3.1.3 Damage to membrane keyboard and display ...................................................................... 31

3.2 Safety notes for hazardous areas ........................................................................................ 31

3.3 Installation conditions........................................................................................................ 31

3.4 Rack-mounted device......................................................................................................... 32

3.4.1 Safety notes for hazardous areas ........................................................................................ 32

3.4.2 Device-specic safety instructions....................................................................................... 33

3.5 Wall-mounted device ......................................................................................................... 34

3.5.1 Safety notes for hazardous areas ........................................................................................ 34

3.5.2 Device-specic safety instructions....................................................................................... 34

3.6 Disassembly....................................................................................................................... 36

4 Connecting .......................................................................................................................................... 37

4.1 Basic safety notes............................................................................................................... 37

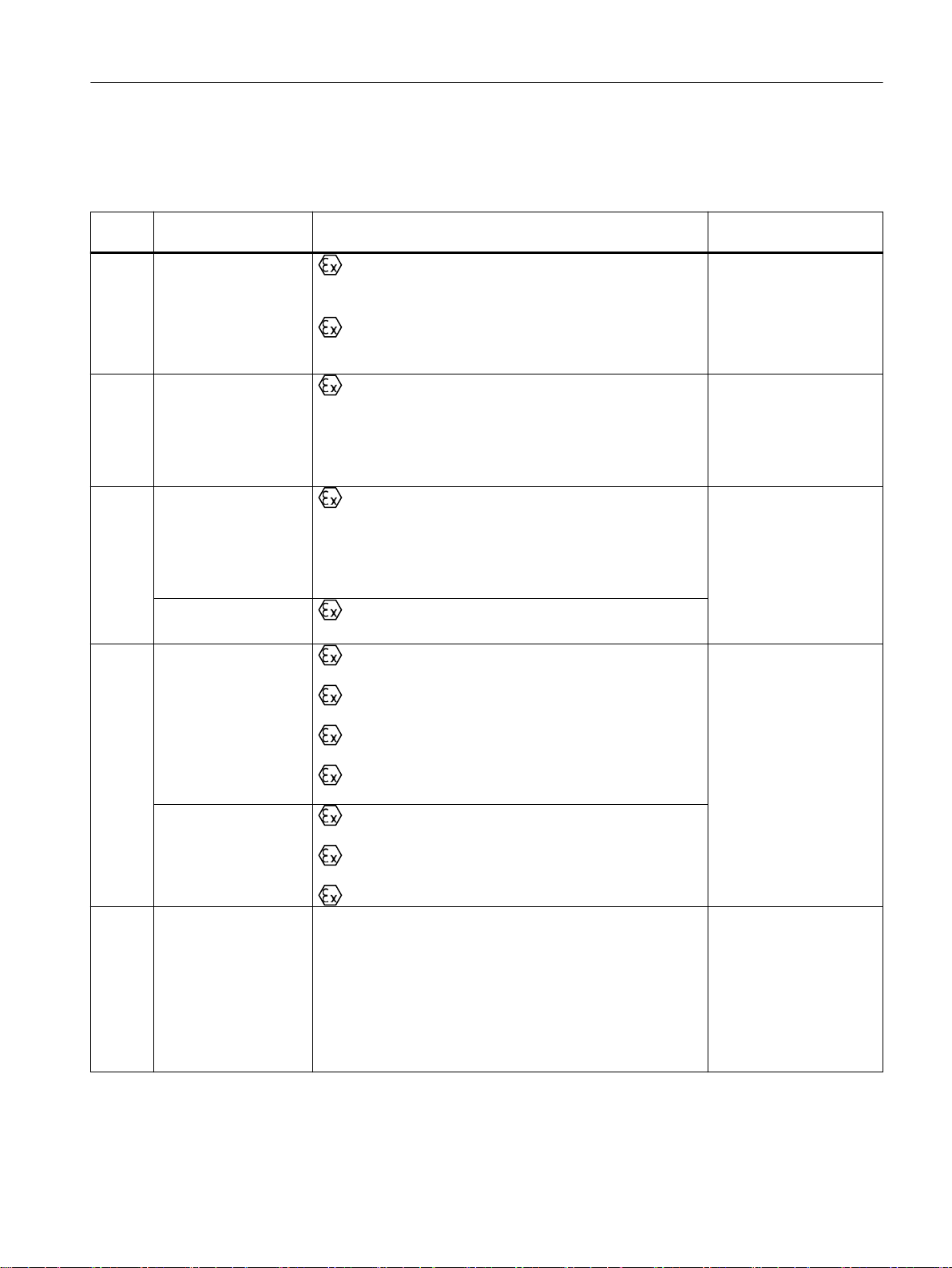

4.2 Safety notes for hazardous areas ........................................................................................ 38

4.3 Safety notes for Ex e or Ex py devices.................................................................................. 41

4.4 Gas connections ................................................................................................................ 41

4.4.1 Connection information..................................................................................................... 41

