Siemens Mobile CFX 65 Setup guide

Company Confidential

Copyright 2004© Siemens AG

1

Service Repair Documentation

Level 2.5 - CFX65 V1.1

Service Repair Documentation

Level 2.5 – CFX 65

Release Date Department Notes to change

1.0 10.11.2004 ICM MP CCQ GRM T New document

1.1 09.12.2004 ICM MP CCQ GRM T Code Changes

Company Confidential

Copyright 2004© Siemens AG

2

Service Repair Documentation

Level 2.5 - CFX65 V1.1

Introduction

This Service Repair Documentation is intended to carry out repairs on Siemens

repair level 2.5. The described failures shall be repaired in Siemens authorized

local workshops only.

All repairs have to be carried out in an ESD protected environment and

with ESD protected equipment/tools. For all activities the international

ESD regulations have to be considered.

Assembling/ disassembling has to be done according to the latest CFX65 Level 2

repair documentation. It has to be ensured that every repaired mobile phone is

checked according to the latest released General Test Instruction document

(both documents are available in the Technical Support section of the C-market).

If you have any questions regarding the repair procedures or technical questions

do not hesitate to contact our technical support team in Kamp-Lintfort, Germany:

Scrap Handling: All Scrap information given in this manual

are related to the SCRAP-Rules and instructions.

Attention: Consider soldering rules, avoid excessive heat

Tel.: +49 2842 95 4666

Fax: +49 2842 95 4302

Company Confidential

Copyright 2004© Siemens AG

3

Service Repair Documentation

Level 2.5 - CFX65 V1.1

Table of content

CFX 65 BOARD LAYOUT ...................................................................................................................... 4

LCM LAYOUT......................................................................................................................................... 6

1. B TO B CONNECTOR (J305) .......................................................................................................... 7

2. RF SWITCH (ANT300) ..................................................................................................................... 8

3. ANTENNA SPRING (J301) .............................................................................................................. 9

4. SPEAKER CONNECTOR (J200)................................................................................................... 10

5. SIDE KEY SWITCH (S400,S401)................................................................................................... 11

6. SIM READER (J302)...................................................................................................................... 12

7. I/O CONNECTOR (J304)................................................................................................................ 13

8. BACKUP BATTERY (BT414R)...................................................................................................... 14

9. IRDA (U103) ................................................................................................................................... 15

10. BATTERY CONNECTOR (J300).................................................................................................... 16

11. FUSE (F300).................................................................................................................................... 17

12. LED ON PCBA................................................................................................................................18

13. CAMERA CONNECTOR................................................................................................................. 19

14. CAMERA MODULE ........................................................................................................................ 20

15. FLASH LED..................................................................................................................................... 21

