Tolomatic IMA Series User manual

2700-4001_22 IMA Manual 1 Last Revision: 12/14/2021

MANUAL

For Installation, Maintenance

and Operation

IMA Series Actuators

LINEAR SOLUTIONS MADE EASY

2700-4001_22 IMA Manual 2 Last Revision: 12/14/2021

Original instructions in English. Translations in community languages supplied as required.

Information furnished is believed to be accurate and reliable. However, Tolomatic assumes no responsibility for its

use or for any errors that may appear in this document.

Tolomatic reserves the right to change the design or operation of the equipment described herein and any

associated motion products without notice. Information in this document is subject to change without notice.

2700-4001_22 IMA Manual 3 Last Revision: 12/14/2021

CONTENTS

CONTENTS....................................................................................................................................................................................3

LIST OF FIGURES & TABLES ......................................................................................................................................................5

1: SAFETY .....................................................................................................................................................................................7

•1.0 SAFETY ......................................................................................................................................................................7

•1.1 SAFETY SYMBOLS .......................................................................................................................................................7

•1.2 SAFETY CONSIDERATIONS ...........................................................................................................................................8

2: IMA PRODUCT OVERVIEW....................................................................................................................................................10

•2.0 GENERAL DESCRIPTION.............................................................................................................................................10

•2.1 PRODUCT FEATURES.................................................................................................................................................10

•2.2 INSTALLATION ...........................................................................................................................................................10

•2.3 CABLE ROUTING........................................................................................................................................................11

•2.4 ACTUATOR ORIENTATION...........................................................................................................................................11

•2.5 EMC WIRING GUIDELINES .........................................................................................................................................12

•2.6 MOTION CONTROL SYSTEM SELECTION RECOMMENDATIONS.......................................................................................12

•2.7 IDENTIFICATION LABEL...............................................................................................................................................12

•2.5 CERTIFICATION .........................................................................................................................................................12

•2.6 MANUFACTURER .......................................................................................................................................................12

3: IMA ACTUATOR PRODUCT CONFIGURATION....................................................................................................................13

•3.1 TOLOMATIC IMA ACTUATOR SERIES CONFIGURATION .................................................................................................13

•3.2 STANDARD CONFIGURATIONS AND OPTIONS................................................................................................................13

•3.2.1 SCREW SELECTION ................................................................................................................................................15

•3.2.2 MOTOR VOLTAGE...................................................................................................................................................15

•3.2.3 INTERNAL HOLDING BRAKE OPTION.........................................................................................................................15

•3.2.4 STANDARD MOUNTING OPTIONS .............................................................................................................................15

•3.2.5 MOUNTING OPTIONS ..............................................................................................................................................15

•3.2.6 STANDARD ROD END..............................................................................................................................................15

•3.2.7 ROD END OPTIONS ................................................................................................................................................16

•3.2.8 OTHER OPTIONS ....................................................................................................................................................16

•3.2.9 SPECIAL OPTIONS ..................................................................................................................................................16

•3.2.10 FEEDBACK DEVICE ...............................................................................................................................................16

•3.2.11 CABLE &CONNECTOR(S)......................................................................................................................................16

•3.2.12 SERVO DRIVE ......................................................................................................................................................17

•3.2.13 ROCKWELL AUTOMATION PARTNERNETWORK™PROGRAM....................................................................................17

4: IMA MECHANICAL INSTALLATION ......................................................................................................................................18

•4.1 TOLOMATIC IMA ACTUATOR SYSTEM CONFIGURATION ................................................................................................18

•4.2 GENERAL OPERATION ...............................................................................................................................................18

•4.3 COLD TEMPERATURE STARTUP PROCEDURE ..............................................................................................................19

•4.4 PLANNING YOUR INSTALLATION..................................................................................................................................19

•4.4.1 ALIGNMENT............................................................................................................................................................20

•4.4.2 SIDE LOAD CONSIDERATIONS..................................................................................................................................20

•4.5 MECHANICAL INSTALLATION INSTRUCTIONS.................................................................................................................20

•4.6 MOUNTING................................................................................................................................................................22

•4.5 FIELD INSTALLATION OF ARO (ANTI ROTATION)OPTION..............................................................................................23

5: ELECTRICAL INSTALLATION ...............................................................................................................................................25

•5.1 CONNECTOR ORIENTATION........................................................................................................................................25

