-5-

W1754S 20" Planer with Spiral Cutterhead

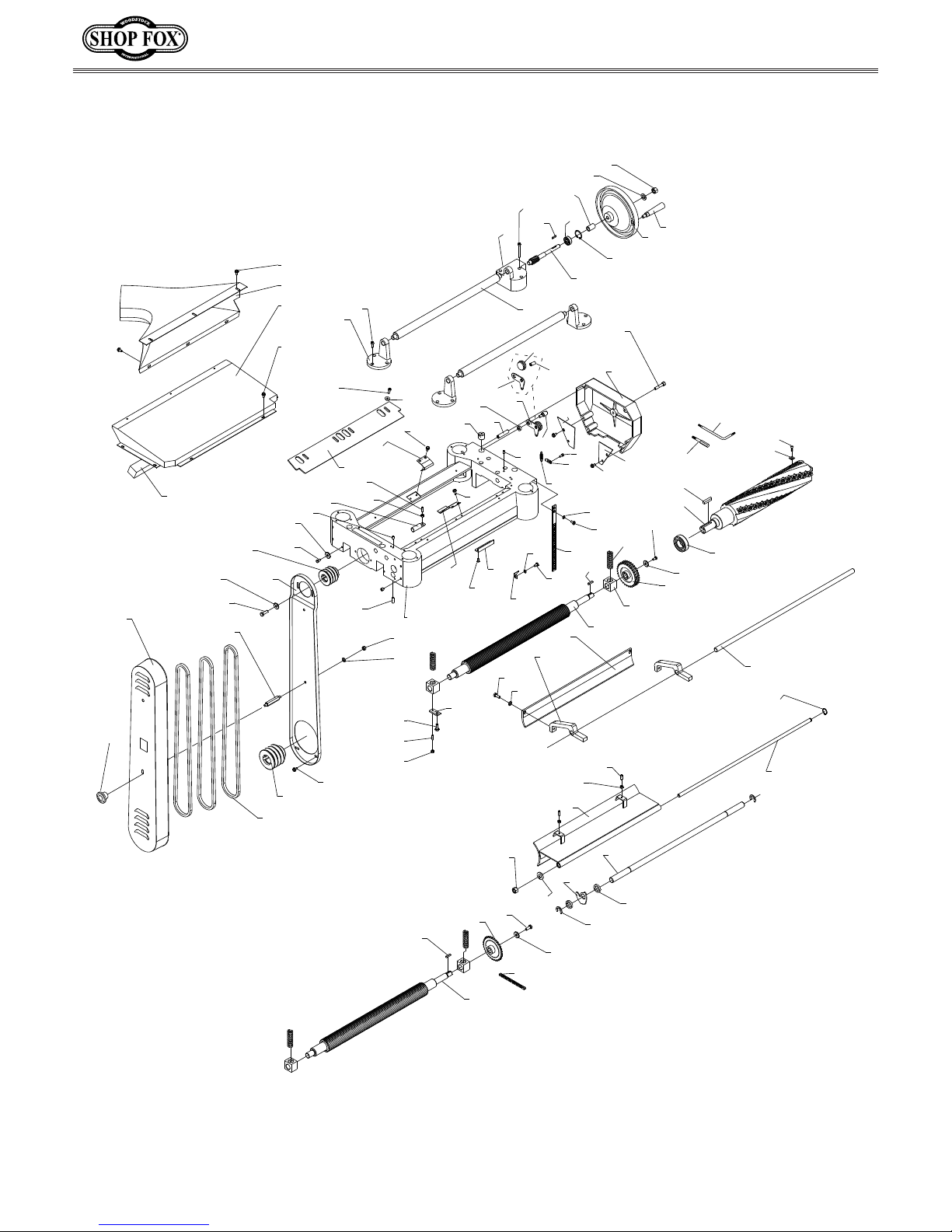