Company Confidential

Copyright 2004© Siemens AG

4

Service Repair Documentation

Level 2.5 - CFX65 V1.1

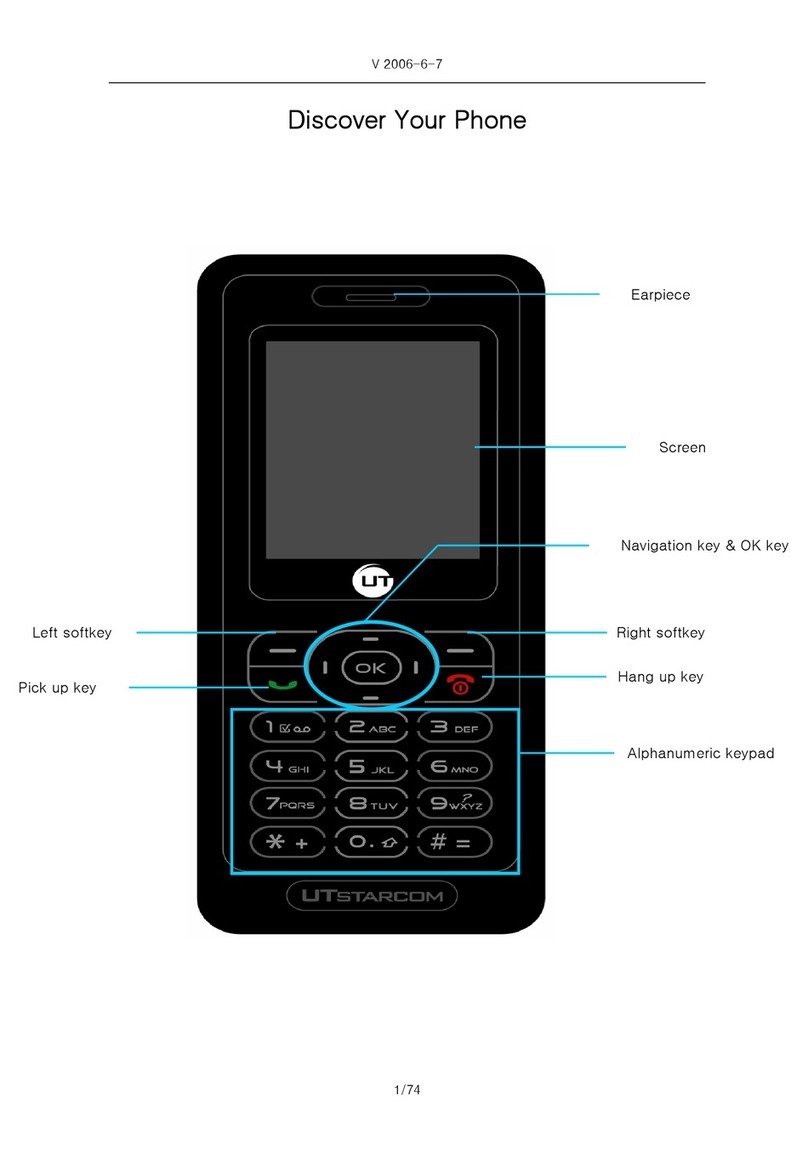

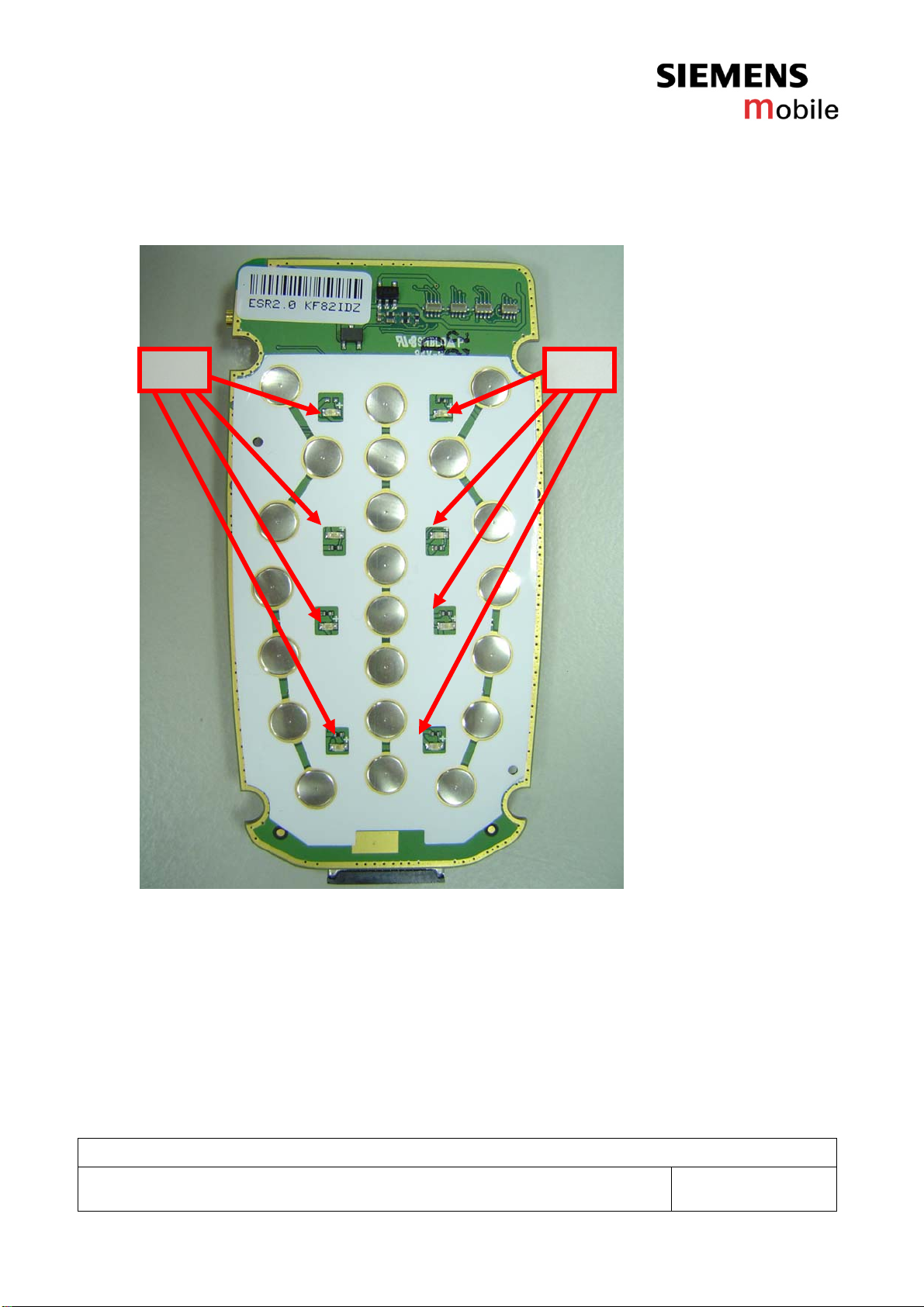

CFX 65 board layout

Jigs, Tools and working materials for all described repairs:

-hot air blower

-soldering iron

-a pair of tweezers

-flux

-solder

(J300)

Battery

c

onnector

(J200)

Buzzer

connector

(J302) SIM

connector

(F300) Fuse

(J304) I/O

connector

(BT414R)

Backup

battery

(U103) IrDA

(S402)

Switch

(ANT330) RF

connector

(J301) RF

switch

(S401)