2700-4001_22 IMA Manual 4 Last Revision: 12/14/2021

•5.2 FEEDBACK INFORMATION ...........................................................................................................................................25

•5.3 FEEDBACK COMMUTATION .........................................................................................................................................26

•5.4 FEEDBACK COMMUTATION DETAILS............................................................................................................................26

•5.5 FEEDBACK SPECIFICATIONS.......................................................................................................................................29

•5.6 THERMAL SENSOR SPECIFICATIONS ...........................................................................................................................30

•5.7 CONNECTOR PINOUTS...............................................................................................................................................31

•5.7.1 TOLOMATIC STANDARD -DT1 .................................................................................................................................31

•

5.7.2

A

LLEN

B

RADLEY

MP

M

OTOR

S

ERIES

-

DA1

.............................................................................................................36

•

5.7.3

A

LLEN

B

RADLEY

VP

M

OTOR

S

ERIES

-

DA2

..............................................................................................................37

•

5.7.4

B

OSCH

R

EXROTH

MSK

M

OTOR

S

ERIES

-

DB1

.........................................................................................................38

•

5.7.5

C

ONTROL

T

ECHNIQUES

FM

M

OTOR

S

ERIES

-

DE1

..................................................................................................39

•

5.7.6

C

ONTROL

T

ECHNIQUES

NT

M

OTOR

S

ERIES

-

DE2

...................................................................................................41

•

5.7.7

L

ENZE

MCS

M

OTOR

S

ERIES

-

DL1

.........................................................................................................................42

•

5.7.8

S

IEMENS

1F

M

OTOR

S

ERIES

-

DS1

.........................................................................................................................44

6: IMA OPERATION AND START UP CONSIDERATIONS .......................................................................................................45

•6.1 ATTACHING CABLES &HOMING /MECHANICAL TRAVEL LIMITS.....................................................................................45

•6.2 BRAKE......................................................................................................................................................................45

7: IMA REPAIR AND MAINTENANCE........................................................................................................................................47

•7.1 LUBRICATION ............................................................................................................................................................47

•7.2 PERIODIC MAINTENANCE ...........................................................................................................................................47

•7.3 PROCEDURE FOR LUBRICATION ..................................................................................................................................50

•7.4 TOLOMATIC IMA MAINTENANCE AND REPAIR ..............................................................................................................50

•7.5 STORAGE RECOMMENDATIONS ..................................................................................................................................52

APPENDIX A: SPECIFICATIONS ...............................................................................................................................................53

•A.1 ACTUATOR SPECIFICATIONS ......................................................................................................................................53

•A.2 MOTOR SPECIFICATIONS:..........................................................................................................................................53

•A.3 BRAKE SPECIFICATIONS ............................................................................................................................................53

•A.4 SPEED VS THRUST GRAPHS ......................................................................................................................................53

•A.5 CALCULATING RMS THRUST AND VELOCITY FOR CONTINUOUS DUTY: .........................................................................53

•A.6 CRITICAL SPEED .......................................................................................................................................................54

•A.7 BALL &ROLLER SCREW LIFE.....................................................................................................................................54

•A.8 STANDARD THERMAL SWITCH SPECIFICATIONS............................................................................................................54

APPENDIX B: TROUBLESHOOTING PROCEDURE.................................................................................................................55

APPENDIX C: WARRANTY ........................................................................................................................................................56

•C.1 WARRANTY ..............................................................................................................................................................56

APPENDIX D: DECLARATION OF CONFORMITY ....................................................................................................................58

2700-4001_22 IMA Manual 5 Last Revision: 12/14/2021

LIST OF FIGURES &TABLES

Figure 1.1: Do not carry IMA by connectors or cables. ..................................................................................................................9

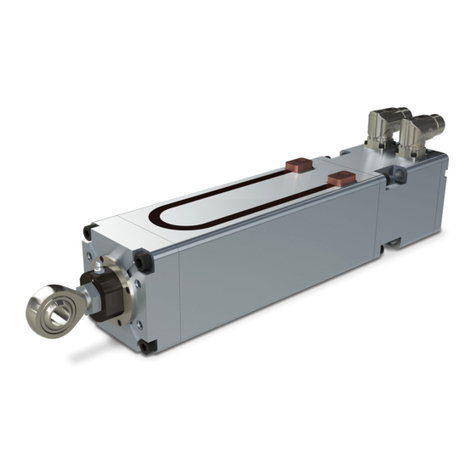

Figure 2.1: Tolomatic IMA Actuator ..............................................................................................................................................10