4.4.2 Leaky gas connections ....................................................................................................... 42

4.4.3 Connecting gas.................................................................................................................. 43

4.4.3.1 Wall-mounted device with analyzer modules, non high-temperature version....................... 43

4.4.3.2 Device with one OXYMAT 7 analyzer module, high-temperature version ............................. 43

4.4.3.3 Device with one ULTRAMAT 7 analyzer module, high-temperature version .......................... 44

4.5 Electrical connections ........................................................................................................ 45

4.5.1 Connection information..................................................................................................... 45

4.5.2 Requirements for electrical connection............................................................................... 45

4.5.3 Connecting the Ethernet cable ........................................................................................... 46

4.6 Connecting the rack-mounted device ................................................................................. 48

4.6.1 Arrangement of the gas connections in the rack-mounted device........................................ 48

4.6.2 Connecting signal and Ethernet cables ............................................................................... 48

4.6.3 Connecting the power supply............................................................................................. 50

4.7 Connecting the wall-mounted device ................................................................................. 51

4.7.1 Arrangement of the gas connections in the wall-mounted device ....................................... 51

4.7.1.1 Overview........................................................................................................................... 51

4.7.1.2 Purging gas connections .................................................................................................... 55

4.7.1.3 Purging gas failure for operation with type of protection Ex py/pz ....................................... 57

4.7.2 Overview conduit connectors............................................................................................. 58

4.7.3 Connecting the power supply............................................................................................. 59

4.7.4 Connecting the signal cables.............................................................................................. 61

4.7.4.1 Permitted signal cables ...................................................................................................... 61

4.7.4.2 Connecting the signal cables.............................................................................................. 62

4.7.4.3 Electrical connections with conduits................................................................................... 63

5 Commissioning .................................................................................................................................... 65