Switch

(J305) B to B connector

Company Confidential

Copyright 2004© Siemens AG

5

Service Repair Documentation

Level 2.5 - CFX65 V1.1

LED LED

Company Confidential

Copyright 2004© Siemens AG

6

Service Repair Documentation

Level 2.5 - CFX65 V1.1

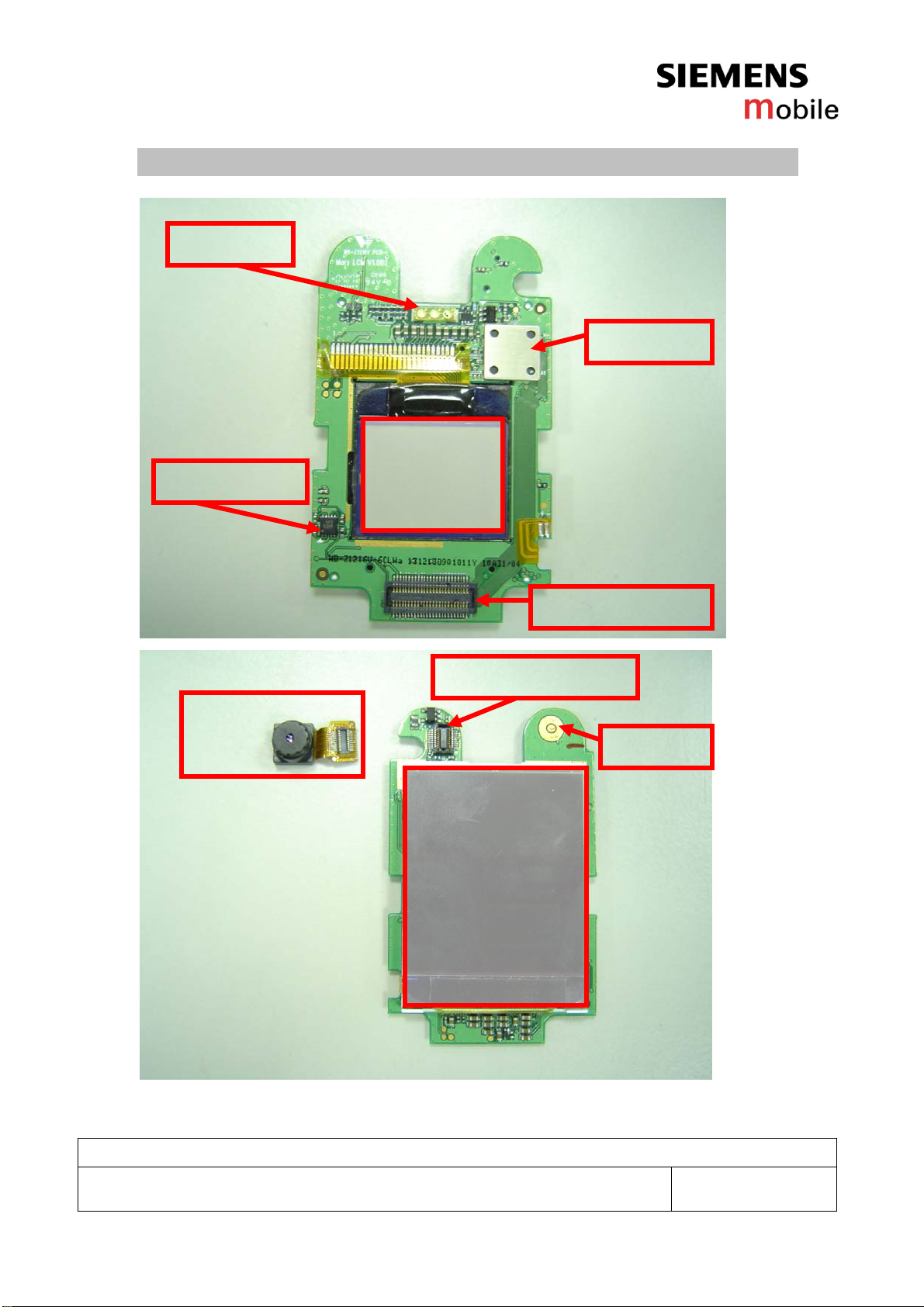

LCM layout

Charge pump

Mono LCM

Flash LED

Backend

B to B connector

65K LCM

Receiver

Camera connector

Camera module

Company Confidential

Copyright 2004© Siemens AG

7

Service Repair Documentation

Level 2.5 - CFX65 V1.1

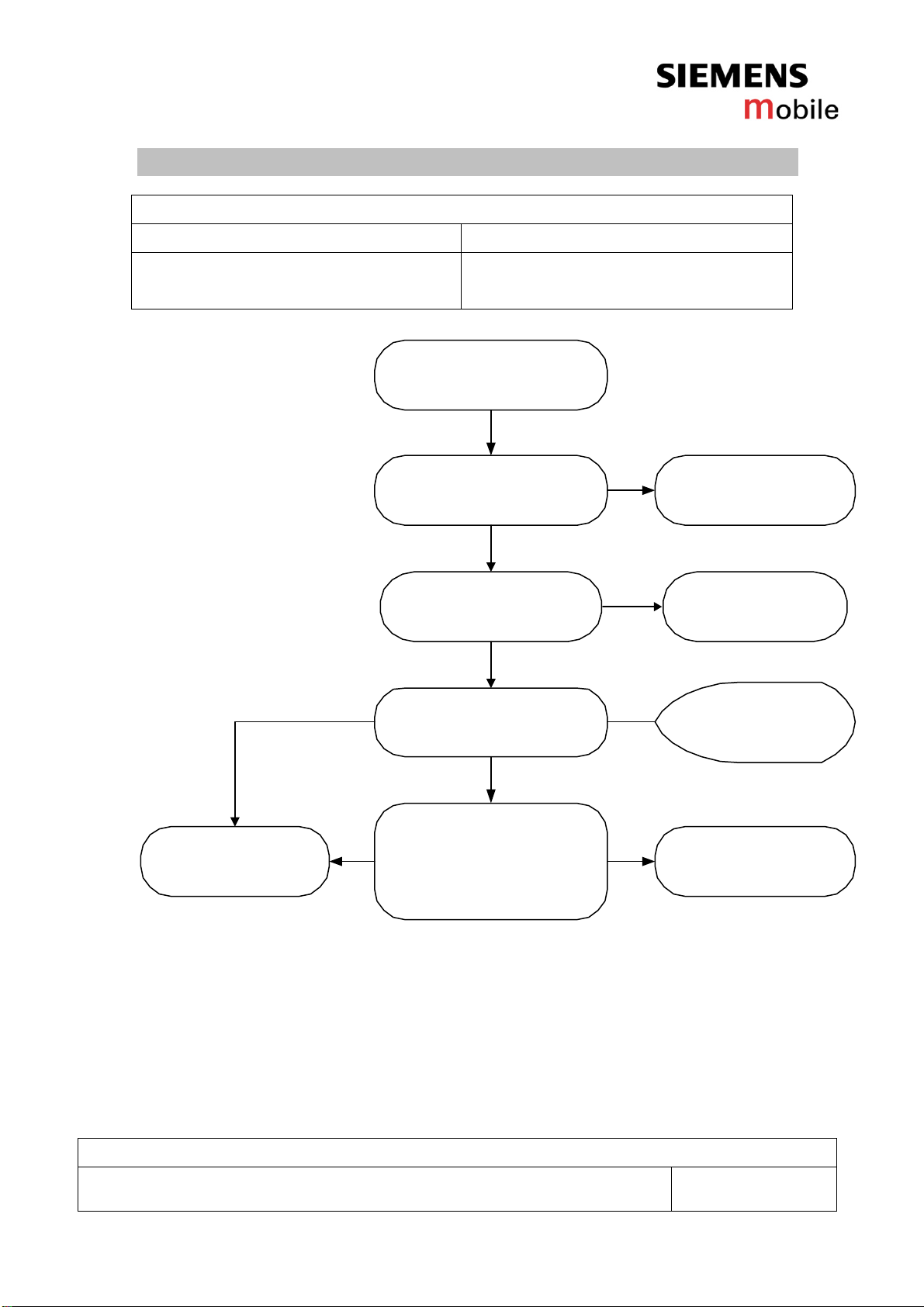

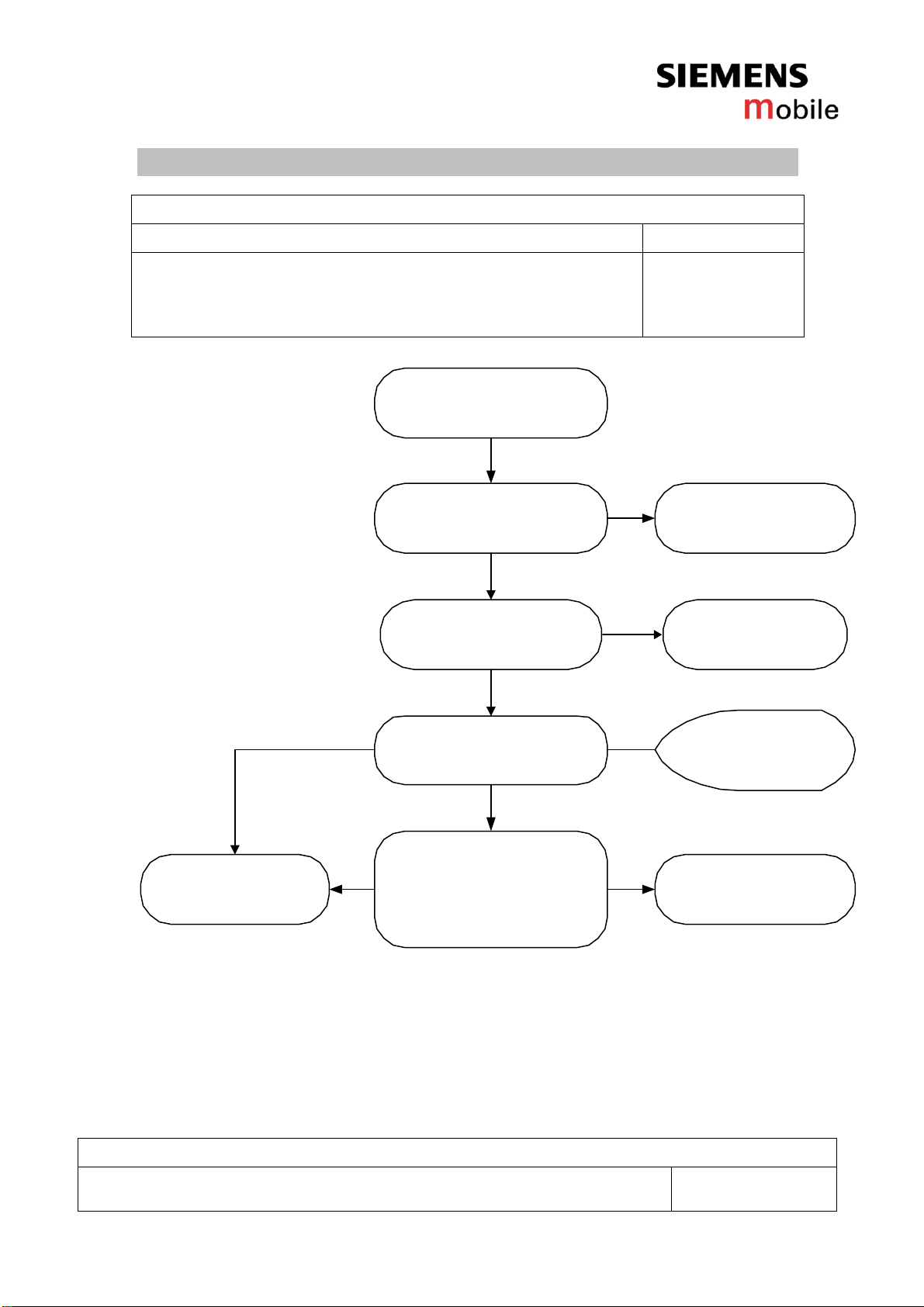

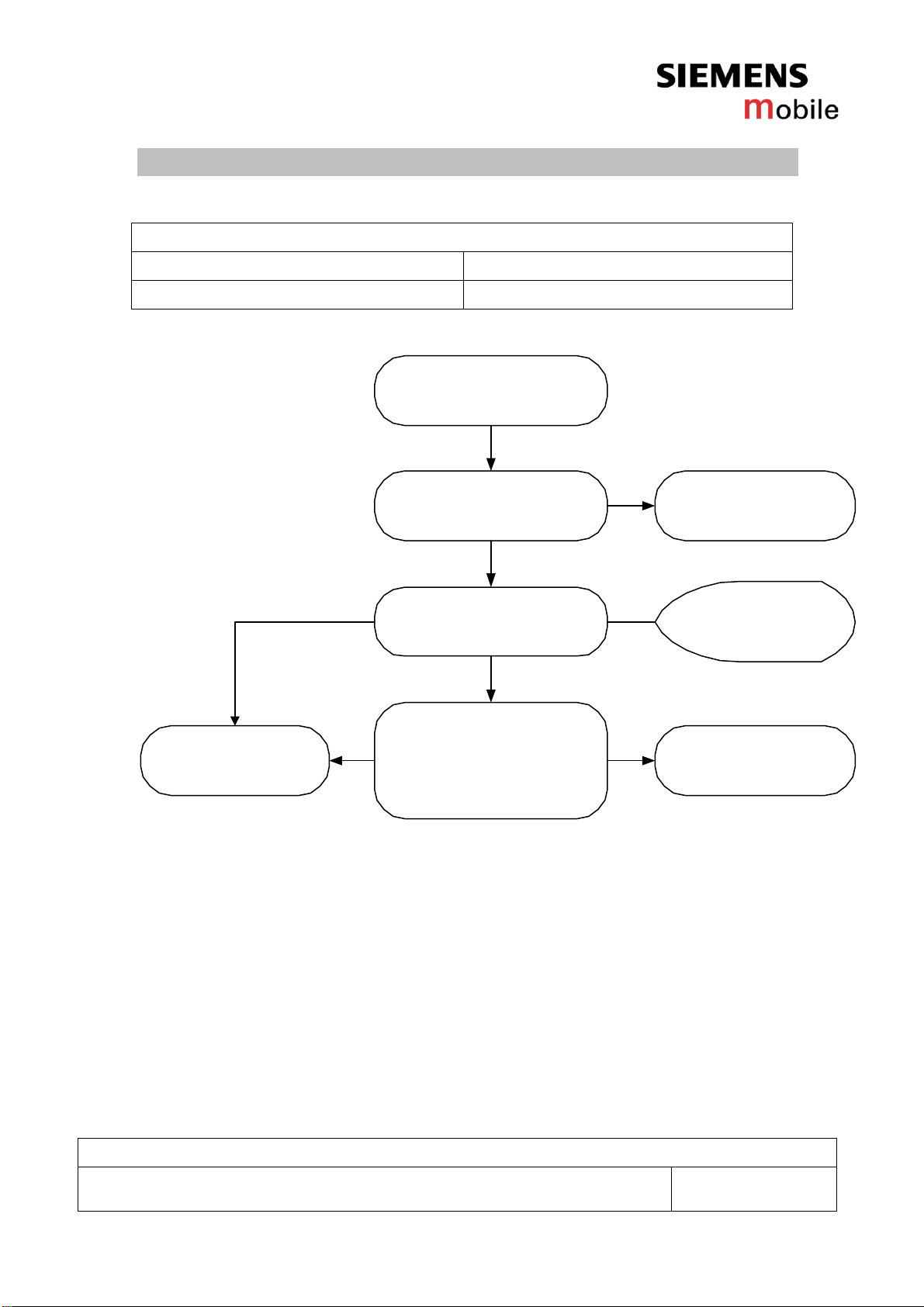

1. B to B connector (J305)

Fault Symptoms

Customer GRT

No display but main board works No GRT support

Camera and/ or earpiece does not work

Level2Repair

Check the status of the

B to B connector visually

- check for twisted or

bendedcontacts

- check for dry joints

B to B connector problems

Watch for oxidation and

damaged padsof the

B to B connector

SCRAP

Exchange

BtoBconnector

okay

okay

not

okay

not okay

-hastobe send

separatelytoWSC

Connector board to board

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C377

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: BA000 Accessories Camera

21000 Display Performance

22000 Display Background Illumination

Company Confidential

Copyright 2004© Siemens AG

8

Service Repair Documentation

Level 2.5 - CFX65 V1.1

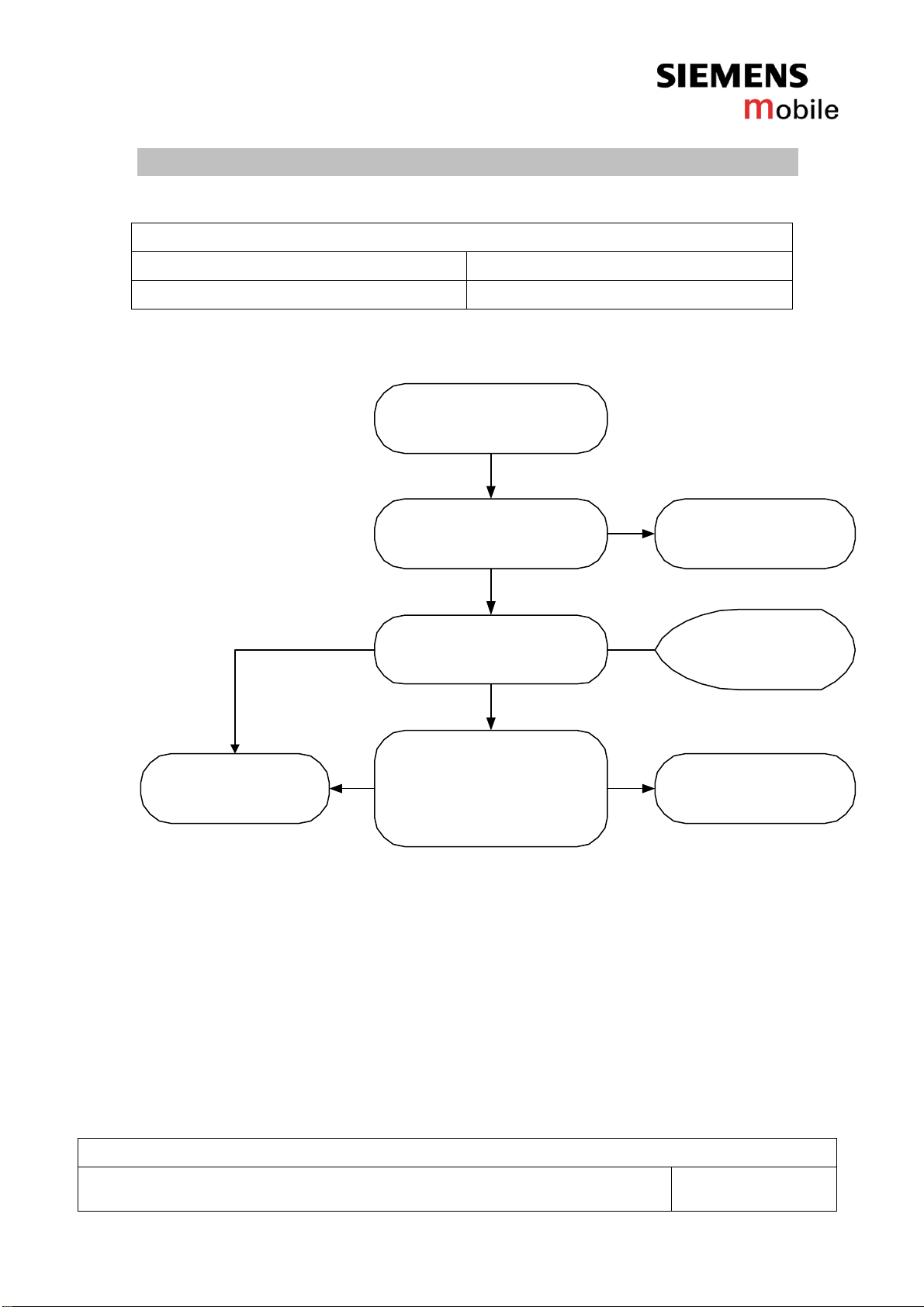

2. RF switch (ANT300)

Fault Symptoms

Customer GRT

Network search No GRT support

No location update No GRT support

Use the resistor test

function of a multimeter

to check connection

between springcontacts

and solderingcontacts.

The value must be ~0Ω

Check the status of the

RFconnectorvisually

- check for twisted or

bendedcontacts