Figure 2.2: IMA major components ..............................................................................................................................................10

Figure 2.3: Recommended routing of Tolomatic IMA Actuator cabling. .......................................................................................11

Figure 2.4: 1. & 2. Recommended IMA thrust rod orientation is down or horizontal. 3. Due to increased risk of contamination

and ingress never orient the IMA actuator with the thrust rod up.................................................................................................11

Figure 2.2: Tolomatic IMA Actuator identification label. ...............................................................................................................12

Figure 3.1: Tolomatic IMA Actuator ordering codes and descriptions..........................................................................................14

Figure 3.2: Standard mounting for the IMA is four (4) threaded holes on the front face (rod end) of the actuator.......................15

Figure 3.3: Optional mounting for the Tolomatic IMA Actuator.....................................................................................................15

Figure 3.4: Standard rod end for the IMA is internal threads........................................................................................................15

Figure 3.5: Rod End Options for the Tolomatic IMA Actuator ......................................................................................................16

Figure 3.5: Rod End Options for the Tolomatic IMA Actuator ......................................................................................................16

Figure 4.1: Typical connections for a single-axis system with an Tolomatic IMA Actuator with optional brake to a RSW servo

system drive .................................................................................................................................................................................18

Figure 4.2: Side load must not exceed maximum values represented by the lines in the graph..................................................20

Figure 4.3: Do not carry IMA by connectors or cables. ................................................................................................................21

Figure 4.4: Use straps and winch to position heavy IMA actuator................................................................................................21

Figure 4.5: Hold thrust rod stationary using a wrench on the flats of the rod end when attaching accessories, linkages or load to

the actuator. Two wrenches are used here: The crescent wrench prevents the thrust rod from rotating, the torque wrench will

fasten the spherical rod eye option to the actuator rod end. Torque values provided in Table 4.1 ..............................................22

Table 4.1: Rod end torque recommendations ..............................................................................................................................22

Table 4.2: Tapped hole torque recommendations........................................................................................................................23

Table 4.3: Mounting Plate (MP2) Clearance Hole Bolt and Torque Requirements (Minimum Fastener Grade 8.8)....................23

Table 4.4: Front Flange Mount (FFG) Clearance Hole Bolt and Torque Requirements (Minimum Fastener Grade 8.8).............23

Figure 4.6: View of ARO (Anti Rotate Option)..............................................................................................................................23

Figure 5.3: Connector rotation. Note that the Tolomatic standard connectors may be rotated from -90° to +180° allowing for

cables to connect toward the front (rod end, as manufactured), to either side, both sides, or back of actuator. .........................25

Figure 5.4: Drawing of box mount connectors used on some Tolomatic IMA Actuators. .............................................................25

2700-4001_22 IMA Manual 6 Last Revision: 12/14/2021

Figure 5.5: Thrust rod movement relative to motor rotation .........................................................................................................26

Figure 5.6: Back EMF Voltage vs Electrical Angle .......................................................................................................................27

Figure 5.7: Back EMF Voltage Phase to Phase vs Electrical Angle.............................................................................................27

Figure 5.8: Hall Alignment ............................................................................................................................................................28

Figure 5.9: Motor rotational position at 0......................................................................................................................................28

Figure 5.10: Motor rotational position at 90..................................................................................................................................29

Figure 6.1: Fastest Engage / Disengage time, least protection....................................................................................................45

Figure 6.2: Increased Engage / Disengage time, best protection.................................................................................................46

Figure 7.1: Roller Screw Lubrication Interval Graph.....................................................................................................................48

Figure 7.1: A standard grease zerk allows periodic relubrication for Tolomatic IMA Actuators. This can be done without

removing the actuator from its installation. ...................................................................................................................................50

2700-4001_22 IMA Manual 7 Last Revision: 12/14/2021

1: SAFETY

1.0 Safety

1.1 Safety Symbols

General

Read completely through the applicable sections of the manual before the equipment/unit is unpacked, installed or

operated. Pay careful attention to all of the dangers, warnings, cautions and notes stated in the manual.

Serious injury to persons or damage to the equipment may result if the information in the manual is not followed.

