Company Confidential

Copyright 2005© Siemens AG

Page 3of 16

Service Repair Documentation

Level 2.5 – SF65

Table Of Content

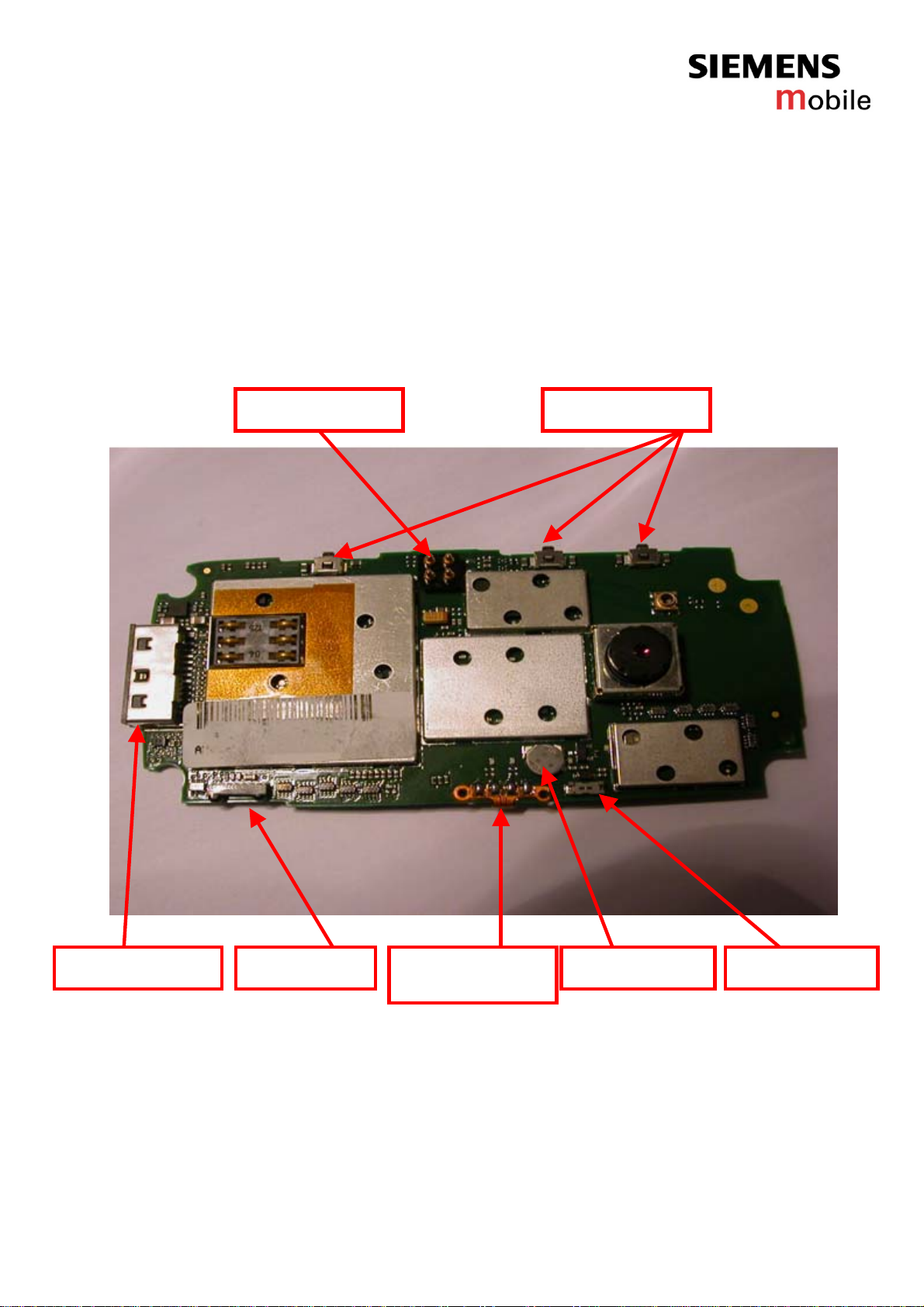

1. SF65 Board Layout ..............................................................................................4

2. System Connector ................................................................................................6

3. Display Connector – Board to Board Connector ...................................................7

4. Battery Connector .................................................................................................8

5. White & Red/Green LED.......................................................................................9

6. IRDA Communication Module.............................................................................10

7. Back Up Battery ..................................................................................................11

8. Side TACT Switch...............................................................................................12

9. Sensor Hall .........................................................................................................13

10. Vibra Connector ..................................................................................................14

11. Earphone ............................................................................................................15

12. Flexible Camera Flash Assembly.......................................................................16