- check for dry joints

RFconnectorproblems

Watch for oxidation and

damaged padsof the

RFconnector

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

batteryconnector

okay

okay

okay

not

okay

not

okay

not okay

Check for dust inside

the RFconnector Clean

IOconnector

okay

not

okay

Connector RF

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C375

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 45100 Interface / Antenna connector / No function

Company Confidential

Copyright 2004© Siemens AG

9

Service Repair Documentation

Level 2.5 - CFX65 V1.1

3. Antenna Spring (J301)

Fault Symptoms

Customer GRT

Poor network No GRT support

No network No GRT support

Use the resistor test

function of a multimeter

to check connection

between springcontacts

and solderingcontacts.

The value must be ~0Ω

Check the status of the

Antennaspringvisually

- check for twisted or

bendedcontacts

- check for dry joints

Antennaspringproblems

Watch for oxidation and

damaged padson the

PCB

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

Antennaspring

okay

okay

okay

not

okay

not

okay

not okay

Check for dust inside

theAntennaspring Clean

IOconnector

okay

not

okay

Antenna Spring

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50658-A136-B16

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 83140 TX power fault internal antenna

Company Confidential

Copyright 2004© Siemens AG

10

Service Repair Documentation

Level 2.5 - CFX65 V1.1

4. Speaker connector (J200)

Fault Symptoms

Customer GRT

No sound from speaker No GRT support

The speaker is sometimes barely to hear No GRT support

Use the resistor test

function of a multimeter

to check connection

between springcontacts

and solderingcontacts.

The value must be ~0Ω

Check the status of the

Speakerconnectorvisually