Safety Symbols

Items that are specifically marked DANGER, WARNING, CAUTION, PROHIBITIVE, MANDATORY ACTION, or

NOTE! are arranged in a hierarchical system and have the following meaning:

Indicates a very hazardous situation which, if not avoided, could result in death or serious injury. This signal word

is limited to the most extreme situations.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in property damage, minor or moderate

injury.

Indicates Prohibited Action

Indicates Mandatory Action

Information that requires special attention is stated here.

WARNING! Normal operating temperature of weld actuator can range from 135 degrees F (57°C) to 175 degrees

F (79°C).

2700-4001_22 IMA Manual 8 Last Revision: 12/14/2021

1.2 Safety Considerations

Proper and Safe Use of Product

Fail Safe e-Stop Recommendations

A means for a fail safe e-stop is highly recommended to ensure equipment and personal safety. The e-stop should

provide a means to remove main power from the actuator to cease and prevent any unwanted motion.

Device Damage Prevention

To prevent permanent damage to the device, proper care should be taken not to exceed published voltage,

current, temperature, and load/force ratings. In addition, proper mechanical assembly and proper wiring should be

verified and safety measures checked before applying power to the complete equipment package.

The only field maintenance that may be performed on the IMA include lubrication and replacement of the rod wiper.

All other repair or maintenance for the IMA must be performed at Tolomatic.

Personal Safety

During normal operation the actuator can become hot, especially the motor housing. It is highly recommended to

display proper safety notices and implement proper safety measures to prevent contact with hot surfaces. In

addition, the case ground should be tied to an earth ground to prevent the presence of case voltage.

During normal operation, the actuator rod travels in and out creating a possible pinch point.

Proper guarding and signage must be used prevent entry into possible pinch zones and contact with hot surfaces.

It is highly recommended to display proper safety notices and implement proper safety measures to prevent

contact with hot surfaces.

Handling and Unpacking

When unpacking and handling the actuator, care should be taken not to drop the actuator as this can damage the

connectors, internal electronics, or cause misalignment of the actuator feedback device. Damage the internal

mechanical components may cause poor performance or render the actuator non-functional. Since this is an

electromechanical device, proper ESD measures should be taken to avoid static electricity from contacting the

signal and power lines of the device. as this can damage the internal mechanical components rendering the

actuator damaged or non-functional.

Packing and Transport

Package actuator to prevent damage during transport. It is recommended that the actuator be returned in its

original packaging. If the original packaging is not available, the follow these recommendations.

1. Foam in place if possible.

2. Reinforce ends of box with multiple layers of cardboard or wood to prevent the actuator

from breaking through the packaging during shipment.

3. Support the connectors or cables so that enough packaging or foam is in place to

prevent shipping damage.

4. It is best to ship one unit per container because individual items that are not isolated

with stable packaging (foam in place) from each other often get damaged during

shipment.

5. When shipping more than one unit in a single container, it is recommended to foam in

place to prevent damage during shipping to both the units and the packaging.

6. Add the RMA on the outside of the packaging. Failure to do so will delay processing.

2700-4001_22 IMA Manual 9 Last Revision: 12/14/2021

Figure 1.1: Do not carry IMA by connectors or cables.

The Tolomatic IMA Actuator weight range is approximately 3.0 to 42 kg ( 6.6 to 93 lb). Special care must be taken

when lifting this device. Do not carry by the connectors or cables. The connectors are not rated to support the

weight of the actuator.

Modifications to the Equipment

The manufacturer takes no responsibility whatsoever if the equipment is modified or if the equipment is used in any

way beyond performance specifications. Unauthorized modifications or changes to the equipment are strictly

forbidden, and void all warranties.

Repair and Maintenance

All power and supply media must be shut OFF before any work is performed on any equipment that is associated

with the Tolomatic IMA Actuator. The only field maintenance that may be performed on the Tolomatic IMA Actuator

is lubrication. All other repair or maintenance for the Tolomatic IMA Actuator must be performed at Tolomatic.

Requirement Regarding Personnel

All personnel must be completely informed regarding all safety regulations and the function of the equipment.

Risk Area and Personnel

When installed, pinch points are generated capable of high damaging forces. The risk area surrounding the

Tolomatic IMA Actuator must either be enclosed or clearly marked, including display signage in accordance with all

applicable national and international legal requirements. The risk area must be protected by a safety system that

stops the equipment if anyone enters the risk area. Personnel who enter the risk area must be authorized, trained

and qualified for the different tasks inside the risk area.