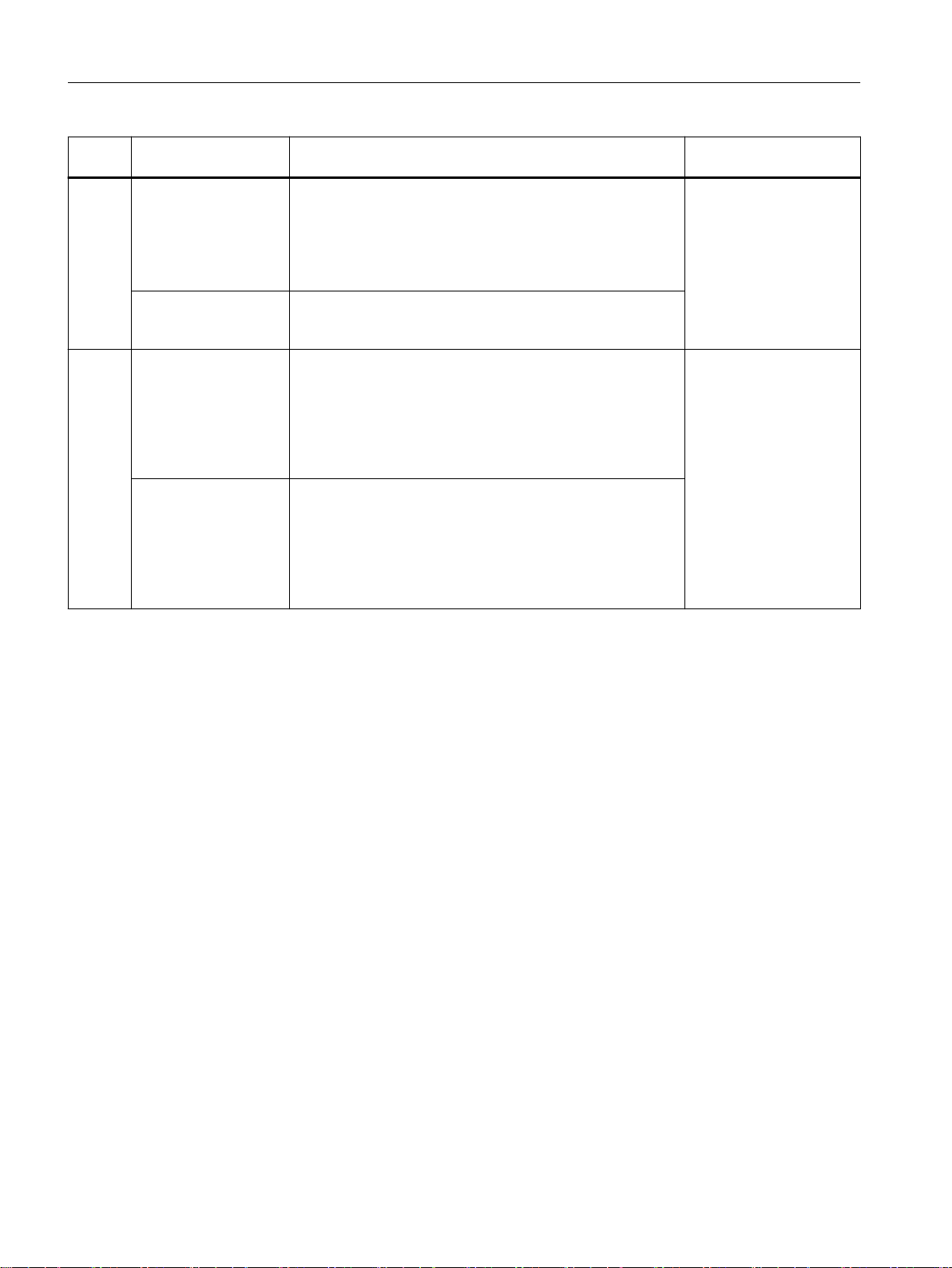

5.1 Basic safety notes............................................................................................................... 65

5.2 Information on commissioning........................................................................................... 67

5.3 Requirements for commissioning ....................................................................................... 68

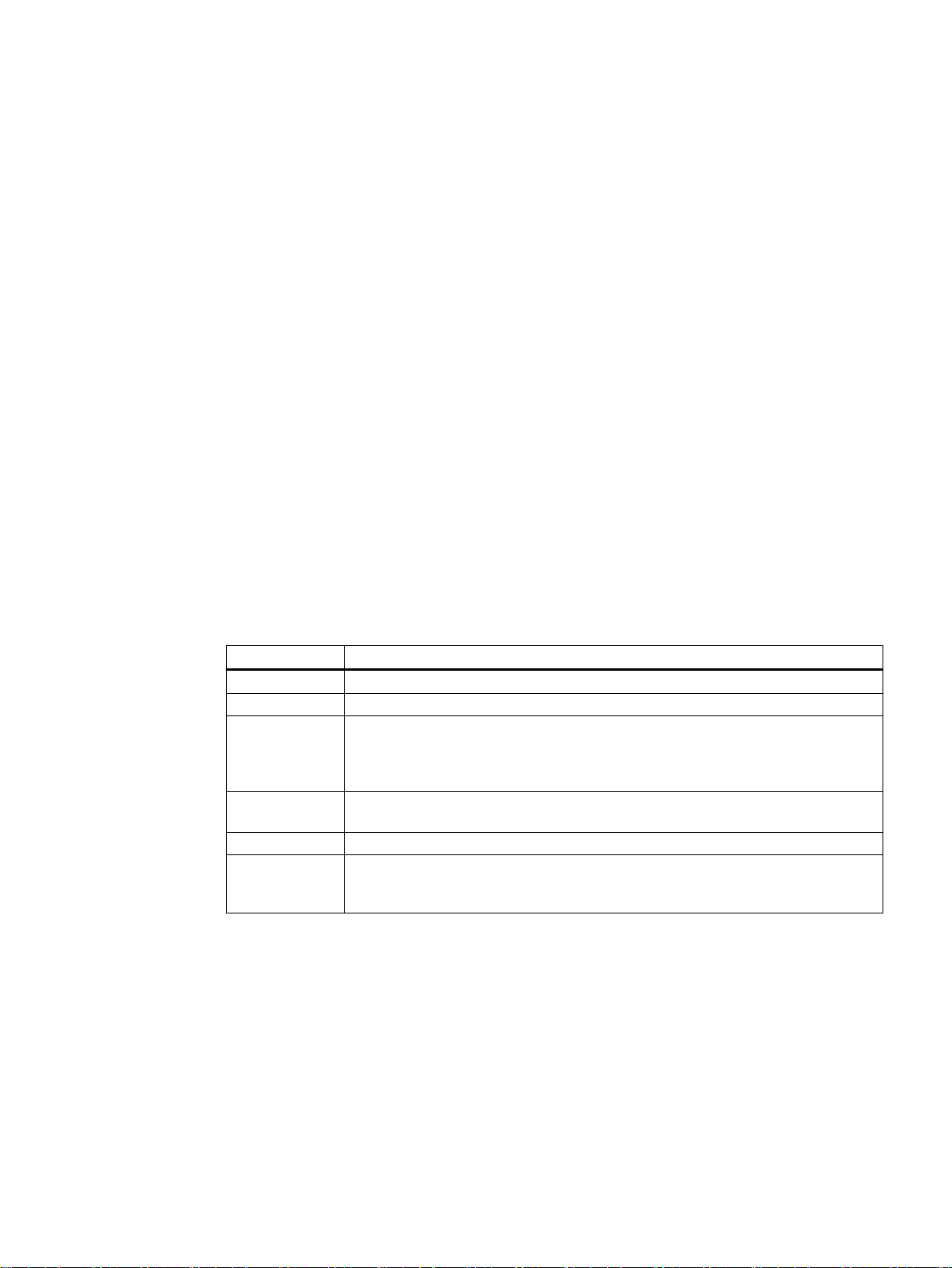

Table of contents

SIPROCESS GA700 rack and wall mounted devices

4Compact Operating Instructions, 06/2023, A5E35134047-AB