4.3.2 Minimum distance from the hazardous point....................... 28

4.3.3 Minimum distance to reflective surfaces............................... 31

4.3.4 Protection against interference from systems in close prox‐

imity to each other................................................................... 33

4.3.5 Reduced resolution................................................................. 38

4.3.6 Muting....................................................................................... 39

4.3.7 Smart Box Detection................................................................ 47

4.4 Integration in electrical control................................................................ 54

4.4.1 Restart interlock...................................................................... 56

4.4.2 External device monitoring (EDM).......................................... 57

4.4.3 Application diagnostic output................................................. 58

4.4.4 Signal lamp.............................................................................. 58

4.4.5 Connection of sender and receiver........................................ 59

4.4.6 Laser alignment aid................................................................. 60

4.4.7 Cascading................................................................................. 61

4.4.8 Smart presence detection....................................................... 64

4.4.9 IO-Link...................................................................................... 64

4.4.10 Muting....................................................................................... 64

4.4.11 Connection diagrams.............................................................. 65

4.5 Testing plan............................................................................................... 71

4.5.1 Test rod check.......................................................................... 72

4.5.2 Visual check of the machine and the protective device........ 75

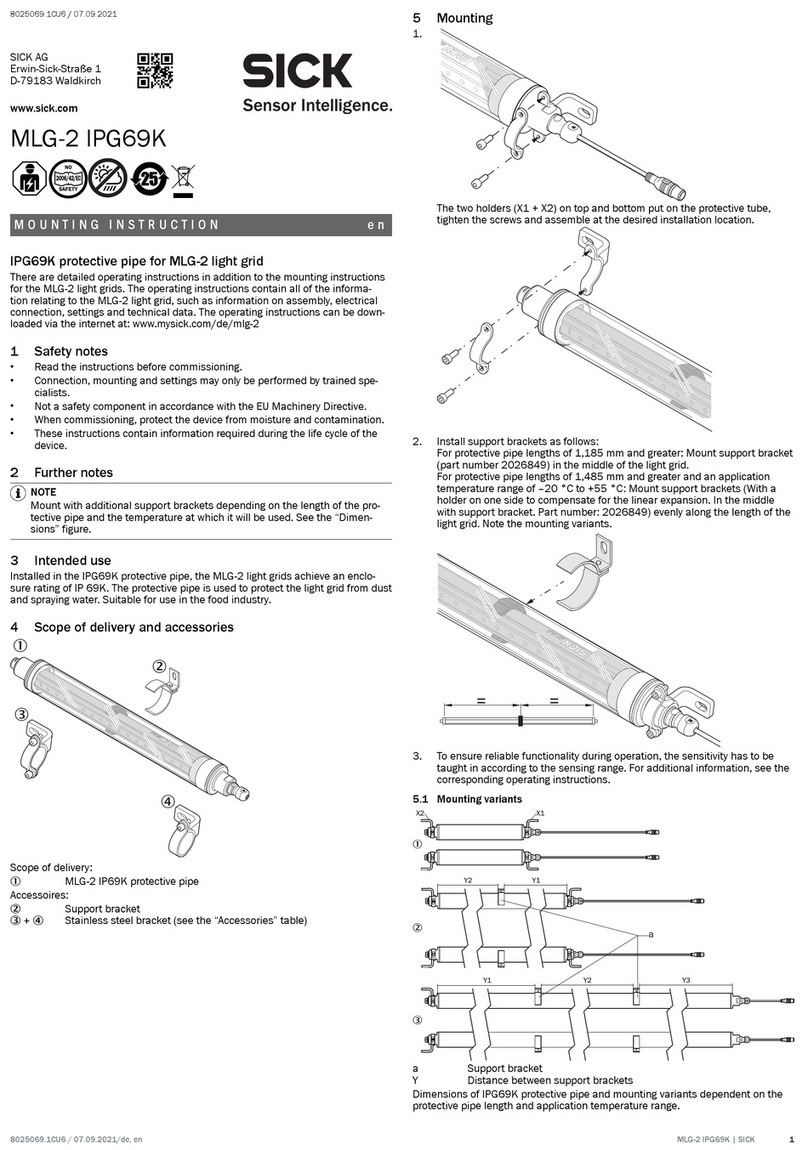

5 Mounting............................................................................................. 76

5.1 Safety......................................................................................................... 76

5.2 Unpacking.................................................................................................. 76

5.3 Mounting the system plug........................................................................ 76

5.4 Installation................................................................................................ 78

5.4.1 Mounting the QuickFix bracket............................................... 81

5.4.2 Mounting the FlexFix bracket.................................................. 82

5.4.3 Mounting the upgrade bracket............................................... 85

6 Electrical installation........................................................................ 86

6.1 Safety......................................................................................................... 86

6.2 System connection (M12, 5-pin)............................................................. 87

6.3 System connection (M12, 8-pin)............................................................. 88

6.4 Extension connection (M12, 5-pin)......................................................... 89

7 Configuration..................................................................................... 91

7.1 Overview.................................................................................................... 91

7.2 Possible combinations of functions on SP2 system plug...................... 93

7.3 Factory settings......................................................................................... 93

7.3.1 Reset to factory settings......................................................... 94

7.4 Configuration mode.................................................................................. 95

7.5 Configuring beam coding......................................................................... 96

7.6 Configuring muting................................................................................... 97

CONTENTS

4O P E R A T I N G I N S T R U C T I O N S | deTec4 8021645/1EB0/2022-04-28 | SICK

Subject to change without notice