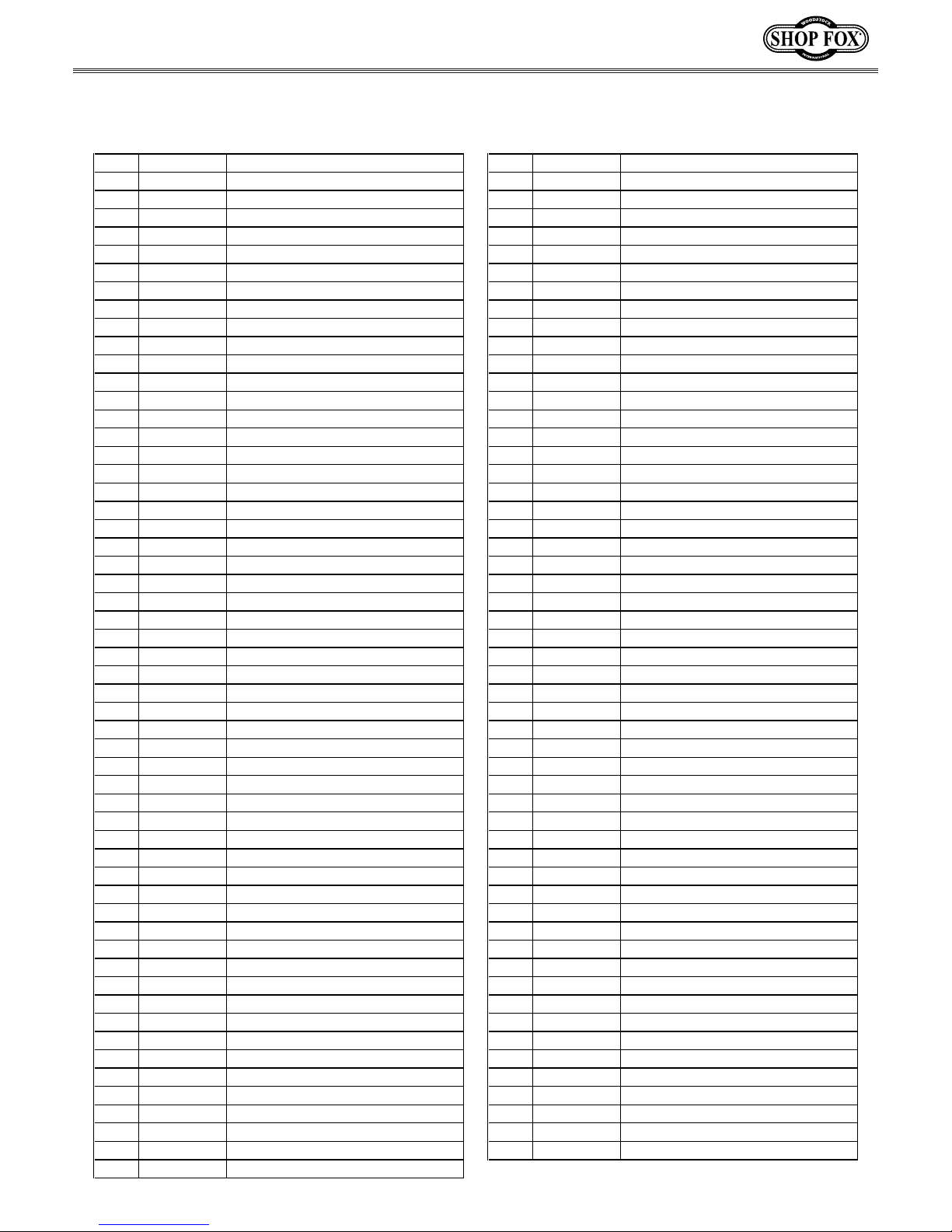

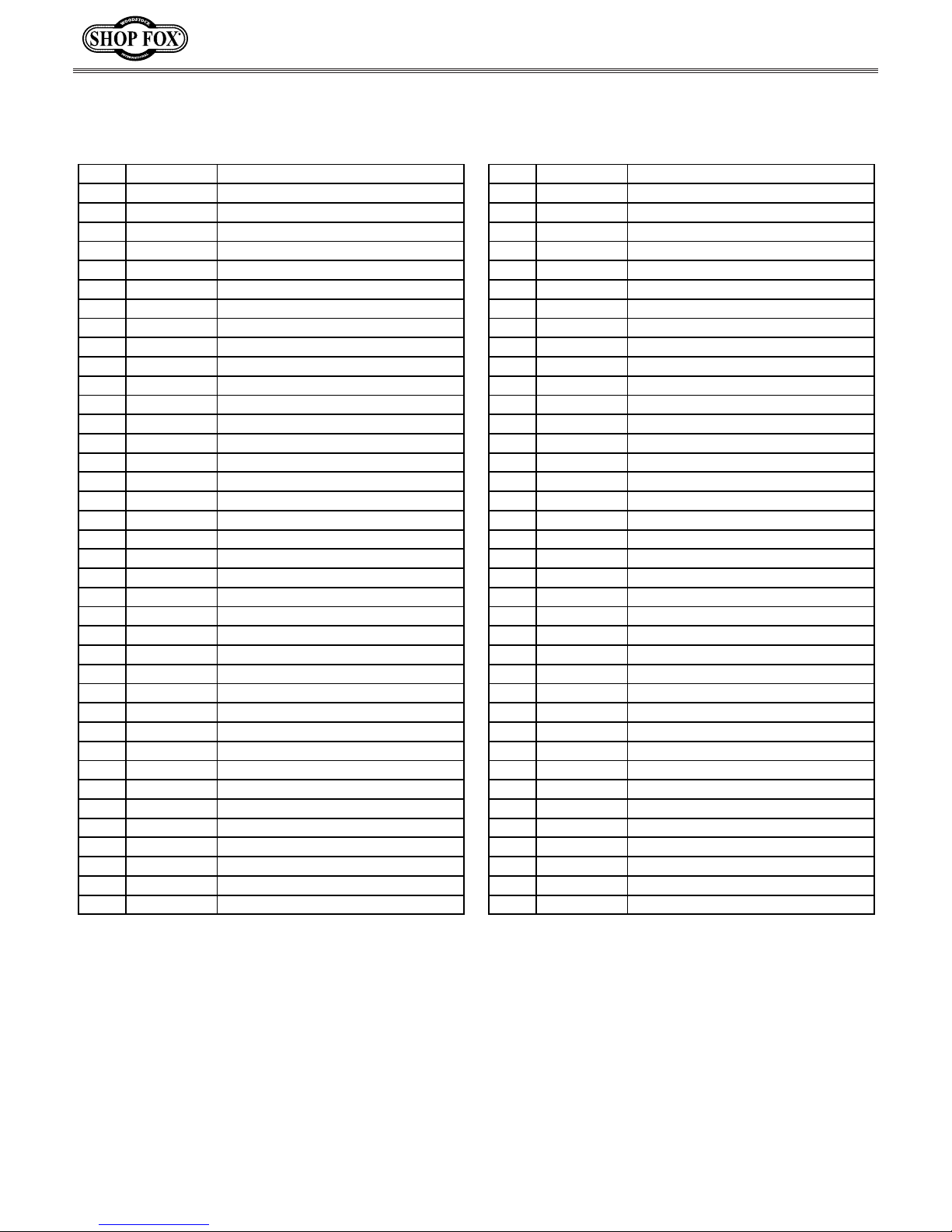

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 X1754001 HANDLE 60 XPW03M FLAT WASHER 6MM