- check for twisted or

bendedcontacts

- check for dry joints

Speakerconnector

problems

Watch for oxidation and

damaged padson the

Speakerconnector

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

Speakerconnector

okay

okay

okay

not

okay

not

okay

not okay

Check for dust inside

theSpeakerconnector Clean

IOconnector

okay

not

okay

Speaker connector

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C381

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 72110 Accustics

Company Confidential

Copyright 2004© Siemens AG

11

Service Repair Documentation

Level 2.5 - CFX65 V1.1

5. Side key switch (S400,S401)

Fault Symptoms

Customer GRT

No function while pressing No GRT support

Pressing feeling is bad No GRT support

Use the resistor test

function of a multimeter

to check connection

between springcontacts

and solderingcontacts.

The value must be ~0Ωwhen

switch is pressed.

Check the status of the

Side key switch visually

- check for twisted or

bendedcontacts

- check for dry joints

Side key switch

problems

Watch for oxidation and

damaged padson the

Side key switch

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

Side keyswitch

okay

okay

okay

not

okay

not

okay

not okay

Check for dust inside

the Side key switch

Clean

IOconnector

okay

not

okay

Side key switch

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50615-Z77-C240

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 34100 Keys / Side

Company Confidential

Copyright 2004© Siemens AG

12

Service Repair Documentation

Level 2.5 - CFX65 V1.1

6. SIM reader (J302)

Fault Symptoms

Customer GRT

Handset does not accept SIM No GRT support

Can not read SIM No GRT support

Use the resistor test

function of a multimeter

to check connection

between springcontacts

and solderingcontacts.