2700-4001_22 IMA Manual 10 Last Revision: 12/14/2021

2: IMA PRODUCT OVERVIEW

2.0 General Description

Tolomatic IMA Actuators

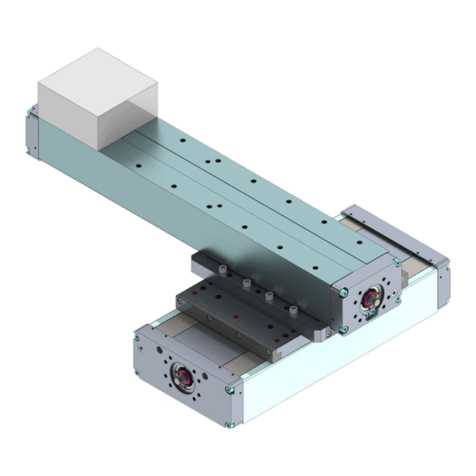

Figure 2.1: Tolomatic IMA Actuator

The IMA is a compact, durable, high force rod-style actuator. The IMA integrates a servo motor into the mechanical

design to minimize the overall envelope. The patented design allows for easy re-lubrication without disassembly for

extremely long service life.

2.1 Product Features

Figure 2.2: IMA major components

2.2 Installation

The IMA is a compact high force screw drive servo actuator. The IMA provides linear motion of the moveable rod

2700-4001_22 IMA Manual 11 Last Revision: 12/14/2021

developing the required thrust force and velocity in a variety of applications.

Before installation and commissioning of the equipment, this manual and all accompanying manufacturer

documents and manuals MUST be completely read by the appropriate personnel. All warning texts must be given

special attention.

2.3 Cable Routing

It is recommended that the power and signal cables for Tolomatic IMA Actuators be routed as far apart as possible

to minimize electrical noise in communication cables.

Over time, liquid contaminants such as oil and cleaning solutions may accumulate on the cables and into the

connectors if they are an exposed type. To minimize the introduction of contaminants to the connector, route the

cables so that there is a loop in the cable just prior to its attachment to the connector.

Examples are shown depending on the orientation of the connectors. Units mounted in such a way that the

connectors are on the bottom surface of the actuator require no looping.

Figure 2.3: Recommended routing of Tolomatic IMA Actuator cabling.

The standard cables from Tolomatic are not flex rated and have a minimum bend radius of 3.75 in (95mm). Any

repeated flexing or excessive bending can result in broken conductors and intermittent faults.

2.4 Actuator Orientation

1. Rod End Down (Best) 2. Rod End Horizontal (Good) 3. Rod End Up (Never)

It is not recommended to mount the IMA with the thrust rod pointing upwards. Mounting the thrust rod vertically

increases risk of contamination and ingress..

Figure 2.4: 1. & 2. Recommended IMA thrust rod orientation is down or horizontal. 3. Due to increased risk of

contamination and ingress never orient the IMA actuator with the thrust rod up.

2700-4001_22 IMA Manual 12 Last Revision: 12/14/2021

2.5 EMC Wiring Guidelines

Shielding and grounding

Tolomatic supplied cables have the proper shielding and are recommended for proper installation. If additional or

alternate cables are require, braided shield cables are recommended. The standard cables provided by Tolomatic

have an overall braided shield. To minimize EMI and ensure system reliability, all shield drain wires from all cables

should be tied to a common earth ground. Also, make sure to follow the drive manufacturer’s recommendations on

proper cable dressing, shield and ground connections to ensure reliable operations. To minimize EMI and ensure

system reliability, shield drain wires from all cables should be tied to a common earth ground.

Thrust rod is not electrically connected to ground. The thrust rod should be earth grounded during installation for

safety when possible.

2.6 Motion Control System Selection Recommendations

It is recommended that all servo drives be selected based on the following important parameters:

a) CE and UL approved system

b) Thermal switch input

c) Servo drive sizing key parameters for IMA-S

i) Peak current

ii) Voltage

iii) Peak RPM

iv) Max current switching frequency

2.7 Identification Label

Figure 2.2: Tolomatic IMA Actuator identification label.

Do not remove the identification label. Do not render it unreadable.

2.5 Certification

2.6 Manufacturer

Tolomatic, Inc.

