Operating Instructions

ICR845-2

8012377/0000/2008-01-30

©SICK AG·Division Auto Ident ·Germany·All rights reserved 3

Contents

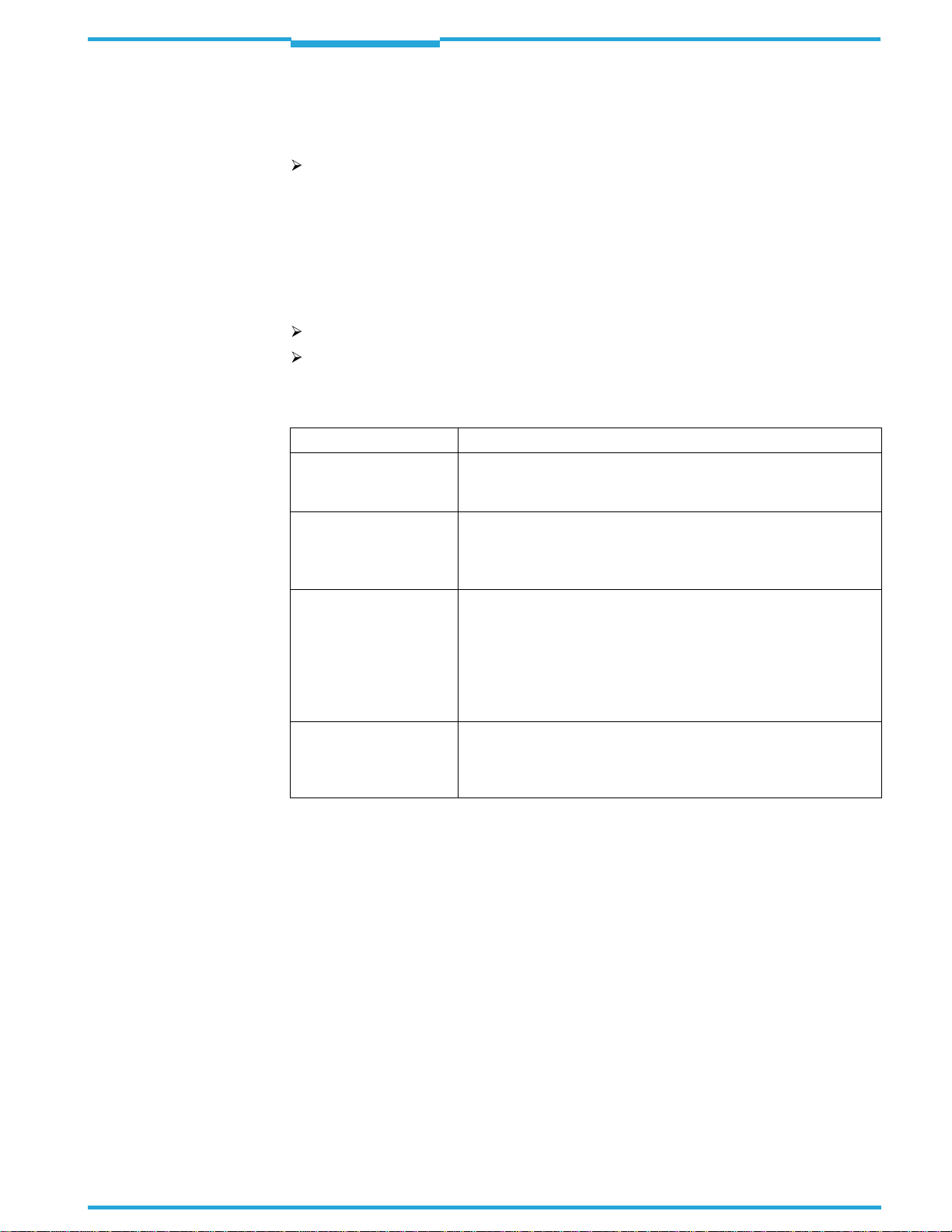

Table of Contents

1 Noteson this document.................................................................................................7

1.1 Purpose.....................................................................................................................

....7

1.2 Target group................................................................................................................

.7

1.3 Depth of information ...................................................................................................7

1.4 Used symbols...............................................................................................................8

2 SafetyInformation..........................................................................................................9

2.1 Authorized users..........................................................................................................9

2.2 Intended use................................................................................................................9

2.3 General safetyprecautions and protection measures...........................................10

2.4 Quick stop and quick restart....................................................................................12

2.5 Environmental information.......................................................................................12

3 Product description......................................................................................................13

3.1 Design of device........................................................................................................13

3.2 System requirements...............................................................................................16

3.3 Product features and functions(overview).............................................................16

3.4 Method of operation.................................................................................................18

3.5 Indicators and control elements..............................................................................20

4 Installation ....................................................................................................................23

4.1 Overviewof installation sequence...........................................................................23

4.2 Installation preparations..........................................................................................23

4.3 Installation location..................................................................................................25

4.4 Installing and adjustingthe ICR845-2.....................................................................29

4.5 Installingexternal components................................................................................29

4.6 Removing the device................................................................................................30

5 Electrical installation...................................................................................................31

5.1 Overviewof the installation sequence....................................................................31

5.2 Electrical installation preparations..........................................................................31

5.3 Electrical connections and cables...........................................................................33

5.4 Pin assignments........................................................................................................36

5.5 Performingelectrical installation.............................................................................37

5.6 Pin assignment and wire coulou

r assignment of pre-fabricated

cables with open ends..............................................................................................45

6 Startup and configuration...........................................................................................47

6.1 Overviewot the startup procedure..........................................................................47

6.2 CLV-Setup configuration software...........................................................................47

6.3 Establish communication with the ICR845-2 .........................................................48

6.4 The image transfer program ImageFTP...................................................................58

6.5 Usingthe function key..............................................................................................68

6.6 First startup...............................................................................................................

69

6.7 Establish communciation with theICR845-2 manually.........................................70

6.8 Configuringthe ICR845-2.........................................................................................71

6.9 Operatingmodes and outputtingthe readingresult..............................................74

6.10 ICR845-2 messages.................................................................................................89

6.11 Default settings.........................................................................................................91

6.12 Adjustingthe ICR845-2............................................................................................93

6.13 Configuration guide..................................................................................................94

6.14 Switchingthe ICR845-2 off....................................................................................100

7 Maintenance...............................................................................................................101

7.1 Maintenance duringoperation ..............................................................................101

7.2 Cleaningthe ICR845-2 ...........................................................................................101

7.3 Checkingthe incremental encoder........................................................................103

7.4 Replacingan ICR845-2 ..........................................................................................103

7.5 Disposal...................................................................................................................1

04

8 Troubleshooting..........................................................................................................105

8.1 Overview of errors and malfunctionswhich could occur.....................................105