The value must be ~0Ω

Check the status of the

SIM Cardreader visually

- check for twisted or

bendedcontacts

- check for dry joints

SIM Card Problems

Watch for oxidation and

damaged padsof the

SIM Cardreader

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

SIM Cardreader

okay

okay

okay

not

okay

not

okay

not okay

SIM Reader

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C374

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 43300 Interface / SIM Cardreader / Mechanical Damage

Company Confidential

Copyright 2004© Siemens AG

13

Service Repair Documentation

Level 2.5 - CFX65 V1.1

7. I/O connector (J304)

Fault Symptoms

Customer GRT

Charging problems No GRT support

Problems with external loudspeaker or microphone when using a car kit No GRT support

Problems with accessories connected at the I/O connector No GRT support

Use the resistor test

function of a multimeter

to check connection

between springcontacts

and solderingcontacts.

The value must be ~0Ω

Check the status of the

IO connectorvisually

- check for twisted or

bendedcontacts

- check for dry joints

IO connectorproblems

Watch for oxidation and

damaged padsof the

IOconnector

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

IOconnector

okay

okay

okay

not

okay

not

okay

not okay

Check for dust inside

the IO connector Clean

IOconnector

okay

not

okay

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C375

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 46100 Interface/Charging connector/ Mechanical damage

Company Confidential

Copyright 2004© Siemens AG

14

Service Repair Documentation

Level 2.5 - CFX65 V1.1

8. Backup battery (BT414R)

Fault Symptoms

Customer GRT

After removing and reassembling the battery, the time is not

correct or default value. No GRT support

Use the voltage test

function of a multimeter

to check battery voltage

The voltage mustbe ~0Ω

Check the status of the

batteryand

connectorvisually

- check for twisted or

bendedcontacts

- check for dry joints

Backup Battery problems

Watch for oxidation and

damaged padsof the

batteryand

connector

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

BackupBattery

okay

okay

okay

not

okay

not

okay

not okay

Backup battery

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50645-K1310-X320

Soldering temperature: 220 - 230°C

IRIS Diagnose Code: 16000 Battery / Backup Battery Performance

Company Confidential

Copyright 2004© Siemens AG

15

Service Repair Documentation

Level 2.5 - CFX65 V1.1

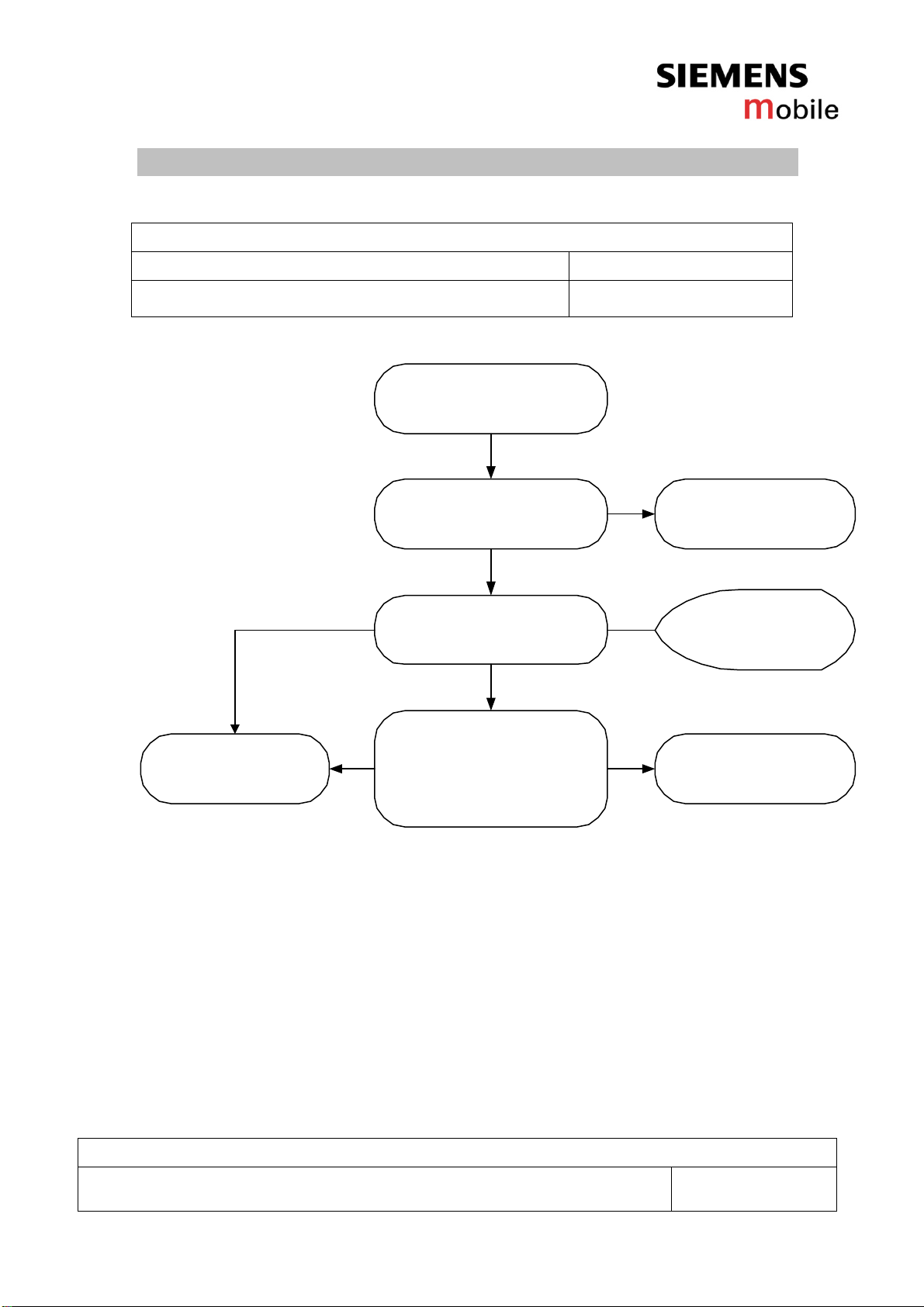

9. IRDA (U103)

Fault Symptoms

Customer GRT

No infrared connection possible No GRT support

Level2Repair

Check the status of the

IRDA visually

- check for twisted or

bendedcontacts

- check for dry joints

IRDAproblems

Watch for oxidation and

damaged padsof the

IRDA

SCRAP

Exchange

IRDA

okay

okay

not

okay

not okay

-hastobe send

separatelytoWSC

IRDA

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50610-U6153-D670

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 41000 Interfaces / IRDA / No function

41300 Interfaces / IRDA / Mechanical damage

Company Confidential

Copyright 2004© Siemens AG

16

Service Repair Documentation

Level 2.5 - CFX65 V1.1

10. Battery connector (J300)

Fault Symptoms

Customer GRT

Mobile does not switch on No GRT support

Use the resistor test

function of a multimeter

to check connection

between springcontacts

and solderingcontacts.