3800 County Road 116, Hamel, MN 55340, USA

Phone: 763-478-8000

Sales@Tolomatic.com

2700-4001_22 IMA Manual 13 Last Revision: 12/14/2021

3: IMA ACTUATOR PRODUCT CONFIGURATION

3.1 Tolomatic IMA Actuator Series Configuration

Tolomatic IMA Actuator Product Overview

•Four sizes: IMA22, IMA33, IMA44, IMA55

•Ball Screw Options: 5, 10, 20 and 25 mm lead

•Roller Screw Options: 4, 5 and 10 mm lead

•Motor windings: 230 Vac & 460 Vac

•IP65 standard; IP67 optional

•External Anti-Rotate

•Feedback choices (but not limited to):

- Digital Incremental

- Multi-turn Absolute Encoder

- Resolver

•Connector choices (but not limited to):

- DT1: Tolomatic Standard

- DE1: Nidec/Control Tech., FM

- DE2: Nidec/Control Tech., NT

- DA1: Allen Bradley MP

- DA2: Allen Bradley VP

- DB1: Bosch Rexroth MSK

- DL1: Lenze MCS

- DS1: Siemens 1F

For performance data and specifications please refer to the Tolomatic IMA Actuator brochure #2700-4000

3.2 Standard Configurations and options

NOTE Please see Tolomatic IMA Actuator brochure #2700-4000 for complete information on ordering codes. Use

3D CAD files (available at www.tolomatic.com) for critical dimensions.

2700-4001_22 IMA Manual 14 Last Revision: 12/14/2021

Figure 3.1: Tolomatic IMA Actuator ordering codes and descriptions

2700-4001_22 IMA Manual 15 Last Revision: 12/14/2021

3.2.1 Screw Selection

Tolomatic IMA Actuator: RN04, RN05, RN10: Roller nuts with 4mm, 5mm or 10 mm lead.

BN05, BN10, BN20, BN25: Ball nuts with 5mm, 10mm, 20mm or 25mm lead

Contact Tolomatic for application review and assistance in selecting a screw technology.

3.2.2 Motor Voltage

Available with 230 Vac or 460 Vac. With 1, and 3 stack windings.

Contact Tolomatic for application review and assistance in selecting voltage and windings.

3.2.3 Internal Holding Brake Option

N=No Brake, B=24V Brake, 3= A spring held electronically released holding brake (parking brake) is available. The

holding force of the brake is capable of holding the continuous force of the actuator. The brake is spring set and

releases when voltage is applied to the brake. A separate power source is required.

3.2.4 Standard Mounting Options

Figure 3.2: Standard mounting for the IMA is four (4) threaded holes on the front face (rod end) of the actuator.

Standard mounting for the IMA is four (4) threaded holes on the front face (rod end) of the actuator. There are also

Side Mounting Holes, 2 sides & bottom (no photo)

3.2.5 Mounting Options

Other mounting options include: Side mounting holes (a total of 12 mounting holes on both sides and bottom of

actuator), mounting plates, rear clevis, front flange, front trunnion and rear trunnion.

Mounting Plates

Rear Clevis

Front Flange

Trunnion, Rear or Front

Figure 3.3: Optional mounting for the Tolomatic IMA Actuator

3.2.6 Standard Rod End

Figure 3.4: Standard rod end for the IMA is internal threads.

2700-4001_22 IMA Manual 16 Last Revision: 12/14/2021

3.2.7 Rod End Options

Other rod end options include: External threads, clevis, spherical eye and alignment coupler.

External Threads

Clevis

Spherical Eye

Alignment Coupler*

Figure 3.5: Rod End Options for the Tolomatic IMA Actuator

NOTE: ALC (Alignment Coupler) requires ARO (Anti-Rotate) for proper operation.

3.2.8 Other Options

Other IMA options available are: IP67 rating for protection against water and dust ingress; anti rotate option

The IMA is available with a standard ingress rating of IP65. The IP67 option can be added to help further protect

against water and dust ingress.

IP67

ARO Anti Rotate

For protection against water

and dust ingress

Cables

• Signal Cable (6m)

• Power Cable (6m)

Figure 3.5: Rod End Options for the Tolomatic IMA Actuator

3.2.9 Special Options

Include: Longer stroke length other than standard; White Paint; Food Grade Grease; Hex Rod; Special Options

3.2.10 Feedback Device

Contact Tolomatic for application review and assistance in selecting feedback device. The IMA is offered with the

following feedback device technologies as standard: Incremental, Resolver, and SICK Hiperface, SICK Hiperface

DSL, and Heidenhain EnDat 2.2 multi-turn absolute feedback devices.