2 XPN09M HEX NUT M12-1.75 61 XPS14M PHLP HD SCR M6-1 X 12

3 XPW06M FLAT WASHER 12MM 62 X1754062 CUT LIMIT POINTER

5 X1754005 HAND WHEEL 63 XPW03M FLAT WASHER 6MM

6 X1754006 COLLAR 64 XPS14M PHLP HD SCR M6-1 X 12

7 XPR29M INT RETAINING RING 32MM 65 X1754065 CUT LIMITER PLATE

8 XP6201 BALL BEARING 6201 66 XPB107M HEX BOLT M5-.8 X 12

9 XPK48M KEY 4 X 4 X 20 67 X1754067 HEAD CASTING

10 X1754010 WORM GEAR 68 X1754068 OUTFEED ROLLER

11 X1754011 WORM HOUSING 69 XPK01M KEY 5 X 5 X 22

12 XPSB83M CAP SCREW M6-1 X 55 70 X1754070 COMPRESSION SPRING

13 X1754013 ROLLER 71 X1754071 SPECIAL OILER SET SCREW

14 X1754014 ROLLER STAND 72 X1754072 BUSHING

15 XPSB01M CAP SCREW M6-1 X 16 73 X1754073 PLATE

19 X1754019 DUST HOOD 74 XPB09M HEX BOLT M8-1.25 X 20

20 XPFB01M FLANGE BOLT M6-1 X 12 75 XPSS25M SET SCREW M6-1 X 20

21 X1754021 UPPER COVER 76 XPN01M HEX NUT M6-1

22 XPFB01M FLANGE BOLT M6-1 X 12 77 X1754077 SHAFT

23 X1754023 GASKET 78 XPSS11M SET SCREW M6-1 X 16

24 X1754024 GEAR BOX COVER 79 X1754079 CHIP BREAKER

