If the motor does not start up:

- check that the motor power supply cable is connected correctly;

- check motor operation.

If when commanding the spin (or when lowering the guard or pressing the Start key and the button) the wheel turns in the opposite direction

(i.e. toward the operator), replace the PEAL32F power supply card.

In fact this irregularity is caused by the incorrect operation of the relay “RL1”, which manages the inversion of current for wheel braking.

When switched on, the machine is blocked (it does not accept any command)

Check the keyboard is undamaged and is working. In this case, the keyboard itself should be replaced.

When the machine is switched on, the motor is powered

Probably, the relay “RL2” which is used to power the spin motor does not function correctly, i.e. it remains activated permanently. In that case,

replace the PEAL32F power supply card.

The diameter and/or distance values acquired automatically with the sensors diverge from the real values.

Within the service environment, check the efficiency of the sensors (paragraph "Internal and external sensor").

For slight variances (maximum one inch), noted above all with alloy rims of greater thickness than usual, bear in mind the consideration already

outlined in the paragraph specified above.

The width value acquired automatically with the sensors diverges from the real value.

If the potentiometer presents no irregularities, it may be sufficient to carry out a correct calibration of the external sensor.

The wheel balancer produces inconsistent imbalance values for a number of successive spins (differences greater than 3 grammes for imbalance values of

approximately 30 grammes)

Check (in this order):

- the machine is resting firmly on the floor and the feet are undamaged;

- the weight tray is correctly positioned i.e. not rubbing against the bell of the swinging unit during the spin;

- the anchor, fixed to the hub, does not touch the brake during the signal acquisition phase

- the wheel is well blocked on the shaft i.e. there is no sliding between the wheel and the resting flange during the spin phase.

- To check this condition, make two reference marks with a piece of chalk, one on the flange and the other on the wheel, perfectly in line with

each other. Check there has been no reciprocal movement between the two reference points after a few spins;

- the two pick-ups are correctly tightened (refer to the values of the signals visualised on the service page);

- the efficiency of the main board, replacing it with a new one.