The value must be ~0Ω

Check the status of the

batteryconnectorvisually

- check for twisted or

bendedcontacts

- check for dry joints

Batteryconnectorproblems

Watch for oxidation and

damaged padsof the

batteryconnector

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

batteryconnector

okay

okay

okay

not

okay

not

okay

not okay

Battery connector

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C376

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 13000 Battery / Mechanical damage

Company Confidential

Copyright 2004© Siemens AG

17

Service Repair Documentation

Level 2.5 - CFX65 V1.1

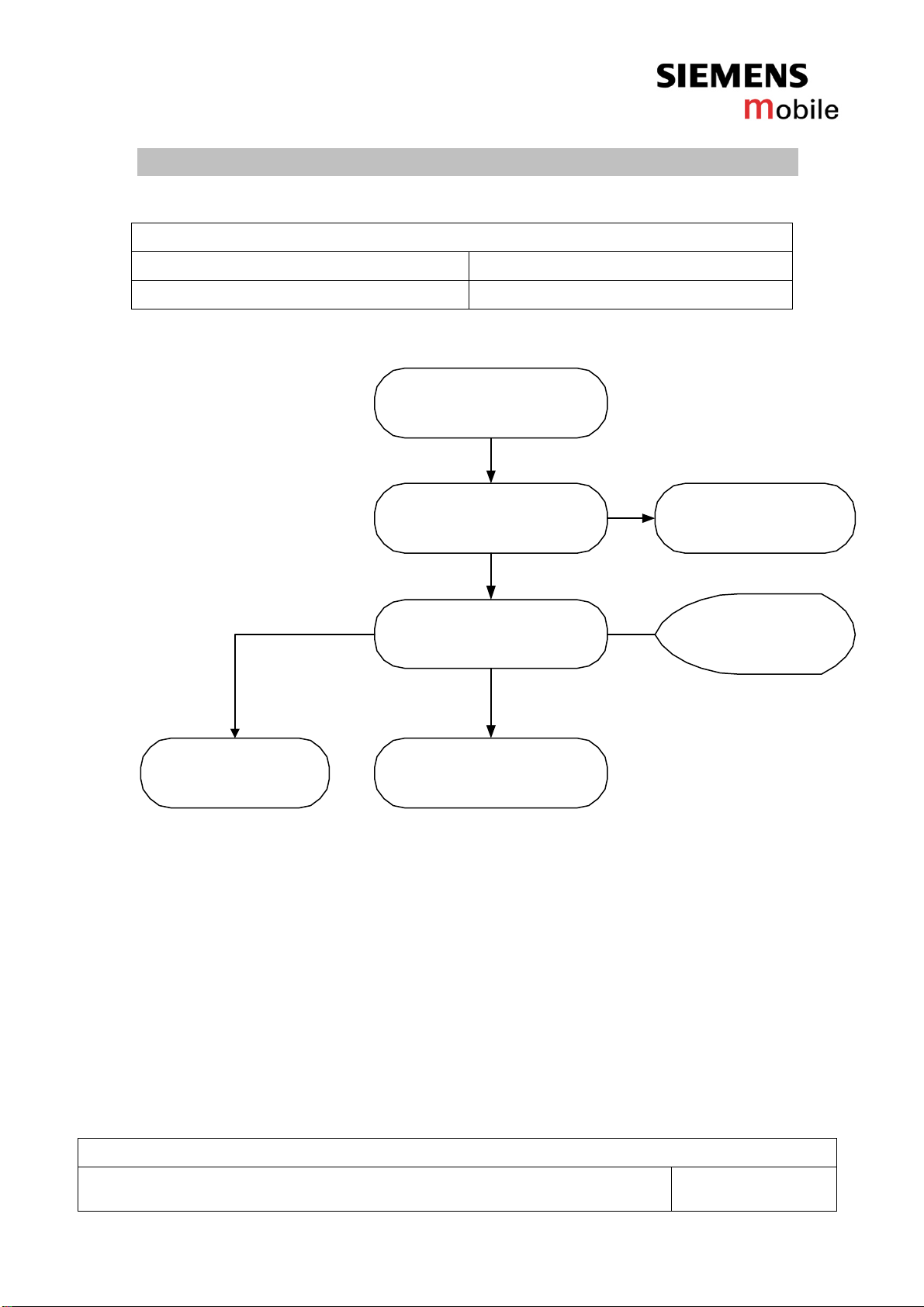

11. Fuse (F300)

Fault Symptoms

Customer GRT

Battery charging does not work No GRT support

Use the voltage test

function of a multimeter

to check battery voltage

The voltage mustbe ~0Ω

Check the status of the

Fuse visually

- check for twisted or

bendedcontacts

- check for dry joints

Fuseproblems

Watch for oxidation and

damaged padson the

PCB

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

Fuse

okay

okay

okay

not

okay

not

okay

not okay

Fuse

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50645-A820-Y20

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 11000 Battery / No charging / Deep discharge

Company Confidential

Copyright 2004© Siemens AG

18

Service Repair Documentation

Level 2.5 - CFX65 V1.1

12. LED on PCBA

Fault Symptoms

Customer GRT

LED does not work or not bright No GRT support

Use the diode test

function of a multimeter

to check the status of the

diode.Thetypicalvoltage

drop on the diode is 1.7 V

when testing the diode

functoin with the multimeter.

Check the status of the

LED pads visually

- check for twisted or

bendedcontacts

- check for dry joints

LED on PCBA problems

Watch for oxidation and

damaged padsof the

LED

SCRAP -hastobe send

separatelytoWSC

Level2Repair

ExchangeLED

okay

okay

okay

not

okay

not

okay

not okay

LED

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50640-L2123-D670

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 36000 Keys / Illumination

Company Confidential

Copyright 2004© Siemens AG

19

Service Repair Documentation

Level 2.5 - CFX65 V1.1

13. Camera connector

Fault Symptoms

Customer GRT

Camera malfunction No GRT support

Use the resistor test

function of a multimeter

to check connection

between springcontacts

and solderingcontacts.