3.2.11 Cable & Connector(s)

Connectors are matched to selected feedback device. Contact Tolomatic for application review and assistance in

selecting feedback device.

Cable Leads Information

CR5 and CR10: Cables are matched for each feedback / motor combination in 5 and 10 meter lengths.

In applications with lengths exceeding 10 meters for both feedback and power cables, there will be potential for

2700-4001_22 IMA Manual 17 Last Revision: 12/14/2021

issues related to excessive feedback noise and partial discharge inception voltage (PDIV) that can break down the

servo motor's insulation system eventually causing shorts.

3.2.12 Servo Drive

The Tolomatic IMA Actuators functions in the same way as a brushless servo motor. A servo drive is used to

power and control the actuator. Please consult the servo drive manufacturer when sizing and selecting a servo

drive for use with Tolomatic IMA Actuator.

The Tolomatic IMA Actuator must be ordered with all desired options. Field installation of options generally cannot

be done. Call Tolomatic for complete details.

3.2.13 Rockwell Automation PartnerNetwork™ Program

Bronze Technology Partner

Tolomatic has aligned with Rockwell to provide customers with the best automation solutions for their motion

control applications. Through the Encompass third-party product referencing program, you can quickly locate

products that best solve your application challenges. Available Tolomatic products include the RSA, GSA, ERD,

and IMA electric rod actuators and the MXE rodless screw drive and MXB rodless belt drive actuators. All these

products are compatible with Rockwell Automation's servo products and extended motion control solutions. Visit

Rockwell's PartnerNetwork™ Encompass program site for more information.

Enabled™ Technology Licensing Partner

The Rockwell Automation Enabled Technology partnership ensures that Tolomatic's IMA integrated servo motor

actuators perform with the same compatibility as Rockwell servo motors. The results are the ability to integrate the

Rockwell architecture to a larger variety of products to better service our customer base.

Tolomatic Resources

For additional information regarding the integration of the IMA to an Allen Bradley/Rockwell drive see:

TECH NOTE: Interfacing the Tolomatic IMA Actuator and Absolute Encoder with Allen Bradley Servo Drives:

https://www.tolomatic.com/info-center/resource-details/324

SOFTWARE: IMA-Rockwell CMF (blb file) Import Tool: https://www.tolomatic.com/information-center/resource-

details/687

TECH NOTE: IMA-Rockwell Logix CMF (blb file) File Import Instructions: https://www.tolomatic.com/info-

center/resource-details/688

2700-4001_22 IMA Manual 18 Last Revision: 12/14/2021

4: IMA MECHANICAL INSTALLATION

Before installation and commissioning of the equipment, this manual and all accompanying manufacturer

documents and manuals MUST be completely read by the appropriate personnel. All warning texts must be given

special attention.

4.1 Tolomatic IMA Actuator System Configuration

Tolomatic IMA Actuator series actuators incorporate an integral brushless servo motor. The design of the motor

with the proper feedback device allows the IMA to be powered by nearly every brand of brushless drive on the

market. This flexibility allows the IMA actuator to be used in the highest performing single and multi-axis motion

control systems. It is recommended that all servo amplifiers and drives be selected based on the following

important parameters:

a) CE and UL approved system

b) Thermal switch input

c) Drive sizing key parameters for Tolomatic IMA Actuator

i) Peak current ii) Voltage

iii) Peak RPM iv) Max current frequency

Figure 4.1: Typical connections for a single-axis system with an Tolomatic IMA Actuator with optional brake to a

RSW servo system drive

4.2 General Operation

General Operation

The IMA actuator functions by translating the rotary motion of the integral brushless servo motor into linear motion

using a screw mechanism. The linear travel, speeds and forces are controlled in conjunction with a brushless

servo drive.

When ordered the IMA actuator can be configured with any one of the following feedback devices: Digital encoder,

resolver, multi-turn absolute encoder. Please confirm you are using a version of software that supports the correct

feedback device and operation of IMA actuators.

