with the socket head bolt

M3 ×40 (2 bolts), springwasher M3(2locations), flatwasher M3 (4 locations), andnut M3 (2 locations).

* Always insert the tighteningparts in the facing shownin Fig. 2-29.

Fig.2-28 Fig.2-29

12) With the force coil ASSY (L1) height adjusted by the magnet spacer (J9), tighten the lever ASSY (U7).

(35kgf·cm)

Fig.2-30

Magnetspacer

Blue

Yellow

Yellow

Blue

15

13) Examine the unit from the top, align the center of the magnet ASSY (U9) and of the force coil ASSY (L1),

andthentightentheforcecoilASSY (L1).

Fig.2-31

14) Slide the four magnet lids (U16) horizontally to mount, and use the pan head screw M2.5× 5 (4 screws) to

tighten.

15) Insert the gap setting shim (J3) into the space between the upper edge of the lever ASSY (U7) and the

stopper lever (U15) to obtain positioning, and use the screw P3 M3 ×8 (2 screws) to tighten the stopper

lever(U15).

Fig.2-32

16) Solderthetwo Pt-Ni bands(U17)totheleverASSY (U7) side.

* When soldering, apply the solder tilted and upward facing to ensure that the Pt-Ni band (U17)

doesnot come into contact with the lever ASSY (U7).

17) See 2.3.9 toremovethedetectorASSY (U11).

18) Extract the lever fixing pin (J1) from the unit ASSY (1), shake the unit ASSY (1) lightly to move the lever

ASSY (U7) up and down, and if it contacts the stopper lever (U15) with a clear sound, the unit ASSY (1)

assemblyis complete.

* If it does not make a clear sound, the lever ASSY (U7) pin and stopper plate (U14), or the force

coil ASSY (L1) and magnet ASSY (U9), maybe in contact. Check each part to seeif anyareout of

position,andreadjust the position.

19) Use theprocedures in2.3.8inreversetomounttheunitASSY(1)tothebaseASSY (B1).

* Always insert the lever fixing pin (J1) beforemounting the unit ASSY(1) to thebaseASSY (B1).

20) With the stopper plate (U14) in a position aligned to the center of the force coil ASSY (L1) pin, use the pan

headscrewM3 ×6(2 screws)andflatwasherM3 (2 locations)to tighten.

Fig.2-33

21) Perform "4.2Adjusting theTilt Error," "4.3AdjustingtheBalance," and "4.4AdjustingtheCornerloadError."

Align the center.

Gapsetting shim

Pin

Stopperplate

16

22) Use the procedures in"2.2 InspectingtheBalance Interior"in reverse to restoretheoriginal state.

2.3.11. Replacing theStopper Plate (U14)

1) Use theprocedures in "2.2 InspectingtheBalanceInterior"toremoveas faras the unitcover(B5).

2) Loosen the pan head screw M3 ×6 (2 screws) and flat washer M3 (2 locations), and remove the stopper

plate(U14).

3) With the stopper plate (U14) in a position aligned to the center of the force coil ASSY (L1) pin, use the pan

headscrewM3 ×6(2screws) andflat washerM3(2 locations) totighten.

4) Use the procedures in"2.2 InspectingtheBalance Interior"in reverse to restoretheoriginal state.

2.3.12. Replacing theStopper Lever (U15)

1) See 2.3.8 toremove theunitASSY(1).

2) Use the cable ASSYjig (J10) connector to connect the detector ASSY (U11) and the analog board ASSY

(B3).

* Leave the cable ASSY C (U19) (soldered cable with 2 pins) removed from the analog board

ASSY (B3).

3) Connectthetester(+)terminaltothedetectorASSY (U11)CP1pin, andthe(-) terminaltothe CPG pin.

4) Extracttheleverfixingpin(J1)fromtheunitASSY (1)leverfixing hole.

* Lift up on the lever ASSY (U7) to extract the pin.Proceed carefully to avoid scratching the elastic

support.

5) ConnecttheAC adaptor tothebalance,andenergizeit.

6) With the screw P3 M3 ×8 (2 screws) connecting the stopper lever (U15) slightly loosened, press lightly on

the lever ASSY(U7) up and down until it contacts the top of the stopper lever (U15), and then tighten the

stopper lever (U15) in a position where the absolute value is the same (where the tester display reverses

(+)(-)).

* Press lightly on the balance weight (U21), and adjust so that the direction the tester display

points (direction where the shutter rises) becomes (-).

* Detector ASSY (U11) output adjustment standard: Within 0.3[V] between + side and –side

Allowable range of outputvoltage +1.5to+2V,

-1.5 to-2V

7) Extract the lever fixing pin (J1) from the unit ASSY (1), shake the unit ASSY (1) lightly to move the lever

ASSY (U7) up and down, and if it contacts the stopper lever (U15) with a clear sound, the unit ASSY (1)

assemblyis complete.

* If it does not make a clear sound, the lever ASSY (U7) pin and stopper plate (U14), or the force

coil ASSY (L1) and magnet ASSY (U9), maybe in contact. Check each part to seeif anyareout of

position,andreadjust the position.

8) Inserttheleverfixing pin(J1) intotheleverfixing holeonthetop ofunitASSY (1).

* Lift up on the lever ASSY (U7) to insert the pin. Proceed carefullyto avoid scratching the elastic

support.

9) See 2.3.8 tomount the unitASSY(1).

10) RemovetheAC adaptor,andremovethetesterterminalsfrom thedetectorASSY (U11).

11) Remove thecableASSYjig (J10).

12) Use the above procedures 2) to 3) inreversetorestore the originalstate.

13) See 2.3.8 torestoretheoriginalstate.

Other manuals for ATX224

1

This manual suits for next models

5

Table of contents

Other Shimadzu Scale manuals

Shimadzu

Shimadzu ATX-R Series User manual

Shimadzu

Shimadzu ATX224 User manual

Shimadzu

Shimadzu UW620HV User manual

Shimadzu

Shimadzu ELB120 User manual

Shimadzu

Shimadzu UPX Series User manual

Shimadzu

Shimadzu TW223L User manual

Shimadzu

Shimadzu TW Series User manual

Shimadzu

Shimadzu ELB Series User manual

Shimadzu

Shimadzu BL3200H User manual

Shimadzu

Shimadzu UW220H User manual