26 XPSB12M CAP SCREW M8-1.25 X 40 80 XPSS25M SET SCREW M6-1 X 20

27 XPRP07M ROLL PIN 6 X 20 81 XPN01M HEX NUT M6-1

28 X1754028 SAFETY HATCH 82 X1754082 BRACKET

29 X1754029 SAFETY HATCH 83 X1754083 LOCKING ROD

30 XPFB09M FLANGE BOLT M6-1 X 10 84 XPR03M EXT RETAINING RING 12MM

31 X1754031 BRACKET ASSEMBLY 85 XPN09M HEX NUT M12-1.75

31-1 X1754031-1 BRACKET 85-1 XPLW05M LOCK WASHER 12MM

31-2 X1754031-2 IDLE PULLEY 86 X1754086 PRESSURE PLATE

31-3 X1754031-3 IDLE SHAFT 87 XPB09M HEX BOLT M8-1.25 X 20

32 X1754032 SHAFT 88 XPLW04M LOCK WASHER 8MM

33 X1754033 COLLAR 89 XPEC05M E-CLIP 15MM

34 X1754034 EXTENSION SPRING 90 X1754090 COLLAR

35 X1754035 HANGER 91 X1754091 ANTI-KICKBACK FINGER

36 XPSB04M CAP SCREW M6-1 X 10 92 X1754092 SHAFT

37 X1754037 CHIP DEFLECTOR PLATE 93 XPSS14M SET SCREW M8-1.25 X 12

38 XPFB10M FLANGE BOLT M6-1 X 15 94 XPB83M HEX BOLT M6-1 X 16

39 XPW03M FLAT WASHER 6MM 95 XPW03M FLAT WASHER 6MM

40 X1754040 PLATE SPRING 96 X1754096 SPROCKET

41 XPFB01M FLANGE BOLT M6-1 X 12 97 X1754097 CHAIN 06B-1 X 67