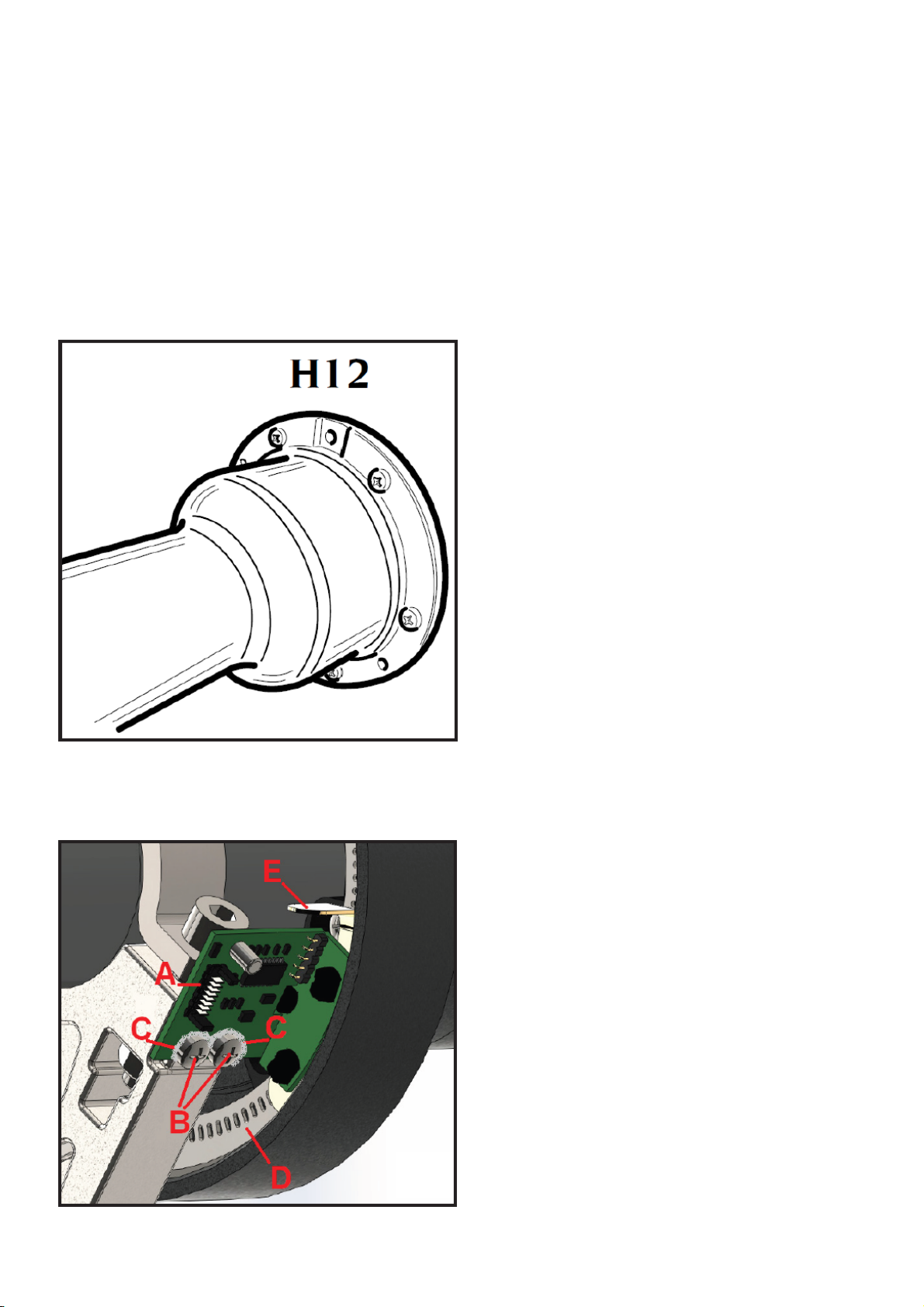

- warns of air in the cylinder when the wheel is clamped. To check, disconnect the pipe (A, Fig.21); there should only be a very small quantity of

residual air in the release circuit. If this is not the case, modify the pneumatic circuit with the kit P/N 5-107159.

If the above checks have produced a favourable result, replace the swinging unit and, if necessary, check for any noise from the bearings.

It is impossible to balance the wheel: applying the weights indicated by the wheel balancer, and performing a check spin, new unbalance values appear at

random

Make the checks listed in the previous point.

Check also:

• that the geometric dimensions set are correct;

• the machine is not out of calibration (carry out the sensitivity calibration procedure);

- the anchor, fixed to the hub, does not touch the brake during the signal reading phase

• the cable connecting the search board (encoder) to the main board is correctly inserted and wired;

• the search board (encoder) is working correctly (via the values visualised in service - see the paragraph “Service programmes”). An operational

defect in the search board prevents the machine from correctly calculating the position of the unbalances. In this case it is necessary to check:

• that the photodiodes of the search card are clean;

• the mechanical adjustment of the fork in relation to the search disk.

If the irregularity persists, replace the search board and, if necessary, the search disk (if damaged).

If the fault still does not disappear, replace the main board.

The motor remains activated, keeping the wheel in traction, and the current spin does not end

Perform all checks on the Mother board that were listed in the previous point.

Probably, the relay “RL2” which is used to power the spin motor does not function correctly, i.e. it remains activated permanently. In that case,

replace the PEAL32F power supply card.

If instead after sampling (i.e. acquisition of wheel unbalance signals)in fall, the machine continues to spin the wheel instead of braking, check

the operation of the relay “RL1” which inverts the current for braking.

If the relay functions correctly, at the beginning of braking, you will hear a mechanical tone coming from the power supply card. Otherwise,

replace the PEAL32F power supply card.

During a spin:

• unknown characters appear on the monitor;