CONTENTS

3

8027092/AE00/V1-0/2022-10 | SICK O P E R A T I N G I N S T R U C T I O N S | VISIC100SF

Subject to change without notice

1 About this document................................................................................. 5

1.1 Function of this document.............................................................................. 5

1.2 Scope of application ....................................................................................... 5

1.3 Target groups .................................................................................................. 5

1.4 Further detailed information .......................................................................... 5

1.5 Symbols and document conventions ............................................................. 5

1.5.1 Warning symbols ............................................................................5

1.5.2 Warning levels and signal words.................................................... 5

1.5.3 Information symbols ....................................................................... 6

1.6 Data integrity ................................................................................................... 6

2 For your safety............................................................................................ 7

2.1 Basic safety information ................................................................................. 7

2.1.1 Electrical safety............................................................................... 7

2.1.2 Dangerous substances................................................................... 8

2.2 Intended use ...................................................................................................8

2.3 Requirements for personnel qualification ..................................................... 8

3 Product description ................................................................................... 9

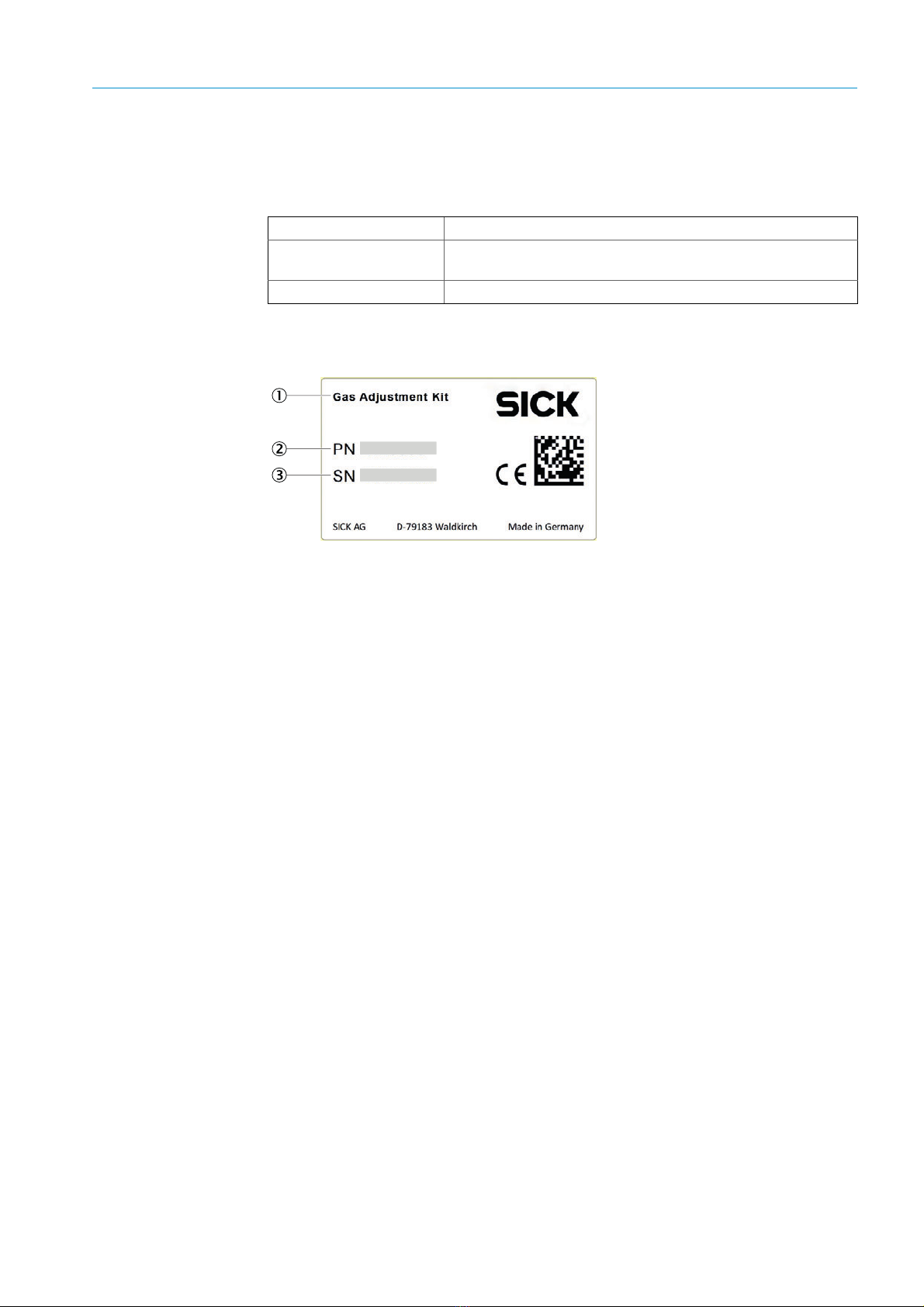

3.1 Product identification...................................................................................... 9

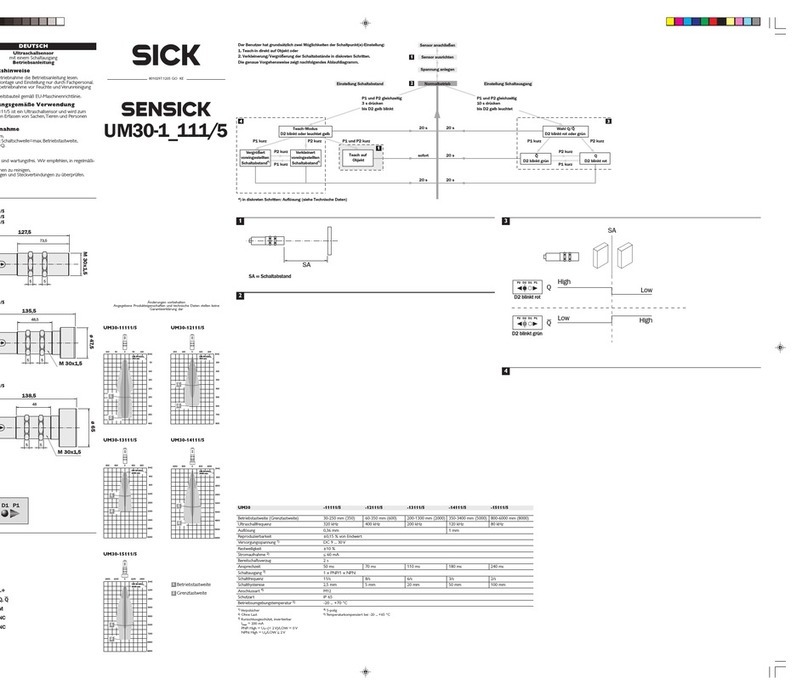

3.2 Layout and function ......................................................................................10

3.2.1 Gas Adjustment Kit.......................................................................10

4 Transport and storage.............................................................................11

4.1 Transport, VISIC100SF Gas Adjustment Kit.................................................11

4.2 Storage, VISIC100SF Gas Adjustment Kit and accessories........................11

4.3 Transporting and storing test gases.............................................................11

4.3.1 Regulations applicable for VISC100SF........................................11

4.3.2 Securing loads ..............................................................................11

4.3.3 Valve protection ............................................................................11

4.3.4 No smoking allowed .....................................................................11

4.3.5 Hazard labels ................................................................................11

4.3.6 Ventilation .....................................................................................11

4.3.7 Transport document .....................................................................12

4.3.8 Vehicle equipment ........................................................................12

4.3.9 Other equipment...........................................................................12

4.3.10 Marking .........................................................................................12

4.3.11 Accident leaflet .............................................................................12

4.3.12 Training .........................................................................................12

4.3.13 Disposal.........................................................................................12

5 Operation ..................................................................................................13

5.1 Operating concept.........................................................................................13

Contents

Contents