42 X1754042 PLATE SPRING 98 XPK01M KEY 5 X 5 X 22

43 XPFB01M FLANGE BOLT M6-1 X 12 99 X1754099 INFEED ROLLER

44 X1754044 ADJUSTING SHAFT 100 XPB02M HEX BOLT M6-1 X 12

45 XPSS04M SET SCREW M6-1 X 12 101 XPW03M FLAT WASHER 6MM

46 XPSS25M SET SCREW M6-1 X 20 102 X1754102 CUTTERHEAD PULLEY

47 XPN01M HEX NUT M6-1 103 X1754103 MOTOR PULLEY

48 X1741S164 INDEXABLE INSERT 14 X 14 X 2 104 XPW01M FLAT WASHER 8MM

50 X1741S166 FLAT HD TORX SCR T20 M6-1 X 15 105 XPB07M HEX BOLT M8-1.25 X 25

51 X1741S228 L-WRENCH TORX T20 106 X1754106 BELT GUARD

52 X1741S227 DRIVER BIT TORX T20 107 XPFB09M FLANGE BOLT M6-1 X 10

53 X1754S053 SPIRAL CUTTERHEAD 108 X1754108 SPECIAL BOLT

54 XPK129M KEY 8 X 8 X 36 109 XPW01M FLAT WASHER 8MM

55 XP6206 BALL BEARING 6206ZZ 110 XPN03M HEX NUT M8-1.25

56 XPB83M HEX BOLT M6-1 X 16 111 X1754111 COGGED V-BELT MX-60

57 XPW03M FLAT WASHER 6MM 112 X1754112 BELT COVER

58 X1754058 SPROCKET 114 X1754114 STAR KNOB M8-1.25

59 X1754059 SCALE

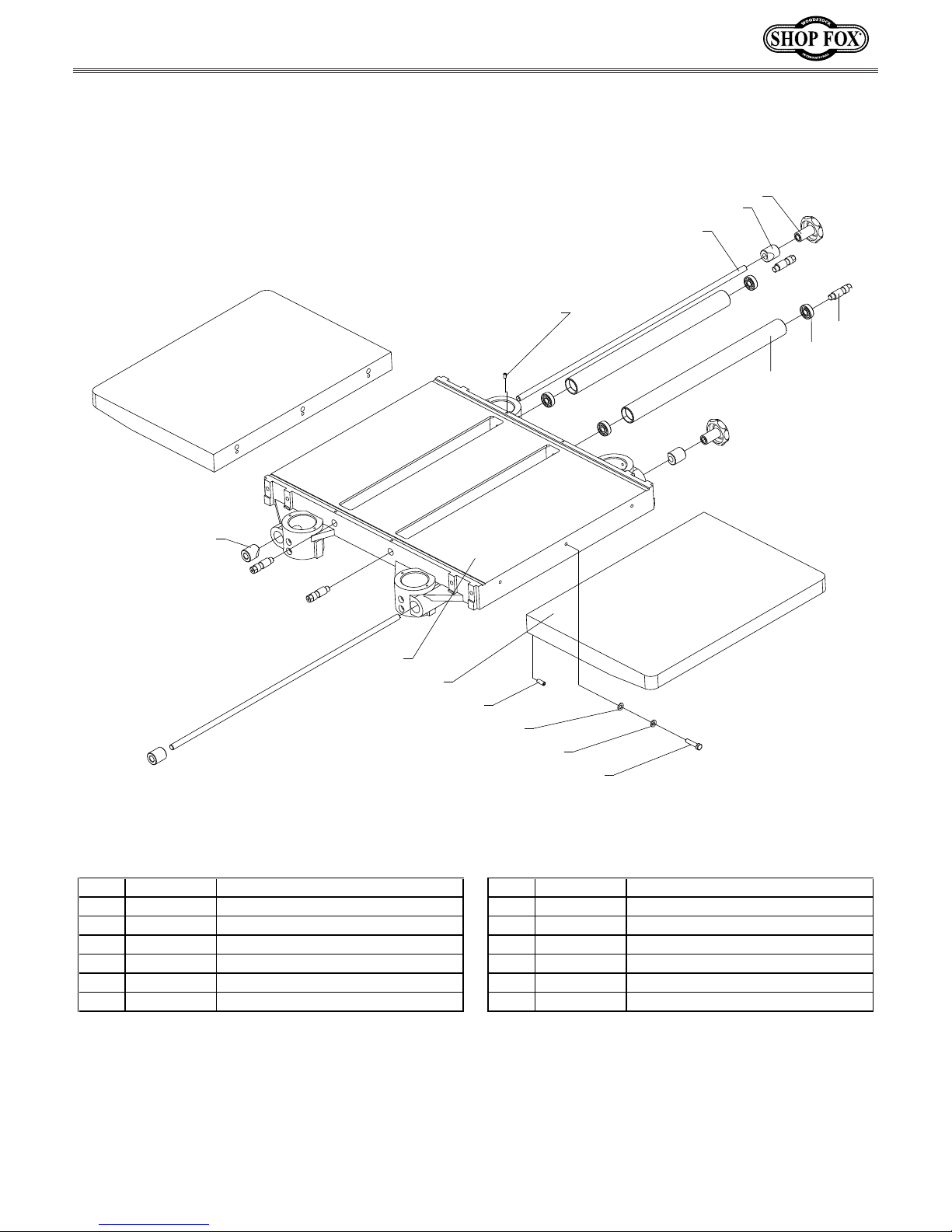

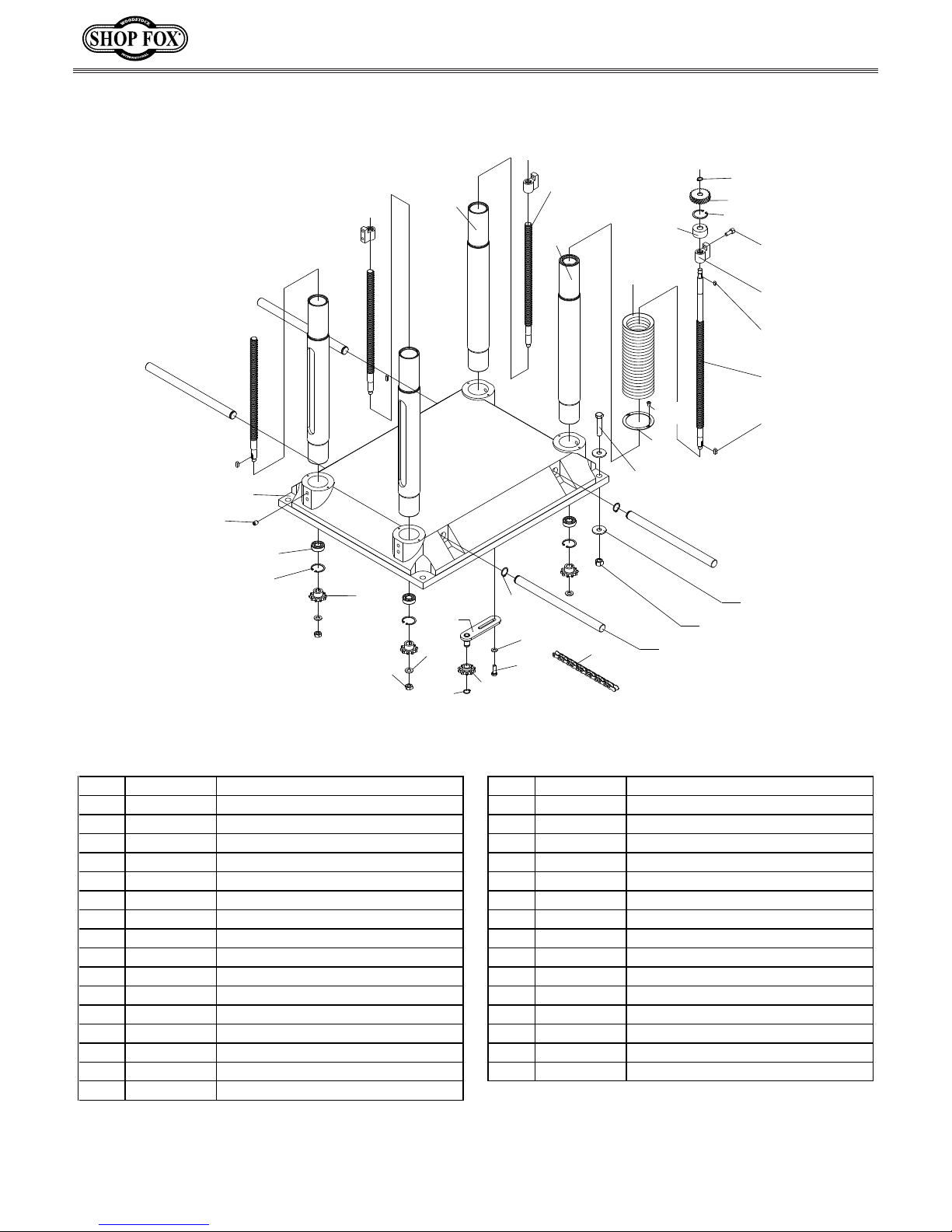

Headstock Parts List