The relationship between the rotary motion of the motor and the linear motion of the actuator corresponds to the

following relationships:

2700-4001_22 IMA Manual 19 Last Revision: 12/14/2021

Linear distance traveled = (motor revolutions) * (screw lead)

Linear Speed = ([motor RPM]/60) * (screw lead)

Linear Thrust (kN) = Motor torque (Nm) * 2 * π * pitch (rev/mm) * screw efficiency

or

Linear Thrust (lbf) = Motor torque (in•lb) * 2 * π * pitch (rev/in) * screw efficiency

Motor RMS current must be maintained at a level below the continuous current rating of the Tolomatic IMA

Actuator or damage to the motor stator will result.

The peak current setting must be maintained at a level below the peak current rating of the Tolomatic IMA Actuator

or damage to the motor stator will result.

Care should be taken to not exceed the physical travel limits of the Tolomatic IMA Actuator. Doing so will cause the

actuator to reach mechanical end of stroke internally. Although protected by the end of stroke bumpers, repeatedly

reaching internal end of stroke can physically damage the screw and the internal components of the actuator.

Power and Feedback cable lengths shall not exceed 10 meters. If the application requires cable lengths longer

than 10 meters, please contact Tolomatic engineering for review.

4.3 Cold Temperature Startup Procedure

If startup ambient temperature is between 0-10 degrees Celsius, it is recommended to cycle the Tolomatic IMA

Actuator (see recommended motion profile below) to bring the temperature up to operating temperature before

proceeding with operating or calibrating the system. Initiating this startup procedure will lower the friction caused by

cold temperatures and result in more accurate calibration of the system and better force repeatability performance

during operation. If a motion profile other than recommended below will be used for the Cold Temperature Startup

Procedure, contact Tolomatic for review of the motion profile before operating the actuator.

Recommended Motion Profile:

•Extend & retract full stroke of actuator at linear speed of 150 mm/sec for 5 or 4 mm lead screws and 300

mm/sec for 10 mm lead screws

•Dwell 1 second

•Repeat 75 times

4.4 Planning Your Installation

To operate the actuator in compliance with the relevant safety regulations maximum performance limits must be

observed.

When mounting your actuator in vertical or inclined positions be sure to include safety measures that control the

2700-4001_22 IMA Manual 20 Last Revision: 12/14/2021

working mass should the drive screw fail. Uncontrolled moving masses can cause injury or damage to property. If

the screw drive fails, due to wear or excessive load, gravity may cause the working mass to drop.

For bench or fixture setup and testing of Tolomatic IMA Actuators, the actuator thrust rod must be anti-rotated by a

fixture and the actuator securely retained to the bench or fixture. Never use a hand held wrench/device to provide

the anti-rotate function while the motor is powered as contact with the internal end of stroke may send the

wrench/device flying and may harm the operator or damage the actuator.

4.4.1 Alignment

Alignment of the actuator with respect to the application load and axis of motion is essential to minimize side

loading. The IMA is not meant to be used in applications where side loading occurs as side loading will reduce the

life of the actuator and rod seals.

4.4.2 Side Load Considerations

Excessive side load on the output thrust rod of the actuator will dramatically reduce the life of the actuator and

should be avoided. Side load can be caused from misalignment or loading that is not inline with the actuator output

thrust rod.

The graph shows the maximum side load values for the Tolomatic IMA Actuators. Measures shall be established to

limit any side loading that exceeds these values.

For maximum service life, external guiding is recommended to minimize side loading to the thrust rod and provide

consistent alignment throughout service life.

Figure 4.2: Side load must not exceed maximum values represented by the lines in the graph

4.5 Mechanical Installation Instructions

1. Remove packaging

2. Carefully remove linear actuator from package. *Consider the weight of the actuator. Depending on the

configuration, the actuator can weight up to approximately 42 kg (92.6 lb)

Table of contents

Other Tolomatic Controllers manuals

Tolomatic

Tolomatic RSX User manual

Tolomatic

Tolomatic ACS Manual

Tolomatic

Tolomatic 3604-9651 Manual

Tolomatic

Tolomatic ServoWeld CSW Owner's manual

Tolomatic

Tolomatic SmartActuator Series User manual

Tolomatic

Tolomatic MXP16P Series User manual

Tolomatic

Tolomatic TRS Series User manual

Tolomatic

Tolomatic BCS10 Operator's manual

Tolomatic

Tolomatic ACS Manual

Tolomatic

Tolomatic Axidyne AXIOM PLUS PV Series User manual