CONTENTS

48010100/YU52/V4-1/2016-04 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

1 Safety Information..................................................................................... 8

1.1 Main hazards .................................................................................................. 8

1.1.1 Electrical safety .............................................................................. 8

1.1.2 Grounding the device ..................................................................... 8

1.1.3 Protection against hazards through gases .................................. 9

1.1.4 Protection against laser radiation ............................................... 10

1.1.5 Behavior during purge air failure................................................. 12

1.2 Intended use ................................................................................................. 12

1.2.1 Purpose of the device .................................................................. 12

1.3 Responsibility of user ................................................................................... 12

1.3.1 Disposing of device parts harmful to the environment ............. 13

2 Product Overview..................................................................................... 14

2.1 Product identification .................................................................................. 14

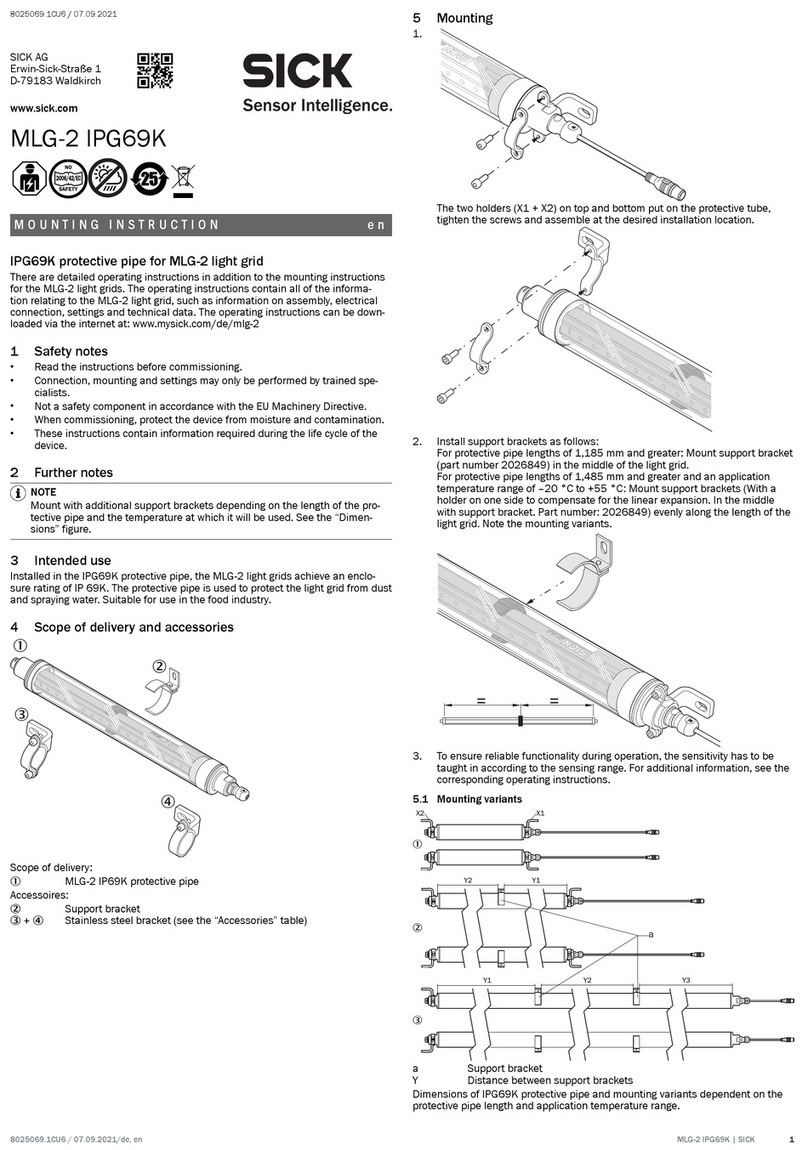

2.2 GM700 system, measuring probe version, layout ...................................... 15

2.2.1 Measuring probe in detail ............................................................ 17

2.2.1.1 GPP measuring probe............................................... 17

2.2.1.2 GMP probe with open measuring gap ..................... 18

2.2.1.3 GPP gas diffusion probe in dry or wet version......... 19

2.2.1.4 GM700 measuring probes in comparison............... 20

2.2.1.5 Special versions........................................................ 20

2.3 GM700 options and accessories ................................................................. 20

2.4 Measuring principle ...................................................................................... 21

2.4.1 Reference cuvette for wavelength stabilization.......................... 21

2.4.2 Signal evaluation.......................................................................... 21

3 Project planning....................................................................................... 22

3.1 Work steps from system selection to start-up............................................. 22

3.2 Project Planning Checklist............................................................................ 23

3.3 Initial onsite installation ............................................................................... 25

3.3.1 Installation preparation at the measuring point ......................... 25

3.3.2 Uncovering the duct ..................................................................... 26

3.3.3 Installing the flange with tube ..................................................... 26

3.3.3.1 Performing installation ............................................. 27

3.3.4 Installation preparation for the purge air unit (for GMP probe) . 27

3.3.5 Duct insulation ............................................................................. 28

3.3.6 Installation preparation for the evaluation unit .......................... 28

3.4 Preparations for electrical installation ........................................................ 29

3.4.1 Signal and power supply cables .................................................. 29

3.4.2 CAN bus wiring ............................................................................. 31

4 Installation................................................................................................ 32

4.1 Preparations ................................................................................................. 32

4.1.1 Checking the scope of delivery .................................................... 32

4.1.2 Installation prerequisites ............................................................. 32

Contents