CONTENTS PAGE

INTRODUCTION ........................................................................................................2

About Your New Planer ........................................................................................2

Woodstock Service and Support ..............................................................................2

Warranty and Returns ..........................................................................................3

Specifications ....................................................................................................3

SAFETY FIRST! ..........................................................................................................4

Safety Instructions ..............................................................................................4

Additional Safety Instructions for Planers ..................................................................6

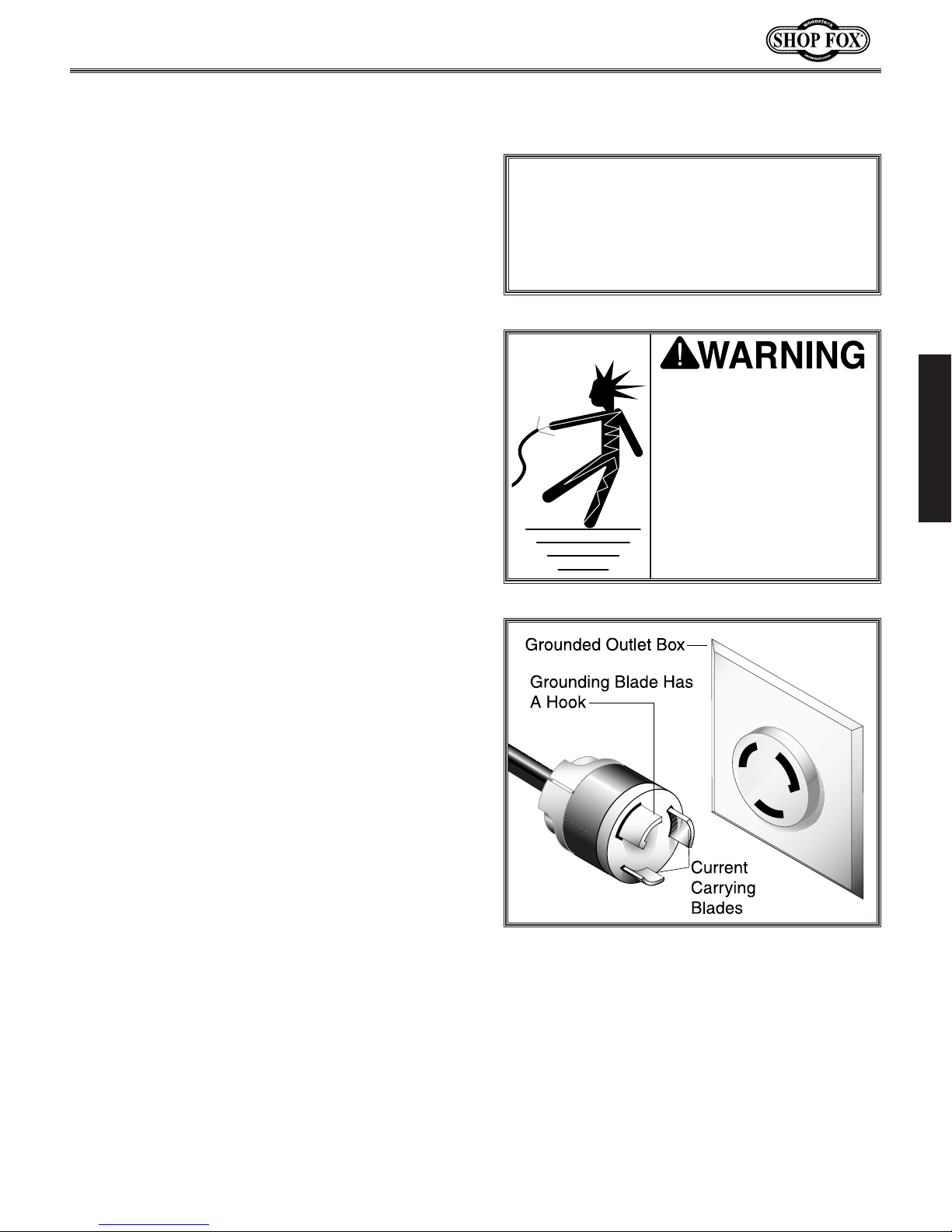

ELECTRICAL ............................................................................................................7

220V Operation ..................................................................................................7

Extension Cords ..................................................................................................7

Grounding ..........................................................................................................7

