3(28)

Content

1. General Description..................................................................................... 5

1.1 CodingPrinciple......................................................................................6

1.2 Feature....................................................................................................6

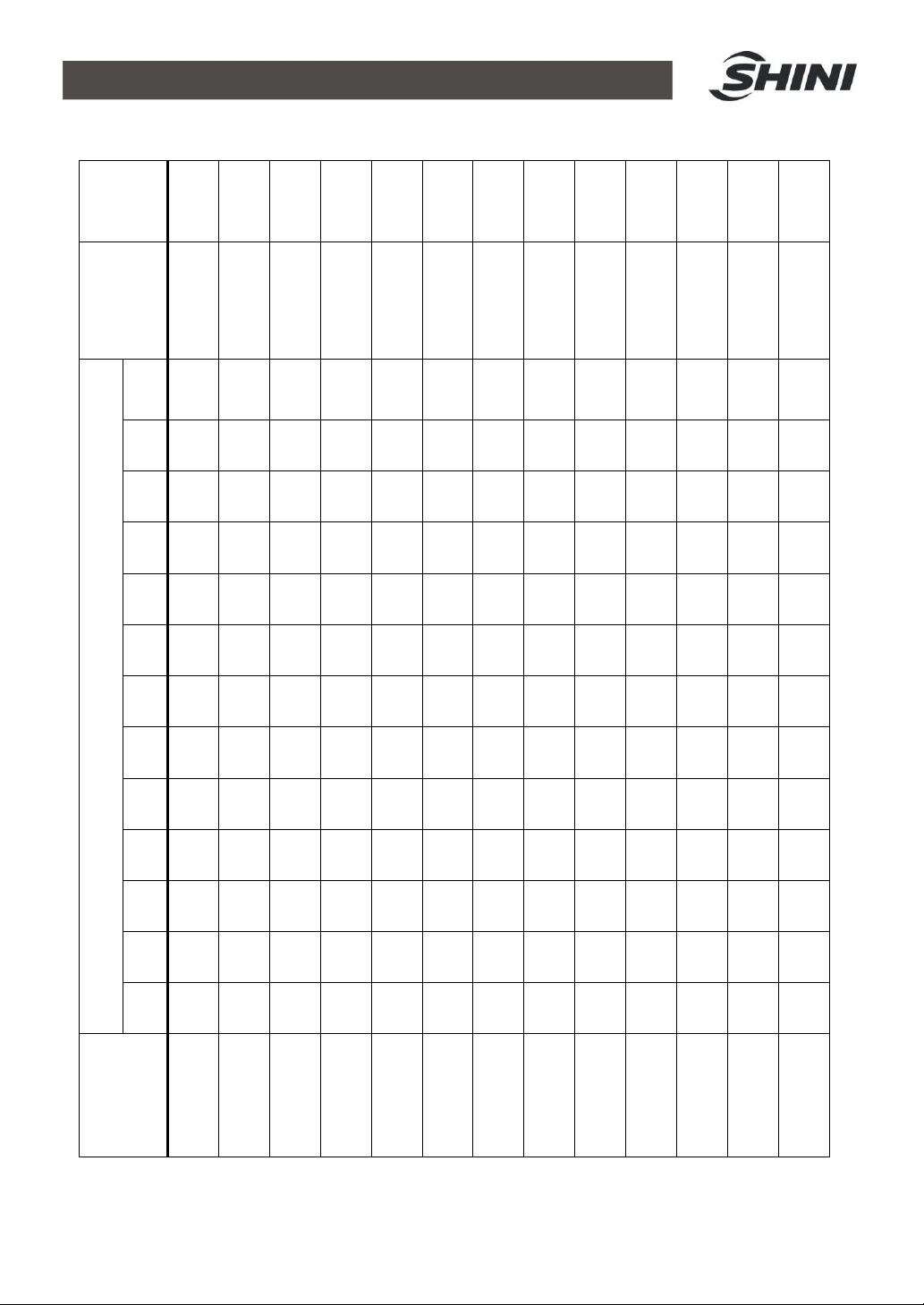

1.3 TechnicalSpecifications..........................................................................8

1.3.1 ExternalDimensions......................................................................8

1.3.2 Specification..................................................................................9

1.4 SafetyRegulations................................................................................ 11

1.4.1 SafetySignsand Labels.............................................................. 11

1.4.2 Signsand Labels......................................................................... 12

1.5 ExemptionClause................................................................................. 12

2. StructureCharacteristics and WorkingPrinciple.................................... 13

2.1 WorkingPrinciple.................................................................................. 13

2.2 Options.................................................................................................. 14

2.2.1 Air Filter....................................................................................... 14

2.2.2 BlowerInlet Filter......................................................................... 14

2.2.3 MagneticBase............................................................................. 14

2.2.4 Hot Air Recycler........................................................................... 15

2.2.5 HopperMagnet............................................................................ 15

2.2.6 MaterialSuction Box/Shut-off Suction Box.................................. 16

2.2.7 N-Type FloorStand..................................................................... 16

3. Installation and Debugging........................................................................ 17

3.1 Direct Installation................................................................................... 17

3.2 FloorStand Installation......................................................................... 18

3.3 Connectingthe PowerSource.............................................................. 18

3.4 TheHopperDryerTest......................................................................... 18

3.5 Installation of the Options...................................................................... 19

3.5.1 Installation of Air-Exhaust Filter................................................... 19

3.5.2 SuctionBoxInstallation............................................................... 19

3.5.3 BlowerInlet FilterInstallation....................................................... 20

3.5.4 Hot Air RecyclerInstallation......................................................... 20

4. Operation Guide......................................................................................... 22