The value must be ~0Ω

Check the status of the

cameraconnectorvisually

- check for twisted or

bendedcontacts

- check for dry joints

Cameraconnectorproblems

Watch for oxidation and

damaged padsof the

cameraconnector

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

cameraconnector

okay

okay

okay

not

okay

not

okay

not okay

Camera connector

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C378

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: BA000 Accessories / Camera

Company Confidential

Copyright 2004© Siemens AG

20

Service Repair Documentation

Level 2.5 - CFX65 V1.1

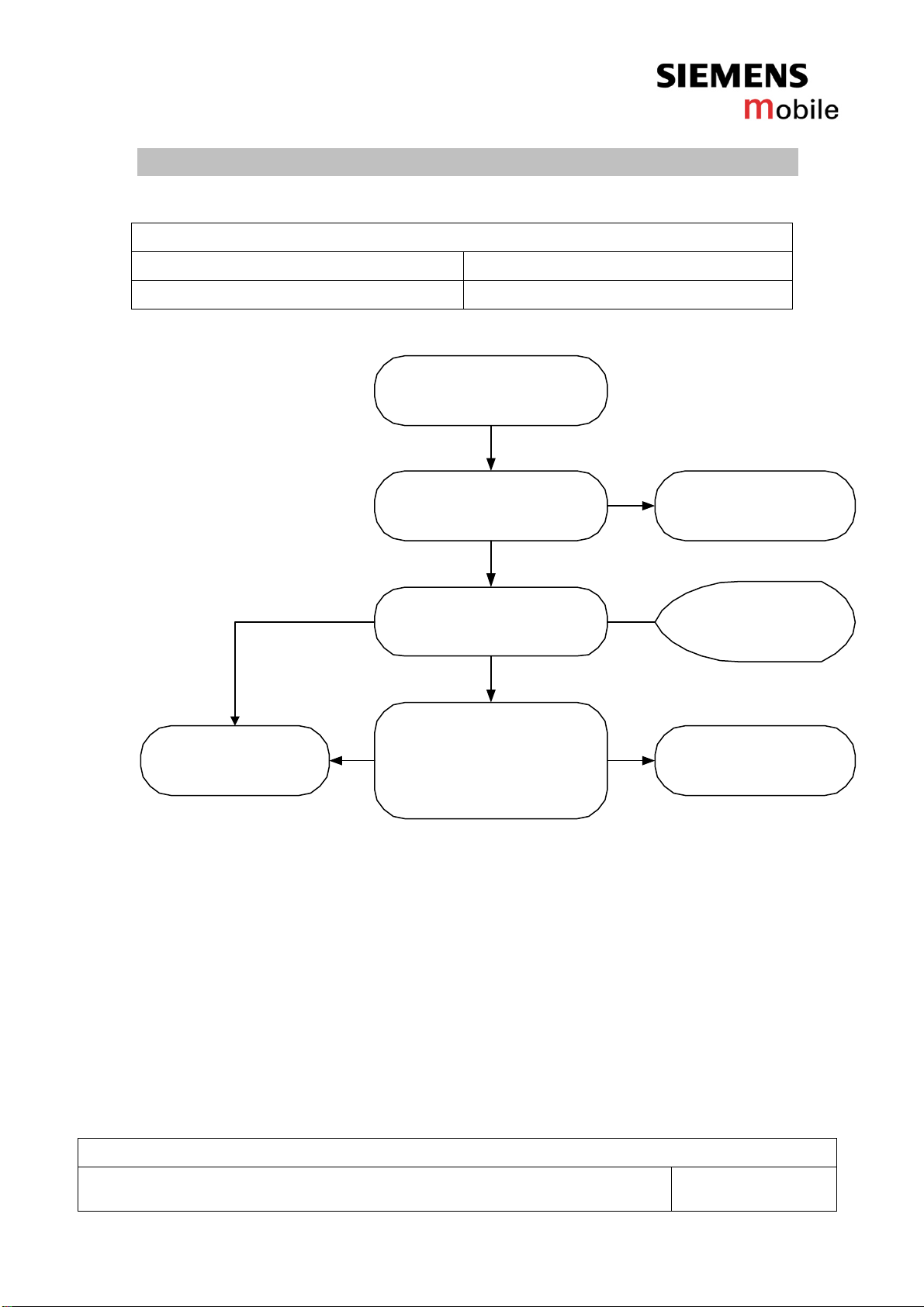

14. Camera module

Fault Symptoms

Customer GRT

Camera malfunction No GRT support

Use the resistor test

function of a multimeter

to check connection

between springcontacts

and solderingcontacts.

The value must be ~0Ω

Check the status of the

camera modulevisually

- check for twisted or

bendedcontacts

- check for dry joints

Cameramoduleproblems

Watch for oxidation and

damaged padsof the

cameramodule

SCRAP -hastobe send

separatelytoWSC

Level2Repair

Exchange

cameramodule

okay

okay

okay

not

okay

not

okay

not okay

Camera module

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50653-Z5-C297

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: BA000 Accessories / Camera

Other manuals for CFX 65

1

Table of contents

Other Siemens Mobile Cell Phone manuals

Siemens Mobile

Siemens Mobile C65 User manual

Siemens Mobile

Siemens Mobile CX65 User manual

Siemens Mobile

Siemens Mobile A65 User manual

Siemens Mobile

Siemens Mobile SF65 Setup guide

Siemens Mobile

Siemens Mobile SK65 User manual

Siemens Mobile

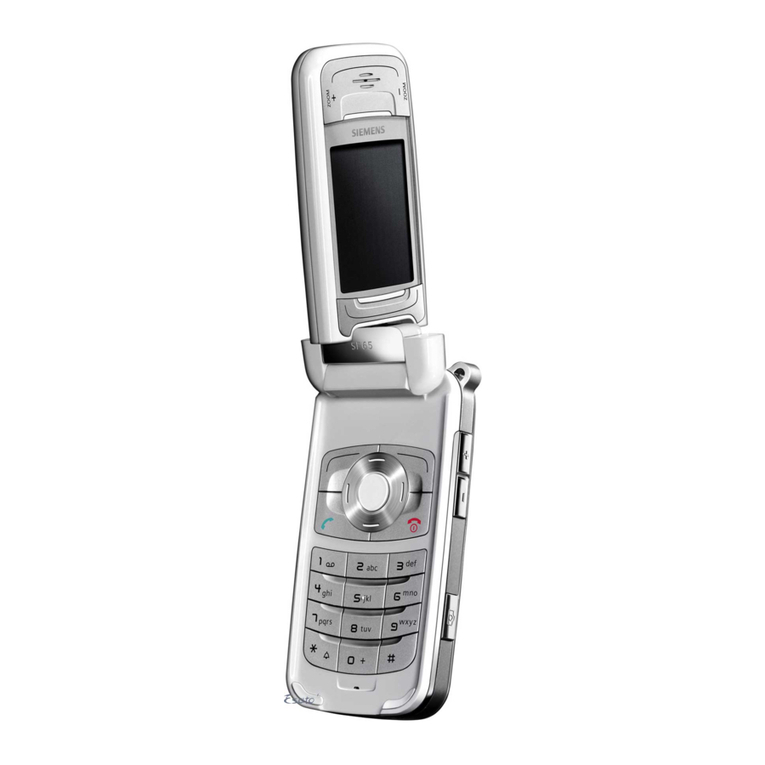

Siemens Mobile CFX 65 Setup guide

Siemens Mobile

Siemens Mobile SF65 Setup guide