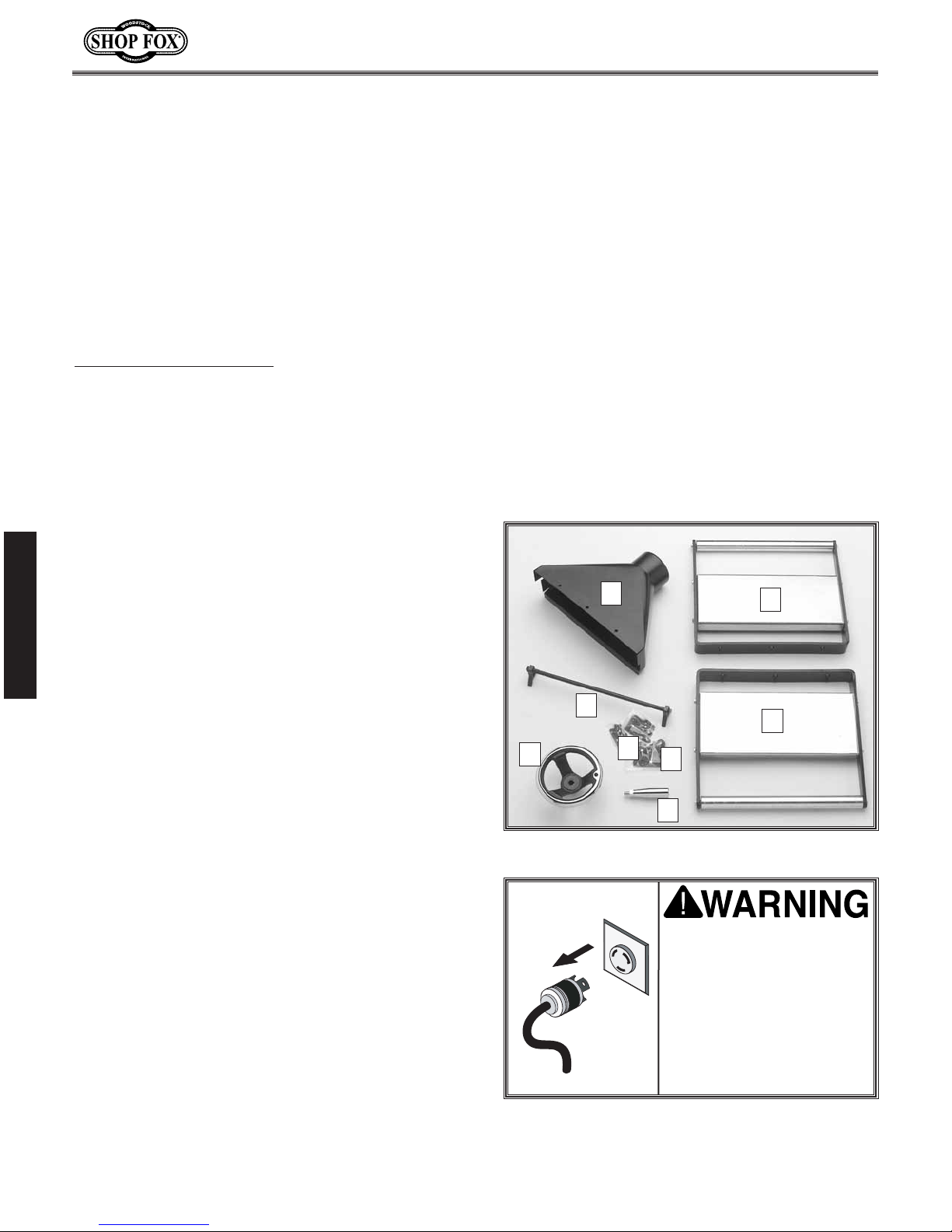

ASSEMBLY................................................................................................................8

Box Contents ......................................................................................................8

Overview ..........................................................................................................8

Shop Preparation ................................................................................................9

Cleaning Planer ..................................................................................................9

Extension Rollers ..............................................................................................10

Hand Wheel ......................................................................................................11

Dust Hood ........................................................................................................11

Control Panel Assembly ......................................................................................12

Knife Setting Jig ................................................................................................12

ADJUSTMENTS ........................................................................................................13

Planer Overview ................................................................................................13

Table ..............................................................................................................14

Inspecting Knives ..............................................................................................17

Knife Adjustment ..............................................................................................18

Feed Rollers and Chip Breaker ..............................................................................20

Chip Deflector ..................................................................................................20

Anti-Kickback Pawls ............................................................................................22

Roller Spring Tension ..........................................................................................23

Table Rollers ....................................................................................................24

OPERATIONS ..........................................................................................................25

Test Run ..........................................................................................................25

Feed Rate ........................................................................................................25

Operational Tips ................................................................................................26

Troubleshooting Planing Results ............................................................................27

MAINTENANCE ........................................................................................................28

General............................................................................................................28

Cleaning ..........................................................................................................28

Table ..............................................................................................................28

Lubrication ......................................................................................................29

Belt Tension......................................................................................................30

Pulley Alignment ................................................................................................30

Wiring Diagram ..................................................................................................31

Troubleshooting Planer Operation ..........................................................................32

Closure ............................................................................................................33

Planer Accessories..............................................................................................34

Parts Lists ....................................................................................................36-41

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

ELECTRICAL ADJUSTMENTS OPERATIONS MAINTENANCE

ASSEMBLYSAFETYINTRODUCTION